Paint Spray Guns Airless: A Contractor's Guide to Efficient Painting

- DLL Studios

- 3 days ago

- 15 min read

If you’ve ever seen a professional painter cover a massive wall in what feels like minutes, chances are they were using an airless paint sprayer. These machines are workhorses, built for speed and efficiency.

Unlike a can of spray paint or a traditional spray gun that mixes paint with compressed air, an airless system is all about raw power. It uses intense hydraulic pressure to atomize the paint, forcing it through a tiny nozzle at up to 3,000 PSI. This process creates a perfectly fine, even spray pattern without any added air, allowing you to lay down a thick, high-quality finish fast.

How Airless Paint Sprayers Actually Work

The best way to think about an airless sprayer isn't to compare it to an aerosol can, but to a high-powered pressure washer that’s been fine-tuned for coatings. Instead of using air as a vehicle for the paint, the system relies on pure, brute-force pressure to do the heavy lifting. This is the secret behind its ability to handle thick, unthinned paints right out of the can.

It all starts with the pump—the heart of the machine. A powerful motor drives a piston that sucks paint directly from a bucket and pressurizes it. From there, the paint travels through a specially reinforced hose to the spray gun. When you pull the trigger, you’re releasing that pent-up pressure, forcing the paint through a tiny, precisely engineered opening in the spray tip. It’s the sudden, violent drop in pressure as the paint exits this opening that atomizes it into a uniform, fan-shaped spray.

Core Components of an Airless System

Every part of an airless sprayer plays a vital role in delivering that flawless finish. Knowing what each component does is key to getting the most out of your machine and troubleshooting on the fly.

The Pump and Motor: This is the engine of the whole operation. It’s what creates the immense pressure needed to atomize heavy-bodied materials like latex and acrylics.

The Hose: This isn't your average garden hose. It’s built to withstand thousands of pounds of pressure safely, ensuring a consistent flow of paint reaches the gun without fail.

The Gun: This is where you take control. It houses the trigger to start and stop the flow, and a filter in the handle acts as the last line of defense against tip clogs.

The Spray Tip: Don't let its size fool you; this little piece is critical. It shapes the spray pattern and controls how much paint is released, making it a key factor in your final finish quality.

This technology is a game-changer for pros, and the numbers back it up. The airless sprayer market was valued at a massive USD 404.50 million in 2023. By 2025, these machines are expected to make up over 41% of the entire spray painting market. That’s a powerful testament to how much they boost productivity and cut down on wasted material.

For contractors working in San Luis Obispo and the surrounding communities like Paso Robles, Atascadero, Arroyo Grande, and Pismo Beach, mastering this equipment isn't just an advantage—it's a necessity. Having a reliable sprayer means you’re ready for anything, from a residential repaint in Templeton to a large-scale commercial job in Grover Beach.

To get a closer look at what's out there, check out our professional painter's guide to portable airless sprayers. Getting a solid handle on the basics is the first step toward delivering professional results every single time.

Decoding Sprayer Specs and Tip Sizes

Stepping up to a professional airless sprayer means learning to speak its language. Those numbers and acronyms you see on the side of a machine or a spray tip aren't just for decoration—they're the roadmap to a perfect finish. When you know what they mean, you can translate raw power into precise application, making sure you get the most out of your gear on every single job.

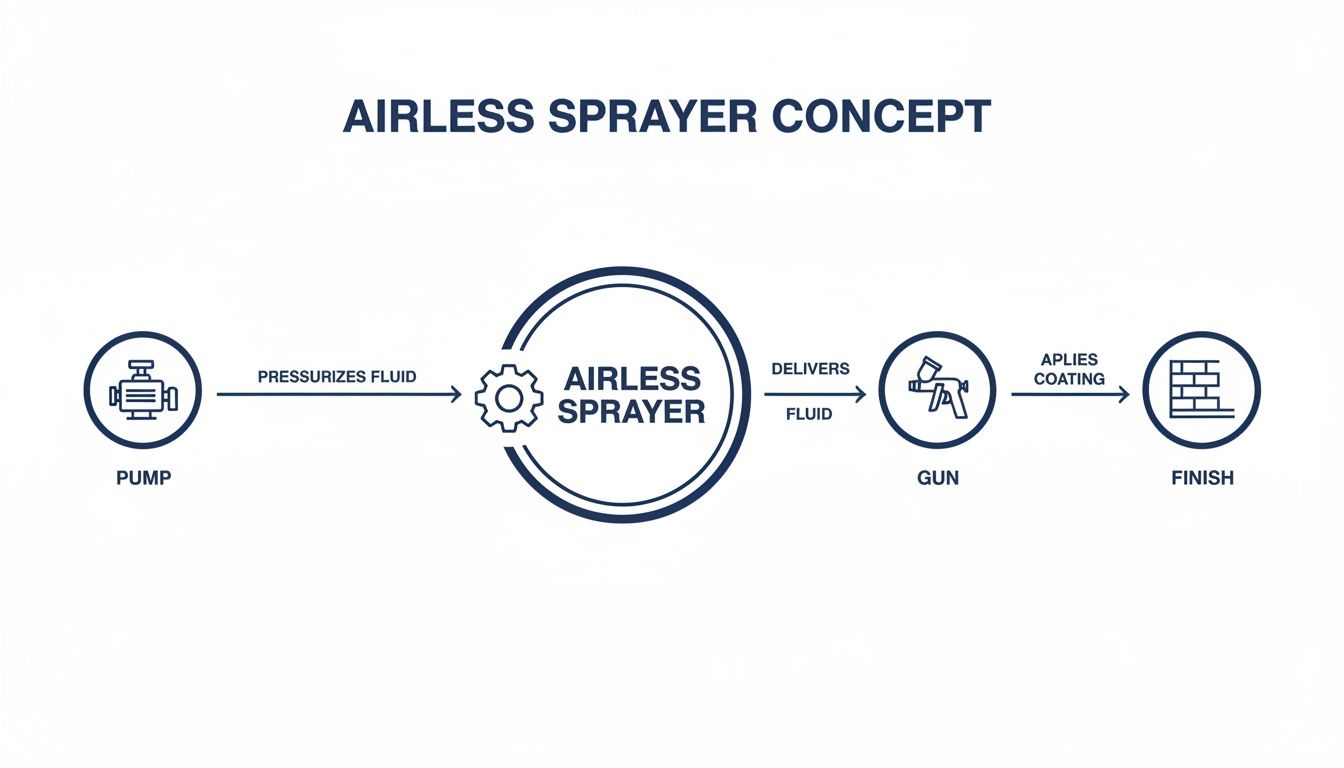

This visual breaks down the simple yet powerful journey paint takes from the pump, through the gun, and onto the surface.

The key takeaway here is that every stage matters. High pressure from the pump is what allows the gun and tip to atomize the material properly, which is how you get those superior results.

Pressure and Flow Rate: The Power Duo

Two of the most important specs you’ll run into are PSI (Pounds per Square Inch) and GPM (Gallons Per Minute). Just think of them as the strength and speed of your sprayer.

PSI is all about the force your pump can generate. You need higher pressure to atomize thick, heavy-bodied coatings like exterior latex or elastomeric paints. If your pressure is too low, you'll end up with an uneven spray pattern with ugly "fingers" or "tails," forcing you to lay down a second coat and wasting valuable time. A sprayer that can consistently push 3,000 PSI has the muscle needed to break down those viscous materials into a fine, even mist.

GPM, on the other hand, is what dictates your painting speed. This number tells you exactly how much material the sprayer can move in a minute. A higher GPM means you can use larger tip sizes and cover more ground faster—a make-or-break factor for big commercial projects in places like San Luis Obispo or Paso Robles.

For any professional contractor, the sprayer's performance is a direct reflection of job site efficiency. The right blend of pressure and flow doesn't just improve the finish quality; it shaves serious time off the labor clock.

The Secret Language of Spray Tips

That small, replaceable spray tip might just be the most critical piece of the puzzle when it comes to controlling your finish. The three-digit number stamped on every tip, like a 517, tells you everything you need to know.

First Digit (Fan Width): Multiply this number by two, and you've got the approximate width of the spray fan in inches when you're spraying about 12 inches from the surface. So, the "5" in a 517 tip gives you a 10-inch wide fan. Wider fans are perfect for big surfaces like walls and ceilings, while narrower fans (like a 211 for a 4-inch fan) give you more control for trim or railings.

Last Two Digits (Orifice Size): These numbers represent the size of the tip's opening in thousandths of an inch. A "17" on a 517 tip means the orifice is 0.017 inches in diameter. This is what controls the GPM—a bigger hole lets more paint flow through.

Choosing the right orifice size is all about matching it to the material you're spraying. Thin stuff like lacquers and stains needs a small orifice (think .009" to .013"), while thick paints need a larger one (like .017" to .021"+) to prevent clogs and ensure proper atomization.

Matching the Tip to the Task

Here’s a quick guide to some common pairings you’ll see out in the field:

Fine Finish Work (Cabinets, Trim): A tip like a 311 is your go-to. It provides a 6-inch fan with a small .011" orifice, which is ideal for thin materials and gives you incredible control for detailed work.

Interior Walls (Latex Paint): The versatile 517 is a workhorse for many painters in Morro Bay and Atascadero. It delivers a 10-inch fan and a .017" orifice that handles most interior paints perfectly.

Exterior Surfaces (Thick Acrylics): For those big jobs in Nipomo or Arroyo Grande with heavy coatings, a 621 tip is a great choice. It gives you a wide 12-inch fan and a larger .021" orifice to really maximize your coverage and flow.

Once you master these numbers, your sprayer goes from being just a tool to a true precision instrument. To dig in even deeper, check out the ultimate paint spray tip chart for a perfect finish to find the exact tip for any coating you might run into.

Choosing the Right Airless Sprayer for Your Jobs

Picking the right sprayer isn't just buying another tool—it's a serious investment in your business's productivity. The machine you choose has a direct line to your speed, the quality of your finish, and the kinds of jobs you can confidently bid on. It’s all about matching the sprayer’s horsepower to your specific workflow to get the best possible return.

This decision is only getting more critical. The global market for paint spray guns was valued at a whopping USD 4.19 billion in 2024 and is expected to climb to USD 6.33 billion by 2033. That kind of growth shows just how much the construction and industrial sectors rely on high-performance gear. Making the right choice gives you a real competitive edge.

Matching Sprayer Tiers to Job Demands

Not all professional paint spray guns airless models are built the same. Top brands like Graco and Titan have different tiers for a reason—some are for light residential work, while others are built for punishing industrial jobs. Figuring out these tiers is the first step to a smart buy.

Entry-Level Professional (e.g., Graco Contractor Series): Think of these as the workhorses for most residential and light commercial painters. They're perfect for interior and exterior repaints, easily handling latex paints, stains, and acrylics. They're tough, but they're designed for pros spraying a few hundred gallons a year, not for day-in, day-out abuse with heavy coatings.

Heavy-Duty and Industrial (e.g., Graco Industrial Models): These are the tanks. Built for the toughest jobs, they come with bigger motors, more rugged pumps, and the power to run longer hoses or even multiple guns at once. You'll need one for large commercial projects, new construction, or when you're pushing thick materials like block fillers or elastomeric coatings. The upfront cost is higher, but for high-volume work, they deliver durability and performance that pays for itself.

For any contractor working across San Luis Obispo County, whether you’re doing residential repaints in Templeton or new construction in Paso Robles, matching the sprayer tier to your bread-and-butter work is non-negotiable.

Electric vs. Gas: The Power Source Showdown

Your sprayer’s power source determines where you can work and how you work. Each has its own set of pros and cons that can make or break a job.

Electric Sprayers

Pros: They run quiet, which is a huge plus for interior jobs. They're also lighter, produce zero fumes, and are simpler to maintain. They are the clear winner for residential repaints and indoor commercial spaces.

Cons: You're tethered to a power outlet, which can be a real headache on new construction sites. You also have to use a heavy-duty extension cord to avoid frying the motor.

Gas-Powered Sprayers

Pros: Unbeatable portability and a higher GPM output. These are the champs for big exterior jobs, remote sites, or any project in areas like Atascadero or Nipomo where power is scarce or nonexistent.

Cons: They're loud, pump out exhaust fumes (making them a no-go for indoor use), and the engine adds another layer of maintenance.

In the end, your typical job site makes the decision for you. If you spend most of your days inside occupied homes in Pismo Beach or Morro Bay, an electric sprayer is the only logical choice. But if your focus is large-scale exterior work, a gas rig gives you the freedom and raw power you need to get it done.

Beyond just picking the right equipment, smart professionals are always looking for ways to advance their careers. That often means finding helpful guides and resources for painters and decorators jobs. Choosing the right tools and the right career moves really do go hand-in-hand for long-term success.

Essential Maintenance to Prevent Downtime

In this business, your airless sprayer isn't just a tool—it's your money-maker. When it’s running like a top, jobs get done, and you get paid. But when it quits on you mid-job, the whole operation grinds to a halt. Suddenly, you're losing time, and that means you're losing money. This is why proactive maintenance isn't just a "nice-to-do." It’s the single best way to protect your investment and keep your projects on schedule.

The stakes are even higher now. Modern paint spray guns airless systems are packed with sophisticated electronics for managing pressure and giving you that perfect finish. All this tech is fantastic for performance, but it also adds complexity. That just reinforces the need for both sharp operator care and knowing who to call when you need expert service.

Your Daily and Weekly Maintenance Checklist

A little consistent care goes a long way. Think of these simple checks as your first line of defense against the kind of surprises that ruin a perfectly good workday.

Daily Maintenance (End of Day)

Thorough Flushing: This one is non-negotiable. Always flush your sprayer with the right cleaning solvent—water for latex, mineral spirits for oil-based coatings—until it runs completely clear. Skipping this is the fastest ticket to a hopelessly clogged machine.

Clean Filters: Pop out the gun filter (in the handle) and the manifold filter (on the pump) and give them a good cleaning. Clogged filters kill your flow, make the pump work way too hard, and are the number one cause of frustrating tip clogs.

Wipe Down: Give the outside of the pump, hose, and gun a quick wipe. This stops paint from building up and gumming up the controls and moving parts.

Weekly Inspection

Inspect Hoses: Give your paint hose a once-over, looking for kinks, cuts, or bulges. A damaged hose under thousands of PSI is a serious safety hazard you don't want to mess with.

Check Packings: See any paint or fluid weeping from the top of the pump section? That's the tell-tale sign your packings are wearing out and need to be replaced soon.

Examine Spray Tip: Take a close look at your spray tip. If you’re getting an oval-shaped spray instead of a sharp, tight fan, the orifice is worn out. A worn tip wastes a ton of paint and leaves a shoddy finish.

A sprayer that's clean and well-maintained is a sprayer that's ready to work. Spending 15 minutes on cleaning at the end of the day can save you hours of troubleshooting and lost income the next morning.

For a deeper dive into keeping your rig spotless, check out our step-by-step contractor's guide on how to clean an airless paint sprayer.

Troubleshooting Common Sprayer Problems in the Field

Even with the best maintenance, things happen. Knowing how to quickly diagnose and fix the usual suspects will keep your crew moving and the project on track, whether you're working in San Luis Obispo or Paso Robles.

Problem 1: The Gun Spits or Produces an Uneven Pattern

This is probably the most common headache out there, and it almost always comes down to one of three things.

Diagnosis: First, suspect a clogged tip. Flip it to the reverse position and give it a quick spray onto some cardboard to clear it. No luck? Check your gun and manifold filters for gunk. If the pattern has "tails" or "fingers," your pressure is probably too low.

Solution: Dial up the pressure just enough to get a full, even fan. If you've got clean filters and plenty of pressure but the problem is still there, your spray tip is likely worn out. Time for a new one.

Problem 2: Sudden Loss of Pressure

Nothing stops you in your tracks faster than the pressure suddenly dying.

Diagnosis: Start with the obvious: did you run out of paint, or did the suction tube pop out of the bucket? Check that first. Next, make sure the prime/spray valve is clicked all the way to the "spray" position. If that all looks good, you might have a stuck ball valve in the lower part of the pump.

Solution: A gentle but firm tap on the side of the lower pump housing with a mallet can often free a stuck ball. If this keeps happening, the valve seat is probably dirty or worn and needs a proper cleaning or replacement.

For painters in communities from Atascadero to Arroyo Grande and Nipomo, having reliable local support is a game-changer. When you’ve tried everything in the field and are still stuck, you need an expert. For those complex repairs or warranty work here in the San Luis Obispo area, our service center has the pro diagnostics and parts to get your rig back on the job, fast.

Your Local Expert for Sprayer Service in San Luis Obispo

Even the most reliable paint spray guns airless systems need a pro's touch eventually. When that day comes, having a local expert you trust isn't a luxury—it's a business necessity.

You can't afford to ship your main rig across the state and wait weeks for a fix, especially on a tight deadline. Downtime is lost money, plain and simple.

That's where a dedicated local partner changes everything. For painting contractors across the Central Coast, that partner is Contractor's Maintenance Service. We're the authorized service and warranty center for top brands like Graco and Titan, located right here in San Luis Obispo.

Your One-Stop Shop for Sprayer Support

We get it. When a sprayer dies on a job site in Paso Robles or Atascadero, you need solutions, not excuses. Our entire focus is getting your equipment fixed and back in your hands so it can start earning you money again. Fast.

We’ve built our services around the needs of professional painters:

Expert Diagnostics: We'll quickly pinpoint the real problem, whether it's a simple pressure drop or a complex motor failure.

Warranty Repairs: As an authorized center, we handle all warranty claims for you. No more headaches dealing with manufacturers.

Routine Maintenance: Let us take care of the packings, filters, and fluid section upkeep to keep your sprayer running longer.

Genuine Parts Inventory: We keep a huge stock of genuine parts for Graco and Titan sprayers, so you get what you need without waiting.

A local service center that stocks the right parts and knows how to do the repair quickly is a game-changer. It turns a project-killing breakdown into a minor hiccup.

Serving the Entire San Luis Obispo County

Our support doesn't stop at our front door. We're proud to back the hardworking contractors who are building and beautifying our communities every day. We provide expert repair and maintenance services for painters, contractors, and property managers throughout the region.

Our primary service areas include:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Templeton

Nipomo

Los Osos

Cambria

Cayucos

Santa Margarita

Whether you're on a residential repaint in Morro Bay, a new commercial build in Arroyo Grande, or an industrial coating project down in Nipomo, we've got your back. Our team serves the entire county, offering the kind of hands-on help and expert advice you can only get from a local business. Don't let equipment trouble throw your project off schedule. With fast turnarounds and a team that’s committed to your success, we help you keep your paint spray guns airless in peak condition so you can focus on what you do best.

Frequently Asked Questions About Airless Sprayers

Even the most experienced pros hit a snag now and then. Getting quick, clear answers to common questions about paint spray guns airless can save you a ton of time and headaches out on the job. We've gathered the questions we hear most from contractors right here in San Luis Obispo and up and down the Central Coast.

Think of this as your field guide for troubleshooting on the fly, dialing in your technique, and getting to know your most important tool a little better.

What Is the Difference Between an Airless and HVLP Sprayer

The real difference boils down to power versus finesse. It’s like choosing between a sledgehammer and a finishing hammer—both are essential tools, but you wouldn't use one for the other's job.

An airless sprayer is all about production. It uses raw hydraulic power to force thick, heavy coatings through a tiny tip, atomizing the paint without any air. This is what makes it so ridiculously fast for big jobs like exterior siding, interior walls, and sprawling commercial buildings. Speed is the name of the game.

On the flip side, an HVLP (High Volume, Low Pressure) sprayer uses a large volume of air at very low pressure to create a soft, fine spray. This gives you incredible control and a beautiful, smooth finish, making it the go-to for detail work like cabinets, trim, and furniture. When you can't afford overspray, HVLP is your answer.

How Do I Stop My Airless Sprayer Tip from Clogging

A clogged tip is probably one of the most frustrating things that can happen on a job, but it's almost always preventable. A couple of good habits will keep you spraying without interruption.

First, always strain your paint before it ever touches your machine. This is your number one defense, catching any junk or dried bits that will absolutely cause a blockage. Second, start every job with clean gun and manifold filters. It takes two minutes and saves hours of frustration.

If a clog happens anyway, that's what the reversible tip is for. It's a lifesaver.

Twist the spray tip 180 degrees into the reverse position.

Point the gun at a scrap piece of wood or a spot that won't be seen.

Squeeze the trigger for a quick blast to blow the clog out.

Flip the tip back around, and you're back in business.

Can I Use an Extension Cord with My Electric Sprayer

Yes, but this is one of those things you have to get right. Using the wrong cord is a quick way to kill your sprayer’s motor, and it's a mistake we see all too often. Your standard-issue, light-duty orange cord from the garage just won't cut it.

An airless sprayer motor needs a ton of power, and a thin cord starves it of the electricity it needs to run properly. This forces the motor to work overtime, causing it to overheat and eventually burn out.

Always grab a heavy-duty, 12-gauge cord for any run up to 100 feet. If you need to go further, you have to step up to a thicker 10-gauge cord. The golden rule is to keep the cord as short as you possibly can and always check the sprayer's manual for what the manufacturer recommends. Don't risk a multi-thousand dollar machine on a cheap cord.

How Often Should I Replace My Sprayer's Packings

There’s no magic number here. How long packings last depends entirely on what you're spraying and how often you're using the machine. Instead of going by a set schedule, you need to learn to spot the warning signs.

Your sprayer will tell you when its packings are shot. Look for these clues:

Paint leaking from the top of the pump's fluid section.

The pump struggles to hold consistent pressure.

You hear the motor cycling constantly, even when you're not spraying.

As a rule of thumb, a full-time painter might get through 300-500 gallons before needing a change. But the best advice is to replace them as soon as you see signs of wear. Pushing it will only cause more expensive damage to the piston rod. And even with a perfectly running machine, issues like paint overspray can crop up, so knowing how to deal with it is part of the job.

When you need straight answers or professional service for your gear, Contractor's Maintenance Service is here for you. We’re the trusted, authorized service center for all the top brands here in San Luis Obispo and the surrounding areas.

Visit us online or swing by the shop to get the parts, repairs, and support you need to keep your jobs moving.

Comments