A Professional Painter's Guide to Portable Airless Sprayers

- Dec 15, 2025

- 17 min read

Imagine completing large painting jobs with a flawless, even coat in a fraction of the time it takes with a brush and roller. That’s the power of portable airless sprayers. These tools use high pressure to atomize paint into a fine, uniform mist, delivering professional-grade results with remarkable speed and efficiency.

How Portable Airless Sprayers Work

The core principle behind airless technology is simple yet powerful. Instead of using compressed air to propel paint, an airless sprayer uses a high-pressure pump to force the material through a small orifice in the spray tip. Think of how a pressure washer nozzle turns a stream of water into a wide, powerful fan of spray; an airless sprayer does the same with coatings like latex, stains, and lacquers.

This process of atomization creates a fine mist of tiny paint droplets that land smoothly and evenly on the surface. Because there's no compressed air mixing with the paint, you get a thicker, more uniform coat that adheres better and covers imperfections with a single pass. This method dramatically reduces the time spent on large-scale projects compared to traditional rolling or brushing.

The Professional Advantage Speed and Quality

For painting contractors, the benefits of using portable airless sprayers are clear and measurable. The most significant advantage is a massive increase in productivity. A skilled operator can paint a large exterior or multiple interior rooms in a single day, a task that might take several days with a roller. This speed allows professionals to complete more jobs and increase their profitability.

Beyond speed, the quality of the finish is a key selling point. An airless sprayer delivers a consistent, glass-smooth coating free of brush marks or roller stipple. This pristine finish is essential for modern residential projects and commercial spaces where appearance is critical. The technology also provides:

Superior Coverage: The atomized spray penetrates uneven surfaces and textures, ensuring complete coverage on materials like stucco, brick, or popcorn ceilings.

Material Efficiency: With proper technique, airless sprayers can reduce paint waste by minimizing overspray compared to older air-based systems.

Versatility: These tools handle a wide range of materials, from thin stains to thick exterior latex, without needing to be thinned.

At its core, an airless sprayer transforms a labor-intensive task into a highly efficient process, enabling a single painter to achieve what would typically require a small team. It’s an investment in both speed and craftsmanship.

Local Support for Central Coast Professionals

For contractors working in San Luis Obispo and the surrounding areas, having reliable equipment is only half the battle. That's why having local support is so important. We proudly provide sales, service, and parts for professionals who depend on their portable airless sprayers.

Our service area covers all of San Luis Obispo County, ensuring that painters in Paso Robles, Atascadero, San Miguel, Templeton, and Santa Margarita have access to expert maintenance. We also serve the coastal communities of Morro Bay, Cayucos, and Cambria, as well as the Five Cities area, including Arroyo Grande, Pismo Beach, Grover Beach, Oceano, and Nipomo. We offer fast turnarounds to keep your projects on track and minimize downtime.

Comparing Sprayer Technologies for Professional Use

Picking the right sprayer isn't just a small choice—it's a decision that shapes your project's speed, the quality of your finish, and ultimately, your bottom line. For pros in the field, it really boils down to three main players: portable airless sprayers, High-Volume Low-Pressure (HVLP) sprayers, and the old-school conventional air sprayers. Each one works differently and shines in its own unique way.

So what’s the big difference? An airless sprayer uses a high-pressure pump to blast paint through a tiny tip, atomizing it without any compressed air. It’s all muscle, which makes it blazing fast for big jobs. On the flip side, HVLP and conventional sprayers use compressed air to do the work, which gives you a finer touch but at a much slower pace.

The Case for High-Volume Low-Pressure Sprayers

Think of HVLP as the artist's brush in the world of sprayers. These systems are all about finesse. They use a massive amount of air at a very low pressure—usually under 10 PSI—to create a super-fine, soft spray. The result is almost zero overspray and a finish so smooth it looks like it came from a factory.

This is your go-to tool for detail-oriented projects. We're talking kitchen cabinets, custom furniture, or intricate trim work where every little bit of control counts. The downside? HVLP systems are slow and picky about what they spray. They love thin materials like lacquers and stains but will choke on thick, unthinned latex paint.

Conventional Air Sprayers: The Old Guard

Before HVLP came along, conventional air sprayers were the standard. They operate with high-pressure compressed air and can atomize just about any material you throw at them, producing a quality finish. The problem is, they're incredibly wasteful. A huge amount of paint literally bounces off the surface as overspray, wasting material and leaving a mess everywhere.

You might still find them in some auto body shops or industrial settings, but their high paint consumption and environmental impact make them a tough sell for most painters today. For any professional in San Luis Obispo working on homes or commercial buildings, the sheer wastefulness of a conventional sprayer just doesn't make business sense.

Why Portable Airless Sprayers Dominate

This is where portable airless sprayers really pull ahead, especially for contractors. By ditching compressed air and relying purely on high-pressure fluid, they offer the perfect blend of speed and versatility. They can handle heavy-bodied materials like exterior latex paint right out of the bucket, laying it down up to ten times faster than you ever could with a brush or roller.

That kind of productivity boost is a total game-changer on big jobs like interior walls, ceilings, and entire building exteriors.

The numbers don't lie. Airless sprayers, including the portable models, grabbed a massive 35% of the market revenue in 2023, a year when the total sector was valued at $3.8 billion USD. That makes them the undisputed king for large-scale applications in construction and industry. Their strength comes from the ability to push viscous paints at pressures up to 3000 PSI, creating a uniform finish that brushing just can't replicate.

To really get the most out of an airless sprayer, you need to pair its power with the right accessories. A great place to start is our guide on choosing the right tip size for airless sprayer finishes, which will help you dial in your results for a flawless look every time.

For painters serving communities from Paso Robles and Atascadero down to Arroyo Grande and Nipomo, the job is all about covering large surfaces quickly and perfectly. Portable airless technology delivers the raw power and efficiency needed to conquer the diverse projects you'll find all across the Central Coast.

Sprayer Technology Head-to-Head Comparison

To make the choice clearer, let's put these three technologies side-by-side. Seeing how they stack up on key features can help you decide which tool is the right fit for your specific needs and the kind of work you do most often.

Feature | Portable Airless Sprayer | HVLP Sprayer | Conventional Air Sprayer |

|---|---|---|---|

Primary Use Case | Large surfaces (walls, ceilings, exteriors) | Fine finishing (cabinets, furniture, trim) | Automotive, industrial finishing |

Speed & Efficiency | Very High. Fastest application speed. | Low. Slow and meticulous. | Moderate. Faster than HVLP, slower than airless. |

Finish Quality | Good to excellent, uniform coverage. | Excellent. Glass-smooth, factory-like finish. | Very Good. High-quality, fine atomization. |

Overspray | Moderate. More than HVLP, less than conventional. | Very Low. Minimal waste, high transfer efficiency. | Very High. Significant material waste. |

Material Viscosity | Excellent. Handles thick paints (latex) unthinned. | Poor. Requires thin materials (lacquers, stains). | Good. Handles a wide range of material thicknesses. |

Power Source | Electric or gas engine. | Turbine or compressed air. | Compressed air (requires a large compressor). |

Portability | High. Designed for job site mobility. | Moderate. Turbine units are portable. | Low. Tied to a large, stationary air compressor. |

Ultimately, the best sprayer depends entirely on the job. While an HVLP offers unmatched precision for fine-finish work, its slow speed makes it impractical for large-scale painting. For the professional contractor focused on speed, efficiency, and the versatility to handle a wide range of architectural coatings, the portable airless sprayer is the clear winner.

Choosing the Right Portable Airless Sprayer for Your Business

Picking the right portable airless sprayer isn't just about buying a new tool; it's a direct investment in your business's efficiency, the quality of your finish, and ultimately, your reputation. Forget simple brand loyalty for a moment. A smart purchase comes down to the performance specs that directly impact your daily grind and how much money you make on each job.

Making a good call means understanding a few key numbers. These aren't just technical jargon—they're the language that tells you how a machine will perform in the real world, whether you're spraying a home in Atascadero or a commercial building down in Paso Robles.

Decoding the Critical Performance Specs

The first spec you absolutely need to master is Gallons Per Minute (GPM). This number tells you the maximum flow rate the sprayer can handle. A higher GPM, say 0.50 or more, is built for big jobs that need larger tip sizes and faster work. A lower GPM, on the other hand, is perfect for smaller projects and fine-finish jobs.

Next up is Maximum Pressure (PSI). Pressure is what turns paint into a fine mist. If you're spraying thick stuff like unthinned exterior latex or elastomeric coatings, you need high PSI—often 3000 PSI or more—to get a smooth, even pattern. Lighter materials like stains and lacquers spray just fine at lower pressures.

Finally, don’t overlook Maximum Tip Size. The sprayer's pump has to be strong enough to support the tip size your coating requires. Using a tip that’s too big for the machine is a classic rookie mistake that leads to a terrible, uneven finish.

The goal is to match the machine's capabilities to the type of work you do most often. A sprayer that's overpowered for your typical jobs can lead to unnecessary overspray, while an underpowered one will slow you down and compromise your finish quality.

Power Source Showdown: Corded vs. Cordless

The choice between a battery-powered or a corded electric model usually comes down to a classic trade-off: do you need ultimate mobility or unstoppable, sustained power? Each has its place on the job site.

Battery-Powered Sprayers: These things offer incredible freedom. They’re perfect for quick touch-ups, knocking out a punch list, or working in spots where finding an outlet is a pain. Modern lithium-ion batteries can go for hours, so they're more than capable of handling more than just tiny tasks.

Corded Electric Sprayers: For those all-day jobs like large interior repaints or new construction, a corded model gives you unwavering, consistent power. You never have to sweat about a battery dying mid-pass, which means steady performance from the first minute to the last.

The industry trend is clear: pros want both. The electric airless market, which was valued at $1.2 billion USD in 2023, is on track to more than double to $2.5 billion USD by 2032. This boom shows just how much demand there is for high-pressure tools that are also highly mobile.

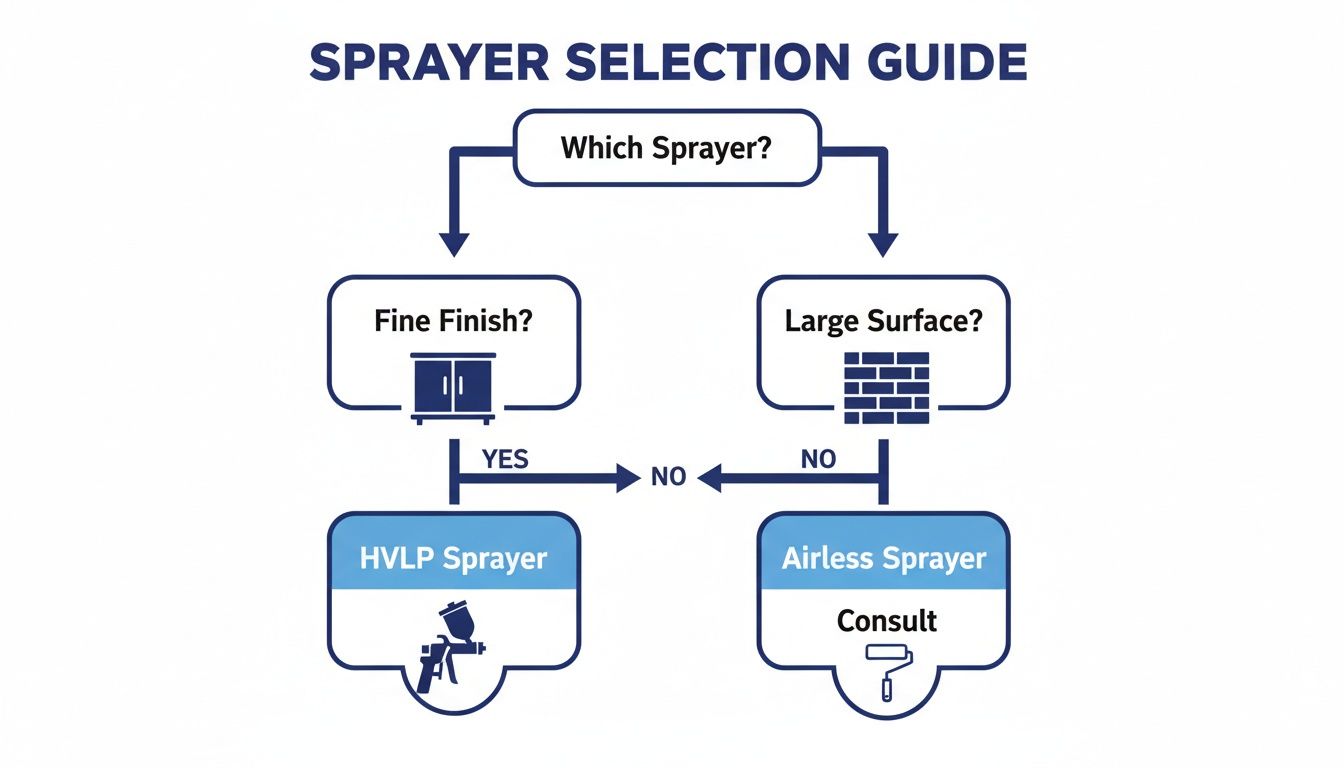

This decision tree gives you a quick visual on whether an HVLP or an airless sprayer is the right tool for your specific project.

As the guide shows, when you're tackling large surfaces, the raw power and speed of an airless sprayer are impossible to beat. Fine-finish work, however, is where HVLP systems really shine.

Essential Features That Boost Your ROI

Beyond the core specs, keep an eye out for features that make your life easier and your equipment last longer. Adjustable pressure control is a must-have. It lets you fine-tune the spray pattern and cut down on overspray, saving you a ton of money on paint over time.

A durable pump with easily replaceable parts is another big one for long-term value. You'll find that in a reliable workhorse like the Graco Ultra 390 Airless Paint Sprayer. Thinking about ergonomics is also smart. A lightweight, well-balanced gun means you get less tired, which is huge for keeping your quality high during a long day.

By looking at all these pieces, you can pick a portable airless sprayer that becomes a real money-maker for your business. And as your business grows, thinking beyond just the tools is a good next step. Many pros find that setting up a dedicated business workspace is a game-changer for staying organized and efficient.

Mastering Sprayer Operation and Maintenance

A high-performance portable airless sprayer is a powerful asset, but its true value is unlocked by the professional operating it. Mastering the right techniques and committing to a solid maintenance routine are the keys to a flawless finish. It’s what separates the pros from the amateurs, preventing costly downtime and getting the most life out of your gear.

It all starts with a solid pre-spray setup.

Before a single drop of paint leaves the gun, a methodical priming process is non-negotiable. This isn’t a step you can rush. Priming clears the pump and hose of air, filling them with material to prevent sputtering, inconsistent spray patterns, and potential damage to the pump itself.

The Priming and Spraying Process

Properly preparing your sprayer sets the stage for a smooth, efficient job. Rushing this is a common mistake that leads to nothing but frustration and subpar work.

Prime the Pump: First, place the suction tube into your paint and the smaller return tube into a waste bucket. Flip the sprayer to "prime" mode, which lets the paint circulate without pressurizing the hose. Turn the unit on and slowly dial up the pressure until you see a steady stream of paint, totally free of air bubbles, flowing from the return tube.

Prime the Hose and Gun: Now, switch the sprayer over to "spray" mode to pressurize the system. Take off the spray tip and guard, point the gun into your waste bucket, and pull the trigger. Hold it down until you get a solid, uninterrupted stream of paint. That’s how you know all the air has been purged from the hose.

Test Your Pattern: Reattach the tip and guard. Grab a piece of cardboard and do a quick test spray. If you see thick lines on the edges of your fan pattern—what painters call "tailing"—your pressure is probably too low. Slowly increase the pressure until you get a soft, even spray pattern.

Once the machine is dialed in, it's all about technique. Hold the gun about 12 inches from the surface, keeping it perfectly perpendicular the entire time. The secret to a professional finish is to keep your arm moving at a consistent speed. Trigger the gun just after you start moving and release it just before you stop. Each pass should overlap the last one by about 50% to guarantee a seamless, uniform coat.

Non-Negotiable Daily Cleaning Routines

The single most important thing you can do for the life and reliability of your sprayer is to clean it thoroughly after every single use. No exceptions. Leftover paint will dry and harden inside the pump, lines, and gun, leading to stubborn clogs and repairs that are both expensive and time-consuming.

A disciplined cleaning routine isn't just about maintenance; it's a core part of your professional workflow. The ten minutes spent cleaning today can save you from hours of troubleshooting and hundreds of dollars in repairs tomorrow.

A proper cleanup means more than just running some water through the system. You have to flush the machine until the cleaning fluid runs completely clear. Then, take the time to clean the gun, tip, guard, and all filters separately. This diligence is what prevents the gradual buildup of dried gunk that causes most problems down the line.

When you're working with portable airless sprayers, especially with flammable paints and solvents, personal safety is paramount. It’s wise to consult an ultimate guide to flame resistant jackets to make sure you've got the right protective outerwear for the job.

The Secret to Long-Term Storage

If you're storing the sprayer for more than a day or two—or putting it away for the winter—cleaning alone isn't enough. After a thorough cleaning, you must circulate a pump protectant fluid through the system. This special liquid prevents any leftover water from causing corrosion and keeps all the internal seals lubricated and pliable, protecting them from drying out and cracking.

This simple final step is the secret to ensuring your sprayer is always ready for the next job. It saves you from the nasty surprise of a seized pump right when you need your equipment the most.

Sticking to a consistent cleaning and storage protocol is fundamental. For a deeper dive, our guide offers a preventive maintenance schedule template that can help you build a bulletproof routine. The portability of these tools has revolutionized how projects get done, and the data backs it up. Portable airless sprayers excel at applying thick paints evenly at high pressure, reducing overspray by up to 50% compared to old-school methods. That saves you both time and materials. This efficiency has totally changed the game for home renovations, letting pros cover fences or decks in a matter of hours, not days.

Troubleshooting Common On-Site Sprayer Issues

Nothing grinds a profitable workday to a halt faster than a sprayer quitting on you. For a painting contractor, downtime isn't just an inconvenience—it's lost money and a wrecked schedule. Think of this as your field guide for getting your portable airless sprayer back up and running, right on the job site.

When you can pinpoint the cause of a problem, you can often fix it yourself in minutes. That saves you a trip to the repair shop and keeps the project moving. Most sprayer problems start small and just need a logical, step-by-step approach to solve.

Diagnosing an Inconsistent Spray Pattern or Tailing

One of the most common headaches is an uneven spray pattern. You'll see heavy lines on the edges, a classic sign of "tailing" or "fingers." All this means is the paint isn't atomizing correctly into that soft, even fan you need.

Before you assume the worst, check the simplest thing first: the pressure. Tailing is almost always caused by not having enough pressure for the material you're spraying.

Action Step: Slowly turn up the pressure in small increments. After each adjustment, do a quick test spray on some cardboard. More often than not, a little bump in PSI is all it takes to get that smooth, fully atomized spray.

If more pressure doesn't fix it, the next culprit is usually a worn-out spray tip. Over time, that tiny hole in the tip gets bigger and loses its shape, which completely messes up the pattern. A good tip should last for about 40-50 gallons of latex paint before it needs to be replaced.

"A faulty spray pattern is your sprayer’s way of communicating. 90% of the time, it’s telling you one of two things: either 'I need more pressure' or 'my tip is worn out.' Learning to listen to these cues is key to on-site problem-solving."

Clearing a Clogged Nozzle Safely

A clog is another job-site classic. The sprayer builds pressure just fine, but nothing comes out of the gun. This is usually just a bit of dried paint or debris stuck in the tip, and thankfully, modern tips are designed for a quick fix.

Most professional spray guards let you flip the tip 180 degrees. Here's how to safely clear it:

Engage the Trigger Lock: First thing's first—safety. Make sure the gun's trigger lock is on.

Reverse the Tip: Spin the spray tip so it's facing backward.

Clear the Clog: Flip the trigger lock off, point the gun into a waste bucket, and give it a quick pull. The pressure will shoot the clog right out.

Return and Test: Put the trigger lock back on, turn the tip to its normal spraying position, and test your pattern.

If that doesn't work, the clog might be deeper in the gun filter. Always, always relieve the system pressure completely before you try to take apart and clean that filter.

When Your Portable Airless Sprayer Fails to Prime

What if your sprayer is running but just won't pull paint into the system? It's failed to prime. This usually boils down to an air lock or a stuck ball valve down in the fluid section.

Start simple. Is your suction tube fully submerged in the paint? Are all the connections tight? A loose fitting will make the pump suck air instead of paint. If everything looks good, the inlet check ball is probably stuck.

Often, a gentle tap on the fluid section with a screwdriver handle is enough to knock the ball valve loose. This lets it seat properly and start creating suction. If that doesn't do the trick, you'll need to check the manufacturer's guide for manually cleaning the valve.

For contractors in San Luis Obispo County, we know how frustrating stubborn equipment can be. If you're in Paso Robles, Atascadero, Arroyo Grande, or anywhere on the Central Coast and can't solve the problem on-site, our expert techs are here to help. We'll get your portable airless sprayers back in action fast to keep your downtime to a minimum.

Local Sprayer Sales, Service, and Parts in San Luis Obispo

For any professional painting contractor, having solid local support isn't a bonus—it's a necessity. Downtime kills your bottom line, plain and simple. That's why we're your go-to source in San Luis Obispo for new portable airless sprayers, expert repairs, and a full stock of replacement parts. Our whole mission is to get you back on the job fast and keep you productive.

Our factory-trained techs are on deck to help pros across the entire county. We’re proud to serve the communities of Paso Robles, Atascadero, and Morro Bay, delivering the quick, professional service your business relies on. From the north county down to the coast, we've got you covered.

Your Central Coast Support Hub

We get it—working on job sites across the Central Coast comes with its own set of demands. That's why our service area also covers Arroyo Grande, Pismo Beach, and Grover Beach. Whether you're tackling a residential repaint or a big commercial project, our team is ready with the parts and know-how you need.

Our commitment to local contractors means:

New Equipment Sales: Get your hands on the latest models from the top brands.

Expert Repair Services: We turn around diagnostics and repairs quickly to minimize downtime.

Genuine Parts Inventory: We stock a wide selection of tips, hoses, filters, and packings.

Routine Maintenance: Let us handle proactive service to prevent those costly on-the-job breakdowns.

In an industry driven by deadlines, a local partner who truly understands your equipment is a massive advantage. We aim to be that partner for painters in Nipomo and all surrounding areas.

Whether you need a new rig, have a portable airless sprayer that needs urgent repairs, or just want to schedule some routine maintenance, you can trust our team to keep your tools running at their best. We're here to make sure your equipment is always ready for whatever the next job throws at you.

Got Questions About Portable Airless Sprayers? We’ve Got Answers.

When you’re on the job, you need clear, quick answers. Let’s cut through the noise and tackle the most common questions professionals have about portable airless sprayers. Getting these details right helps you work smarter and make better decisions when it's time to buy or rent.

Can I Really Use a Portable Airless Sprayer for Thick Paints Like Latex?

Absolutely. In fact, that's one of their biggest strengths. These sprayers are built with powerful, high-pressure pumps designed specifically to handle thick, unthinned coatings like interior and exterior latex paint.

This is a huge step up from other spray technologies like HVLP, which almost always force you to thin your material, messing with the paint's consistency and coverage.

How Often Should I Be Replacing the Spray Tip?

There’s no magic number, as it really depends on what you're spraying and at what pressure. A good rule of thumb? A quality tip pushing standard latex paint will usually last for about 40 to 50 gallons.

You’ll know it’s time for a new one when your spray pattern starts looking sloppy. If you see distinct lines on the edges of your spray fan—a classic sign of "tailing"—the orifice is worn out. Time for a replacement.

A worn tip doesn't just leave a bad finish; it wastes a ton of paint by applying it unevenly. Checking your tip regularly is a small habit that protects your reputation and your wallet.

Cordless or Corded: Which Sprayer is Better for a Pro?

This one comes down to your typical job site and the kind of work you do. Neither is "better"—they just solve different problems.

Cordless Models: These are all about mobility. They're perfect for quick jobs, touch-ups, punch lists, or working in places where finding an outlet is a hassle.

Corded Models: When you need non-stop power for big, all-day projects in a concentrated area, corded is the way to go. You can't afford to stop and swap batteries when you're knocking out a whole interior.

What's the Single Most Important Maintenance Task?

If you only do one thing, make it this: thoroughly clean the sprayer after every single use. No exceptions.

Leftover paint dries fast inside the pump, lines, and gun, leading to stubborn clogs and serious damage to the guts of your sprayer. A disciplined cleaning routine, followed by flushing the system with a pump protectant for storage, will add years to your equipment's life.

It’s the simplest way to prevent the downtime that costs professionals money all over San Luis Obispo County, from Paso Robles and Atascadero to Arroyo Grande and Nipomo.

For reliable equipment, expert advice, and fast service on all your portable airless sprayers, trust the team at Contractor's Maintenance Service. We're here to keep your tools running right. Find out more at https://www.contractorsmaintenanceservice.com.

Comments