Your Preventive Maintenance Schedule Template Guide

- DLL Studios

- Dec 2, 2025

- 15 min read

Unplanned downtime isn’t just an inconvenience—it’s a direct hit to your bottom line. Sticking with a "fix-it-when-it-breaks" approach is a surefire way to face catastrophic failures that could have been easily avoided. A simple preventive maintenance schedule template is all it takes to shift your team from a constant state of emergency to one of control and predictability.

Why Reactive Maintenance Is Costing You Money

Operating without a plan is like navigating without a map; you’re bound to run into expensive, unforeseen obstacles. This reactive approach, sometimes called breakdown or run-to-failure maintenance, might seem cheaper at first glance since you only spend money when something actually breaks.

But the hidden costs pile up fast, creating a serious drain on your resources and profitability.

Imagine a critical hydraulic press on your production line goes down without warning. The immediate problem is obvious: production grinds to a halt. The financial damage, however, goes way beyond the initial repair bill.

The True Cost of Unplanned Downtime

When equipment fails unexpectedly, it triggers a cascade of expensive problems. These are the costs that often get overlooked but have a massive impact on your operational budget. The most common hidden expenses include:

Emergency Repair Bills: Technicians charge a premium for urgent, after-hours service calls. No one likes paying that invoice.

Expedited Parts Shipping: Overnighting a crucial component can cost hundreds, if not thousands, of dollars more than standard delivery.

Team Overtime: Your staff has to work extra hours just to catch up, leading to inflated labor costs and employee burnout.

Lost Production Output: Every hour of downtime is an hour of lost revenue. That can be devastating when you're trying to meet tight client deadlines.

This reactive cycle traps your team in a loop of constant fire-fighting. They're always scrambling to solve the latest crisis instead of focusing on strategic improvements. It becomes impossible to plan budgets accurately when unpredictable, high-cost repairs can pop up at any moment.

The switch from reactive to preventive maintenance isn't just an operational change; it's a fundamental financial strategy. Each dollar invested in planned maintenance directly prevents a much larger, unplanned expense down the road.

A Smarter Financial Approach

Adopting a preventive maintenance schedule is a strategic move toward financial stability. The data overwhelmingly backs this up, with 80% of manufacturing personnel favoring a preventive strategy. A well-run program saves approximately 8% to 12% compared to reactive maintenance, and in some cases, those savings can skyrocket to 40%.

Better yet, every dollar spent on a preventive program saves an average of five dollars in future repair costs. You can explore more maintenance statistics to see the full financial picture.

By anticipating your needs, you can schedule repairs during planned downtime, order parts with standard shipping, and allocate your resources efficiently. This predictability transforms your maintenance budget from a chaotic, reactive expense into a controlled, strategic investment in your company’s long-term success.

Anatomy of an Effective Maintenance Template

A good preventive maintenance schedule is the backbone of your entire program, but just downloading a blank spreadsheet won't get you very far. To turn that template into a powerful tool, you have to understand what each column is for and then shape it to fit how your operation actually works. That’s how you transform it from a simple list into a command center for your entire maintenance team.

The real goal here is to create a document that everyone just gets. When a technician pulls up the schedule, there should be zero confusion about what needs to be done, which machine they’re working on, or when it’s due. That level of clarity is what stops expensive mistakes before they happen and gets your whole crew on the same page.

Core Components Every Template Needs

While you can—and should—add fields specific to your industry, a few components are completely non-negotiable for keeping things on track. Think of these as the essential DNA of any solid maintenance schedule.

Without them, you’re just making a glorified to-do list.

These are the absolute must-haves:

Asset ID or Name: This has to be a unique identifier for every single piece of equipment. Vague names like "Forklift 2" are a recipe for confusion. A much better practice is to create a clear naming system, like (Facility 1, Forklift, Unit 002), and put a physical label on the asset that matches.

Location: Be specific about where the equipment is (e.g., "Bay 3, West Wall" or "Assembly Line 2"). This simple detail saves technicians a ton of time they’d otherwise waste just looking for the machine.

Task Description: Give a clear, concise summary of the work. Ditch the internal jargon. Instead of something vague like "PM Service B," spell it out: "Inspect and lubricate conveyor belt drive chain; check tension."

Task Frequency: Define how often the task needs to happen. This could be time-based (Weekly, Monthly, Quarterly) or usage-based (Every 200 hours, Every 5,000 cycles).

Structuring your template this way ensures all the critical information is captured consistently. It makes the whole schedule easy for anyone on your team to read and, more importantly, act on.

A great template doesn't just list tasks; it provides context. The difference between a schedule that gets used and one that gets ignored often comes down to how easily a technician can find the information they need to do their job correctly.

Bringing Your Template to Life with Actionable Data

Okay, you've got the basics down. Now, let's add the fields that provide real operational value. These columns are what help you with scheduling, tracking your progress, and building a historical record that’s priceless during audits or when you're trying to improve your process.

Consider adding these columns to make your preventive maintenance schedule truly dynamic:

Assigned To: The name or team responsible for getting the task done. This creates clear ownership and accountability.

Last Completed Date: The date the task was last performed. This is crucial for calculating the next due date, especially if your schedule isn't fixed.

Next Due Date: The upcoming deadline for the maintenance task. This is the most forward-looking part of your schedule and is key for planning resources.

Status: The current state of the work order (Scheduled, In Progress, Completed, Overdue). Using a dropdown menu here is a pro-tip for keeping the data clean and consistent.

Notes/Comments: A spot for technicians to log important observations, like parts they used, signs of abnormal wear, or suggestions for future PMs.

Below is a quick breakdown of these essential fields and what makes them so important for effective tracking.

Key Fields in Your Preventive Maintenance Template

A breakdown of essential columns to include in your schedule for effective tracking and management.

Field Name | Purpose & Best Practice |

|---|---|

Asset ID / Name | Uniquely identifies equipment. Use a consistent naming convention (e.g., ) and physically label the asset to match. |

Location | Specifies the asset's physical spot. Be precise (e.g., "Bay 3, West Wall") to save technicians time. |

Task Description | Clearly states the required work. Avoid jargon; use direct, actionable language like "Inspect and lubricate chain." |

Frequency | Sets the schedule (e.g., Weekly, Monthly, Every 200 hours). Base it on manufacturer recommendations and your own operational data. |

Assigned To | Assigns responsibility to a person or team. This drives accountability and makes it easy to see who's doing what. |

Last Completed | Records the date the task was last done. Essential for calculating the next due date and tracking history. |

Next Due Date | Shows the upcoming deadline. This is your primary field for planning work and allocating resources. |

Status | Tracks the current state of the task (e.g., Scheduled, Completed, Overdue). A dropdown menu ensures consistent data entry. |

Notes / Comments | Captures important observations from technicians. This field is a goldmine for troubleshooting and process improvement. |

By filling out these fields, you’re creating a living document that gives you a real-time snapshot of your entire maintenance operation. If you're looking for more ideas on structuring your program, check out the top preventive maintenance best practices, which tie in perfectly with building an effective template. This kind of detailed record-keeping is what separates a world-class maintenance program from a simple checklist.

Building Your Maintenance Schedule From Scratch

A blank template is a solid starting point, but it's the data you feed it that really brings it to life. This process is about turning a simple spreadsheet into a command center for your entire operation—transforming it from a generic document into a workflow that truly reflects the unique demands of your equipment and facility.

It all starts with knowing what you actually have. You can't maintain what you don't track, so the first step is always building a complete inventory of every piece of equipment that needs attention. Don't just focus on the big-ticket items; this includes everything from your primary production machines to the often-overlooked but critical HVAC systems that keep the lights on.

Create a Comprehensive Asset Inventory

Before you can schedule a single task, you need a full and accurate list of your assets. This inventory is the bedrock of your entire PM program. Without it, you're guaranteed to miss critical equipment until it’s already down.

Get started by walking the floor and documenting everything. For each piece of machinery, make sure you capture these key details:

Asset Name & ID: Give every asset a unique, logical identifier (e.g., for Press 1). This simple step eliminates a ton of confusion down the line.

Location: Be specific. "Bay 3, near the east door" is far more helpful than just "Warehouse."

Make, Model, and Serial Number: This info is gold when you're trying to order parts or track down an OEM service manual.

In-Service Date: Knowing the age of your equipment helps you predict its lifecycle and start planning for eventual replacement.

Organize this information in the first few columns of your template. This master list ensures no machine gets left behind and gives you a clear, top-down view of your maintenance responsibilities.

Determine the Right Maintenance Frequency

Once you know what you're maintaining, the next question is how often. Nailing the right frequency is a balancing act. Do it too often, and you're wasting labor and resources on unnecessary work. Not often enough, and you risk the very breakdowns you’re trying to prevent.

There's no single magic number here; the ideal interval depends on a few different things. Your best starting point is always the Original Equipment Manufacturer (OEM) manual. These guides give you baseline recommendations straight from the people who designed the machine.

Beyond the manual, you’ll want to fine-tune your schedule by considering these factors:

Operational Demands: A conveyor belt that runs 24/7 is going to need more frequent checks than one that only runs for a single eight-hour shift.

Operating Environment: Equipment sitting in a dusty, high-vibration shop will need more attention than the same machine in a clean, stable setting.

Past Failure Data: Your own maintenance history is a goldmine. If a specific component has failed twice in the last year, you should probably increase its inspection frequency.

This approach helps you build a schedule driven by real data. For example, your high-use conveyors might get a monthly inspection, while a heavy-duty hydraulic press only needs quarterly lubrication.

The real goal here is to tackle one of the biggest threats to profitability: unplanned downtime. It’s more than just a minor inconvenience; the Aberdeen Group calculated that unplanned downtime costs businesses an average of $260,000 per hour. In response, 46% of companies are actively planning to adopt more robust preventive scheduling. When done right, these schedules can slash maintenance costs by 30-40% and cut downtime by as much as 50-60%. You can learn more about these powerful maintenance statistics and trends to see the full impact.

Define Specific Tasks and Assign Responsibility

With your assets listed and frequencies set, it's time to get into the weeds of the actual work. Vague instructions just lead to inconsistent results. "Check motor" isn't an effective task. A much better instruction is, "Inspect motor brushes for wear, check connections for tightness, and listen for abnormal bearing noise."

For each asset and frequency, create a clear, actionable checklist of tasks. It helps to group related tasks together. For instance, a "Quarterly PM for Air Compressor AC-002" might include:

Change oil.

Replace air filter.

Inspect belts for tension and wear.

Drain moisture from the receiver tank.

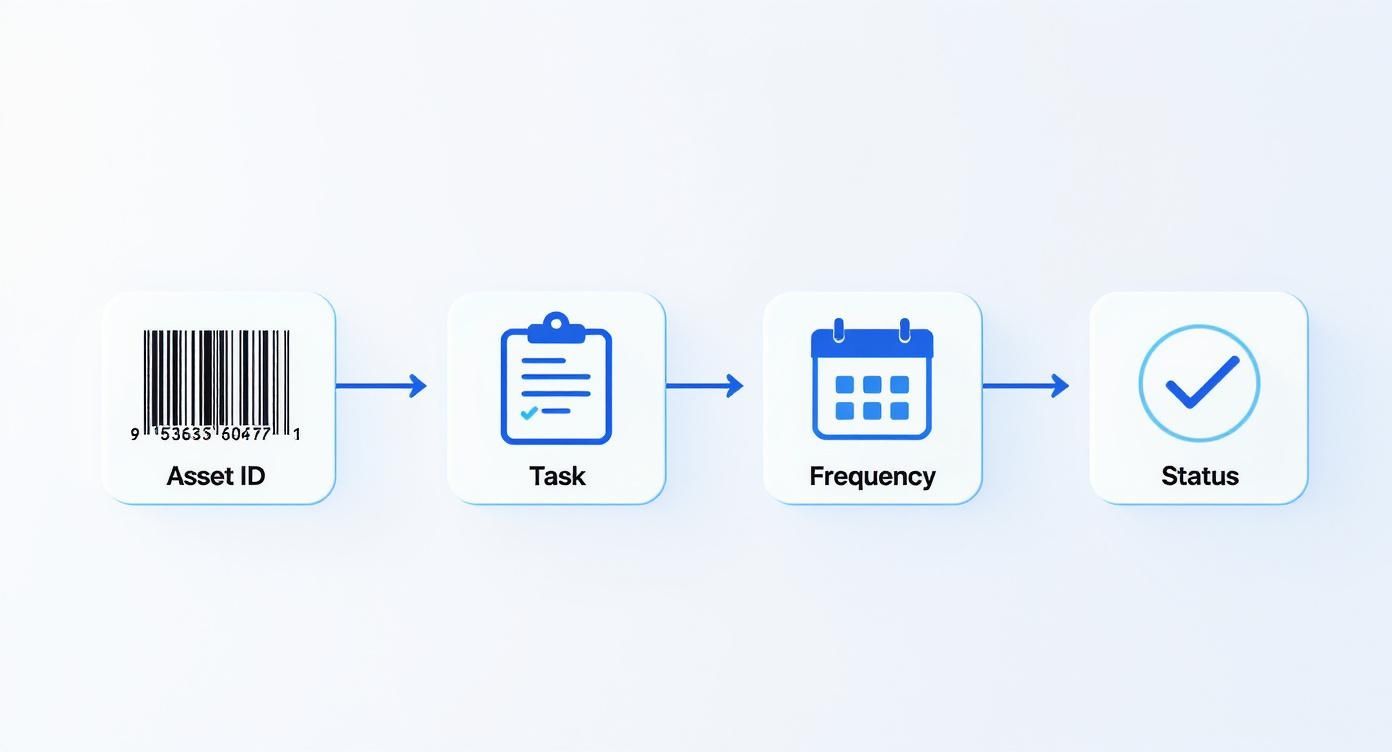

This visual workflow shows how each piece of data, from asset identification to task status, flows logically to create a plan you can actually execute.

This workflow turns raw data into actionable maintenance intelligence, guiding a task from initial identification all the way to completion.

The final piece of the puzzle is assigning responsibility and setting clear deadlines. Every single task needs an owner. Accountability is what turns a plan into action. Whether you assign tasks to an individual tech or a specific team, make sure it’s clearly documented in your template.

A schedule without assigned owners is just a wish list. Accountability is the engine that drives a preventive maintenance program forward, ensuring tasks are not only planned but also completed on time.

Finally, populate the "Next Due Date" for every task. This forward-looking calendar becomes your guide for allocating resources, ordering parts, and planning labor for the weeks and months ahead. With these elements in place, your blank template is no longer just a document—it's a comprehensive, actionable plan ready to protect your assets and your bottom line.

Putting Your New Maintenance Program Into Action

You've got a perfectly filled-out preventive maintenance template ready to go. That’s a huge step, but it's only half the journey. The real test is rolling it out to your team.

A successful launch turns that spreadsheet into a powerful tool that actually prevents breakdowns and saves money. But that transition from planning to action all comes down to one thing: getting your team on board. If your technicians don't understand the schedule, believe in the process, or find it a pain to use, the whole program will stall out before it even gets going.

Get Your Team On Board With Clear Communication

From what I’ve seen, the number one reason new maintenance programs fail is a lack of clear communication. You can't just drop a new schedule on your team and expect them to follow it—that's a surefire way to meet resistance. You have to explain the why, not just the what.

Hold a kickoff meeting to walk everyone through the new schedule. Focus on the benefits that directly affect them:

Fewer emergency calls. Proactive work means fewer middle-of-the-night breakdowns and stressful, last-minute repairs.

Safer working conditions. Well-maintained equipment is safer equipment. This isn't just about compliance; it's about their personal well-being. Regular checks can prevent a worn hydraulic line from bursting under pressure, for example. Our guide on industrial hose safety dives deep into how critical these small checks are.

More predictable workdays. A schedule brings structure, which means less chaos and better planning for everyone.

When your team sees the program as a tool to make their jobs better, they become its biggest advocates.

Nail Down Your Training and Record-Keeping

Once your team understands the mission, it’s time for practical training. Never assume everyone knows how to use the new template or what you expect. Walk them through it, column by column, showing them exactly how to log their work.

Define your terms. Does "Completed" mean the task is done, or that the paperwork is also filed? Does a "Note" need to include specific part numbers? Consistency is what makes your data valuable over time.

A well-maintained schedule is more than a to-do list; it’s a detailed historical log of your asset health. This documentation becomes invaluable during safety audits and compliance checks, serving as concrete proof of your commitment to operational integrity.

This detailed data collection has a real impact on your bottom line. A PWC study found that a solid preventive maintenance strategy decreases operational costs by 12%, improves asset availability by 9%, and extends equipment lifetime by 20%. These aren't just abstract numbers; they’re tangible returns on your investment.

Create a Feedback Loop for Continuous Improvement

Your PM schedule should be a living document, not something set in stone. The people who know your equipment best are the technicians working on it day in and day out. Their insights are pure gold for refining your program.

Set up a formal way for them to give feedback—maybe it’s a weekly huddle, a dedicated section on their work orders, or a digital channel. Encourage them to share what they're seeing.

Ask them direct questions to get the ball rolling:

Is the frequency for this task too high or too low?

Is the task description clear enough?

Are we missing a critical check that could prevent a common failure?

For instance, a tech might notice a specific bearing is showing premature wear despite the quarterly lubrication schedule. Their feedback could lead you to bump the frequency to monthly for that component, heading off a costly failure down the road. This collaborative approach not only makes your schedule more effective but also gives your team a sense of ownership. They're no longer just following orders; they're helping build a better, smarter operation.

When to Partner with Maintenance Professionals

Even the best preventive maintenance schedule can’t account for everything. Sometimes, managing the entire program in-house just isn’t practical. Your team might be stretched thin, or you might have specialized equipment that requires a unique skill set your technicians don't have.

Recognizing when to call for backup is a strategic move, not a sign of failure.

Think about complex machinery like high-pressure hydraulic systems or specialized industrial engines. Trying to tackle a complex repair without the right tools or experience can quickly turn a minor hiccup into a major outage. A good maintenance partner acts as a valuable extension of your team, bringing in specialized skills right when you need them most.

Filling Critical Gaps in Your Program

A maintenance partner can step in to fill several key roles, keeping your program from falling behind. This isn't about replacing your team but augmenting it to handle specific challenges that can easily overwhelm an in-house crew.

Common situations where a partner adds immediate value include:

Initial Asset Audits: If you're building your schedule from the ground up, a professional can run a thorough asset inventory to make sure no critical equipment gets missed.

Specialized Service Calls: For jobs like custom hydraulic hose fabrication or diagnostics on proprietary equipment, an expert technician gets the job done faster and more safely.

Sourcing Hard-to-Find Parts: When a machine goes down, every minute spent waiting for a specific part costs money. A service provider with an established supply chain can often track down components much faster, minimizing your downtime.

Scaling Your Maintenance Capacity

Sometimes, the issue isn't a lack of skill but a simple lack of manpower. During peak production seasons or when multiple assets need service at the same time, your team can get overloaded in a hurry. This is where a professional service can provide the extra capacity to keep your schedule on track.

Partnering with a maintenance service isn't about outsourcing your entire operation. It's about strategically bringing in expertise and manpower to handle high-stakes tasks, ensuring your preventive maintenance program runs smoothly without burning out your staff.

Instead of pulling your technicians away from their core responsibilities, you can bring in a team to handle a planned overhaul or a series of complex inspections. This gives you the flexibility to scale your maintenance efforts up or down based on operational demands—all without the overhead of hiring more full-time staff.

At Contractor's Maintenance Service, we've built our reputation on providing this exact kind of support. You can learn more about how we partner with businesses by exploring our story and services. This collaborative approach ensures your assets get the expert attention they deserve while your team stays focused and productive.

Got Questions? We’ve Got Answers.

Even with the best template in hand, putting a new preventive maintenance program into practice always brings up a few questions. It’s completely normal. Here are some straightforward answers to the things we hear most often from managers and technicians getting their hands dirty with a new PM schedule.

How Often Should I Actually Review My PM Schedule?

Think of your PM schedule as a living document, not something you carve in stone and forget about. A good rhythm is a quick check-in quarterly and a much deeper, more thorough review annually.

But don't wait for the calendar. You should jump in and update the schedule immediately when certain things happen:

You install a new, critical piece of equipment.

An old asset is finally retired or replaced.

You’re seeing the same failure over and over, which tells you the current frequency isn't cutting it.

Your operations change in a big way, like adding a second shift or changing production demands.

Constant tweaks and reviews are what keep your schedule relevant to what’s actually happening on the floor. It’s this continuous loop of improvement that turns a basic checklist into a powerful, strategic asset for your facility.

What’s the Difference Between Fixed and Floating Schedules?

Getting the timing right is everything. The two most common ways to schedule tasks are fixed and floating, and knowing when to use each one makes a huge difference in efficiency.

Fixed Schedules: These are tied to the calendar. Think "first Monday of every month," no matter what. This approach is perfect for compliance-driven tasks like safety inspections or for equipment that degrades over time, not based on how much you use it. The due date is locked in.

Floating Schedules: These are triggered by when the last task was completed. If a 30-day task gets done five days late, the next one is due 30 days from that new completion date. It’s a more flexible method that stops tasks from piling up, which works great for equipment where the exact calendar date doesn’t matter as much.

Most facilities end up using a mix of both. Your fire suppression system might be on a rigid, fixed quarterly schedule for regulatory reasons, while a forklift’s oil change is on a floating 200-hour schedule based on actual run time.

How Do I Get My Technicians to Actually Use This Thing?

This is the big one. You can have the perfect system, but if your team doesn't buy in, it's worthless. The trick is to show them how this new schedule makes their lives easier, not just adding more paperwork.

First, explain the "why." Nobody likes change for the sake of change. Talk about how proactive maintenance means fewer emergency calls on a Saturday night and less time scrambling to fix unexpected breakdowns. Then, bring them into the process. Ask for their input on the task lists and frequencies. After all, they’re the ones who know this equipment inside and out.

When your team sees that their expertise is valued and that this new system is designed to eliminate their biggest headaches, they’ll go from just using the program to actively championing it.

Finally, make it dead simple to use. If the process is clunky or confusing, people will find a way around it. Whether you’re using a digital tool or a well-designed spreadsheet, it needs to be easy for a tech to see what’s due, log their work, and move on. The less friction, the better your chances of success.

Putting a solid preventive maintenance program together is a massive step forward, but you don’t have to go it alone. When you need expert support with parts, diagnostics, or those really tough service calls, Contractor's Maintenance Service is here to help. Learn how our solutions can keep your operations running smoothly.

Comments