Your Essential Guide to Air Compressor Pressure Gauges

- DLL Studios

- 5 days ago

- 17 min read

Think of your air compressor's pressure gauge as more than just a dial—it's the command center for your entire operation. It's the one thing telling you exactly what’s happening inside your powerful equipment. A lot like a speedometer keeps you from getting a speeding ticket, a good pressure gauge keeps you from dealing with costly downtime, wasted paint, or even a catastrophic failure.

An accurate reading is everything.

Why Your Pressure Gauge Is Your Most Important Tool

A bad reading can ruin a job. It can lead to splotchy paint finishes, weak soil compaction, or dangerous system overloads that bring everything to a halt. Getting this one component right is the first step to mastering your equipment, delivering better results, and protecting your bottom line. It's the silent partner making sure every tool runs exactly like it's supposed to.

For contractors and service shops, the stakes are always high. Whether you're running Graco sprayers for that perfect finish or Multiquip compactors to build a solid foundation, precise pressure isn’t just a nice-to-have; it's non-negotiable. When a gauge is off, it’s not just frustrating—it costs you real money in rework and wasted materials.

How Accurate Pressure Impacts Your Bottom Line

It’s easy to overlook a small part like a gauge, but its impact on profitability is huge. The correct pressure setting directly influences everything from how much material you use to how long your equipment lasts. Inaccurate pressure, on the other hand, introduces risk and waste into every job.

This table breaks down the real-world consequences across different applications:

Application | Impact of Correct Pressure | Risk of Inaccurate Pressure |

|---|---|---|

Commercial Painting | Flawless, even finish. Up to 20% less material waste. | Uneven coats, runs, and wasted paint. Potential damage to the sprayer pump. |

Pressure Washing | Efficient cleaning without surface damage. Faster job completion. | Stripped paint, etched concrete, or ineffective cleaning. Increased labor time. |

Soil Compaction | Meets engineering specs for a solid foundation. Prevents future settling. | Failed inspections, structural issues, and costly rework. |

Pneumatic Tools | Tools operate at peak power and efficiency. Longer tool lifespan. | Reduced tool performance, premature wear, and potential safety hazards. |

As you can see, a reliable gauge isn't just a component—it's a tool for quality control, safety, and cost management. Keeping your pressure in the sweet spot is key to running a tight, profitable operation.

The True Cost of Inaccuracy

There's a reason the global air compressor gauge market is valued between USD 650 million and USD 950 million—these devices are absolutely essential. The market's growth is all about the increasing need for precision to avoid expensive operational headaches. Just look at commercial painters using airless sprayers. Hitting the optimal pressure, typically between 2,000 to 4,000 PSI, can slash material waste by up to 20%. You can discover the full research on the air compressor gauge market to see just how critical these components are across the board.

This guide will walk you through everything, from picking the right gauge to keeping it calibrated, so your tools run safely and profitably. A good pressure gauge is a small investment that protects the much bigger ones you've made in your heavy equipment.

Think of it this way: a pressure gauge is your equipment's translator. It converts invisible force into a clear, actionable number, giving you the control to execute a job perfectly or stop before a disaster happens. Ignoring it is like ignoring your most experienced crew member.

Local Expertise for California's Central Coast

For contractors and maintenance shops from San Luis Obispo and Arroyo Grande to Paso Robles and Atascadero, downtime is the enemy. That's why having a local partner who can get you what you need—fast—is a game-changer. We provide expert service and stock genuine parts for the industry's leading brands, right here in our community.

We're proud to serve professionals throughout the area, including:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

When a critical gauge fails on a job site in San Luis Obispo County, you can’t afford to wait a few business days for a part to be shipped. Our team is here to provide the parts and know-how to keep your operations running smoothly. Consider us your local partner in keeping every piece of equipment running perfectly.

Understanding the Different Types of Pressure Gauges

When you're outfitting your rig, choosing the right pressure gauge isn't as simple as grabbing one that fits the thread. Different gauges are built for specific jobs, environments, and levels of precision. Think of it like using a framing hammer versus a finishing hammer—both drive nails, but you'll get lousy results using the wrong one for the job. The same logic applies here; the right gauge ensures your equipment performs exactly how you need it to.

You'll come across all sorts of gauges on a job site, from the classic analog dials on a shop compressor to the fancy digital readouts on a high-end paint sprayer. Each type serves a distinct purpose, whether it’s giving a tough, reliable reading on a compactor or delivering pinpoint accuracy for a flawless finish.

Bourdon Tube Gauges: The Industry Workhorse

The most common gauge you'll run into is the good ol' Bourdon tube gauge. It's the dependable, analog workhorse you see on countless air compressors, and its design is brilliantly simple. Inside the casing, there’s a curved, flattened metal tube connected to whatever you’re measuring the pressure of.

Picture a coiled party blower. When you blow into it, the whole thing tries to straighten out, right? A Bourdon tube works exactly the same way. As air pressure builds, the tube tries to uncoil. This movement is hooked up to a series of gears and springs that turn the needle on the dial, giving you a pressure reading. It's simple, purely mechanical, and incredibly reliable.

Digital Gauges for Unmatched Precision

When getting the pressure exactly right is non-negotiable, digital gauges are the only way to go. These give you a precise numerical readout, taking all the guesswork out of trying to interpret where a needle is pointing between two lines. For a professional painter using a Graco sprayer, that level of precision is the difference between a good finish and a perfect, factory-like one.

Digital technology has really changed the game for contractors. These models are now dominating the market, with sales climbing from USD 1,355 million in 2021 to a projected USD 1,850.3 million by 2025. For pros running Multiquip compactors or Honda engines in places like San Luis Obispo, these gauges offer real-time data that can slash over-pressurization incidents by as much as 35%, according to industry safety reports. You can see the market trends for yourself and understand how this shift is impacting the tools we use every day.

A digital gauge is like using a laser measure instead of a tape measure. Sure, both get the job done, but one gives you an indisputable, exact number that removes all doubt. That's vital when your reputation is on the line.

Gauges for Harsh and Demanding Environments

Job sites are tough places, and sometimes you need a gauge built to handle more than just clean air pressure. This is where the specialty gauges earn their keep.

Diaphragm Gauges: These are your go-to for durability when dealing with thick or nasty materials. A flexible diaphragm acts as a barrier, separating the delicate internal workings from whatever you're measuring. This setup is perfect for slurries, chemicals, or anything corrosive that would clog up or destroy a standard Bourdon tube in a heartbeat.

Glycerin-Filled Gauges: Ever seen a gauge where the needle is vibrating so much you can't even read it? That's a classic problem on equipment like compactors or pressure washers where the vibration is constant. A glycerin-filled gauge solves this by submerging the internal parts in glycerin. The liquid dampens the vibrations, stabilizes the needle for a clear reading, and lubricates all the moving parts, making the gauge last a whole lot longer.

For any contractor working in Paso Robles or Atascadero, where gear gets bounced around in the back of a truck and put through hell on the job, a rugged glycerin-filled gauge is often the smartest investment to prevent constant replacements. Picking the right gauge for the environment is just as critical as picking one for the application itself.

Choosing the Right Gauge for Your Contractor Equipment

With several options available, it's easy to feel overwhelmed. Use this table as a quick cheat sheet to match the right gauge type to your specific equipment, environment, and need for precision.

Gauge Type | Best For | Key Advantage | Common Application |

|---|---|---|---|

Bourdon Tube | General-purpose, stable environments | Cost-effective and reliable | Shop air compressors, pneumatic tools |

Digital | High-precision applications | Exact numerical readout, eliminates guesswork | High-end paint sprayers, calibration tools |

Diaphragm | Corrosive or thick media (slurry, chemicals) | Protects internal parts from contamination | Chemical sprayers, wastewater equipment |

Glycerin-Filled | High-vibration equipment | Dampens needle flutter, extends gauge life | Pressure washers, plate compactors |

Ultimately, the goal is to select a gauge that not only provides an accurate reading but can also withstand the daily abuse of your specific work environment. Taking a moment to consider these factors upfront will save you from frustration and costly replacements down the road.

How to Select the Perfect Gauge for Your Air Compressor

Picking the right gauge for your air compressor is about more than just finding one that fits. Think of it like choosing the right tires for a truck; the details make all the difference for performance, safety, and how long it lasts. Get it right, and you prevent early failures, get dead-on accurate readings, and keep your gear running like a champ.

This quick guide will walk you through the key specs you need to nail down, from the pressure range and dial size to the materials inside. Once you get a handle on a few core ideas, you'll be able to make a smart choice that protects your equipment and helps you deliver quality work.

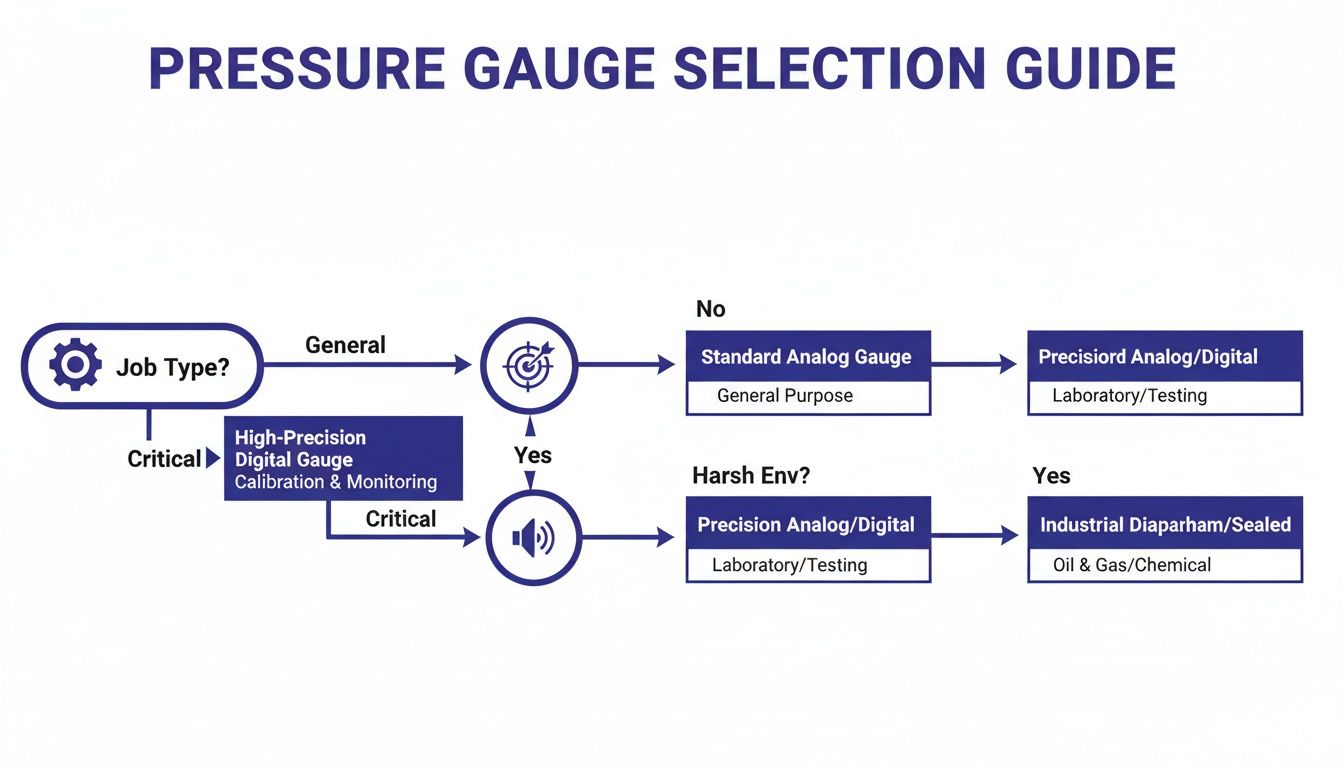

This visual decision tree is a great starting point. It simplifies the process, walking you from your specific job to the right gauge features based on how precise you need to be and how tough the environment is.

The main takeaway here is simple: let your application do the talking. Whether you're doing high-end paint jobs or dragging equipment around a dusty job site, those demands should dictate your choice.

Follow the "Rule of Double" for Pressure Range

The single most critical factor in picking air compressor pressure gauges is getting the pressure range right. A classic rookie mistake is grabbing a gauge with a max reading that’s too close to the system's normal operating pressure. That's where the "Rule of Double" saves the day.

Your gauge's maximum pressure reading should be roughly double your system's normal operating pressure. So, if your compressor usually hums along at 90 PSI, you should be looking for a gauge with a range of at least 160 PSI to 200 PSI.

Why? Sticking to this rule protects the gauge’s guts—specifically the Bourdon tube—from being constantly pushed to its limit. This simple step prevents premature wear and tear, ensuring the gauge stays accurate for the long haul. A maxed-out gauge is an unhappy, inaccurate, and short-lived gauge.

Match Accuracy Grade to the Task

Not every job needs laboratory-level precision. Pressure gauge accuracy is standardized by ASME B40.1, which assigns grades based on the percentage of error across the entire dial. It sounds technical, but it’s pretty straightforward in the real world.

Grade 3A (±0.1%) & 4A (±0.25%): These are the super-precise gauges you’d find in a calibration lab. You won't see these on your typical job site compressor.

Grade 1A (±1%): This is the sweet spot for professional work where consistency is everything, like automotive refinishing or industrial coating. A 1% variance on a 100 PSI scale means your reading is accurate to within 1 PSI. That’s pretty tight.

Grade B (±3-2-3%): This is the workhorse grade for general-purpose gear like shop compressors and tire inflators. The accuracy is ±3% in the first and last quarter of the scale, and a bit better at ±2% in the middle half where you'll be working most of the time.

For contractors and service shops, matching the grade to the job is just plain smart business. A high-end paint sprayer needs that Grade 1A accuracy to lay down a perfect finish. For a deeper dive, check out our guide on how to choose a compressor for painting to see just how much pressure impacts the final product.

Consider Dial Size and Material Compatibility

Finally, don't forget the practical stuff. The dial size needs to be big enough to read easily from where you'll be standing. A 2.5-inch or 4-inch dial is a solid, standard choice for most industrial equipment.

Material compatibility is just as important. For most compressed air systems, a brass connection with a steel case does the job just fine. But if that gauge is going to be exposed to corrosive chemicals or the salty, damp air we get in coastal areas like Morro Bay, spending a little extra on a stainless steel or glycerin-filled model is a wise investment. It’ll save you from dealing with rust and internal damage down the line.

Best Practices for Gauge Installation and Mounting

A top-notch pressure gauge is only as good as its installation. Get it wrong, and you're looking at dangerous leaks, bogus readings, and even a busted compressor. Following a few simple best practices ensures your gauge works like it's supposed to, protecting both your gear and your wallet. Think of it this way: a small mistake at the start can turn into a huge headache down the line.

For anyone who takes their work seriously, proper installation isn't optional. Even a tiny leak from a poorly sealed thread can make your compressor cycle on and off constantly. That just burns electricity and puts a ton of unnecessary wear on expensive parts like the motor and pump.

Step 1: Safety First Depressurize the System

Before you even think about grabbing a wrench, the absolute first rule is to completely depressurize the system. Trying to swap a gauge on a live, pressurized line is a recipe for disaster. That gauge can turn into a projectile, and you don't want to be in the way when it does.

Always, always verify the system is at 0 PSI. You can check another gauge or just crack open a drain valve. Never just assume it's empty. This is a non-negotiable first step for any professional contractor or maintenance crew.

Step 2: Seal the Threads Correctly

Getting an airtight seal is the name of the game. You've got two main choices here: Teflon tape or a liquid pipe sealant, often called pipe dope. Most of the time, it just comes down to personal preference, but there are a few tricks to getting it right.

Teflon Tape: When you're using tape, make sure to wrap it clockwise on the male threads—the same direction you'll be tightening the fitting. This keeps the tape from bunching up or shredding. 2-3 wraps is usually the sweet spot; any more is just overkill.

Pipe Dope: Just brush a thin, even coat onto the male threads. A good tip is to leave the first one or two threads bare. This stops the sealant from getting squeezed into the system where it could clog up the tiny opening in the gauge.

A good seal prevents those slow, annoying leaks that kill your system's efficiency. For a complete overview of how pressure connects to other system components, you can learn more about air pressure regulator performance in our detailed guide.

One of the most common mistakes we see is over-tightening. You're trying to create a seal, not weld the parts together. Put your wrench on the fitting—never the gauge case itself—and tighten until it’s snug. Then, just give it another quarter to half a turn. Cranking down too hard can crack the fitting or wreck the delicate guts of the gauge.

Step 3: Isolate Gauges from Vibration

Vibration is the silent killer of air compressor pressure gauges. On equipment like compactors or even big stationary compressors, the constant shaking can demolish the sensitive pointer mechanism and gears inside a standard gauge. This is something we see all the time on equipment that comes into our shop from job sites across San Luis Obispo and Paso Robles.

Luckily, you can protect your gauge from all that rattling.

Use a Snubber: This little device screws in between the gauge and the system. It has a porous metal disc inside that evens out pressure spikes and dampens vibration before it ever reaches the gauge.

Install a Pigtail Siphon: While these are mainly for steam or high-temp lines, a pigtail siphon creates a water barrier that protects the gauge from heat. As a bonus, it also helps absorb some vibration.

Opt for a Glycerin-Filled Gauge: As we covered earlier, liquid-filled gauges are the best defense against vibration. The glycerin inside naturally soaks up all the shaking and keeps the needle rock-steady.

For contractors working in demanding spots from Atascadero to Arroyo Grande, spending a few extra bucks on these accessories is cheap insurance. It ensures your gauges last and give you readings you can actually trust.

Troubleshooting Common Pressure Gauge Failures

Even the toughest air compressor pressure gauges eventually give out. On a busy job site, a faulty gauge isn’t just an annoyance—it's a full-stop problem that costs you time and money. Knowing how to quickly spot and fix the issue means you can get back to work faster, whether you're on a project in San Luis Obispo or finishing up in Atascadero.

Think of this section as your field guide to troubleshooting. We'll walk through the tell-tale signs of a gauge in distress, pinpoint the likely culprits, and give you clear, actionable steps to get your equipment running right.

The Pointer Is Stuck or Won't Zero Out

One of the most common problems we see is a pointer that doesn't return to zero when the system is depressurized. This is a dead giveaway that the gauge has been permanently damaged and can no longer be trusted.

The cause is almost always over-pressurization. When a gauge is hit with pressure way beyond its maximum rating, the internal Bourdon tube gets bent out of shape for good. It's just like over-stretching a spring—it never quite bounces back.

Solution: There’s no reliable fix for this. The only safe and professional move is to replace the gauge immediately. Using a gauge with a zero-point error is a serious safety risk, as every single reading it gives will be wrong.

Erratic or Fluttering Needle

Ever see a gauge needle vibrating so wildly you can't get a solid reading? That erratic dance is called pointer flutter, and it’s a classic sign that your gauge is dealing with intense vibration or rapid pressure pulses.

This is a frequent headache for equipment that shakes hard, like the compactors and pressure washers we service for crews from Paso Robles to Arroyo Grande. The constant shaking just destroys the delicate internal gears and linkage controlling the pointer, leading to a quick and early failure.

Luckily, a simple fix can prevent this:

Install a liquid-filled gauge: The glycerin inside the case acts as a shock absorber, dampening vibrations and stabilizing the needle.

Use a pressure snubber: This small device installs right before the gauge to smooth out pressure spikes and absorb the jarring motion.

If your current gauge is already fluttering, its guts are likely toast. Your best bet is to replace it with a glycerin-filled model to stop the problem from happening all over again.

The Gauge Lens Is Cracked, Fogged, or Leaking

A gauge's face is a critical window into your system, but it's also exposed and vulnerable. A cracked, fogged, or leaking lens means the gauge's protective case has been breached.

Cracked Lens: Usually the result of a direct hit. A crack lets dirt and moisture sneak in, which will quickly corrode and ruin the internal components.

Fogged Lens (Condensation): This tells you moisture has gotten inside the case. As the compressor cycles on and off, temperature changes cause that moisture to condense on the inside of the lens, blocking your view.

Leaking Liquid: If you see glycerin weeping from a liquid-filled gauge, a seal has failed. It can no longer do its job of dampening vibration and protecting the internal parts.

For any of these issues, the solution is simple: replace the gauge. A compromised case can't be repaired effectively and will eventually lead to total failure. For contractors working in the damp, coastal air of Morro Bay, a sealed, weatherproof gauge is a must to prevent moisture problems from the get-go. We keep a full stock of durable, sealed gauges ready for quick pickup or delivery throughout San Luis Obispo County.

Maintaining Your Gauges for Safety and Accuracy

When it comes to your equipment, proactive maintenance is what separates the pros from the amateurs. Taking care of your air compressor pressure gauges isn't just about protecting your investment; it's a core safety practice that protects your gear, your crew, and your reputation on every job site across the Central Coast.

A well-maintained gauge gives you readings you can trust. A neglected one is a liability waiting to happen. A few simple, consistent checks can prevent catastrophic failures and expensive downtime, keeping your operations in San Luis Obispo and beyond safe and efficient.

The Critical Role of Calibration

For any job where precision is key—from applying industrial coatings to hitting exact engineering specs—calibration isn't optional. Think of it as tuning your gauge. We compare its readings to a certified standard to make sure it’s still accurate. Over time, things like vibration, pressure spikes, and daily wear and tear can cause a gauge to "drift," giving you bad information.

To keep everything running safely and smoothly, you have to stay on top of maintenance. This includes understanding the importance of regular calibration so you can always rely on your pressure readings. For high-stakes jobs, a gauge that’s off by just a few PSI can mean shoddy finishes or failed inspections.

Your System's Built-In Safety Net

Your pressure gauge doesn’t work alone. It has a crucial partner: the pressure relief valve (PRV). You can think of them as a team—the gauge is the lookout, and the PRV is the bodyguard. While the gauge tells you the system's pressure, the PRV is a spring-loaded valve designed to automatically pop open and vent excess pressure if it climbs past a safe limit.

This partnership is your last line of defense against a catastrophic failure. If a compressor's pressure switch fails and the system over-pressurizes, a functioning PRV will prevent the tank from rupturing. A well-maintained gauge allows you to spot rising pressure long before the PRV has to activate.

Maintenance Schedules and Local Service

How often you test and calibrate really depends on how you use your gear. For critical applications or equipment that takes a beating from vibration, an annual check is a smart move. For general shop use, checking in every two years might be enough. Of course, extending equipment life also means using quality components, a topic we dive into in our guide to using synthetic oil in your air compressor.

The numbers don't lie. The global pressure gauge market was valued at USD 929.88 million and is growing, proving just how vital these parts are for industrial safety. For example, after OSHA's 29 CFR 1910.169 required gauges with ±2% accuracy, their use skyrocketed, leading to a 50% drop in high-pressure compressor incidents since 2000. These figures show that quality air compressor gauges save lives and can slash prevention costs by up to 30%.

For all the contractors out there in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, and Morro Bay, we offer professional gauge testing, calibration, and replacement services to keep your operation compliant, safe, and running smoothly.

Frequently Asked Questions About Air Compressor Gauges

Even the most seasoned pros run into questions about air compressor pressure gauges out in the field. Getting a straight answer fast can be the difference between a five-minute fix and hours of frustrating downtime. Here are some of the most common questions we get from contractors and service shops up and down the Central Coast.

Think of this as your quick-reference guide for handling those specific, on-the-fly situations. It also reinforces the core safety and maintenance habits that keep your gear running right and your crew safe.

How Often Should I Replace My Air Compressor Gauge?

There’s no single, hard-and-fast rule, but a good practice is to inspect your gauges annually and plan on swapping them out every 3-5 years. However, if a gauge is on a piece of equipment that's constantly vibrating—like a compactor—or lives in a particularly grimy or corrosive environment, you’ll want to replace it every 1-2 years as part of your preventive maintenance schedule.

Bottom line: you must immediately replace any gauge that shows visible damage, is leaking, or is clearly inaccurate. The classic sign of a dead gauge is a pointer that doesn't return to zero when the system is completely depressurized.

Can I Use a Water Pressure Gauge on My Air Compressor?

Absolutely not. This is a common question, but doing this is a huge safety risk. Gauges are built for specific jobs. A water gauge is designed for an incompressible liquid, while an air compressor gauge is engineered to measure a compressible gas. They are not interchangeable.

Using the wrong type of gauge won't just give you unreliable readings; it can lead to a sudden mechanical failure. More importantly, it gives you a dangerously false sense of security about your system's pressure. Stick with gauges specifically designed and rated for compressed air. No exceptions.

What Does the Red Line on My Pressure Gauge Mean?

That red line isn't just for decoration—it's a critical safety warning. It marks the Maximum Allowable Working Pressure (MAWP) for the gauge and, often, for the entire piece of equipment it's attached to. Pushing the needle into that red zone is like playing with fire.

Operating in the red means you're pushing your equipment way past its design limits, risking a catastrophic failure of the tank or other components. If you ever see your gauge's needle creep into the red, your first move is to safely and immediately depressurize the system. Don't even think about using it again until you've figured out why it over-pressurized and fixed the root cause.

Why Is My Glycerin-Filled Gauge Leaking?

If you see glycerin weeping from your gauge, it usually points to a failed case seal or a busted O-ring. This doesn't just happen on its own. The common culprits are:

Physical Impact: Getting dropped or smacked can easily compromise the case seals.

Extreme Temperature Swings: Quick, drastic temperature changes can cause the gauge's case to expand and contract, eventually breaking the seal.

Chemical Damage: Exposure to harsh solvents or other chemicals can eat away at the rubber seals over time.

While a small leak might not kill the gauge’s accuracy right away, it means it has lost its ability to dampen vibration and protect its internal guts. It's a clear sign the gauge is on its last legs. The best move is to replace it before it fails completely.

For expert advice, parts, or service on your equipment in San Luis Obispo, Arroyo Grande, Paso Robles, Atascadero, and Morro Bay, trust the professionals. Contractor's Maintenance Service has the inventory and expertise to keep you operational. Visit us online or at our local service counter today.

Comments