A Contractor’s Guide to Choosing a Compressor for Painting

- Dec 26, 2025

- 15 min read

Choosing the right compressor for painting isn't just about picking a piece of equipment—it's about laying the groundwork for quality, efficiency, and a profitable job. For professional contractors and facility managers, having the right tool for the job is non-negotiable if you want to deliver exceptional results, every single time. This guide is built to help you make that critical choice.

Your Essential Guide to a Flawless Finish

We're going to cut through the jargon and get straight to what you need to know about compressor types, performance specs like CFM and PSI, and how to perfectly match your compressor to your paint sprayer. Whether you're laying down tough industrial coatings or tackling a detailed commercial project, your air compressor is the heart of the entire operation.

Get it wrong, and you're looking at inconsistent spray patterns, wasted paint, and frustrating downtime. But get it right? You unlock a new level of speed and precision that guarantees a perfect finish.

Why Your Compressor Choice Matters

Think of your compressor as the lungs of your painting system. Just like an athlete needs strong lungs to go the distance, your paint sprayer needs a steady, powerful supply of air to perform at its best. Without it, the paint won't atomize properly, leaving you with runs, drips, and an unprofessional finish.

A mismatched compressor is one of the most common causes of paint defects. It forces contractors to spend extra time and money on rework, which hits project timelines and profits right where it hurts.

Local Expertise for Central Coast Professionals

For pros working on the Central Coast, having local support is a huge advantage. A reliable equipment partner means less downtime and faster solutions when something goes wrong. We're proud to serve contractors and businesses throughout the region, making sure you have the tools and support you need to get the job done.

Our service areas include San Luis Obispo and all surrounding cities, such as:

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Templeton

Santa Margarita

Cayucos

Cambria

Nipomo

Santa Maria

From helping you select the right machine to keeping it running with ongoing maintenance, having an expert in your corner is a game-changer. Our local expertise ensures your equipment is always in peak condition, so you can walk onto any job site confident that your compressor for painting will deliver the flawless finish your clients expect.

Getting to Know Your Compressor: CFM, PSI, and Horsepower

To pick the right compressor for painting, you have to speak its language. It all boils down to three key terms: CFM (Cubic Feet per Minute), PSI (Pounds per Square Inch), and HP (Horsepower). Get these right, and you're already on your way to a flawless, professional finish.

Think of CFM as the volume of air your compressor can push out. It’s like the amount of water flowing from a garden hose—for a big job, you need a steady, high-volume flow. For painting, a higher CFM is non-negotiable. It guarantees your sprayer gets an uninterrupted supply of air, which prevents sputtering and gives you that smooth, even coat you’re after.

PSI, on the other hand, is all about pressure. It’s the force behind that air. In our hose analogy, it’s how hard the water blasts out of the nozzle. Different spray guns and coatings need specific PSI levels to atomize the paint correctly. Too little pressure and you get a blotchy, uneven mess. Too much, and you're just creating a cloud of overspray and wasting material.

Horsepower: The Metric That Can Steer You Wrong

Now, let's talk about horsepower. While HP tells you how powerful the compressor’s motor is, it can be a really misleading number if you look at it alone. A compressor with a big HP number but a low CFM rating is like a sports car with bicycle wheels—it has plenty of power but can’t actually deliver it where it counts. For contractors in San Luis Obispo or Paso Robles, focusing only on HP is a classic and costly mistake.

The real measure of a compressor's ability to handle a paint job is its CFM rating at a specific pressure. The industry standard is almost always 90 PSI. This number tells you exactly how much usable air the machine can actually produce for your tools.

Why Air Volume Beats Raw Power Every Time

Understanding how these three specs work together is everything. A professional-grade HVLP (High-Volume, Low-Pressure) spray gun might need 10-15 CFM to run properly. Your small, high-HP "pancake" compressor from the hardware store just can't keep up with that kind of demand.

The golden rule for professional results is to match your compressor's CFM output to what your sprayer needs, then add a 25-50% buffer. This ensures that even when you're spraying continuously on a big commercial job in Atascadero or Arroyo Grande, your compressor won’t falter.

This need for consistent, reliable airflow is why compressed air systems are the backbone of so many industries. In fact, the global industrial air compressor market was valued at USD 22.08 billion in 2023 and is only expected to grow. Manufacturing, where precision coating is a must, makes up 39.1% of this demand, since compressed air powers roughly 80% of all pneumatic tools. You can learn more about the stationary air compressor market and its growth.

By making CFM at 90 PSI your top priority, you’re aligning your choice with professional standards. You’re making sure your compressor for painting can handle any coating you throw at it and deliver the pristine finish your clients demand.

Matching Your Compressor to Your Paint Sprayer

Think of your compressor and paint sprayer as a professional duo—they have to be perfectly in sync to deliver a flawless performance. If your compressor and sprayer are mismatched, you're going to fight for a professional finish every step of the way. Each type of sprayer has its own specific air requirements, and getting that pairing right is non-negotiable for any serious contractor.

Without the right match, you’re just asking for trouble. Inconsistent spray patterns, poor paint atomization, and a finish that screams "amateur" are practically guaranteed. This is especially true for projects in demanding environments, whether you're tackling a big commercial build in Paso Robles or a detailed historical restoration in San Luis Obispo.

Decoding Sprayer Air Requirements

Different spray guns have vastly different appetites for air, and understanding those needs is the first step in picking the right compressor for painting. Let's break down the two most common types you'll see on the job.

High-Volume, Low-Pressure (HVLP) Sprayers: These are the artists of the painting world. They’re prized for their ability to lay down exceptionally fine finishes with high transfer efficiency. But all that precision comes at a cost—they are extremely air-hungry and demand a high, continuous CFM to atomize paint just right.

Conventional Sprayers: These are the classic workhorses. They operate at a much higher pressure (PSI) than HVLP models and are less efficient with paint transfer, but they excel with certain heavy industrial coatings. Their biggest need is a compressor that can consistently maintain high PSI without faltering under load.

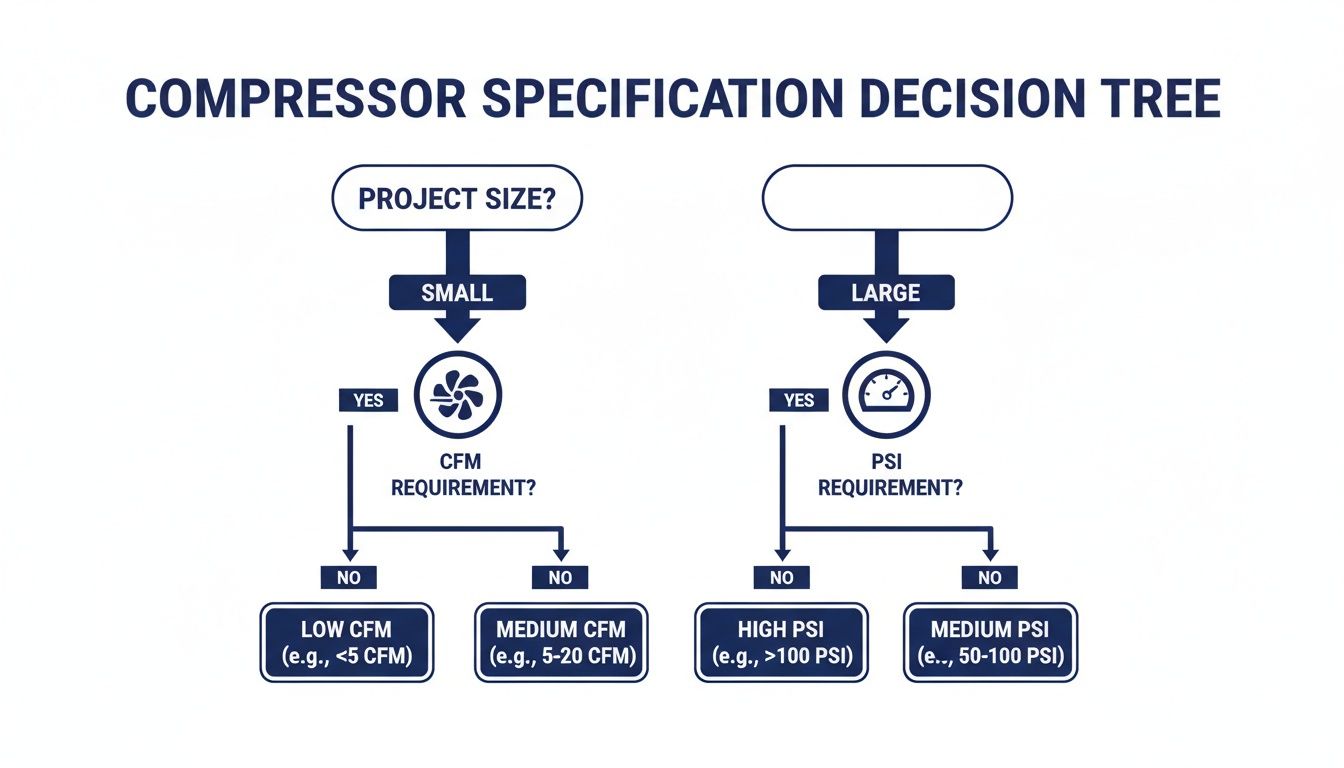

This decision tree helps visualize how to prioritize compressor specs based on your project's scale.

As you can see, for smaller, detailed jobs, CFM is the main concern for achieving that fine atomization. But for large-scale industrial projects, you really need high, sustained PSI to push heavier coatings all day long.

Before we dive deeper into sizing, here’s a quick-reference table to give you a ballpark idea of what different sprayers typically demand.

Compressor Sizing Guide for Common Paint Sprayers

This table provides a general guide for matching compressor specs to various sprayer types. Remember to always check your specific tool's manual for the most accurate requirements.

Sprayer Type | Required CFM @ 90 PSI | Required PSI Range | Best For |

|---|---|---|---|

HVLP (Gravity/Siphon) | 10-15+ CFM | 25-40 PSI | Fine finishing, automotive, cabinetry |

Conventional | 8-12 CFM | 40-60 PSI | General purpose, thicker coatings |

Detail/Touch-Up Gun | 3-6 CFM | 20-30 PSI | Small repairs, intricate details |

LVLP (Low Volume) | 5-10 CFM | 10-25 PSI | Woodworking, thin materials |

Getting these numbers right is the key to a professional finish and making sure your equipment works for you, not against you.

Calculating Your Total Air Demand

To make sure your compressor can keep up, you need to figure out your total air demand. This isn't just about matching the sprayer's CFM rating; it’s about building in a safety margin so your gear performs reliably, every single time. The pro standard is to add a solid buffer to your sprayer's requirements.

The Rule of Thumb: Take your paint sprayer's required CFM and add a 25-50% buffer. This ensures your compressor never struggles to keep up, preventing pressure drops that can completely ruin a paint job.

For example, if your HVLP gun requires 10 CFM at 90 PSI, you should be looking for a compressor that delivers at least 12.5 to 15 CFM. This buffer also accounts for potential air leaks, the length of your hose, and keeps the motor from running constantly, which will absolutely extend its lifespan.

Sizing for Job Scale and Multiple Users

Your calculation has to factor in the scale of your work, too. A single contractor doing touch-up work in Pismo Beach has very different needs than a crew running multiple guns on a large commercial site over in Atascadero.

If you plan to run two spray guns simultaneously that each require 10 CFM, your total demand is 20 CFM. Applying that buffer, you’d need a compressor capable of consistently delivering 25-30 CFM. Underestimating your needs when running multiple tools is a common and costly mistake that leads to poor performance and project delays.

To effectively match your compressor, it's also vital to understand the tool options available. Similar principles apply whether you're a pro or choosing the best paint sprayer for home use.

And for those curious about how air-powered systems stack up against their counterparts, our team put together a contractor's guide to using a paint spray gun airless system, which explores a totally different application method.

Ultimately, putting your money into a properly sized compressor for painting isn't an expense—it's an investment in quality and efficiency. It ensures that whether you're working in Arroyo Grande, Grover Beach, or Morro Bay, your equipment is a reliable partner, not a bottleneck holding you back.

Choosing the Right Compressor Type: Reciprocating vs. Rotary Screw

When it comes to picking a compressor for painting, you'll mainly run into two types: reciprocating (or piston) and rotary screw models. Getting a handle on how they differ is the key to making a smart, cost-effective choice that actually fits your workload, whether you're a painter in San Luis Obispo or run a big facility out in Paso Robles.

Here’s a simple way to think about it. A reciprocating compressor is like a sprinter—it gives you incredible power in short, intense bursts. That makes it the perfect rig for intermittent use, like for smaller shops or contractors who aren't spraying paint all day, every day. It gets the job done when you need it, but it also needs downtime to cool off.

On the other hand, a rotary screw compressor is a marathon runner. It’s built for endurance and can handle a 100% duty cycle, which means it can run nonstop without breaking a sweat. This makes it the clear winner for large-scale industrial painting, production lines, or any job where a steady, uninterrupted flow of air is non-negotiable.

The Reciprocating Piston Compressor

For most contractors, the reciprocating compressor is the workhorse of choice. They’re generally easier on the wallet upfront, and their parts are easy to find, which is a huge plus when you need a quick repair. These compressors work by using pistons to pull in and compress air, building pressure inside the tank.

They come in two main flavors:

Single-Stage Compressors: These models compress air in a single piston stroke. They're best for smaller, less demanding jobs and are a common sight in home workshops and garages.

Two-Stage Compressors: These are the more heavy-duty option. They compress the air once, cool it down, and then compress it again to a higher pressure. This process makes them more efficient and ready for longer run times and higher PSI demands—perfect for professional painters in Atascadero and Arroyo Grande who need reliable power.

The Rotary Screw Compressor

Rotary screw compressors work on a totally different principle. Inside, two interlocking helical screws spin together, trapping and compressing air as they go. This design delivers some serious advantages in high-demand settings. They provide a continuous, pulse-free stream of air, run much quieter, and are way more energy-efficient than their piston-driven cousins.

For businesses where painting is a core, daily operation, the efficiency and reliability of a rotary screw compressor often provide a lower total cost of ownership over time, despite the higher initial investment. This makes them a smart long-term choice for busy shops.

Their ability to deliver consistent, high-volume airflow is why you see them everywhere in industrial settings. Rotary screw compressors own the stationary air compressor market with a 47.2% share. That market, valued at a whopping USD 16.7 billion in 2023, shows just how much industries rely on them to power high-demand tools like professional-grade paint sprayers. You can learn more about the stationary air compressor market and its growth.

Making the Right Choice for Your Work

So, which one is for you? The decision really boils down to your workflow.

A contractor tackling residential projects in Grover Beach, Pismo Beach, or Morro Bay will probably find that a two-stage reciprocating compressor hits the sweet spot between performance and cost. It’s got plenty of muscle for most spray guns without the hefty price tag of a rotary screw unit.

But for a large manufacturing facility or a high-volume commercial paint shop, the choice is clear. The need for continuous operation makes a rotary screw compressor for painting the only practical option. It cuts out downtime, delivers cleaner air, and can support multiple painters at once without missing a beat. Investing in the right type of compressor from the get-go turns your equipment into an asset, not a bottleneck.

What Else to Look for: Essential Features and Accessories

Getting the core specs right on a compressor for painting is a great start, but it's only half the story. To really get your setup working like a well-oiled machine, you need the right features and accessories. These aren't just nice-to-haves; they’re what separate a frustrating job from a flawless finish.

On-the-Go vs. In-the-Shop

For any painter hauling gear between job sites in San Luis Obispo or Paso Robles, portability is everything. A clumsy compressor is a daily headache. Think about how you work. Wheelbarrow models are great for maneuvering over uneven ground, while truck-mount or skid-mounted units are perfect for secure transport.

Noise level is another huge deal, especially when you're working in occupied spaces like commercial buildings or quiet residential neighborhoods in Atascadero. The last thing you want are noise complaints. Look for a compressor that runs below 75 dB—it’s much less disruptive and keeps clients happy.

Air Quality Control is Non-Negotiable

The air that comes straight out of a compressor tank is a painter's worst enemy. It’s full of moisture, tiny oil particles, and dust, all of which will ruin your paint job. You absolutely need a good air treatment system to clean it up.

Getting clean, dry, and regulated air to your spray gun is the most critical step after picking the compressor itself. Skipping it is the number one cause of common paint defects like fisheyes, orange peel, and chipping.

A solid setup includes three key pieces installed in line between the compressor and your spray gun:

Moisture Separators/Filters: This is your first line of defense. They trap condensed water and bigger bits of debris right out of the gate.

Regulators: A regulator with a good, clear gauge lets you fine-tune the PSI for your specific spray gun. This gives you consistent atomization and cuts down on overspray.

Oil Removers/Coalescing Filters: These are for capturing the really fine stuff, like oil aerosols. They’re essential for getting that pristine air needed for automotive or fine-finish work.

Hoses, Fittings, and Permanent Setups

Your air hose is the lifeline connecting your compressor to your sprayer. A cheap or undersized hose will cause a major pressure drop, starving your spray gun of the air it needs to work properly. Don’t skimp here. Invest in a quality, durable hose with the right inner diameter to keep your pressure steady, even over long runs. Good fittings are just as vital for stopping those annoying air leaks that make your compressor run constantly.

Want to learn more? Check out our ultimate guide to the perfect paint sprayer hose.

For facility managers in places like Arroyo Grande or Grover Beach planning a permanent compressed air system, a little extra planning goes a long way. This usually means installing rigid piping—copper or specialized aluminum works best—to run air throughout a workshop. A proper installation needs to include automatic tank drains to purge moisture, plenty of ventilation to keep the compressor from overheating, and strategically placed air drops with filtration at every workstation. A well-designed system ensures every tool gets clean, reliable air while protecting your investment for the long haul.

Local Compressor Service and Support in San Luis Obispo

For contractors and facility managers across San Luis Obispo County, having a reliable local equipment partner isn’t just a nice-to-have—it’s a game-changer.

When your compressor for painting suddenly quits mid-job, every minute of downtime bleeds money and throws your entire schedule off track. This is where having real, local expertise makes all the difference.

Contractor's Maintenance Service is your on-the-ground support team right here on the Central Coast. We get the unique pressures of working in this region and are geared up to keep your projects running smoothly, without those costly interruptions.

Your Central Coast Service Partner

We’re not just another sales counter. We are an authorized service center for the industry’s top brands, which means we’re equipped to handle everything from routine tune-ups to complex warranty claims and emergency repairs. Our goal is simple: keep your equipment running at peak performance.

Our dedicated service area covers the heart of the Central Coast, including San Luis Obispo and the surrounding cities:

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Templeton

Santa Margarita

Cayucos

Cambria

Nipomo

Santa Maria

Having a trusted local expert who understands your work means you get the right parts and advice, fast. Whether you need a custom hydraulic hose fabricated on the spot or a hard-to-find fitting, our priority is to maximize your uptime. You can explore our extensive inventory of hose kits and paint accessories to find exactly what you need.

Why Proactive Maintenance Matters

Staying ahead of equipment failure is the secret to staying profitable. This is especially true as the industrial air compressor market continues to expand, with projections showing growth from USD 19.90 billion in 2025 to USD 29.81 billion by 2035.

Efficient models like rotary screw compressors are a big part of that growth, holding a 31% market share thanks to their reliability on high-volume jobs. Keeping your gear in top condition is essential to stay competitive. The best way to do that is by sticking to a flawless preventive maintenance schedule. Regular check-ups catch the small issues before they become major breakdowns.

By partnering with a local service center, you gain more than just repairs; you gain a proactive maintenance partner dedicated to preventing downtime before it happens. This approach saves money, extends the life of your equipment, and protects your professional reputation.

Our team is here to help you build and follow a maintenance plan that keeps your compressor for painting ready for any job. That way, you can deliver the quality finish your clients expect, every single time.

Painting Compressor FAQs

Even with a solid plan, questions pop up. It's just part of the job. Here are some of the most common ones we hear from contractors, with straight answers to help you solve problems and get back to work.

Can I Use a Small Pancake Compressor for Professional Painting?

In a word, no. While a pancake compressor is a great little tool for a brad nailer or filling up tires, it's just not cut out for professional painting. Paint sprayers are thirsty for air, and these small units simply can't deliver on two critical fronts: a high CFM rating and a decent-sized tank.

You'll end up with constant pressure drops, which makes your sprayer sputter and spit. The result is an uneven, blotchy finish that looks unprofessional. For any serious painting job, especially around San Luis Obispo, you need to step up to a larger machine. Think of a compressor with at least a 20-30 gallon tank that meets your sprayer's CFM specs as your starting line for a quality finish.

How Do I Keep Moisture Out of My Paint Job?

Moisture is the number one enemy of a perfect paint finish. It’s what causes those dreaded "fisheyes" and bubbling, forcing you to strip everything down and start over. Keeping your air supply clean and bone-dry requires a multi-step approach.

Here's how to build a solid defense against moisture:

Drain Your Tank Daily: This is non-negotiable. At the end of every workday, open the drain valve on your compressor tank. This gets rid of all the water that naturally condenses inside.

Filter at the Source: Install a good air filtration and drying system right at the compressor's outlet. A water separator or a coalescing filter will catch the bulk of the moisture and oil before it ever enters your hose.

Filter at the Gun: For the ultimate protection, add a final desiccant dryer or filter right before your spray gun. This is your last line of defense, ensuring the air is perfectly clean at the moment of use.

Moisture contamination is one of the most common—and most preventable—causes of paint failure. A proper filtration setup isn't just an accessory; it's a mandatory part of any professional painting system.

Why Is a Compressor's Duty Cycle So Important for Painting?

The duty cycle tells you how long a compressor can run in a ten-minute window before it needs to cool down. For instance, a compressor with a 50% duty cycle can run for five minutes straight, but then it must rest for the next five to avoid burning itself out. That might work for framing a wall, but it’s a non-starter for painting.

When you're spraying, you need continuous, uninterrupted airflow. That's why for almost any professional painting project, you need a compressor with a 100% duty cycle. This means the machine is engineered to run all day long without a break, letting you spray for hours without stopping. Rotary screw compressors are built for this, as are many industrial-grade reciprocating models.

Matching the duty cycle to your work isn't just about convenience—it's about protecting your equipment. Pushing a light-duty compressor on a heavy-duty job will quickly lead to overheating and catastrophic failure, bringing your project in Paso Robles or Arroyo Grande to a dead stop. Making sure your machine can handle the workload protects your investment and keeps your jobs on track. Whether you're in Atascadero or Pismo Beach, understanding this spec is crucial for choosing a reliable compressor for painting.

For expert advice, sales, and service on all your painting equipment needs, trust the local team at Contractor's Maintenance Service. We help professionals across the Central Coast choose the right tools and keep them running. Visit us at https://www.contractorsmaintenanceservice.com to learn more.

Comments