Your Ultimate Guide to the Perfect Paint Sprayer Hose

- Dec 16, 2025

- 17 min read

Think of your paint sprayer hose as more than just a tube—it's the main artery of your entire painting system. The quality, length, and diameter of this one component directly control your pressure, flow rate, and ultimately, the look of your final project. Honestly, choosing the right hose is one of the biggest secrets to getting professional results every time.

Why Your Paint Sprayer Hose Is Key to a Flawless Finish

Let's imagine your paint sprayer is the heart of the operation and the paint is the lifeblood. In that scenario, the paint sprayer hose is the critical artery delivering that lifeblood exactly where it needs to go. If that artery gets constricted, kinked, or starts to leak, the whole system fails. It’s a simple analogy, but it perfectly explains why a high-quality hose is completely non-negotiable if you want a flawless finish.

A lot of common painting frustrations—like inconsistent spray patterns, major pressure drops, and annoying clogs—can be traced right back to a mismatched or cheap hose. The hose's material, diameter, and length aren't just minor details; they're the technical specs that dictate how your whole rig performs. The wrong hose can even force your sprayer to work harder than it should, leading to premature wear and tear on your expensive equipment.

The Foundation of a Great Paint Job

At the end of the day, your hose is the bridge between your machine’s power and your hand’s skill. Picking the right one ensures you’re getting the full potential out of your Graco, Titan, or Wagner sprayer. Throughout this guide, we’ll get into how to choose the perfect hose, maintain it so it lasts, and troubleshoot any issues that pop up along the way.

Your paint sprayer hose isn't just an accessory; it's a core component that influences everything from material flow to the final texture. A great hose translates your sprayer’s power into a smooth, even coating.

This is especially true in today's global paint sprayer market, which was valued at a whopping USD 1.31 billion back in 2022. Hose technology is constantly getting better. Modern hoses have to withstand extreme pressures, often up to 3000 PSI, and premium models now feature multi-layered constructions that can extend their lifespan by 30-50% compared to basic rubber ones. You can find more insights on paint sprayer market trends over on Arizton.com.

Your Local Hose Experts on the Central Coast

For pros and dedicated DIYers here in San Luis Obispo County, getting the right gear is easy. We're proud to serve painters and contractors all across the Central Coast, offering expert advice and top-tier products. Our service areas include:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

By the time you finish this guide, you’ll have the know-how to select, use, and maintain your paint sprayer hose like a seasoned pro, saving you time, money, and headaches on every single job.

Choosing the Right Hose Material and Type

Think of your paint sprayer hose like the tires on a race car. You can have the most powerful engine in the world, but if the tires can't grip the track, all that power is wasted. In the same way, your hose is the critical link between your sprayer and the surface, and its material directly impacts flexibility, durability, and how your whole setup performs under pressure.

Not all hoses are built the same. The material it's made of dictates how it will behave on the job site—whether it will fight you every step of the way or feel like a natural extension of your arm. Getting a handle on the differences between materials like polyurethane, nylon, and rubber is the first step to getting the right tool for your work.

H3: Decoding Hose Materials

Let's start with what your hose is actually made of. Each material brings something different to the table, much like athletic wear is designed for different sports. Some are built for flexibility in the cold, while others are all about pure strength and resisting a beating.

Polyurethane: This is your modern, do-it-all material. Polyurethane hoses are fantastic because they're incredibly flexible, even when it's cold outside. That means less kinking, less wrestling with the hose, and less fatigue for you. They're also lightweight and tough against scrapes and scuffs, making them a solid choice for daily professional use.

Nylon and Braided Nylon: When you need brute strength, you need nylon. Usually found as a reinforcement layer, braided nylon is what gives a hose the backbone to handle serious pressure. Hoses with nylon braiding can take the extreme force from airless sprayers without stretching, bulging, or worse, bursting.

Rubber: The old-school classic for a reason. Rubber hoses are known for being tough and standing up to all sorts of chemicals and solvents. They can be heavier and not as flexible as polyurethane, but a high-quality rubber hose is still a reliable workhorse, especially for industrial jobs where it might get exposed to some nasty stuff.

A hose’s material isn’t just about how it feels in your hand; it's about how it performs under stress. A good polyurethane hose keeps you from fighting kinks on a ladder, while a tough nylon-braided hose gives you the confidence it can handle 3,000+ PSI all day long without a problem.

For anyone working in the varied climates around San Luis Obispo—from the chilly coastal fog in Morro Bay to the summer heat in Paso Robles—the right material makes a huge difference. A cheap, stiff hose can feel like a steel pipe on a cold morning, but a quality polyurethane one stays pliable and ready to go.

To help you visualize the trade-offs, here’s a quick comparison of the most common hose materials.

Paint Sprayer Hose Material Comparison

Material | Key Benefit | Flexibility | Max Pressure | Best For |

|---|---|---|---|---|

Polyurethane | Lightweight & Flexible | Excellent | High | General use, cold weather, reducing fatigue. |

Braided Nylon | Strength & Durability | Good | Very High | High-pressure airless systems, heavy-duty jobs. |

Rubber | Chemical Resistance | Moderate | High | Industrial settings, solvent-based materials. |

Each material has its place. The key is matching its strengths to the demands of your specific job and environment.

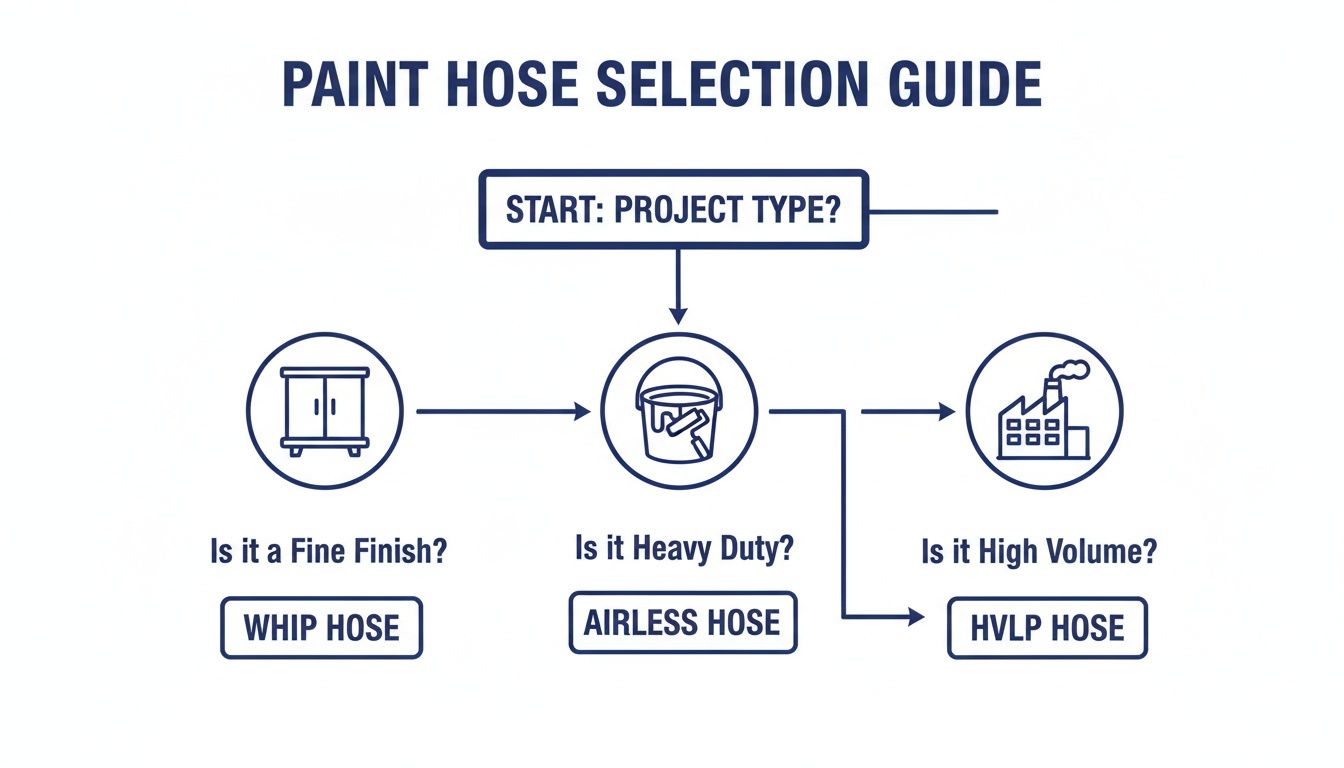

H3: Distinguishing Hose Types for Specific Jobs

Beyond the raw material, hoses are designed for specific spray systems. The main players you'll run into are airless, HVLP, and whip hoses, and each one has a distinct job to do.

Airless HosesThese are the heavy-lifters of the painting world. Built to take a beating and handle extreme pressures—often 3000 PSI or more—airless hoses are tough enough for high-volume jobs like spraying house exteriors or big commercial buildings. Their rugged construction, typically reinforced with braided nylon, ensures they can safely push thick paints like latex over long distances. If you want to dive deeper into what makes these hoses so resilient, you can learn more about high-pressure hoses in our detailed guide.

HVLP HosesHVLP stands for High Volume, Low Pressure. These systems use a wider hose to move a large amount of air at a much lower pressure. This air is what atomizes the paint, creating that super-fine, controlled finish you need for things like cabinets, trim, and cars. Since they're moving air instead of high-pressure fluid, these hoses are much lighter and more flexible than their airless cousins.

Whip HosesA whip hose is an absolute game-changer for control and comfort. It's a short (usually 3-6 feet) and super-flexible hose that acts as a bridge between your main hose and your spray gun. By connecting this "wrist," you isolate your hand from the weight and stiffness of the main line. This drastically cuts down on fatigue and allows for much smoother, more precise movements—a must-have for any fine-finish work or long days of spraying.

Matching Hose Size and Pressure Rating to Your Project

Once you’ve landed on the right hose material, the next big decision is matching its size and pressure rating to your specific project. These two specs aren't just numbers on a package; they're the core factors that dictate your flow rate, the quality of your finish, and the safety of your entire setup.

Getting this right is the difference between a smooth, professional-looking job and a frustrating day filled with clogs and uneven coats.

Think of it like the plumbing in your house. You wouldn’t try to supply water to an entire building with a tiny pipe, and you wouldn't use a fire hose for a delicate flower pot. The same logic applies here. The hose's inner diameter controls how much paint can move through it, while the pressure rating ensures it can handle the force your sprayer is putting out.

The Critical Link Between Hose Diameter and Flow Rate

The inner diameter of your paint hose is a lot like the width of a highway. A wider highway lets more cars travel at once, preventing traffic jams. In the same way, a larger hose diameter lets thicker materials flow freely, which stops pressure drops and keeps your sprayer from working overtime just to push paint through a narrow opening.

This relationship is absolutely key for proper atomization—the process of breaking down paint into a fine, even mist. If the hose is too narrow for the material, the sprayer has to work way harder, causing a big pressure drop by the time the paint hits the gun. That loss of pressure leads to poor atomization, which means spitting, splotchy patterns, and a rough, unprofessional finish.

This simple chart can help you see how your project's demands point you to the right hose.

As you can see, the complexity of your job dictates your choice, from a nimble whip hose for detail work to a heavy-duty airless hose for thick coatings.

Choosing the Right Diameter for Your Material

Picking the right hose diameter is a balancing act between flow rate and how easy it is to handle. A larger hose moves more paint, but it's also heavier and a lot less flexible.

1/4-Inch Hose: This is the industry standard and what you'll find on most job sites for residential and commercial painting. It’s perfect for thinner materials like stains, lacquers, enamels, and most latex paints. Its flexibility makes it easy to work with, especially when you pair it with a whip hose for the final few feet.

3/8-Inch Hose: When you move up to thicker materials like block fillers and elastomeric coatings, a 3/8-inch hose is a must. It's also the right call if you're running hose lengths over 100 feet. The larger diameter dramatically reduces pressure loss, making sure those heavy coatings hit the gun with enough force to atomize properly.

1/2-Inch Hose: This one's for the big guns. Reserved for the most demanding industrial jobs, a 1/2-inch hose is what you'll use for spraying extremely thick materials like drywall mud or fireproofing coatings. It gives you maximum flow, but it's also the heaviest and toughest to wrangle.

Understanding PSI Pressure Ratings

Every paint sprayer hose has two pressure ratings you absolutely need to know for both performance and safety.

Working Pressure: This is the maximum pressure the hose is built to handle continuously during normal use. This number must be higher than your sprayer's maximum PSI output.

Burst Pressure: This is the point of no return—the pressure at which the hose is expected to fail. It's usually three to four times higher than the working pressure and acts as a critical safety buffer. Never, ever operate a sprayer anywhere near its hose's burst pressure.

Key Takeaway: Always match your hose's working pressure rating to your sprayer's output. Using an underrated hose is incredibly dangerous. It can lead to a sudden burst, causing serious injury and a catastrophic mess.

The paint spray guns market, now valued at over USD 1.21 billion, is driven by industries where precision is everything. In the U.S. construction sector, where spending tops USD 2 trillion a year, a 50-foot, high-pressure hose is a common choice to balance reach and performance. It cuts down on setup time while keeping the pressure consistent.

As you consider all the different paints you might use, it's helpful to brush up on understanding handling guidelines for various spray paints. For pros working in areas from Arroyo Grande to Paso Robles, choosing the right size and pressure rating from the start means fewer headaches and better results on every job.

Navigating Fittings and Brand Compatibility

Stepping into the world of paint sprayer accessories can feel like trying to match nuts and bolts from different hardware stores. You've got different brands, a bunch of fitting sizes, and various connector types—it's easy to get turned around. The good news? The industry has mostly settled on a few key standards, which makes your life a whole lot easier than you might think.

Once you get a handle on these standards, you can confidently buy a new paint sprayer hose, add an extension, or hook up a whip hose without sweating about leaks or mismatches. Knowing the basics lets you mix and match gear from different brands and dial in your setup for any job. It takes the guesswork out of the equation so you can focus on what really matters: laying down a perfect finish.

The Universal Language of Hose Fittings

The key to all this is the fitting size. Think of it as the universal adapter that lets all the different parts of your spray rig talk to each other. For the vast majority of professional and prosumer airless sprayers, the undisputed industry standard is a 1/4-inch National Pipe Straight Mechanical (NPSM) fitting.

This standardization is a game-changer for painters. It means a hose from one major brand will almost always connect smoothly to a gun or sprayer from another. Here’s the simple breakdown:

Male Ends: These are the threaded ends that screw into another part. Your spray gun and the fluid outlet on your sprayer typically have male fittings.

Female Ends: These are the swivel nuts on both ends of your hose. They screw onto the male fittings, and the swivel action lets you tighten everything down without twisting the whole hose into a pretzel.

Because this setup is so common, you can usually connect a Graco hose to a Titan gun or use a Wagner hose with a Graco sprayer. This kind of interchangeability gives you the freedom to build the exact rig that works best for you.

Pro Tip: While most connections are standard, it never hurts to double-check the fitting size before you buy. Some really specialized equipment or older, vintage models might have their own proprietary connections. But for modern airless systems, 1/4" NPSM is the golden rule.

Brand-Specific Connections and Adapters

Even though Graco, Wagner, and Titan largely stick to that 1/4" standard, you'll sometimes run into exceptions, especially with older gear or highly specialized systems. The most common reason you'll need an adapter is when you want to connect hoses of different diameters—for instance, hooking up a beefy 3/8-inch main hose to a flexible 1/4-inch whip hose at the gun.

For that job, you'll need a high-pressure coupler or adapter. These small but mighty parts bridge the gap between different sizes, letting you extend your reach or add a whip for finer control. A complete package, like a Graco Contractor PC Gun and Hose Kit, often comes with a gun, a standard 50-foot hose, and a whip hose, all perfectly compatible right out of the box.

Custom Solutions for Central Coast Painters

For pros working up and down San Luis Obispo county, from the vineyards in Paso Robles to the coastal homes of Morro Bay and Pismo Beach, a reliable and versatile setup isn't just nice to have—it's essential. Here at Contractor's Maintenance Service, we know the unique challenges of working in this region. Whether you're in Atascadero, Arroyo Grande, or Grover Beach, we're your local source for everything paint sprayer related.

If you ever run into a tricky compatibility problem or need a custom-length hose for a particular project, our team is here to help. We offer custom hose fabrication and have the know-how to track down the exact adapters and fittings to connect any part of your system. We’ll make sure a simple mismatch never slows you down on the job.

Mastering Hose Maintenance and Troubleshooting

Your paint sprayer hose might be a tough piece of gear, but it isn't invincible. Like any tool you rely on, its lifespan and performance boil down to good care and knowing how to spot trouble early. If you neglect maintenance, you're not just risking the hose itself—you're setting yourself up for project-killing clogs, dangerous leaks, and frustrating downtime.

Think of cleanup as an investment, not a chore. A few minutes spent flushing the system after a job prevents dried paint from building up inside the hose lining. This one simple habit is the best thing you can do to protect your equipment and ensure you get a perfect finish, every single time.

A Step-by-Step Cleaning Process

The right way to clean your hose depends on what kind of paint you were spraying. First things first: always throw on the right personal protective equipment (PPE), like gloves and safety glasses, before you get started.

For Water-Based Paints (Latex, Acrylic)

Grab a bucket and fill it with warm, soapy water.

Drop the sprayer's intake tube into the clean water and point the gun (tip removed) into an empty waste bucket.

Run the sprayer on low pressure. Keep it going until the water coming out is completely clear. This flushes everything—the pump, the hose, and the gun.

For Solvent-Based Paints (Oils, Lacquers)

The initial steps are the same, but you’ll use the right cleaning solvent (like mineral spirits or lacquer thinner) instead of soapy water.

Run the solvent through the system until it’s running clear.

Crucial final step: Flush the whole system again, this time with water or a pump-preserving fluid. This gets rid of any leftover solvent that could eat away at your seals over time.

A good flush is non-negotiable. Airless sprayers rely on heavy-duty hoses that can handle pressures up to 3000 PSI, letting you cover surfaces 4-5 times faster than with a roller. But the solvents in certain coatings are harsh and can break down standard hoses. This has led to better options like PTFE-lined hoses, which can last twice as long and even help cut VOCs by up to 40%, a nice bonus for meeting modern green standards.

Common Paint Sprayer Hose Problems and Solutions

Even with the best maintenance routine, stuff happens on the job. When your hose starts acting up, you need to diagnose the problem fast. This quick guide will help you pinpoint and solve the most common issues you'll run into.

For trickier problems tied to your specific machine, our guide on Wagner paint sprayer troubleshooting for common issues is a great resource.

Common Paint Sprayer Hose Problems and Solutions

Problem | Potential Cause | Solution |

|---|---|---|

Leaks at Fittings | The connection is loose, or the internal seal is worn out. | Use two wrenches to get a firm grip and tighten the connection. Don't go overboard. If it still drips, it's time to replace the small seal inside the fitting. |

Clogs in the Hose | Dried paint bits or material that wasn't strained properly. | Disconnect the hose, take off the gun and filters, and try flushing it with water or solvent. If it's really stuck, you might need a hose cleaning kit with a brush to clear it out. |

Persistent Kinking | Storing it wrong or using a cheap, stiff hose. | Always uncoil your hose completely before you start spraying. When you're done, coil it in big, loose loops, not tight circles. If it's still a pain, think about upgrading to a more flexible polyurethane hose. |

Pinhole Leaks/Bulges | Internal wear, getting banged up, or pushing too much pressure. | Stop what you're doing immediately. Depressurize the system and replace the hose. A pinhole leak is a major red flag for a blowout and can cause a serious high-pressure injection injury. |

Running through these checks can save you a lot of headaches and keep you spraying safely. When a hose starts to bulge or leak, it's not a suggestion—it's a warning.

Your Local Partner for Sprayer Maintenance

For painters and contractors in San Luis Obispo, Paso Robles, Atascadero, and all over the Central Coast, professional help is right around the corner. At Contractor's Maintenance Service, we’re the local pros for everything from a quick tune-up to a major repair.

We work on all the big brands, so you know your equipment is in good hands. Whether you're working in Morro Bay, Pismo Beach, Grover Beach, or Arroyo Grande, our team is here to provide the reliable service and expert advice that keeps your projects moving forward.

Your Local Paint Sprayer Experts in San Luis Obispo

Knowing the technical side of a paint sprayer hose is one thing, but sometimes you just need more than a manual. When you're facing a tricky repair, need a custom part for a unique job, or just want some hands-on help, having a local expert in your corner changes everything. That’s where we come in.

For professional painters and serious DIYers across San Luis Obispo County, we’re the go-to partner for all things paint sprayers. We don't just sell equipment; we provide dependable tools, expert support, and practical, fast solutions to keep your projects moving and your gear running like it should.

Your Partners on the Central Coast

We’re proud to serve the entire region, bringing our expertise to communities all over the Central Coast. Whether you're tackling a residential repaint in a quiet neighborhood or a massive commercial job downtown, we've got your back.

Our main service areas include:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Morro Bay

Pismo Beach

Grover Beach

We know the unique challenges and opportunities that come with working in these local spots because we're right here with you.

Services Built for Professionals

Our commitment goes way beyond just selling parts off a shelf. We offer a full range of professional services designed to solve real-world problems for contractors and painters who depend on their equipment every single day.

When your gear is your livelihood, you can't afford to be down for a day, let alone a week. We provide authorized warranty service, custom hose fabrication, and fast parts shipping to make sure you're always ready for what's next.

This means if you have a specific need—like a non-standard paint sprayer hose length to reach a difficult area—we can build it for you right here. As an authorized service center for the big names like Graco and Titan, we also handle warranty repairs, getting your equipment fixed correctly and back in your hands fast. To make sure your local paint sprayer business in San Luis Obispo gets noticed, it's a good idea to explore strategies for Local SEO to connect with customers actively looking for these exact services.

Got Questions About Paint Sprayer Hoses? We've Got Answers.

Even the most seasoned pros run into questions on the job. When it comes to something as critical as your paint sprayer hose, you want clear, direct answers. Here are some of the most common questions we hear from painters, answered in plain English.

Can I Connect Two Paint Sprayer Hoses Together?

Absolutely. It's a common move on bigger projects where you need more reach. All you need is a high-pressure hose coupler, which is a small but tough fitting designed to securely join two hose ends.

The one thing you cannot overlook is the PSI rating. Make sure the coupler’s rating matches or, even better, exceeds your sprayer’s maximum output. You don't want that connection to be the weak link. Keep in mind that adding length can lead to a slight pressure drop. If you're running more than 100 feet, a pro trick is to use a larger 3/8-inch hose for the main run and then connect your standard 1/4-inch hose or a whip hose at the gun.

How Often Should I Replace My Paint Sprayer Hose?

There’s no magic expiration date on a hose. Its lifespan really comes down to how you use it, how well you clean it, and what kind of materials you're pushing through it. A hose that only sees latex paint and gets cleaned properly could last for years. But if you’re constantly running hot solvents or dragging it across rough concrete, you’ll be replacing it a lot sooner.

The best habit you can get into is giving your hose a quick inspection before every single job. You're looking for:

Cracks, especially up near the fittings where the stress is greatest.

Any weird bulges or soft spots along the hose wall.

Leaks or even just "weeping" at the connections.

If you spot any of that, or if the hose is just permanently kinked and stiff, don’t risk it. Replace it immediately. It’s a cheap insurance policy against a high-pressure blowout that can ruin your day and your job site.

What Is a Whip Hose and Do I Really Need One?

Think of a whip hose as a short, super-flexible extension cord for your spray gun. It’s typically a 3 to 6-foot hose that connects between your main line and the gun. Its only job is to make your life easier by reducing fatigue and giving you more control. It isolates your hand from the weight and stiffness of the main hose, which lets you move the gun much more smoothly.

So, is it essential? Technically, your sprayer will work without one. But ask any professional painter, and they’ll tell you it's a non-negotiable piece of kit. If you're spraying anything that requires finesse—like cabinets, trim, or doors—a whip hose is a total game-changer for your ergonomics and the final finish quality.

How Do I Stop My Paint Sprayer Hose from Kinking?

Kinking is the absolute worst, but you can definitely minimize it. The number one rule is to fully uncoil the hose and lay it out as straight as you can before you pressurize the system. And whatever you do, stop pulling your sprayer around by the hose! That’s the fastest way to create sharp bends that lead to kinks and put a ton of strain on the fittings.

While you're working, try to manage the slack in big, gentle loops instead of tight coils. It also helps to invest in a quality, flexible hose made from polyurethane. They are far less prone to kinking than the cheaper, stiffer hoses that come with some entry-level sprayers.

For all the painters here on the Central Coast, from Paso Robles down to Arroyo Grande, we know reliable gear is what keeps you working. Whether you're in San Luis Obispo, Atascadero, or out in the coastal towns like Morro Bay and Pismo Beach, our team is here to help you get the right hose for the job.

When you need reliable parts, expert service, or a custom-built hose for your next big project, Contractor's Maintenance Service is your local partner. We have the inventory and the know-how to keep your equipment running at its best.

Explore our full range of products and services at https://www.contractorsmaintenanceservice.com.

Comments