A Contractor’s Guide to Using a Paint Spray Gun Airless System

- Dec 18, 2025

- 16 min read

If you're a busy contractor or maintenance pro, you know that time is money. An airless paint spray gun isn't just a tool; it's a serious investment in speed and quality, especially when you're tackling big jobs. Unlike systems that use compressed air, an airless sprayer relies on pure, raw pressure to atomize paint. The result? You can lay down a flawless, professional-grade finish across huge surfaces in a fraction of the time.

How Do Airless Paint Sprayers Work?

Think of how a pressure washer uses a focused stream of water to blast away dirt. An airless paint sprayer works on a similar principle, but with paint. The system pulls paint straight from a bucket, sends it through a high-pressure pump, and cranks the pressure up to 3,000 PSI or even higher.

This incredible force pushes the paint through a tiny, precision-engineered opening in the spray tip. The extreme pressure is what atomizes the material, creating a fine, perfectly controlled fan of spray without needing an air compressor.

This method is an absolute game-changer for productivity. We're not talking about a small improvement; you can often get the job done up to 10 times faster than with old-school brushing and rolling. It's also fantastic for getting a thick, even coat on tricky surfaces like stucco, brick, or popcorn ceilings.

To give you a clearer picture, here’s a quick summary of what makes an airless system tick.

Airless Paint Sprayer At a Glance

Attribute | Description |

|---|---|

Power Source | High-pressure fluid pump (gas, electric, or pneumatic) |

Atomization Method | Hydraulic force; paint is forced through a small tip orifice |

Operating Pressure | Typically 1,500 to 3,000+ PSI |

Speed | Covers large areas up to 10x faster than rolling |

Finish Quality | Creates a smooth, uniform, and professional-grade coating |

Material Compatibility | Handles a wide range, from thin stains to thick latex and epoxies |

This combination of power and precision is why airless sprayers have become the go-to tool for so many professional painters.

Why Do Pros Swear By Airless Systems?

It all comes down to one word: efficiency. With an airless sprayer, contractors can power through massive jobs like exterior walls, commercial interiors, warehouses, and endless stretches of fencing. That speed translates directly to lower labor costs and quicker project turnarounds, which means more jobs on the books.

The versatility is another huge plus. These machines can handle almost anything you throw at them, from thin stains and lacquers to heavy-bodied latex paints and tough industrial coatings. Their dominance in the professional world is undeniable; airless systems are on track to make up an estimated 41.2% of the global spray-painting machine market revenue by 2025. It's a testament to their sheer speed and reliability.

If you're a contractor on the Central Coast, we're here to provide expert support and service for your equipment. We're proud to serve pros in San Luis Obispo and the surrounding areas, including:

Paso Robles

Atascadero

Arroyo Grande

Pismo Beach

Morro Bay

Grover Beach

Cambria

Cayucos

Los Osos

Nipomo

Santa Margarita

Templeton

An airless sprayer’s ability to deliver a consistent mil thickness across large surfaces is what sets it apart. It’s not just about speed; it's about achieving a durable, protective coating that looks flawless every single time.

Of course, having the best gear is only half the battle. A successful painting contractor also needs a rock-solid online presence. It's well worth learning about the common SEO mistakes painting contractors make to make sure local customers can actually find you when they need a pro.

How an Airless Paint Sprayer Actually Works

To really get the hang of an airless paint sprayer, you have to know what’s going on under the hood. It’s not about compressed air; it's a brute-force system running on pure hydraulic power. The best way to think of it is like a high-pressure circulatory system designed just for paint.

It all starts when you drop the fluid section (the siphon tube) into a bucket of paint. Flick the switch, and a powerful piston pump immediately roars to life. This pump is the heart of the whole operation, pulling paint straight from the bucket and into the machine.

From there, the paint gets shoved into a high-pressure hose, which acts like the system's main artery. The pump puts the paint under some serious pressure—we're talking anywhere from 1,500 to 3,000 PSI. That immense force is what gives an airless sprayer its incredible speed and coating power.

The Magic of Atomization

All the real action happens right at the very end. The super-pressurized paint flows down the hose and into the spray gun. The moment you pull the trigger, that paint is forced through a tiny, precisely engineered hole in the spray tip.

This sudden, violent drop in pressure causes the paint to literally tear itself apart. This process is called atomization, and it creates a fine mist of tiny paint droplets. The result is a perfectly controlled, fan-shaped pattern that lays down a smooth, even coat on the surface.

The key thing to remember is that the tip controls everything. The size of the hole and the angle of its design determine both the width of your spray fan and how much paint comes out. Bigger holes are for thick stuff like latex, while smaller ones are for thin coatings like stains.

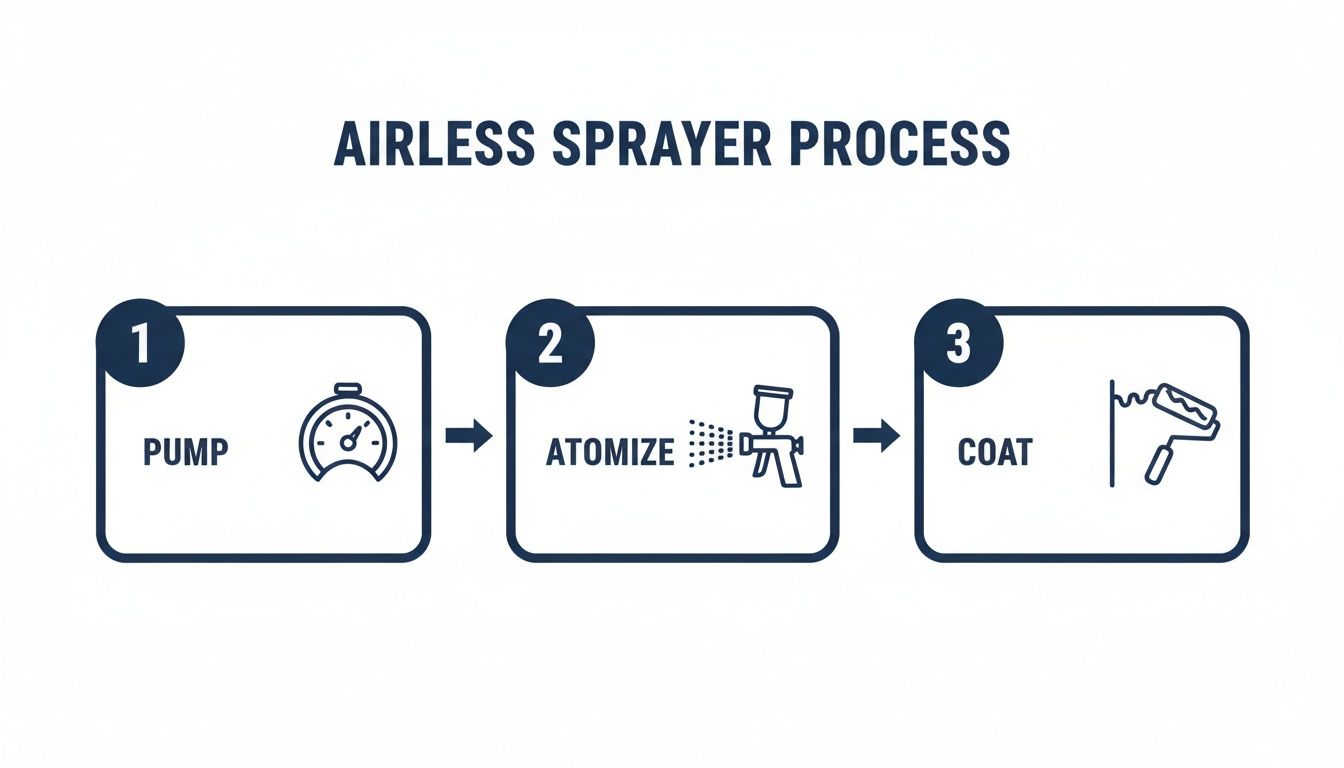

This entire trip—from the bucket to the wall—happens in the blink of an eye. The diagram below breaks down this simple but powerful three-step process.

As you can see, it's a straightforward path from high-pressure pumping to fine atomization, giving you that clean, uniform finish jobs demand.

Key Parts and What They Do

A few critical parts work in concert to make this happen reliably. Knowing them will help you operate the machine better and troubleshoot faster when you're on a job.

The Pump (Fluid Section): This is your sprayer's engine. Its whole job is to suck up the material and build the insane pressure needed to atomize it.

The Hose: This isn't just a simple tube. It’s built to handle thousands of PSI without bursting. The length and diameter matter, too—they can affect your pressure, especially on bigger projects.

The Gun: This is where you take control. It houses the trigger valve that releases the pressurized paint and holds the tip and tip guard.

Filters: Sprayers have several filters—usually at the intake, in the gun handle, and sometimes inside the pump itself. They are absolutely essential for preventing tip clogs, which can bring your workflow to a screeching halt.

The Spray Tip: This tiny component is arguably the most important piece for getting a quality finish. It shapes the spray pattern and meters the flow rate. Tips wear out, and a worn tip will give you an uneven pattern and waste a ton of paint.

Understanding how these pieces fit together is what separates a novice from a pro. When your spray pattern is off, you know to check the tip first. If the machine won't prime, you check the intake tube and filters. This knowledge turns you into a problem-solver who can keep the job moving, no matter what.

Choosing the Right Airless Sprayer for Your Job

Picking the right paint spray gun airless system is just as critical as your spraying technique. The machine you choose is a major investment and will directly impact your speed, the quality of your finish, and ultimately, your bottom line. It's not about finding the cheapest or most powerful option; it's about matching the machine's capabilities to the work you do day in and day out.

Think of it like choosing a work truck. You wouldn't show up to a massive commercial job in a small pickup, nor would you use a semi-truck for a quick touch-up. Airless sprayers work the same way. Each one is built for a specific scale of work, so you need to look past the price tag and get into the specs to find the right fit for your business.

Decoding the Numbers GPM and PSI

Two numbers will jump out at you on any sprayer: GPM (Gallons Per Minute) and PSI (Pounds Per Square Inch). These aren't just marketing fluff; they're the core indicators of what a sprayer can handle in the real world.

PSI (Pounds Per Square Inch): This tells you how much muscle the pump has. Higher PSI is what allows a sprayer to properly atomize thick, heavy-bodied materials like unthinned latex, tough elastomerics, or block fillers. A rig with low PSI will struggle to break these coatings apart, leaving you with a spattery, uneven finish.

GPM (Gallons Per Minute): This is all about flow rate—how much paint the sprayer can push out. A higher GPM means you can support a larger spray tip and cover huge surfaces much faster. If you're tackling big jobs like new construction interiors or sprawling commercial buildings, a high GPM is non-negotiable if you want to be productive.

These two specs work as a team. You need enough PSI to atomize the paint and enough GPM to keep up with the tip size you need for the job. Striking that balance means your machine runs efficiently without being overworked or underused.

The rule of thumb is simple: match the machine to the material and the project size. For a professional, a sprayer rated for at least 0.50 GPM and 3000 PSI is a solid starting point for residential and light commercial work.

For contractors here on the Central Coast, from the wineries of Paso Robles to the salt-sprayed homes in Morro Bay, having a versatile sprayer is a must. We regularly help pros in San Luis Obispo, Atascadero, Arroyo Grande, Pismo Beach, Grover Beach, and all surrounding areas find the right gear for our unique local building styles and climate.

Airless Sprayer Model Comparison for Different Project Scales

Before you pull the trigger on a purchase, it helps to see how the specs translate to real-world jobs. Let's compare the two main classes of sprayers you'll encounter: a standard contractor model and a heavy-duty industrial rig. This side-by-side look makes it clear how a machine’s numbers align with its intended use.

For pros who primarily handle residential projects, a more portable unit might be the perfect fit. If that sounds like you, check out our professional painter’s guide to portable airless sprayers for a deep dive into smaller, more mobile setups.

The table below breaks down what you can expect from each category.

Specification | Entry-Level Contractor Model | High-Production Industrial Model |

|---|---|---|

Power Rating | 0.5 - 1.0 HP | 2.0+ HP (Often Gas-Powered) |

Max GPM | 0.47 - 0.95 GPM | 1.5 - 2.5+ GPM |

Max PSI | 3000 - 3300 PSI | 3300 - 4500+ PSI |

Ideal Materials | Stains, lacquers, latex, enamels | Latex, block fillers, epoxies, elastomerics |

Typical Use Cases | Residential interiors/exteriors, single-family homes, small commercial jobs | Large commercial buildings, industrial facilities, bridges, multi-family housing |

Portability | Lighter weight, typically on a stand or small cart for easy transport | Heavier, mounted on a robust wheeled cart for job site durability |

Ultimately, choosing the right paint spray gun airless model comes down to an honest look at your typical workload. Overbuying means you've sunk cash into power you'll never use. But underbuying is even worse—it leads to a machine that's constantly breaking down, slowing you down on big jobs, and costing you money in the long run.

Getting Your Setup and Technique Dialed In for a Flawless Finish

Owning a powerful paint spray gun airless system is one thing, but making it sing is another. The real magic happens when you pair that machine with a solid setup and flawless technique. This is what takes a good job and makes it great, leaving you with professional-grade finishes that are smooth, durable, and crazy efficient to apply.

The difference between a seasoned pro and a rookie often comes down to mastering the workflow, from the first roll of tape to the final pass of the gun. Nailing this process ensures consistency, cuts down on wasted paint, and produces results that look sharp on any job site.

Prepping for a Perfect Spray Job

Before you even think about pulling that trigger, you have to get the prep work right. Rushing this stage is the #1 reason for headaches and sloppy results down the line. A few extra minutes here will save you hours of cleanup and touch-ups later.

Start by meticulously masking and covering everything that isn't getting painted. Use quality painter's tape and plastic or paper sheeting to get those clean, sharp lines and protect floors, windows, and fixtures. If you're working outside, pay attention to the wind—cover up cars, landscaping, and anything else nearby to avoid an overspray nightmare.

Next up, strain your paint. Seriously, don't skip this. Even a fresh can of paint can have tiny lumps or debris that will clog your spray tip in a heartbeat and bring the whole job to a screeching halt. Pouring your material through a mesh strainer into a clean bucket is a must for reliable spraying.

Finally, prime the pump following your sprayer’s manual. This is a critical step that purges air from the system and gets the pump and hose filled with paint. It ensures you get a solid, consistent stream of material the second you start spraying.

Dialing In Your Sprayer and Technique

With your area prepped and the pump primed, it’s time to dial in your pressure and practice your motion. Start with the pressure control on low and slowly crank it up until the spray pattern is fully atomized, with no "tails" or "fingers" at the edges. A perfect pattern looks like a soft-edged, even fan.

The goal is to use the lowest possible pressure that still creates a clean spray pattern. Spraying at an excessively high pressure not only increases overspray but also causes premature tip wear, costing you money in both wasted paint and replacement parts.

Once your pressure is set, it all comes down to these core techniques:

Keep Your Distance: Hold the spray gun a consistent 10 to 12 inches from the surface. Too close, and you'll get runs and drips. Too far, and you'll end up with a thin, dusty coat.

Stay Perpendicular: Always point the gun straight at the surface—never tilted. Your arm should move parallel to the wall, not swing in an arc like you're throwing a frisbee.

Overlap by Half: Each pass you make should overlap the previous one by about 50%. This is the key to getting a perfectly uniform coat without any stripes or light spots.

Find Your Pace: Walk at a comfortable, steady speed. If you move too fast, the coat will be too thin. Too slow, and the paint will build up and start to sag.

Technique is huge, but you also need the right gear for the material you're shooting. For a deep dive on matching your tip to your paint, check out our guide on choosing the right tip size for airless sprayer finishes.

For all the contractors working up and down the Central Coast, from Paso Robles to Arroyo Grande, mastering these skills is what sets you apart. Whether you're in San Luis Obispo, Atascadero, Pismo Beach, Morro Bay, or Grover Beach, we're your local source for the parts, service, and advice you need to keep your jobs moving and your finishes looking perfect. Combine killer prep with precise application, and you'll unlock the full power of your airless sprayer every single time.

Essential Maintenance and Troubleshooting in the Field

Your paint spray gun airless system is a serious investment—it's the engine driving your productivity on every job. And just like any other high-performance tool, it needs consistent care to stay reliable. Ignoring maintenance is the fastest way to end up with downtime, and that costs you both time and money.

Don't worry, proper maintenance isn't complicated. It's really just about building simple, consistent habits. A few minutes spent cleaning at the end of the day can save you hours of headaches and troubleshooting in the middle of a project. This basic upkeep is what ensures your sprayer delivers that flawless finish you need, every single time.

Daily and Weekly Maintenance Routines

Let's be clear: the single most important thing you can do is clean your sprayer thoroughly after every use. Leftover paint dries inside the pump, hose, and gun, leading to clogs that wreck critical parts like packing seals. Think of it as a non-negotiable part of your end-of-day pack-up.

A solid daily cleaning routine is all about flushing the entire system until it runs perfectly clear. Start with water for latex paints or the right solvent for other materials. This simple step prevents the kind of buildup that causes pressure loss and messy spray patterns.

Beyond the daily flush, set aside a few minutes each week for a closer look:

Inspect All Filters: Your sprayer has more than one filter, including the rock catcher on the intake tube and the one in the gun handle. Pull them out, give them a good cleaning, and check for any damage or serious wear.

Check the Hoses: Walk the entire length of your hose. You're looking for kinks, bulges, or any signs of abrasion. A damaged hose is a huge safety risk under that much pressure.

Examine the Spray Tip: Get a close look at your spray tip. A worn tip is a bigger deal than you might think—it creates an uneven, "tailed" spray pattern and wastes a ton of paint.

According to paint equipment manufacturers, a worn-out spray tip can waste up to 20% more paint. Swapping it out regularly is a small investment that pays for itself by cutting down on material costs and guaranteeing a quality finish.

On-the-Job Troubleshooting Guide

Even with the best maintenance, things can still go wrong in the field. Knowing how to quickly diagnose and fix common problems is what separates the pros and keeps the job moving. Here’s a quick-hitter guide for the most common sprayer headaches.

Problem | Common Causes & Solutions |

|---|---|

Pump Won't Prime or Loses Prime | 1. Intake tube isn't all the way in the paint.2. Intake filter is clogged with gunk.3. Prime/spray valve is stuck or clogged.4. Outlet ball valve is stuck (give the pump housing a gentle tap). |

Inconsistent Spray Pattern (Tailing) | 1. Pressure is too low (crank it up).2. Spray tip is shot (time for a new one).3. Material is too thick (thin it out per the manufacturer's specs).4. Manifold or gun filter is clogged (clean 'em out). |

Gun Spits or Surges | 1. You've got air in the system (re-prime the pump).2. Paint level in the bucket is too low, letting air in.3. Packing seals are worn out and need to be replaced. |

For contractors working up and down the Central Coast, from Paso Robles to Arroyo Grande, keeping your gear in prime condition is everything. If you hit a snag you can't sort out on-site, our team is here to provide expert service for pros in San Luis Obispo, Atascadero, Pismo Beach, Morro Bay, and Grover Beach. For a deep dive into one of the most common failure points, check out our ultimate guide to the perfect paint sprayer hose. At the end of the day, a well-maintained sprayer is a profitable sprayer.

Local Sprayer Service and Support in San Luis Obispo

Let's face it, even the most bulletproof paint spray gun airless rig will need a pro's touch eventually. When a quick fix on the job site just won't cut it, the last thing you need is downtime. For any contractor working on the Central Coast, having a trusted, local service center is the difference between staying on schedule and losing money.

That’s where we come in. We offer professional diagnostics, repairs, and genuine parts for your airless sprayer right here in San Luis Obispo County. Our techs know the unique challenges of our local climate—from the salty air on the coast to the dry heat inland—and how it all takes a toll on your equipment.

Your Local Partner on the Central Coast

Why ship your machine halfway across the state and wait weeks to get it back? You can get hands-on support from a team that lives and breathes this gear. We’re proud to serve the entire region, with dedicated service for pros in San Luis Obispo and all surrounding areas, including:

Paso Robles

Atascadero

Arroyo Grande

Morro Bay

Pismo Beach

Grover Beach

Cambria

Cayucos

Los Osos

Nipomo

Santa Margarita

Templeton

Having a local service partner means more than just quick repairs. It means access to expert advice, immediate availability of critical parts, and a faster turnaround that gets your most valuable tool back on the job site where it belongs.

We can help you spot the signs that it’s time to bring your sprayer in for the bigger jobs. Think major pump rebuilds, tricky pressure control diagnostics, motor service, and other deep-dive repairs best left to factory-trained technicians. Our goal is to make sure your investment keeps performing at its peak.

For local sprayer services or contractors seeking to enhance their local visibility and attract more clients, exploring comprehensive local business listing optimization strategies can be highly beneficial. When your business is easy to find online, you connect with more customers who need your professional skills. Let our team handle your equipment, so you can focus on what you do best—delivering exceptional results for your clients.

Got Questions About Airless Sprayers? We've Got Answers.

Even the most seasoned pros run into questions now and then. Getting the most out of your paint spray gun airless system means knowing how to fine-tune it, keep it safe, and push its limits. Here are some of the most common questions we get from contractors in the field.

Airless Sprayer vs. HVLP System: What's the Real Difference?

The biggest difference boils down to one thing: speed versus precision.

An airless sprayer is the undisputed champion of high-production work. It uses raw, extreme pressure to atomize paint, letting you cover huge areas like exterior walls or empty commercial buildings with incredible speed.

On the flip side, an HVLP (High Volume, Low Pressure) system is all about finesse. It uses a large volume of air at a much lower pressure to create a soft, highly controlled spray. This makes it the go-to choice for fine-finish work—think cabinets, trim, and furniture, where a flawless finish is everything and speed takes a backseat.

Here's a simple way to think about it: an airless sprayer is your 18-inch roller, built to knock out massive surfaces fast. An HVLP gun is your fine-tipped artist's brush, made for detailed, delicate work that demands absolute control.

How Do I Know When My Spray Tip Is Shot?

A worn-out spray tip is more than just a minor headache—it's actively wasting your paint and wrecking the quality of your finish. The most obvious giveaway is a spray pattern that's "tailing" or "fingering," where you see heavy lines of paint at the top and bottom of the fan.

This happens because the tip's opening has worn from a perfect circle into an oval. A worn tip doesn't just mess up your pattern; it also narrows your fan width and forces you to crank up the pressure to compensate. That means more overspray and more strain on your pump. A new tip is a small investment that pays you back immediately in material and labor savings.

Can I Really Spray Thicker Stuff Like Elastomerics?

You absolutely can, but you have to bring the right tool for the job. Spraying heavy-bodied materials like elastomerics, block fillers, or roof coatings demands a powerful paint spray gun airless system with some serious muscle. We're talking high PSI and a high Gallons Per Minute (GPM) rating.

For these jobs, you'll need a sprayer that can consistently hold 3300 PSI and handle a much larger tip size (think a .025" orifice or bigger). Trying to push these thick coatings through an underpowered machine will just lead to poor atomization, constant clogs, and eventually, a burned-out pump.

If you're tackling tough coatings in San Luis Obispo, Paso Robles, Atascadero, or Arroyo Grande, our team can make sure you're properly equipped. We also provide service for pros working in Pismo Beach, Morro Bay, Grover Beach, and all surrounding areas.

What's the Biggest Safety Risk I Should Know About?

The single most severe risk with an airless sprayer is a high-pressure injection injury. This happens if the pressurized stream of paint pierces the skin, injecting material deep into your tissue.

This is a true medical emergency. It can lead to severe tissue damage, compartment syndrome, and even amputation if it's not treated immediately by a doctor who understands injection injuries. Always keep the tip guard on, never point the gun at yourself or anyone else, and get in the habit of engaging the trigger lock the second you stop spraying.

When your equipment needs a pro's touch, trust Contractor's Maintenance Service. We've got the professional parts, expert service, and practical advice you need to keep your airless sprayer earning money for you. Visit us at https://www.contractorsmaintenanceservice.com to learn more.

Comments