Synthetic Oil Air Compressor: Your Guide to Longer Life and Peak Performance

- DLL Studios

- Jan 15

- 15 min read

You won't find a "synthetic oil air compressor" in a product catalog. It's not a special machine. Instead, it’s a standard compressor that’s running on a highly engineered lubricant for peak performance. Think of it like putting premium fuel in a high-performance engine—the synthetic oil is made to protect your equipment under serious stress, stretch its lifespan, and cut down on expensive downtime.

Why Synthetic Oil Is the Lifeblood of Your Compressor

Imagine trying to run a marathon in a pair of cheap, generic sneakers. You might finish the race, but you’ll probably deal with discomfort, extra wear and tear, and maybe even an injury. Now, picture running that same race in custom-fit, high-tech athletic shoes. That’s the real difference between using conventional mineral oil and a top-quality synthetic oil in your air compressor.

Conventional oils are just refined crude oil. They get the job done, but they’re full of impurities and have irregular molecular structures that break down fast under heat and pressure. This breakdown creates sludge and varnish, clogging up vital components and starving your machine of lubrication. That's a recipe for catastrophic failure.

The Engineered Advantage of Synthetics

Synthetic lubricants, on the other hand, are built from the ground up in a lab. Every molecule is uniform, pure, and designed specifically to handle the brutal conditions inside a compressor. This engineered structure gives you some key advantages that directly impact your bottom line:

Superior Thermal Stability: Synthetic oil doesn't cook and break down at high temperatures. This lets your compressor run hotter and longer without the risk of overheating.

Reduced Varnish Buildup: Because they're so pure, synthetics create far less sludge and gunk. Internal parts like bearings and valves stay clean and run efficiently.

Longer Service Intervals: These oils can last up to 24,000 hours, which blows the typical 8,000-hour life of mineral oils out of the water. That means less frequent maintenance for your crew.

Improved Energy Efficiency: A cleaner, better-lubricated machine has less friction. Over time, that translates into real savings on your energy bills.

This kind of performance is exactly why synthetics have become the standard for any demanding job. For contractors and maintenance managers who can’t afford to have their equipment fail, choosing the right lubricant isn’t optional. When you need solid advice on the best maintenance fluids for your tools, nothing beats a trusted local partner.

Serving Professionals on the Central Coast

Here at Contractor's Maintenance Service, we know the unique challenges our local environment throws at your equipment. From the dry summer heat in Paso Robles and Atascadero to the humid, salty air in coastal towns like Morro Bay, Pismo Beach, Arroyo Grande, and Los Osos, your compressor needs protection that can handle it all. We're proud to serve professionals throughout San Luis Obispo, Santa Maria, Nipomo, Grover Beach, Templeton, and the surrounding communities, making sure you have the right products and expertise to keep your jobs running without a hitch.

Synthetic oils dominate 54.3% of the global compressor oil market for a reason. Their ability to perform in extreme conditions—withstanding pressures over 150 psi and temperatures spiking to 250°F—is simply unmatched. Under the same stress, mineral oils can degrade up to 40% faster. The market trends make it clear why pros are making the switch.

Synthetic Oil Versus Mineral Oil for Compressors

Picking between synthetic and mineral oil for your air compressor isn't just a routine maintenance task. It’s a decision that directly impacts how long your equipment lasts, how reliable it is, and what it costs you to run. Mineral oil might look like the cheaper option on the shelf, but when you dig a little deeper, it becomes clear why a synthetic oil air compressor is the smarter long-term play for any serious professional.

The real difference is down at the molecular level. Mineral oil is just refined crude oil, which means it’s full of molecules of all different shapes and sizes. When you put it under the intense heat and pressure inside a compressor, those irregular molecules start to break down. The result? Performance-killing sludge and varnish that can clog up your machine and cause serious damage.

Synthetic oil, on the other hand, is built from the ground up in a lab. Every molecule is uniform and pure, engineered specifically to handle extreme conditions without falling apart. This fundamental difference is what gives synthetic oil a whole host of performance benefits that keep your tools running smoothly, day in and day out.

Temperature And Lifespan: A Head-To-Head Battle

One of the biggest wins for synthetic oil is its incredible thermal stability. Compressors get hot—really hot—especially when they’re running for hours on a job site in Paso Robles or Atascadero. Mineral oil just can't take the heat. It thins out, stops lubricating properly, and oxidizes, which leads to premature wear and tear or even overheating.

Synthetic oil, however, keeps its cool. It maintains its viscosity and protective qualities even when the temperature skyrockets, allowing your compressor to run hotter and harder without skipping a beat.

This stability also means it lasts a whole lot longer. Just look at the typical service intervals:

Mineral Oil: Needs to be changed roughly every 2,000 to 8,000 hours of runtime.

Synthetic Oil: Can go for up to 24,000 hours—that’s triple the time between oil changes.

Fewer oil changes mean less downtime, lower labor costs, and buying less oil over the life of your equipment. For a busy contractor or maintenance manager in San Luis Obispo, those savings in time and money really add up.

Synthetic vs Mineral Air Compressor Oil Showdown

To make the choice even clearer, let's break down how these two oils stack up against each other on the metrics that matter most. This table gives you a quick, at-a-glance comparison.

Performance Metric | Synthetic Oil | Mineral Oil |

|---|---|---|

Purity & Structure | Engineered with uniform molecules for high purity and stability. | Refined from crude oil with irregular molecules and impurities. |

Operating Temperature | Excellent stability at high temperatures, resisting breakdown. | Prone to oxidation and sludge formation under heat. |

Oil Change Interval | Up to 24,000 hours, extending maintenance cycles significantly. | Typically requires changes every 8,000 hours or less. |

Component Protection | Superior defense against rust, corrosion, and varnish buildup. | Offers basic protection but allows for deposit formation. |

Long-Term Cost | Higher initial price but lower overall cost due to fewer changes and less wear. | Lower upfront cost but higher long-term expenses from frequent maintenance. |

The takeaway is clear: while mineral oil gets the job done, it's a compromise. A synthetic oil air compressor setup is a strategic investment that protects your equipment, ensuring it's ready for whatever the Central Coast throws at it—from the coastal humidity in Morro Bay to the inland heat.

If you want to dive deeper into the science behind it, it's worth exploring the general conversation around the differences between synthetic and regular oil for all kinds of machinery. The core ideas of better performance and protection are true across the board, hammering home the value of choosing a superior lubricant.

How to Choose the Right Synthetic Oil for Your Compressor

Picking the right synthetic oil for your air compressor isn’t as simple as grabbing the first bottle off the shelf. It's a decision that can mean the difference between a smooth-running machine and a catastrophic failure that brings your job to a halt. The wrong oil leads to overheating and premature wear, while the right one acts like a liquid shield, keeping your equipment protected and efficient.

Think about it this way: a painting contractor sweating it out in the Paso Robles summer heat has a completely different set of challenges than a facility manager dealing with the cool, damp air in Morro Bay. Each environment demands an oil with specific properties, and the key to getting it right is understanding viscosity.

Decoding Viscosity Grades

Viscosity is just a fancy word for how thick an oil is—or its resistance to flow. For a compressor, that thickness is what maintains a protective film between all the moving parts. You'll typically run into three common grades: ISO 32, 46, and 68.

ISO 32: This is your thinner, lower-viscosity oil. It's perfect for colder conditions or for rotary screw compressors that don’t get as hot. It flows easily on startup, which means you get immediate lubrication right when you need it.

ISO 46: The all-rounder. This medium-viscosity oil is the go-to for a wide range of operating temperatures and is often the standard recommendation for many rotary screw and reciprocating compressors.

ISO 68: This is a thicker, higher-viscosity oil. It's built for high-heat environments or for hardworking reciprocating compressors that generate a lot of heat. Its thickness guarantees a strong protective film when the machine is under serious strain.

A contractor working in Atascadero might run an ISO 68 in July but switch to an ISO 46 during the cooler months to make sure the oil isn't too thick on those chilly morning startups. The goal is always to match the oil's thickness to both the ambient temperature and the heat your compressor puts out.

The Power of Additive Packages

Viscosity is only part of the story. The real magic in a top-tier synthetic air compressor oil comes from its additive package. These are specialized chemical compounds mixed into the base oil to boost its performance and protective muscle.

A solid additive package isn't a luxury; it’s essential for protecting your investment. Here’s what you should be looking for:

Anti-Wear Agents: These create a sacrificial layer on metal surfaces, preventing direct metal-on-metal grinding under high pressure.

Anti-Foam Additives: Oil that's full of foam can't lubricate properly and will cause overheating. These additives make bubbles pop quickly, ensuring a consistent oil film.

Rust and Corrosion Inhibitors: If you're working anywhere near the coast in places like Pismo Beach or Arroyo Grande, these are non-negotiable. They shield internal parts from the damage moisture can cause.

There’s a reason the global synthetic air compressor oil market is booming—it was valued at US$3.4 billion and is expected to climb to US$5.2 billion by 2029. Contractors and maintenance managers are tired of downtime and are demanding lubricants that deliver. In fact, switching to a quality synthetic can slash maintenance intervals by up to 50%, a huge win for productivity. You can dig deeper into these global synthetic air compressor oil market trends and what they mean for the industry.

But here’s the most important rule of all: Always follow the Original Equipment Manufacturer (OEM) specifications. Brands like Graco and Wagner/Titan design their equipment to run on specific oil types and viscosities. Going against their recommendations is a surefire way to void your warranty and cause serious damage.

If you’re ever unsure, don’t take a guess. The safest bet is to talk to a local expert who gets the unique demands of the San Luis Obispo area. Our team can help you sort through OEM requirements and pick the perfect synthetic oil to keep your compressor humming along for years.

A Step-by-Step Maintenance and Oil Change Guide

Knowing how to look after your equipment is just as important as picking the right synthetic oil air compressor lubricant in the first place. A solid maintenance routine is what guarantees you’ll get the performance and longevity synthetic oil is known for. This guide will walk you through the hands-on steps to keep your compressor running like new, from switching oils to routine checks and troubleshooting.

Proper care is about protecting your investment and avoiding the kind of surprise downtime that throws a whole project off schedule. Whether you're running a job in Arroyo Grande or managing a facility in Paso Robles, these steps will help you lock in a reliable maintenance rhythm.

Switching from Mineral to Synthetic Oil

Making the jump from conventional to synthetic oil isn't just a simple drain-and-fill. Think of it more like a full system reset. To get the real benefits, you have to flush out all the old stuff first. Mineral oil is notorious for leaving behind varnish and sludge that will contaminate your new synthetic oil from day one, cutting its effectiveness and lifespan short.

Here’s how to make a clean transition:

Warm Up the Compressor: Let the unit run for about 10-15 minutes. This warms up the old oil, makes it thinner, and helps stir up contaminants so they drain out more completely.

Drain the Old Oil: Turn the compressor off and make sure it's depressurized. Then, open the drain plug and let every drop of the old mineral oil flow out. Catch it in a proper container for disposal.

Perform a System Flush: This is the most important step. Fill the compressor with a dedicated flushing fluid or even a small amount of the new synthetic oil. Run the compressor with no load for about 15-20 minutes to let the fluid circulate and break down old deposits.

Drain the Flushing Fluid: Get all of the flushing fluid out, just like you did with the old oil.

Change the Filter and Separator: Don't skip this. Always install a new oil filter and air/oil separator when you're switching oil types. The old ones are soaked in mineral oil and will instantly contaminate your fresh synthetic lubricant.

Fill with New Synthetic Oil: Now you’re ready. Refill the compressor to the manufacturer’s recommended level with your chosen synthetic oil.

Following this process ensures your compressor gets a fresh start, letting the new synthetic air compressor oil deliver the protection it was designed for.

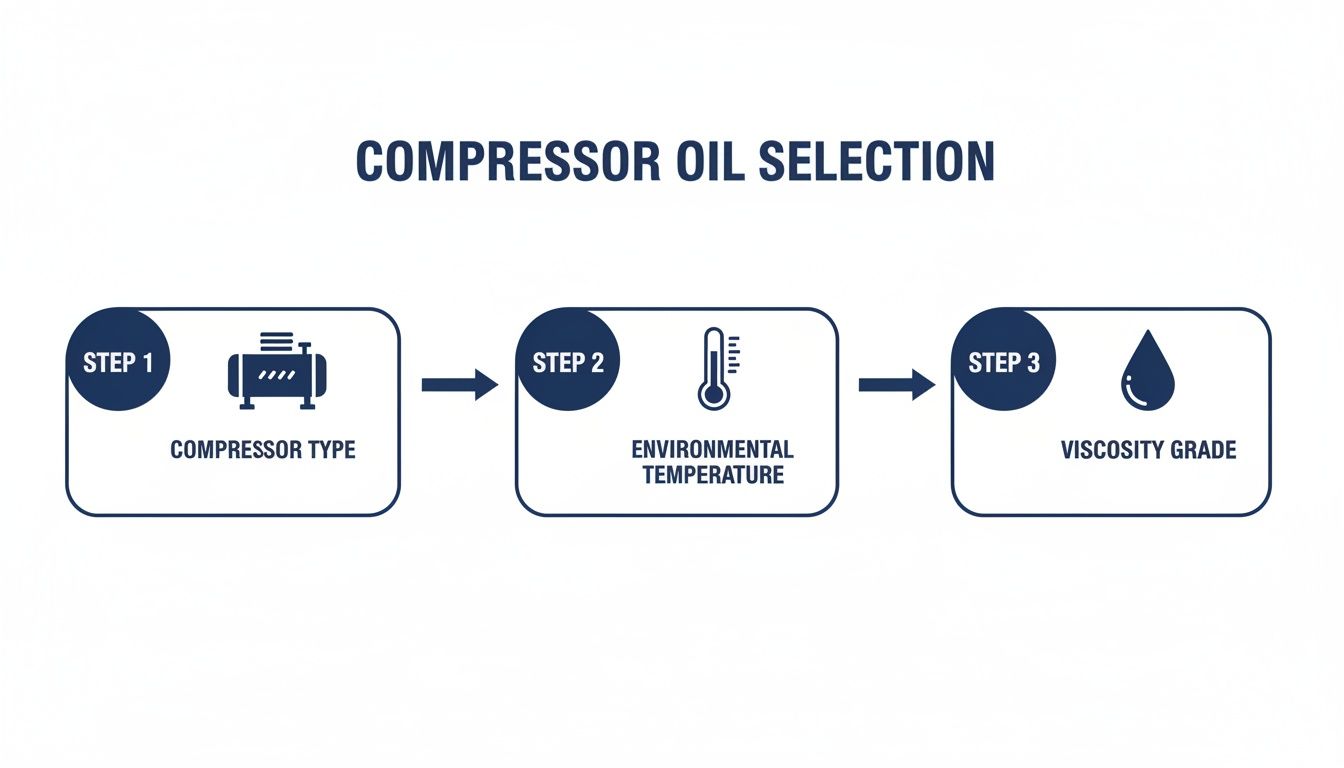

This flowchart breaks down the key decisions when you're selecting a new lubricant, starting with your equipment type and leading you to the right viscosity for the job.

As the visual shows, your compressor type, the environment you're working in, and the oil's viscosity are all connected. You have to consider them together to get the best performance.

Routine Checks and Change Intervals

One of the biggest perks of synthetic oil is how long it lasts. While you’d be changing mineral oil every 2,000 hours, a quality synthetic can go for 8,000 hours or more. But that doesn't mean you can just set it and forget it. Job site conditions play a huge role.

A dusty construction site in Atascadero or a humid coastal environment in Morro Bay will introduce more contaminants into your system. In these tougher conditions, you may need to adjust your oil change interval to protect your equipment.

Regular visual checks are a must. Take a look at the oil sight glass every week. Healthy oil should be clear and have an amber color. If it looks milky, that's a tell-tale sign of water contamination. If it’s dark and murky, it’s probably time for a change, no matter how many hours are on it. A good maintenance log is your best friend for tracking this, and you can learn how to set one up in our guide to a preventive maintenance schedule.

Quick Troubleshooting for Oil-Related Issues

Even with the best maintenance plan, things can go wrong. Here’s a quick guide to help you figure out and fix common oil-related compressor problems on the fly:

Compressor Overheating: This usually points to a low oil level, the wrong oil viscosity, or a clogged oil cooler. The first thing to do is check your oil level. If that's good, confirm you’re using the right ISO grade for the current temperature.

High Oil Carryover: Seeing oil in your air lines? This could mean the air/oil separator has failed or you’ve simply overfilled the oil reservoir. A bad separator is a common problem and needs to be replaced right away.

Milky or Foamy Oil: This is a dead giveaway for water or air getting into the oil. Water contamination is common in humid spots like Pismo Beach and calls for a complete oil change. Foaming can happen if you used the wrong type of oil or if there’s an air leak on the intake side of the pump.

Your Local Partner for Compressor Service in San Luis Obispo

Knowing the benefits of a synthetic oil air compressor is one thing, but having a local partner who can supply the right products and deliver expert service is what really keeps you running. That's where Contractor's Maintenance Service comes in. We’re the hands-on resource for keeping industrial equipment in peak condition across the Central Coast.

As an authorized service center for top-tier brands like Graco and Wagner/Titan, we do more than just hand you parts off a shelf. Our crew provides the diagnostics, preventive maintenance, and critical repairs for the tools you rely on every single day. We’re proud to be the go-to shop for professionals throughout San Luis Obispo County.

Serving Professionals Across SLO County

Our commitment reaches every corner of our community. We proudly serve San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Grover Beach, Pismo Beach, Nipomo, Santa Maria, Morro Bay, Los Osos, Templeton, and all surrounding areas. We know the unique environmental challenges your equipment faces, and we stock the high-performance synthetic oils built to handle them. Our shop is fully equipped with OEM filters, separators, and parts to make sure every job is done right.

Choosing the right lubricant and service partner isn't just about maintenance; it's about reliability. We don’t just sell products—we deliver complete solutions that minimize downtime and maximize your productivity on the job site.

Beyond routine work, we also offer specialized services like custom hydraulic hose fabrication, making us a true one-stop shop for contractors and facility managers who can't afford to cut corners. To get a feel for how our hands-on approach keeps businesses running, check out our guide on comprehensive maintenance services in San Luis Obispo.

Your Partner in Performance and Growth

It’s no secret that demand for better lubricants is on the rise. The synthetic compressor oil market is seeing explosive growth with a 6.5% CAGR, driven by tough sectors like construction and mining—industries we know well and support with our Honda-powered compactors and Multiquip gear. For industrial managers, this trend means fewer headaches; studies show high-quality synthetics can extend component life by 3x in rotary screw compressors common in painting booths.

This industry growth just underscores the need for a strong local presence. For any local partner looking to grow, connecting with customers is everything, which is why resources on mastering HVAC lead generation near me can be so valuable. Our focus has always been simple: be the most reliable and accessible partner for every professional we serve.

Frequently Asked Questions About Synthetic Compressor Oil

Even after getting the rundown on synthetic oils, maintenance managers and contractors usually have a few more specific questions before they're ready to make the switch. Getting straight answers is the key to making a confident call that protects your equipment and your budget. Here are some of the most common questions we get from professionals right here in San Luis Obispo County.

Can I Mix Synthetic and Mineral Compressor Oil?

The short answer is no—you should absolutely never mix synthetic and mineral oils in your compressor. It might seem like a harmless shortcut, but it’s a recipe for disaster. Think of it like trying to mix oil and water; the two just don't play well together.

Mineral and synthetic oils have completely different chemical structures and additive packages. When you pour them together, these chemistries can react in all the wrong ways, causing the lubricant's properties to break down.

This chemical clash can trigger some serious headaches:

Sludge and Varnish Buildup: The mixture can cause additives to fall out of the solution, creating a thick sludge that will clog oil passages, filters, and coolers.

Poor Lubrication: The oil’s ability to form a protective film between moving parts gets compromised, which means more friction and faster wear.

Foaming Problems: Mixing the two can mess with the anti-foaming agents, leading to excessive foam that prevents proper lubrication and makes your compressor run hot.

To sidestep these issues, a full system flush is non-negotiable when you’re upgrading to a synthetic. Just draining the old mineral oil isn’t enough. You have to use a flushing fluid to dissolve and clear out any leftover gunk, ensuring your new synthetic air compressor oil can do its job right from day one.

How Do I Know When It Is Time to Change My Compressor Oil?

While the manufacturer's guidelines give you a solid starting point—often 8,000 hours or more for synthetics—the real-world conditions on a job site in Paso Robles or a facility in Arroyo Grande demand a more hands-on approach. Just watching the hour meter can be a gamble. It's far better to learn the visual and performance cues that tell you the oil is toast.

The most obvious clue is how the oil looks. Healthy synthetic oil is usually clear with a light amber hue. When it starts to break down, you’ll see some pretty clear changes.

Keep an eye on your oil sight glass for these warning signs:

Darkening Color: If the oil has turned dark brown or black, that’s a sure sign of oxidation and contamination. It’s no longer protecting your machine.

Milky or Cloudy Look: Oil that looks milky means it’s contaminated with water. This is a common problem in the humid coastal air of Morro Bay and Pismo Beach, and it kills the oil's ability to lubricate.

Gritty Feel: If you take a small sample and it feels gritty between your fingers, it's full of dirt or metal particles. Running your compressor with that oil is like circulating liquid sandpaper through it.

Beyond what you can see, your compressor's behavior will also tell you it’s time for a change. If the unit starts running hotter than normal or overheats frequently, the oil has likely lost its ability to manage heat. Listening to your equipment and doing regular checks are the best ways to catch these problems before they turn into a catastrophic failure.

Is Synthetic Oil Really Worth the Higher Cost?

Absolutely. The sticker price on a bottle of synthetic oil is higher than its mineral-based cousin, but looking at it as just an expense is a mistake. It’s an investment in reliability and long-term savings, and the payoff is huge.

That initial cost is easily wiped out by some powerful, money-saving benefits that directly hit your bottom line. When you do the math over the life of your equipment, the value is crystal clear.

Here’s how it works out in your favor:

Longer Drain Intervals: Synthetic oil can last up to three times longer than mineral oil. That means buying less oil over time and having less waste oil to get rid of.

Reduced Labor Costs: Fewer oil changes mean your maintenance team spends less time servicing equipment. That’s time they can put toward more productive tasks.

Better Energy Efficiency: Because synthetic oil cuts down on friction so effectively, your compressor’s motor doesn’t have to work as hard. This leads to lower electricity bills, which can add up to serious savings over a year.

Significantly Less Wear: The superior protection from a synthetic oil air compressor lubricant dramatically reduces wear and tear on critical parts like bearings, rotors, and seals. This extends the life of your equipment and prevents expensive, premature rebuilds.

Minimized Unplanned Downtime: This is the big one. A compressor failure on a job site in Atascadero can bring a whole project to a grinding halt, costing you thousands in lost labor and potential penalties. The reliability you get from synthetic oil is the best insurance against that kind of chaos.

Ultimately, the small premium you pay for synthetic oil is a tiny price for the peace of mind and operational efficiency it delivers. It's a strategic move for any serious contractor or maintenance manager in the San Luis Obispo area who knows that equipment reliability isn’t the place to cut corners.

For expert advice on choosing the right synthetic oil for your specific equipment and local operating conditions, or to schedule professional service, trust the team at Contractor's Maintenance Service. We have the products and expertise to keep your compressors running at their best. Visit us online to explore our full range of maintenance solutions at https://www.contractorsmaintenanceservice.com.

Comments