How to Choose Pressure Washer for Your Contracting Business

- DLL Studios

- 2 days ago

- 17 min read

Picking the right pressure washer really just comes down to one thing: matching the machine's power to your most common jobs. For the kind of tough commercial work we see every day, you need higher PSI for brute cutting power and higher GPM for rinsing away the mess.

An easy way to compare machines is to multiply the PSI by the GPM. This gives you a "Cleaning Unit" score, which is a fantastic, no-nonsense way to gauge the true cleaning speed of different models.

Matching Your Cleaning Needs with the Right Machine

Before you even start looking at spec sheets, take a step back and think about what you’ll actually be cleaning day in and day out. The needs of a painting contractor stripping siding in Atascadero are a world apart from a maintenance crew degreasing heavy equipment on a Paso Robles job site.

Getting this part right from the start is crucial. It ensures you invest in a machine that makes you money by boosting efficiency, not one that becomes a bottleneck and costs you time.

Are you mostly dealing with surface-level grime on concrete? Or are you up against caked-on mud, grease, and industrial gunk? The answer points you directly to the two most important numbers on any pressure washer.

Decoding PSI and GPM

Every professional pressure washer is rated by two core specs that tell you everything you need to know about its performance:

PSI (Pounds per Square Inch): This is all about force. Think of it as the raw muscle that blasts away stubborn materials like old paint, dried concrete, or deep-set stains. More PSI means more cutting power.

GPM (Gallons Per Minute): This is the volume of water the machine pushes. Higher GPM gives you more rinsing power, letting you clear away debris and cover large areas much faster.

A common mistake I see is guys focusing only on PSI. A machine with sky-high PSI but low GPM might be great for blasting a tiny, stubborn spot, but it will be painfully slow when you’re trying to clean an entire warehouse floor. Real job site efficiency comes from a solid balance of both.

The Power of Cleaning Units

To cut through the marketing fluff and make a true apples-to-apples comparison, just multiply these two numbers. This gives you a machine's Cleaning Units (CU).

PSI x GPM = Cleaning Units (CU)

This one number gives you a much clearer picture of a machine's real-world cleaning speed. For example, a 4,000 PSI, 4.0 GPM machine (16,000 CU) is going to clean a whole lot faster than a 3,200 PSI, 2.5 GPM unit (8,000 CU), even though both are considered "powerful."

For professional contractors here in San Luis Obispo county, aiming for higher Cleaning Units means finishing jobs faster, which translates directly to lower labor costs and higher profits.

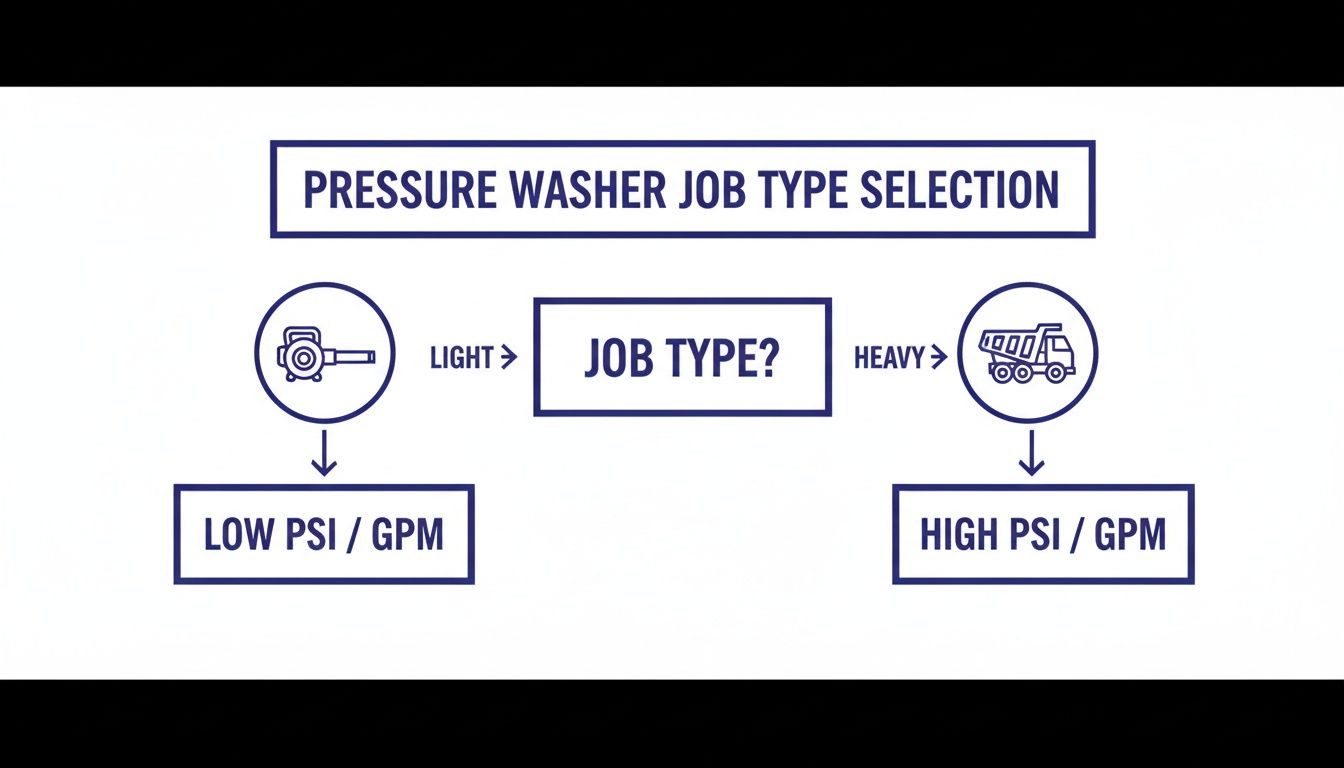

This simple flowchart breaks down the basic decision between light-duty and heavy-duty jobs.

As you can see, it all starts with the job itself. That’s what dictates whether you need a low-power or high-power machine.

Matching Power to the Task

To help you get a better feel for what these numbers mean in the real world, here’s a quick guide matching common tasks with the ideal PSI and GPM ranges.

PSI and GPM Recommendations for Commercial Cleaning Use this quick-reference guide to match common commercial cleaning tasks with the ideal PSI and GPM ranges for optimal performance.

Commercial Cleaning Task | Recommended PSI Range | Recommended GPM Range | Example Use Case |

|---|---|---|---|

Vehicle & Fleet Washing | 1,500 – 2,500 PSI | 3.0 – 5.0 GPM | Washing a fleet of delivery trucks without damaging paint. |

Wood Deck & Siding Prep | 2,000 – 3,000 PSI | 2.5 – 4.0 GPM | Stripping old sealer from a deck before re-staining. |

Concrete Surface Cleaning | 3,000 – 4,000 PSI | 3.0 – 5.0 GPM | Removing oil stains and grime from a parking garage floor. |

Paint Stripping & Graffiti | 3,500 – 4,000+ PSI | 4.0 – 5.0+ GPM | Blasting graffiti off a brick wall or stripping paint from steel. |

Heavy Equipment Degreasing | 3,000 – 4,000 PSI | 4.0 – 6.0 GPM | Cleaning caked-on grease and mud from bulldozers. |

This table should give you a solid starting point for narrowing down your options based on the work you do most often.

For most commercial painters and construction crews I work with, a machine with at least 3,000-4,000 PSI and 2.5-4.0 GPM is the sweet spot. It's got the power to efficiently blast away paint overspray, concrete slurry, and general construction debris without being overkill.

Industry data backs this up. Matching the right PSI and GPM to the job can lead to 20-40% gains in efficiency. Plus, a higher GPM cleans faster, which can slash labor costs by up to 30% on big jobs like fleet washing. This focus on performance is exactly why mobile units are projected to make up 61.35% of global sales revenue by 2025—their versatility is just unmatched on job sites. You can learn more about these pressure washer market insights and how they’re shaping contractor decisions.

Power Source and Water Temperature: Making the Right Call

Once you’ve dialed in your PSI and GPM, the next big decisions are power source and water temperature. These aren't just minor details—they dictate where you can work, what jobs you can handle, and how efficiently you can get them done.

Think about it. A gas engine gives you the freedom to work anywhere, but an electric model is your ticket for indoor or noise-sensitive jobs. And the jump from cold to hot water? That can be the difference between struggling with a greasy mess and blasting it away in half the time. Let’s break down what this means for contractors working here on the Central Coast.

Gas vs. Electric vs. Battery Power

Your power source defines your machine's mobility, maintenance needs, and ideal work environment. Each one has its own set of pros and cons that fit different types of jobs. For contractors working everywhere from remote sites in Santa Maria to indoor facilities in Arroyo Grande, this is a critical choice.

Gas-Powered Pressure Washers: These are the undisputed workhorses for most pros. They crank out the highest PSI and GPM and are completely portable, which is a must-have for new construction or rural properties without power. If you need raw cleaning power and the ability to work anywhere, a gas engine is the way to go.

Electric-Powered Pressure Washers: Quiet operation and zero fumes are the main draws here. That makes electric models perfect for indoor jobs, residential neighborhoods with noise restrictions, or food processing plants where exhaust is a deal-breaker. You'll need an outlet, but they're typically lighter and require less maintenance than a gas engine.

Battery-Powered Pressure Washers: This is a fast-growing category that offers a great mix of portability and quiet operation. They can't match the all-day power of a high-end gas unit yet, but they're fantastic for quick touch-ups, smaller jobs, or any situation where both noise and cords are an issue. Just keep an eye on the runtime.

Industry trends reflect these different uses. While electric models grabbed 54% of the global market in 2024 due to their low noise and emissions, gas-powered units are still seeing huge growth in construction. With North America holding a 43% market share, these choices are incredibly relevant for local contractors. For a deeper dive, check out the latest pressure washer market trends.

Why Hot Water is a Game-Changer

Choosing between a hot or cold water unit is one of the most important decisions you'll make. Cold water washers are great all-rounders for general cleaning—they’ll handle dirt, mud, and loose paint just fine. But throw some oil or grease into the mix, and they just can't keep up.

This is where a hot water unit completely changes the game.

Think of it like trying to wash a greasy pan with cold water. You'll just smear the mess around. But add hot water, and the grease melts away. A hot water pressure washer operates on the exact same principle. It uses an onboard heater, usually diesel-fired, to superheat the water to 200°F or higher.

This high heat dramatically speeds up the cleaning process for tough jobs like:

Degreasing heavy equipment

Washing fleet vehicles

Cleaning industrial food plants

Scrubbing oily shop floors

For these kinds of jobs, hot water isn't a luxury—it's a necessity. It can cut your cleaning time by up to 50% and often means you can use fewer harsh chemical detergents. That saves you both time and money. Of course, that heat puts extra stress on the pump, so knowing how components like the thermal relief valve work is key to keeping your machine running. You can learn more about the thermal relief valve in our guide to see why it's so critical on hot water units.

Once you've nailed down your power and temperature needs, it's time to look at the machine's bones. For a pro, a pressure washer is a serious investment, not just another tool. Its build quality, durability, and how you move it around directly affect your uptime and profitability, especially when you're serving clients all over the Central Coast.

A machine might look great on a spec sheet, but if it's built with cheap parts, a flimsy frame, or an engine that spends more time in the shop than on the job, it quickly becomes a liability. This is where you really see the difference between consumer-grade toys and the professional workhorses built to take a beating on job sites from Paso Robles to Santa Maria.

The Heart of the Machine: The Pump

The pump is probably the single most important part of your pressure washer when it comes to longevity. It’s doing the heavy lifting, and for any serious contractor, picking the right one is non-negotiable.

Axial Cam Pumps: You'll find these on entry-level or homeowner machines. They're simpler and cheaper, but they run at high RPMs, which means more heat and faster wear. An axial pump just isn't cut out for a commercial workload.

Triplex Plunger Pumps: This is the professional standard, period. Triplex pumps are built to last. They run at lower RPMs, which keeps them cooler and reduces friction. They’re also made with better components, like ceramic plungers, and are fully serviceable—meaning you can replace individual parts instead of the whole pump.

For any professional, a triplex pump is the only choice. Yes, it costs more upfront, but its lifespan can be 3-5 times longer than an axial pump. It's a much smarter investment in the long run. Less downtime means more time on the job making money.

Proven Engines and Reliable Frames

Just like the pump, the engine has to be a workhorse. Downtime is the enemy, and a cheap engine is a common culprit. There's a reason brands like Honda and Multiquip have earned their reputation—they start every time, run efficiently, and parts are easy to find. Sticking with a proven engine manufacturer is one of the smartest, simplest ways to protect your business.

The frame holding it all together is just as crucial. Think about it: it has to survive being loaded on and off a truck, dragged across rough job sites, and deal with constant engine vibration.

Steel Frames: These offer maximum strength and durability. They're heavier, but they provide the best possible protection for your pump and engine, making them perfect for tough, demanding work.

Aluminum Frames: These give you a great mix of strength and portability. They're much lighter than steel and won't rust, which is a huge advantage for anyone working near the coast in places like Morro Bay.

Portability for Mobile Operations

How you get your pressure washer from job to job is a massive part of your daily workflow. For mobile contractors covering the wider San Luis Obispo area, from Atascadero down to Arroyo Grande, the right setup makes all the difference in your efficiency.

Cart-Mounted: This is the most common setup, giving you great mobility once you're on-site. The key here is to look for large, pneumatic tires that can handle gravel, uneven ground, and even stairs without a fight.

Skid-Mounted: These units are designed to be bolted right onto a truck bed or trailer. They give you a secure, permanent setup, which is ideal for dedicated pressure washing rigs and contractors who are always on the move.

Trailer-Mounted: This is the ultimate mobile solution. These trailers often combine the pressure washer with a large water tank, hose reels, and tool storage. It allows you to be completely self-contained—a game-changer on job sites that don't have a reliable water source.

Investing in solid build quality isn't just about avoiding headaches; it's about getting a healthy return. The global pressure washer market is expected to hit USD 3.96 billion by 2029, driven by industries where uptime is everything. Mobile units make up 61.35% of revenue, but their triplex pumps can fail 40% faster without proper service. Choosing machines with stainless brass heads and reliable Honda engines—a staple at our shop—can easily double the lifespan over generic alternatives. And with regular maintenance, you can boost that by another 50%. For a deeper dive into how maintenance impacts equipment life, check out these pressure washing industry statistics.

Choosing the Right Hoses, Nozzles, and Accessories

A powerful pressure washer is a great starting point, but the machine is really only half the battle. To get the most out of your investment, you need the right combination of hoses, nozzles, and accessories. This is what turns a brute-force tool into a precise and efficient cleaning system.

Without the correct attachments, you risk either gouging a surface with too much force or, just as bad, wasting hours on a job that should have taken minutes. Think of these accessories as specialized tools in your kit. A mechanic wouldn't use one wrench for every bolt, and a professional cleaner needs the right nozzle for stripping paint and a totally different one for rinsing a vehicle.

Decoding the Color-Coded Nozzle System

Most professional pressure washers come with a set of quick-connect nozzles, each color-coded for a specific spray pattern and intensity. Understanding what each one does is fundamental to getting clean surfaces without causing thousands of dollars in damage.

0° (Red Nozzle): This is the blaster. It shoots a pinpoint stream of water, perfect for hitting extremely stubborn, isolated spots like rust on steel or dried concrete on equipment. Be warned: its intensity makes it extremely dangerous on softer materials like wood or siding. Use it with extreme caution.

15° (Yellow Nozzle): This nozzle creates a 15-degree fan of water, making it your go-to for heavy-duty surface prep. Think stripping paint, knocking tough stains off concrete, or blasting caked-on mud from construction equipment in Santa Maria.

25° (Green Nozzle): The green nozzle is the workhorse for most general cleaning. Its 25-degree spray pattern offers a fantastic balance of power and coverage, ideal for cleaning vehicles, siding, and most concrete surfaces without being overly aggressive.

40° (White Nozzle): When you need to clean delicate surfaces, grab the white nozzle. The wide 40-degree spray is perfect for gently rinsing windows, washing vehicles, or cleaning fragile stucco in areas like Arroyo Grande.

Soap Nozzle (Black): This low-pressure nozzle is designed specifically to pull detergent from your machine's injector and lay it down on a surface. You always apply soap with low pressure before switching to a high-pressure nozzle for rinsing.

Specialized Tools for Maximum Efficiency

Beyond the basic nozzle set, a few key accessories can dramatically boost your speed and effectiveness on commercial jobs.

A turbo nozzle, sometimes called a rotating nozzle, is a must-have for tough concrete work. It combines the pinpoint power of a 0-degree nozzle with a spinning motion, creating a conical spray pattern. This lets it clean large, stubborn areas much faster than a standard nozzle and helps prevent the dreaded "tiger stripes."

For large, flat areas like parking lots in Morro Bay or warehouse floors, a surface cleaner is non-negotiable. This accessory looks a bit like a push mower and uses spinning nozzles under a deck to clean huge areas evenly and quickly. A good surface cleaner can easily cut your cleaning time by 75% or more compared to using a standard wand.

For contractors, efficiency is everything. Investing in a high-quality surface cleaner can pay for itself in just a few jobs by drastically reducing labor hours. It’s one of the best ROI-boosting accessories you can buy.

Selecting the Right Hoses and Fittings

Your hose is the lifeline of your operation, and skimping here is a classic rookie mistake. A cheap, kinking hose will fight you all day, restrict water flow, and fail when you least expect it.

Look for high-quality, non-marring hoses. These are designed not to leave black scuff marks on freshly cleaned surfaces—a critical feature for painters and anyone working on finished properties. Additionally, investing in custom hydraulic fittings from a local shop like ours ensures a perfect, leak-free seal. These custom solutions prevent the frustrating drips and unexpected downtime that plague generic, off-the-shelf connectors.

Choosing the right accessories is a deep topic, and you can get even more insights by exploring our full guide to unlocking power with pressure washer accessories.

Finally, tools like extension wands for reaching high places and foam cannons for applying thick, clinging detergents can round out your toolkit, ensuring you're prepared for whatever the job throws at you.

Why Local Service and Support Matters for Contractors

When you're figuring out how to choose a pressure washer, it's easy to get lost in the specs. PSI, GPM, engine type—they're all important. But the real test comes a year or two down the road when that hard-working machine inevitably needs service. What happens then?

For any professional contractor, downtime is more than an inconvenience; it’s money walking out the door. A breakdown can grind a project to a halt, dent your reputation, and torch your profits. This is where having a dedicated, local service partner really shows its value.

The Big-Box Store and Online Gamble

Let's be honest, the initial appeal of buying from a big-box store or an online retailer is strong. The prices look good, and you can have it delivered right to your door. But that convenience vanishes the second your pump fails or the engine sputters out.

Suddenly, you're tangled up in a warranty process that involves shipping a beast of a machine halfway across the country. A simple repair morphs into weeks of waiting, leaving a massive hole in your tool arsenal. The person who sold it to you can’t fix it, and you're left navigating a faceless 1-800 number.

When your business is on the line, every hour of downtime is critical. A repair that a local partner like us can knock out in a day can easily become a two-week project delay when you're dealing with a remote seller.

The San Luis Obispo Advantage

This is exactly why having a local, full-service partner like Contractor's Maintenance Service is a game-changer for pros on the Central Coast. We aren't just selling you a machine. We're an authorized service center for top-tier brands like Graco, Wagner/Titan, and Honda, right here in San Luis Obispo.

So, what does that actually mean for you?

No-Hassle Warranty Claims: If a machine under warranty has an issue, you bring it to us. We handle everything in-house—the diagnostics, the paperwork, and the repair—to get you back on the job fast. No shipping labels, no waiting on hold.

Expert Diagnostics and Repair: Our technicians live and breathe this equipment. We can pinpoint the root of a problem, from a worn-out pump seal to a complex engine issue, and get it running like it just came out of the box.

Smart Preventive Maintenance: The best repair is the one you never have to make. We offer comprehensive maintenance to keep your equipment running strong and extend its life. To get a head start, check out our guide on how to master pressure washer pump maintenance.

Serving Contractors Across the Central Coast

Our commitment goes way beyond our San Luis Obispo storefront. We are the go-to resource for contractors working throughout San Luis Obispo County and the surrounding areas. Whether you're on a job site in the North County vineyards of Paso Robles and Templeton, handling projects in Atascadero, or working on coastal developments in Morro Bay and Cayucos, we have you covered. Our support extends south to the Five Cities area, including Arroyo Grande, Pismo Beach, and Grover Beach, as well as to our clients in Santa Maria and Nipomo. We understand the unique challenges of working across these diverse Central Coast environments.

Picture this: you're on a job in Arroyo Grande and a hydraulic hose blows. Instead of losing half a day driving to some generic supply house, you come straight to our shop. We have the gear to custom-fabricate hydraulic hoses and fittings while you wait.

We also keep a deep inventory and have the know-how to track down those rare or hard-to-find parts for your specific machine. It's this ability to provide immediate, real-world solutions that sets a local specialist apart. We're invested in your uptime because your success is our success. At the end of the day, choosing a pressure washer is also about choosing a partner who has your back long after the sale is made.

Got Questions About Pressure Washers? We've Got Answers.

You've got the basics down, but when you're about to invest in a new machine, the practical questions always start bubbling up. We hear them all the time from contractors walking into our San Luis Obispo shop.

Here are the straight-up answers to the most common questions we get. These are the real-world details that make a huge difference in your day-to-day work and whether you'll still love your machine a year from now.

Axial vs. Triplex Pump: What's the Real Difference?

This is probably one of the most critical distinctions in build quality, and it's not just jargon. An axial cam pump is what you'll typically find on a machine designed for homeowners. It’s a simpler, more direct design where the pistons are pushed by a "wobble plate" right on the engine shaft. This forces the pump to spin at the same high speed as the engine—usually around 3,400 RPM. All that speed creates a ton of heat and friction, which is why they have a much shorter service life.

A triplex plunger pump, however, is the professional standard for a reason. It operates more like a car engine, using a crankshaft and connecting rods to move its ceramic plungers. This robust design allows it to run at a much lower and cooler RPM, often somewhere between 1,100 and 1,700 RPM.

The bottom line is all about durability and serviceability. A triplex pump is built to be repaired and can easily outlast an axial pump many times over. For any serious contractor, a triplex pump isn't just a nice feature—it's a must-have for reliable, long-term operation.

Can I Just Use Any Detergent in My Machine?

The short answer is a hard no. Tossing the wrong chemical into your pressure washer is a fast track to damaging its pump seals and other internal parts. Bleach, for instance, is extremely corrosive and will chew through a pump in no time. On the other hand, soaps that are too thick or gritty can easily clog up your chemical injector.

Always stick with detergents specifically made for pressure washers. They're formulated to work effectively at the right dilution ratios without causing any harm to your equipment. For specific jobs, it pays to use the right tool:

Degreasers are perfect for cleaning heavy equipment and greasy shop floors.

Vehicle soaps, often with wax additives, are ideal for fleet washing.

House washes are specifically designed to kill and remove mold and mildew from siding safely.

Investing in the right chemical doesn't just protect your machine; it gets the job done faster and better, which saves you time and money.

How Often Should I Service a Commercial Machine?

For a commercial pressure washer getting put through its paces on job sites from Paso Robles to Santa Maria, a regular maintenance schedule is completely non-negotiable. Being proactive is the single best way to avoid that dreaded call from the field about a machine that's dead on arrival.

Here’s a simple, practical schedule to keep you up and running:

After Every Single Use: Do a quick check of the engine oil and pump oil levels. Just as important, inspect and clean the water inlet filter. You'd be surprised what kind of debris it can catch, saving your pump from damage.

Every 50 Hours: Change the engine oil. This is absolutely critical for the longevity of hardworking Honda or Multiquip engines.

Every 100-200 Hours: Change the pump oil. While you're at it, take a look at the air filter and spark plug—clean or replace them as needed.

Annually: Bring it into a certified shop for a full check-up. We can inspect the unloader valve, test the pump seals, check nozzles for wear, and make sure the whole system is hitting peak pressure and flow.

Following this simple routine will dramatically extend the life of your investment.

Does It Make More Sense to Rent or Buy?

This one really boils down to how often you'll be using the machine and what your business model looks like.

Renting is a great option if:

You only need a pressure washer for a specific, one-off job.

You need a beast of a machine (like a 5,000+ PSI industrial unit) for a specialized task you rarely do.

You're just starting out and want to try a few different models before you commit to buying.

Buying is the right move when:

Pressure washing is a core part of the services you offer regularly.

You find yourself renting a machine more than once or twice a month. At that point, the rental costs quickly add up and can easily surpass the purchase price.

You value the convenience of having your own machine, set up exactly how you like it, ready to go whenever a job pops up.

For contractors working in Atascadero, Arroyo Grande, and across the greater San Luis Obispo area, owning a reliable machine from a local dealer who provides service and support is almost always the most profitable long-term strategy. If you're new to the game or just want a refresher, understanding what pressure washing entails can be a huge help in making that final call.

Making the right choice is about more than just numbers—it’s about having a reliable partner to support you. At Contractor's Maintenance Service, we’re here to help you select the perfect machine and keep it running for years to come. Explore our full range of equipment and services at https://www.contractorsmaintenanceservice.com.

Comments