A Contractor's Guide to Spray Nozzles for Pressure Washers

- DLL Studios

- 4 hours ago

- 16 min read

Spray nozzles are the unsung heroes of your pressure washer setup. They're the critical piece that takes all that raw power from the engine and shapes it into a useful stream of water. The right nozzle lets you peel stubborn grime off concrete with surgical precision, while the wrong one can tear up a wooden deck in seconds. For any professional contractor, mastering these small but mighty tools is the difference between a job well done and a costly mistake.

Why Your Nozzle Choice Defines Your Work

Think of your pressure washer like a high-performance engine. The nozzle is the transmission—it’s what translates all that horsepower into controlled, effective work on the ground. Without the right one, even the most powerful machine is just making a lot of noise. A mismatched nozzle means you're either wasting time going over the same spot again and again or, far worse, causing irreversible damage to your client's property.

This guide isn't just about the basic color codes everyone knows. We're going to treat spray nozzles like the precision instruments they are. We'll dig into how tip angle, orifice size, and even the material of the nozzle itself are fundamental to your success on any job site.

Serving Professionals in San Luis Obispo and Surrounding Areas

For contractors working in San Luis Obispo and the surrounding areas, having the right gear is non-negotiable. The jobs here are incredibly diverse. One day you might be cleaning heavy agricultural equipment in Paso Robles, the next you're doing marine maintenance in Morro Bay or prepping a commercial storefront in Atascadero.

We get the unique challenges you face because we're right here with you. That's why we're proud to serve the entire San Luis Obispo County, including key areas like:

San Luis Obispo

Paso Robles & Templeton: Supporting the backbone of our agricultural and winery operations.

Atascadero & Morro Bay: Providing reliable solutions for both residential and commercial property maintenance.

Arroyo Grande & Santa Maria: Equipping contractors for tough industrial and construction site cleanups.

Our goal is to be your local partner, making sure you have the expert advice and high-performance parts needed to walk onto any project with complete confidence.

Choosing a nozzle is a strategic decision. It's about applying the perfect amount of force to the right area to clean effectively without causing harm. Nailing this skill is what separates the true professionals from everyone else.

While understanding nozzles is a huge piece of the puzzle, a solid grasp of the entire pressure washing ecosystem is what really sets the pros apart. This foundational knowledge ensures every part of your rig works together seamlessly. We'll use this guide to build a deep understanding of nozzle mechanics and how they play out in the real world. We'll cover everything from translating nozzle colors into on-the-job performance to matching orifice sizes for peak efficiency. To see how nozzles fit into the bigger picture, check out our guide on https://www.contractorsmaintenanceservice.com/post/unlocking-power-with-pressure-washer-accessories.

Translating Nozzle Colors Into Jobsite Performance

The color-coding system on pressure washer nozzles is more than just a convenient label—it's the language of performance. Each color signals a specific spray angle, and speaking this language fluently allows a pro to grab the perfect tool for any task, instantly. Let's go beyond a simple chart and translate these colors into the real-world results you need on job sites across San Luis Obispo County.

Think of it like this: the nozzle tip is what takes the raw power from your machine and shapes it into a focused, productive stream. A narrow angle channels all that pressure into a tiny point, giving you immense cleaning force but also a high risk of damage. On the flip side, a wide angle spreads that same pressure out, softening the impact while covering more ground.

The Red Nozzle: A Surgical Demolition Tool

The 0-degree red nozzle isn't really a cleaning tool; it's a small-scale demolition instrument. It creates a single, potent jet of water that can deliver blasts up to 40,000 PSI on some industrial machines. This makes it incredibly effective for very specific tasks but also extremely dangerous if you're not careful.

On a commercial job, you’ll only pull this one out for highly specialized situations that demand extreme precision.

Targeting Stubborn Grime: Use it to knock off hardened gunk like caked-on mud from heavy equipment undercarriages or dried concrete from tools.

Removing Nests: It’s great for blasting wasp nests or other insect hives from high-up metal or concrete structures where you can't reach.

Spot-Treating Stains: It can eliminate tough, isolated stains on unpainted concrete that wider nozzles just can’t touch.

Whatever you do, never point this nozzle at wood, siding, vehicles, or any painted surface. Its focused power will etch, splinter, or strip surfaces in a heartbeat.

The Yellow and Green Nozzles: The Workhorses of Cleaning

The 15-degree yellow nozzle is your go-to for aggressive surface prep. It strikes a nice balance between a concentrated stream and wider coverage, making it perfect for stripping old paint, clearing away heavy mildew, or getting hard surfaces like steel ready for a new coat.

The 25-degree green nozzle is, without a doubt, the most versatile and frequently used tip in the box. It offers a solid mix of cleaning power and coverage, making it the default choice for most general cleaning jobs. For contractors working anywhere from Paso Robles to Santa Maria, this is the nozzle you’ll reach for to clean concrete driveways, wash down brick walls, and handle everyday property maintenance.

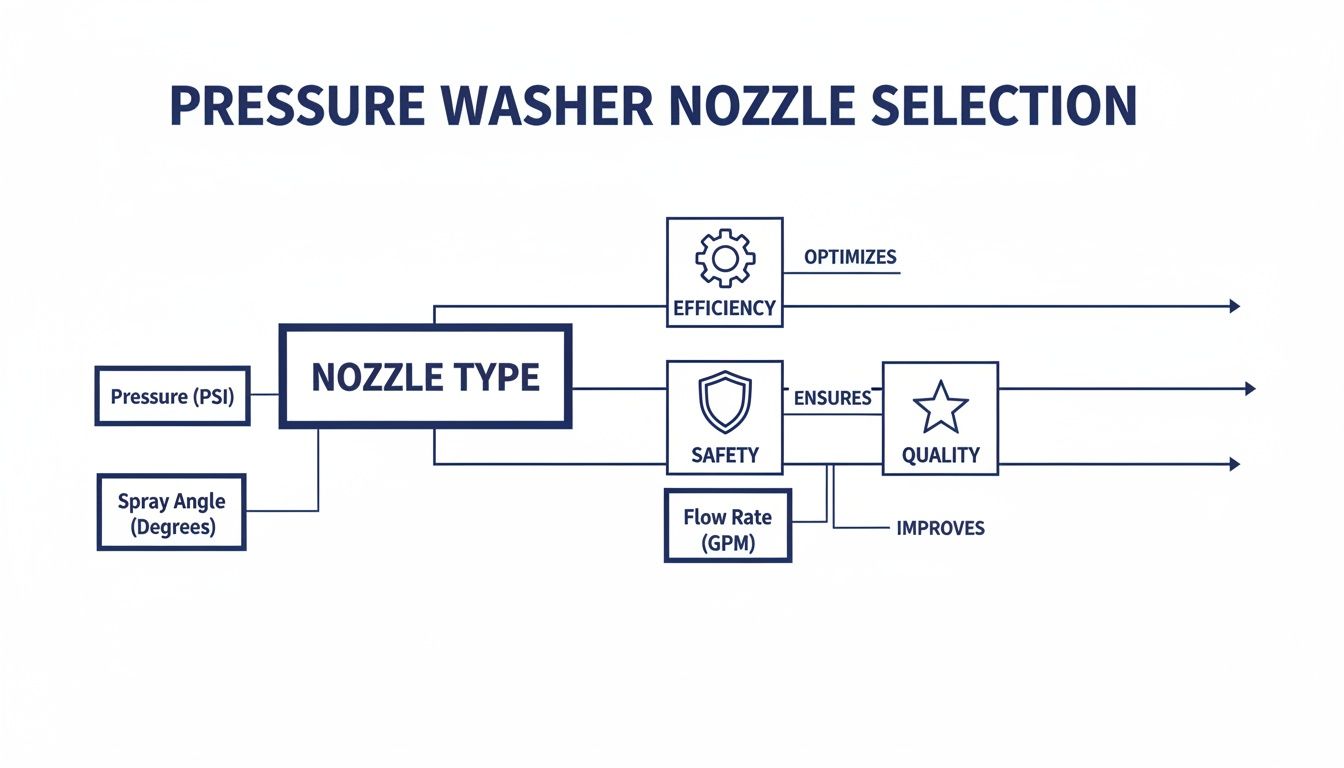

This flowchart shows how your nozzle choice is a strategic decision that directly impacts job efficiency, safety, and the quality of your final result.

As you can see, a calculated nozzle choice isn't just about getting the job done faster. It’s a core part of protecting both the surface you're working on and the operator, all while delivering a superior finish.

The White and Black Nozzles: For Broad Strokes and Application

Think of the 40-degree white nozzle as a wide, gentle broom. Its broad spray pattern is ideal for cleaning large, more sensitive surfaces quickly and safely. This is the nozzle you'll want for washing fleet vehicles, cleaning windows, or rinsing down wooden decks without gouging the material.

Finally, there’s the 65-degree black nozzle, often just called the soaping nozzle. It serves a very different purpose. This tip operates at a much lower pressure, which is exactly what you need to pull detergent through your pressure washer's chemical injector system. Its extra-wide spray lets you apply cleaning solutions quickly and evenly before you switch back to a higher-pressure nozzle to rinse it all away.

Here’s a quick reference guide to help you match the right nozzle to the right job every time.

Commercial Applications for Pressure Washer Nozzles

Nozzle Color | Spray Angle | Primary Use Cases for Contractors | Impact Level |

|---|---|---|---|

Red | 0° | Removing caked-on mud, concrete from tools, spot-treating tough stains | Extreme |

Yellow | 15° | Paint stripping, surface prep, removing heavy mildew and rust | High |

Green | 25° | General cleaning of driveways, sidewalks, brick, and siding | Medium |

White | 40° | Washing vehicles, windows, wood decks, and other delicate surfaces | Low |

Black | 65° | Applying soaps, detergents, and chemical cleaning solutions | Very Low |

Using this table as a starting point will help you work more efficiently and avoid costly mistakes on the job site.

The performance of these nozzles is central to the entire pressure washer market. In fact, the U.S. pressure washer market accounted for a massive 69.7% of North America's revenue, with the global market size hitting USD 2.79 billion. Nozzle selection is the key that unlocks this power, dictating performance across every application. Get more details on the pressure washer market from this in-depth report.

When you truly understand what each color represents in a real-world application, you move from just using a tool to mastering your craft. That knowledge protects your clients' property, makes you more efficient, and ultimately elevates the quality of your work.

Matching Orifice Size to Your Machine's PSI and GPM

While the color-coded tip gets all the attention, the real magic happens inside a tiny, precisely drilled hole called the orifice. It’s the single most critical factor in controlling your pressure washer's power and ensuring it runs for the long haul.

Think of it like putting your thumb over a garden hose. A smaller opening constricts the water, creating a higher-pressure jet. A larger opening lets more water through, which lowers the pressure. The trick is to find the perfect balance between the orifice size, your machine's pressure (PSI), and its water flow (GPM) to get the job done right.

The Dangers of a Mismatched Orifice

Getting the orifice size wrong isn't just inefficient—it can wreck your equipment. Your machine's pump, engine, and nozzle work together in a closed system. Throw one part out of balance, and you create serious strain. For any pro who relies on their gear day in and day out, this is something you absolutely have to get right.

You’ll run into two main problems with a mismatch:

Orifice Too Small: This is the big one. A tiny orifice chokes the water flow, causing pressure to spike dangerously. The pump has to fight against immense backpressure, which can lead to catastrophic failure of the unloader valve, seals, or even the pump itself.

Orifice Too Large: While it's less destructive, an oversized orifice kills your power. It lets water flow too freely, so the machine can't build up to its rated PSI. You end up with a weak, useless stream that forces you to make multiple passes, burning through time, fuel, and water.

Finding the Perfect Match for Your Machine

To pick the right spray nozzles for pressure washers, you need to know two numbers: your machine’s maximum PSI and its GPM rating. You can usually find these specs on the data plate or in the owner's manual. For contractors, knowing these figures for every machine in your fleet—whether it's a Honda, Graco, or Multiquip—is non-negotiable.

The goal is to choose an orifice size that lets your machine hit its peak rated pressure and flow without overworking the pump. This sweet spot delivers maximum cleaning power and extends the life of your most important asset.

Once you have your PSI and GPM, you can use a nozzle sizing chart. These charts cross-reference pressure and flow to give you a specific orifice size number (like 3.0, 4.5, or 5.0). This number, often stamped right on the side of the nozzle, is totally separate from the color code. A 4.0 orifice nozzle, for example, can come in red (0°), green (25°), or white (40°), allowing you to maintain the correct pressure while switching between different spray patterns.

Local Expertise for Your Equipment

For pros working in and around San Luis Obispo, having a local partner who knows their stuff makes all the difference. At Contractor's Maintenance Service, we serve communities from Paso Robles to Arroyo Grande, providing not just the parts but the hands-on expertise to match them perfectly to your gear.

Whether you're running a high-GPM rig for agricultural cleanup or a lower-PSI unit for delicate restoration work, we'll make sure you have the right orifice for the job. Our team can walk you through sizing charts and help you select nozzles that protect your investment.

Choosing the right components is the first step, but a deeper understanding of the machine itself is just as crucial. For more on that, check out our guide on https://www.contractorsmaintenanceservice.com/post/finding-the-best-pressure-washer-for-commercial-use to get your entire setup dialed in for peak performance and longevity.

Why Nozzle Material Matters for Commercial Durability

For any pro, a pressure washer nozzle isn't just a tiny, cheap part—it’s a critical piece of equipment that keeps you working and performing at your best. The material it's made from is a big deal. It determines how long the nozzle will last, how precise its spray will be, and ultimately, whether it's a good investment for your business. Picking the right material for your spray nozzles for pressure washers is a decision that shows up on your bottom line.

Think about it like this: trying to use a cheap brass nozzle for a tough, abrasive job is like trying to cut concrete with a standard wood saw blade. It might work for a second, but it's going to wear out almost immediately, wreck the tool, and leave you with a garbage result. A standard brass nozzle just can't take the daily beating of commercial work.

Standard Brass: The Entry-Level Option

Brass nozzles are everywhere. They're inexpensive, which makes them fine for occasional, light-duty homeowner tasks. But brass is a relatively soft metal alloy. When you force the high-pressure flow of a commercial-grade machine through it day after day, the orifice starts to wear down and warp pretty fast.

And this wear isn't some minor inconvenience. As that tiny hole widens, your machine's operating pressure drops. The carefully engineered spray pattern gets sloppy and ineffective. That means you're spending more time on the job, burning more fuel, using more water, and getting results that just aren't up to professional standards.

Hardened Stainless Steel: The Professional Standard

This is where the pros who work in demanding areas like Paso Robles or Arroyo Grande should start looking. Hardened stainless steel nozzles are a huge leap forward in durability compared to brass. They fight off corrosion and are way more resistant to the wear and tear from high pressure and the chemicals we use every day.

That extra toughness means the nozzle's orifice size and spray pattern stay consistent for a whole lot longer, giving you reliable performance, job after job. For most general cleaning, paint prep, and property maintenance, stainless steel hits that sweet spot of performance and cost.

The evolution of nozzle materials reflects major industrial trends. This progress mirrors the industrial spraying nozzle market's projected climb from USD 2,101.71 million to USD 3,602.38 million by 2033. While brass was standard in the 1950s, the emergence of ceramics in the 1990s boosted durability by 300% against abrasive materials, a critical advance for contractors. Learn more about the growth of the nozzle market and its impact on various industries.

Ceramic Nozzles: The Ultimate in Durability

When you're up against the toughest jobs you can imagine, ceramic nozzles are the top-of-the-line solution. Ceramic is one of the hardest materials out there, offering incredible resistance to both chemical corrosion and abrasive grit.

Picture this: you're soda blasting old paint off a steel structure in Santa Maria or cleaning concrete that's caked in fine, gritty dust in Atascadero. In those scenarios, even a good stainless steel nozzle will eventually wear out. A ceramic nozzle, on the other hand, can last up to ten times longer, holding a perfect spray pattern over hundreds of hours of operation.

They do cost more upfront, no doubt about it. But that investment in ceramic nozzles pays for itself by cutting down on downtime, reducing replacement costs, and delivering flawless performance on your most challenging projects. For contractors whose reputation is built on quality and efficiency, they're an absolute must-have.

Going Beyond the Basics: Advanced Nozzles and Smart Maintenance

Once you’ve got the standard color-coded tips down, it's time to level up. A couple of specialty spray nozzles for pressure washers can seriously cut down your time on specific jobs. Combining these advanced tools with a solid maintenance routine is what really separates the pros from the amateurs. It’s all about working smarter, getting better results, and keeping your gear running longer.

One of the best tools you can have in your truck is the turbo nozzle, sometimes called a rotary nozzle. Think of it as a hybrid that gives you the best of both worlds. It harnesses the raw, concentrated power of a 0-degree red tip but spins it in a tight circle at an incredible speed. The result? You get the stripping force of a pinpoint stream with the wider coverage of a fan spray.

This nozzle is an absolute beast for blasting caked-on grime from concrete or stripping old rust off steel. But all that power comes with a warning. Never, ever use a turbo nozzle on softer materials like wood, vinyl siding, or vehicles. It will chew through them in seconds, leaving permanent damage.

The Right Tools and a Proactive Mindset

For jobs with a little bit of everything—like cleaning a multi-story building from Arroyo Grande to Atascadero with different surfaces—an adjustable nozzle is a lifesaver. These all-in-one tips let you switch between different spray patterns on the fly, from a tight jet to a wide fan, just by twisting the housing. No more stopping to swap tips means more time working and less time fumbling with small parts.

Of course, having the right tool is only half the battle. You have to keep it in top shape. Nozzles are consumable parts; they wear out, and even the best ones won't last forever. Proactive maintenance isn’t just about fixing things when they break—it’s about preventing those breakdowns and protecting the heart of your machine: the pump. A worn-out nozzle makes your pump work overtime, leading to expensive, premature failure.

“A distorted spray pattern is the first warning sign of a worn-out nozzle. If the fan is uneven or you notice a significant drop in pressure, it's time for a replacement. Ignoring it is like running your engine with low oil—it will eventually cause major damage.”

How to Spot Wear and Stay Safe

Every contractor in San Luis Obispo County should know how to spot the signs of a failing nozzle. Make a quick inspection part of your daily pre-work routine.

Distorted Spray Pattern: This is the most obvious red flag. A new nozzle creates a clean, crisp fan of water. A worn one will look uneven, streaky, or just plain messy.

Pressure Drop: Feel like your wand doesn't have the same kick it used to? The nozzle’s orifice has probably widened, causing your machine's pressure to dip below its rated PSI.

Increased Recoil: This one is more subtle, but if the wand’s kickback feels different, it can signal an irregular flow of water through a worn-out tip.

The market for these essential parts is booming. Valued at $87 million, the pressure washing nozzle market is projected to grow at a 15.2% CAGR through 2033. To meet demand, top manufacturers are innovating with materials like ceramics and specialized alloys that can extend a nozzle's life by up to 50% compared to standard brass. That's a huge deal for any business trying to minimize downtime.

Finally, always treat your pressure washer with the respect it deserves. It’s a powerful piece of equipment. Always wear your Personal Protective Equipment (PPE)—safety glasses, gloves, and solid boots are non-negotiable. Double-check that all your connections are tight before you fire it up, and never point the wand at anyone, period. Sticking to these safety rules is what keeps professionals working safely from Paso Robles to Santa Maria.

For a detailed walkthrough, check out our step-by-step nozzle replacement guide.

Your Go-To Pressure Washer Partner in San Luis Obispo County

Choosing the right spray nozzle is a game-changer. As we've covered, matching the spray angle, orifice size, and material to your pressure washer and the job at hand is what separates a professional finish from a costly mistake. But for contractors here on the Central Coast, having the right hardware is only half the battle. You also need a local partner you can count on.

That’s where we come in. We’re here to support professionals across San Luis Obispo County, making sure you have the equipment, parts, and know-how to walk onto any job site with confidence. We get the unique challenges you face because we’re part of this community, too.

Proudly Serving the Central Coast

Our roots run deep throughout the county. We provide specialized parts and service to contractors, whether you're working in:

San Luis Obispo

Paso Robles and Templeton: Keeping equipment running for the demanding agricultural and winery sectors.

Morro Bay and Atascadero: Supporting everything from coastal maintenance to commercial property upkeep.

Arroyo Grande and Santa Maria: Equipping industrial and construction crews for the toughest jobs out there.

Don't think of us as just another supplier. We're an extension of your team, completely focused on cutting your downtime and boosting your bottom line.

A local business lives and dies by its visibility. Attracting clients right here in SLO County is crucial, so it pays to explore effective local SEO strategies to get your name in front of more customers in your service area.

Real Expertise and Service That Keeps You Working

We know that when a machine is down, the clock is ticking and money is on the line. That's why we offer straightforward, expert advice to make sure you get the exact part you need for your Graco, Titan, or other pro-grade sprayer—the first time. Our team doesn't just sell parts; we solve problems.

From helping you pick the perfect nozzle for a tricky paint prep job to offering fast, reliable repair services that get you back to work, your success is our priority. We invite local contractors to give us a call or stop by our San Luis Obispo shop for the kind of personalized support you just won't find at a big-box store. Let's work together to keep your equipment running like new, so every project gets done safely, efficiently, and to the highest standard.

Got Questions About Pressure Washer Nozzles?

When you're out on a job, the last thing you want is equipment trouble. Nozzles might seem like small parts, but they're critical to your pressure washer's performance and health. Here are some quick, straightforward answers to the questions we hear most often from contractors.

How Often Should I Replace My Pressure Washer Nozzles?

Think of your nozzles as wear items, like the tires on your truck—they're not meant to last forever, especially with commercial use. You should give them a quick inspection before every job and plan on swapping them out every 3-6 months if you're running your machine hard.

Why the fuss? A worn-out nozzle makes your pump work overtime to maintain pressure, which is a fast track to expensive repairs. If you see the spray pattern getting distorted or feel a drop in pressure, don't wait. Replace that nozzle immediately. While tougher materials like stainless steel or ceramic can buy you more time, nothing replaces a regular, careful inspection.

Can I Use a Nozzle Rated for a Higher PSI Than My Machine?

This is a common point of confusion, but it's simple: the nozzle's max PSI rating isn't the number to watch. The most critical factor is the orifice size. You have to match the orifice to your machine's specific PSI and GPM.

Get it wrong, and you're asking for trouble. A nozzle with an orifice that's too small will cause dangerous pressure spikes that can wreck your pump and unloader valve. Go too big, and your cleaning power will plummet, wasting your time and making the job harder. Always stick to a sizing chart or talk to an expert to get the right fit.

The right nozzle not only cleans better but also acts as a safeguard for your entire system. Mismatched components are the leading cause of premature pump failure, turning a small oversight into a major expense.

What's the Best All-Around Nozzle for General Cleaning?

If you had to pick just one, the 25° green tip nozzle is the jack-of-all-trades for most commercial cleaning jobs. It strikes a great balance between concentrated force and wide coverage, making it perfect for things like concrete, decks, and siding without being aggressive enough to cause damage.

That said, a true professional never shows up with just one tool. You should always have a full set (0°, 15°, 25°, and 40°) in your truck. This lets you adapt on the fly, switching between different surfaces and grime levels on the same job site for the best results.

Where Can I Get Expert Advice and Parts Locally?

For contractors here on California's Central Coast, downtime is money lost. Having a local supplier you can trust is a game-changer. We're here to offer expert advice and keep a full stock of high-quality nozzles and parts for professionals just like you. Our entire operation is built around supporting the hardworking contractors across San Luis Obispo County.

We're proud to serve our local communities, including:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Santa Maria

Templeton

Morro Bay

Whether you need a hand picking the right orifice size or you need a part yesterday for a critical repair, our team is here to give you the support you need to keep your jobs on track.

At Contractor's Maintenance Service, we're your local partners for everything pressure washers and industrial equipment. Stop by our San Luis Obispo shop or check out our inventory online to get the durable, high-performance parts and real-world advice you need to get the job done right. See our full range of services and products at https://www.contractorsmaintenanceservice.com.