A Guide to Your Thermal Relief Valve for Pressure Washer

- Jan 14

- 16 min read

A thermal relief valve is a small but mighty safety feature that protects your pressure washer’s pump from overheating. When your machine is running but you’re not spraying, this valve automatically dumps hot water to prevent catastrophic failure. Think of it as an essential part for keeping your equipment reliable and long-lasting.

Why Your Pressure Washer Needs This Unsung Hero

Consider the thermal relief valve a silent guardian for your pressure washer's pump—which happens to be its most expensive component. Its job is straightforward but absolutely critical: stop catastrophic overheating before it can start. This tiny, inexpensive part is the only thing standing between a smooth workday and a thousand-dollar repair bill, making it one of the most important safety features on your machine.

When you pause spraying but leave the engine on, the water inside the pump enters bypass mode. It circulates endlessly, and friction makes its temperature skyrocket—sometimes jumping past 190°F in less than a minute. This scalding water can cause immediate and severe damage.

The Dangers of an Overheating Pump

Without a working thermal relief valve, the consequences of overheating are swift and costly. All that intense heat can:

Warp or melt the pump's delicate internal seals and O-rings.

Crack the pump manifold or other metal castings.

Cause the pump to seize entirely, leading to a complete and expensive failure.

The thermal relief valve is basically an emergency release. It senses when the water hits a critical temperature (usually around 145°F) and automatically opens. It dumps the hot water and allows cool water from your supply hose to flow in, instantly protecting the pump from thermal shock and destruction.

Local Expertise for Your Equipment Needs

For contractors and professionals on California's Central Coast, equipment uptime is everything. A failed pump can grind a project to a halt, which is why having a local resource for parts and service is so important. At Contractor's Maintenance Service, we provide expert support and stock essential components like the thermal relief valve for pressure washer models common in our region.

We're proud to serve the communities of:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach & Pismo Beach

Morro Bay and all surrounding areas

Understanding how every component works—even the small ones—is key to proper equipment maintenance. For those who use their pressure washer for specialized work, a detailed guide on cleaning windows with a pressure washer offers valuable insights into operation and care. Recognizing the role of the thermal relief valve is the first step toward protecting your investment and making sure your machine is always ready for the job.

How a Thermal Relief Valve Actually Works

To really get why a thermal relief valve for a pressure washer is so important, you need to understand the simple but clever mechanics behind it. Don't think of it as some complex electronic sensor. It's more like a tiny, self-contained hydraulic system that runs on heat—a purely mechanical process that needs zero electricity or user input to do its job.

At the core of the valve is a small chamber filled with a special wax. This isn't your average candle wax; it's an engineered thermal wax designed to stay solid at normal operating temperatures. But once things heat up to a specific threshold, usually around 145°F to 150°F, it melts and expands fast. That precise melting point is the secret to the whole operation.

The Step-by-Step Activation Process

When your pressure washer is in bypass mode—engine on, but you're not pulling the trigger—the water inside the pump manifold heats up quickly from friction. The thermal relief valve, which is threaded right into the pump body, soaks up that heat.

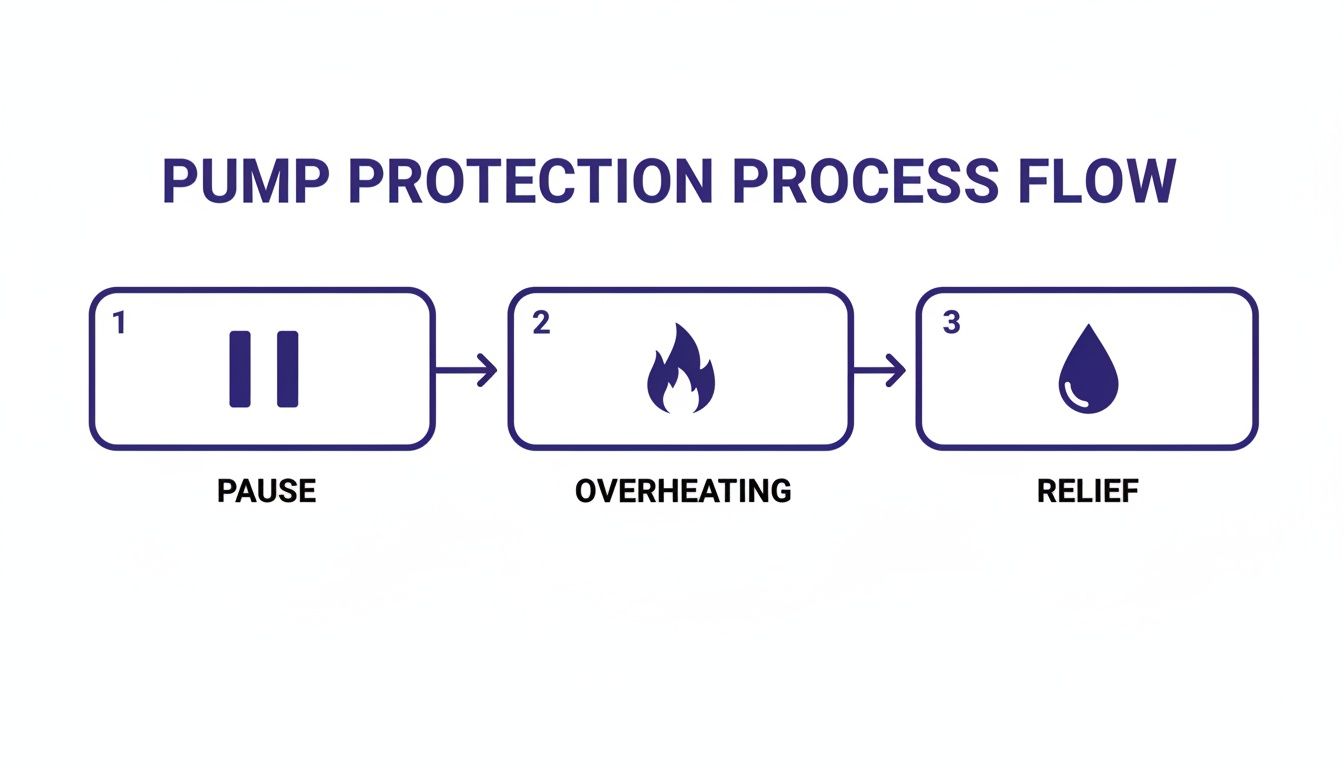

This infographic breaks down the simple, three-step process of how the valve saves your pump from frying itself.

As you can see, the valve works automatically, moving from a paused state to a critical heat buildup and, finally, to a safe pressure release.

Here’s a play-by-play of what’s happening inside the valve:

Heat Transfer: The pump casting gets hot, and that heat moves directly into the metal body of the thermal relief valve.

Wax Expansion: The heat melts the thermal wax inside the valve's piston, causing it to expand and create a powerful, focused force.

Pin Actuation: This expanding wax shoves a small, built-in pin or plunger forward with some serious pressure.

Valve Unseating: The pin pushes against a spring-loaded seal, forcing it off its seat and cracking open a small discharge port.

Hot Water Discharge: Scalding hot water shoots out of the port, relieving the thermal stress. This lets cool, fresh water from your supply hose flow into the pump, bringing the temperature back down to a safe level.

Once the temperature drops, the wax cools, hardens, and shrinks. The spring then shoves the seal back into place, closing the valve until it’s needed again. So, if you ever see a little stream of water coming from your pump after you've paused for a minute, don't panic—that's just the valve doing exactly what it's supposed to do.

The Broader Impact on Equipment Safety

This simple mechanism is a total lifesaver in industrial settings where downtime is money down the drain. Facilities managers and equipment rental pros, like many we serve in San Luis Obispo and surrounding areas like Paso Robles and Atascadero, get this. Overheating pressure washers can account for 20-25% of annual repairs, often because a worn-out thermal relief valve didn't do its job.

This tiny part is a key player in the global pressure relief market, which is expected to grow from $5.1 billion in 2025 to $6.59 billion by 2030. That growth just goes to show the universal need for safety devices that prevent catastrophic failures in high-pressure systems. To see how this trend is playing out across different industries, you can explore the full pressure relief valve market report.

Whether you're on a job site in Arroyo Grande or maintaining a fleet of machines in Morro Bay, making sure this valve is in good working order is non-negotiable for protecting your investment.

Spotting the Signs of a Failing Valve

A thermal relief valve for a pressure washer can fail in two very different ways. One is a nagging annoyance, while the other is an absolute disaster for your pump. Knowing how to read the signs on-site is the key to preventing expensive damage and unexpected downtime.

Think of it as learning your equipment's language—catching the warning whispers before they turn into a full-blown scream for a new pump.

The Annoying Failure: Stuck Open

When a valve gets stuck in the open position, it's the less dangerous of the two failures, but it's still a problem you need to address.

You’ll see a constant drip or a small, steady stream of water coming from the valve, even when the pump is cool and hasn't been in bypass. This is a dead giveaway that something's wrong, usually a worn-out internal seal or a tiny piece of debris lodged inside that's keeping it from closing all the way.

A minor leak might not seem like a big deal, but it will slowly eat away at your machine's pressure and efficiency. More importantly, it’s a clear sign that the part is compromised and might not do its job when you actually need it to.

The Silent Killer: Stuck Closed

The far more dangerous scenario is when the valve fails by getting stuck closed. This failure is silent. It gives you no obvious signs like a leak, but it effectively turns your pump into a ticking time bomb whenever it runs in bypass.

The pump manifold will get incredibly hot to the touch—way hotter than normal. But despite this intense heat, not a single drop of water will come out of the valve. This is the failure that leads to warped seals, cracked castings, and a seized pump, often resulting in damage so severe it requires a complete, and costly, overhaul.

Many pump problems can look similar on the surface. For a bigger picture of what might be going on, our guide on pressure washer pump troubleshooting offers quick fixes and tips.

To help you quickly diagnose the issue, here’s a simple table breaking down the symptoms.

Symptoms of a Faulty Thermal Relief Valve

Symptom | Potential Problem | What It Means for Your Pump |

|---|---|---|

Normal Operation: Short burst of water after 60-90 seconds in bypass. | Valve is working correctly. | Your pump is protected from overheating. |

Constant Drip/Leak: Water leaks from the valve, even when the pump is cool. | Valve is stuck open. | Reduced efficiency and a sign the part is worn out. |

No Water Discharge: Pump gets extremely hot in bypass, but no water is released. | Valve is stuck closed. | Critical danger. The pump is overheating with no protection. |

Knowing these signs can be the difference between a quick, cheap fix and a major repair bill.

How to Run a Quick On-Site Test

You don’t need any special tools to figure out if your valve is working. You can run a simple test right on the job site in just a couple of minutes.

Start your pressure washer, but do not pull the trigger on the spray gun.

Let the machine run in bypass mode for about 60 to 90 seconds.

Keep a close eye on the thermal relief valve. As the water in the pump heats up, a healthy valve will open and release a small burst of hot water.

If the valve spits out some water, you’re good to go—it’s working. If 90 seconds have passed, the pump is getting seriously hot, and there's no water, shut the machine down immediately. Your valve has almost certainly failed and needs to be replaced before you even think about using the machine again.

This simple diagnostic check is one of the most important pieces of preventive maintenance you can do. Catching a stuck-closed valve before it cooks your pump can save you thousands of dollars in repairs and lost work.

For contractors working in San Luis Obispo, Paso Robles, Atascadero, and across the Central Coast, reliable equipment isn't a luxury—it's how you make a living. If you spot a bad valve or aren't sure about a part's condition, don't risk it. Getting the right replacement part quickly from a local supplier like Contractor's Maintenance Service gets you back on the job with a machine that's protected and ready to work.

Choosing the Right Replacement Valve

When your pressure washer's thermal relief valve starts to fail, picking the right replacement is more than just grabbing a part off the shelf. Think of it like using the wrong key for a lock—an incorrect valve just won't work, and it leaves your pump totally unprotected. Nailing the specifications is what guarantees a perfect fit, a leak-free seal, and dependable protection for your machine.

You have three critical factors to get right: the temperature rating, the thread size and type, and the valve's material. Each one plays a huge role in how the valve performs and protects your investment. Miss just one of these details, and you could end up with a valve that doesn't activate correctly or, even worse, a catastrophic pump failure down the line.

Match the Temperature Rating

The temperature rating is, without a doubt, the most important spec to get right. It dictates the exact point where the valve's internal wax melts, opening the port to release hot water. Most pressure washer pumps are built to work with valves rated for either 145°F (63°C) or 190°F (88°C).

145°F Valves: These are the most common by far. You'll find them on the majority of consumer and commercial-grade pressure washers. They offer an early buffer, kicking in long before the water gets hot enough to cause serious damage to the pump's seals.

190°F Valves: You'll typically see these on specialized industrial or hot-water units that are designed to handle higher operating temperatures from the get-go.

Always check your pressure washer’s manual or look for a stamping on your old valve to confirm the correct rating. Putting a 190°F valve on a pump designed for 145°F is a recipe for disaster. It would let the water get way too hot before the valve even thinks about doing its job.

Get the Thread Size and Type Correct

Next up, you have to make sure the new valve will actually thread into your pump manifold. An improper fit will either leak or prevent you from installing the part at all. The two most common thread types for a thermal relief valve are 1/4" NPT and 3/8" NPT.

NPT stands for National Pipe Taper, which means the threads are tapered to create a tighter, more secure seal as you screw the valve in. The easiest way to identify your size is to compare your old valve to a new one at a hardware store or use a thread gauge. A mismatched thread size is one of the most common slip-ups people make.

For contractors and businesses in San Luis Obispo and the surrounding areas—from Paso Robles to Arroyo Grande—you can save yourself a second trip by bringing your old part to an expert like Contractor's Maintenance Service. We can match it perfectly from our in-stock inventory.

Select the Right Material for Your Application

Finally, think about what the valve is made of. The material affects its durability, corrosion resistance, and overall lifespan, which is especially important if you're running harsh chemicals.

Brass: This is the industry standard. It’s a great heat conductor and offers solid corrosion resistance for general use with water and common detergents.

Stainless Steel: If you frequently run aggressive chemicals, bleach, or acidic solutions through your machine, a stainless steel valve is a smart upgrade. It provides far superior resistance to chemical corrosion and will hold up much longer in tough environments.

Picking the right replacement is a critical piece of maintenance. Commercial painters and construction contractors know the story: a pressure washer pump seized by thermal overload can bring a project to a dead stop. This small safety part is a key player in the global pressure relief valves market, which was valued at USD 5.2 billion in 2023 and is projected to keep growing. That growth is driven by industrial demand where protecting equipment is non-negotiable. You can learn more about the global trends in the pressure relief valve market. Getting these three details right ensures your new valve works flawlessly and keeps your equipment safe.

How to Replace Your Thermal Relief Valve

Swapping out a bad thermal relief valve for a pressure washer is one of those simple, satisfying repairs you can knock out in less than 30 minutes with a couple of basic wrenches. It’s a quick fix that not only saves you the cost and hassle of a service call but also keeps your pump safe from catastrophic heat damage.

Getting it right is all about following the steps in the right order. This guide will walk you through the whole process, from safely depressurizing the system to installing and testing the new valve for a perfect, leak-free seal.

With the right approach, you’ll have your machine’s most important safety feature back online, giving you peace of mind on the job.

Preparation and Removal of the Old Valve

Before you even think about putting a wrench on the pump, safety is job one. The first few steps are all about prepping the machine so you can work on it without any surprises.

Depressurize the System: First, kill the power to the pressure washer. Then, just squeeze the trigger on your spray gun until you don't hear any more pressure releasing. This gets all the trapped pressure out of the hose and pump.

Disconnect Hoses: Shut off the water supply at the spigot. Disconnect both your garden hose and the high-pressure hose from the pump. You don’t want water getting in the way while you work.

Locate the Valve: The thermal relief valve is a small fitting, usually made of brass or stainless steel, that threads right into the pump manifold. You can typically find it near the water inlet or outlet connections.

Once you’ve found it, grab an adjustable wrench or the right-sized open-ended wrench and get a firm grip on the hex-shaped body of the old valve. Turn it counter-clockwise to loosen it up and spin it out of the pump head.

Pro Tip: If the valve is really stuck, don't just muscle it. You could strip the threads on the pump manifold, and that's a much bigger problem. A little penetrating oil can work wonders here. Spray some on, let it sit for a few minutes, then try again.

Installing the New Thermal Relief Valve

With the old valve out, you're halfway there. Installing the new one correctly is all about creating a solid, leak-free seal. Take a second to prep the port and the new valve.

First, take a look at the threads on the pump manifold where the old valve was. Use a clean rag or a small, soft wire brush to clean out any old gunk, thread sealant, or dirt. You need a clean surface to get a good seal.

Now, get your new thermal relief valve for pressure washer ready. Wrap the male threads with a thin, even layer of thread sealant tape (like Teflon tape) or apply a liquid pipe sealant.

Wrap the tape clockwise around the threads two or three times.

Make sure the tape doesn't hang over the end of the threads. You don't want little pieces breaking off and getting sucked into the pump.

Time to install. Carefully thread the new valve into the pump manifold by hand until it’s finger-tight. This helps you avoid cross-threading. Then, use your wrench to give it another one to two full turns. You're aiming for snug, not overtightened. Cranking down too hard can crack the pump manifold or damage the new valve itself.

Testing and Final Checks

With the new valve installed, it's time for the moment of truth. Reconnect your water supply and high-pressure hoses. Turn the water on and look for any immediate drips around the new valve. If you spot a leak, you might need to give the valve a slight extra turn.

Once you’re sure it's leak-free, go ahead and start the pressure washer. Let it run in bypass mode (engine on, but not pulling the trigger) for about 60-90 seconds. You should see the new valve do its job by releasing a quick spurt of hot water. That's your confirmation it’s working perfectly.

Taking care of small but critical parts like this is a huge part of keeping your equipment running strong. To dive deeper into overall pump care, check out our guide to master pressure washer pump maintenance for essential tips to extend its lifetime. This quick repair today can prevent some major headaches down the road.

Local Pressure Washer Support in San Luis Obispo

While plenty of repairs, like swapping out a thermal relief valve, are simple enough to handle yourself, sometimes you just need a professional’s eye or a specific part right now. For contractors here on California's Central Coast, equipment downtime isn't just a headache—it’s money walking out the door. That's why having a local expert for pressure washer parts and service you can trust is a game-changer. It gives you peace of mind and keeps the whole operation running without a hitch.

At Contractor's Maintenance Service, we're your dedicated local partner for industrial equipment support right here in San Luis Obispo County. We get it. When a machine goes down on a job site, the clock starts ticking.

Your Go-To Service Center on the Central Coast

We’re proud to serve professionals across the region, making sure you can get your hands on the parts and expertise you need, fast. Our service areas cover:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach & Pismo Beach

Morro Bay and all the surrounding communities.

Whether you need the right thermal relief valve for a pressure washer or a full pump rebuild for a Graco unit, our team has the inventory and the hands-on know-how to get you back to work. And while DIY is great for minor fixes, there are times when the problem runs deeper than a simple part swap.

In the high-stakes world of pressure washing, where contractors push their machines to the absolute limit, the thermal relief valve is the unsung hero preventing total meltdown. These little devices stop pumps from warping under thermal stress that can skyrocket past 200°F in seconds. Here at CMS, swapping a thermal relief valve is a job we can knock out in under 30 minutes, saving our clients thousands compared to a full pump overhaul. If you want to dive deeper into how these parts work in demanding fields, you can explore detailed market insights on pressure relief valves.

When to Call for Professional Help

Knowing when to roll up your sleeves and when to bring your gear to a service center is key to smart equipment management. While installing a new valve is often totally manageable, you should think about calling in the pros if:

You’re not sure what’s actually causing the problem.

You’ve already replaced a part, but the issue is still there.

You spot signs of bigger trouble, like a cracked pump manifold.

Having a reliable local partner for diagnostics, parts, and professional service is a strategic advantage. It cuts down on downtime, stops small issues from turning into wallet-draining failures, and keeps your equipment ready for any job site.

Our expert technicians can diagnose issues quickly, saving you the frustration of chasing down the wrong fix. For more tips on finding the right help when you need it, check out our guide on locating pressure washer repair near you in San Luis Obispo County. From Paso Robles to Pismo Beach, our service counter is here to back you up.

Frequently Asked Questions

Even after you get the hang of how a thermal relief valve for a pressure washer works, a few common questions always seem to pop up. Here are some straight answers to clear up any confusion and drive home the key safety lessons.

Why Is Water Leaking From My New Pressure Washer Pump?

It’s definitely alarming to see a stream of water coming from a brand-new pressure washer pump, but don’t panic. More often than not, it’s a sign that everything is working exactly as it should.

What you're likely seeing is the thermal relief valve doing its job. When you leave the machine running in bypass mode (engine on, but you’re not spraying), the water inside the pump starts to heat up fast. Before it hits a dangerous temperature, the valve opens and dumps the hot water. That little leak is your proof that the safety system is protecting your investment.

Can I Just Remove the Thermal Relief Valve?

In a word: no. Removing the thermal relief valve is a terrible—and incredibly dangerous—idea. Without it, there is absolutely nothing to stop the pump from overheating when it’s left in bypass mode.

Think of it like disabling the smoke detectors in your house just because one went off while you were cooking. The fallout will be severe and expensive:

The pump's internal seals will melt and fail.

The pump manifold can crack under the intense thermal stress.

The entire pump can seize up, leading to a catastrophic failure that costs a fortune to replace.

Removing the valve voids most warranties and turns a reliable machine into a ticking time bomb. It’s a shortcut that leads directly to a massive repair bill and significant downtime.

For professional contractors and maintenance crews in San Luis Obispo, Paso Robles, and Atascadero, equipment safety and reliability are non-negotiable. Whether you're tackling a commercial job or following a DIY guide to power washing your boat, keeping your safety features intact is critical.

How Often Should I Replace the Valve?

A thermal relief valve is a wear-and-tear item, so it should absolutely be part of your regular maintenance schedule. When it comes to these parts, being proactive is always the smartest strategy.

As a best practice, we recommend replacing your thermal relief valve every 1 to 2 years, depending on how heavily you use your pressure washer. Of course, you should replace it immediately if you spot any signs of failure, like constant dripping (stuck open) or no water discharge when the pump gets hot (stuck closed). This small investment is one of the cheapest forms of insurance you can buy for your equipment.

For all your pressure washer parts, diagnostics, and expert advice, trust the team at Contractor's Maintenance Service. Visit us online or stop by our San Luis Obispo service counter to find the exact components you need to keep your equipment running safely and efficiently.

Comments