Pressure Washer Repair Near Me: Your Go-To Guide for San Luis Obispo County

- DLL Studios

- Dec 29, 2025

- 13 min read

When your pressure washer dies mid-job, the scramble to find "pressure washer repair near me" is all too real. If you're working in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Santa Maria, Nipomo, Grover Beach, Pismo Beach, Morro Bay, or Cambria, our team at Contractor's Maintenance Service is your local fix. We specialize in getting pros like you back up and running—fast.

Your First Troubleshooting Steps Before Calling a Pro

But hold on. A sputtering engine or a sudden drop in pressure doesn’t automatically mean a trip to the shop. More often than not, the culprit is something simple you can spot and fix right there on site in just a few minutes. Running through a quick diagnostic can save you a service call, money, and a whole lot of downtime.

Before you jump to the worst conclusion, cover the absolute basics. Is your water spigot turned on all the way? Is the hose kinked? Is the nozzle clogged with gunk? You'd be surprised how often these little things are the real problem, mimicking the signs of a serious pump or engine failure.

Common On-Site Fixes

A lot of frustrating pressure washer issues have surprisingly easy solutions. If your sprayer is pulsating, for instance, it's likely just air trapped in the system. You can usually purge it by running water through the pump for a minute with the engine off. Engine won't start? Check the simple stuff first: fuel level, spark plug connection, and air filter. These are your first lines of defense.

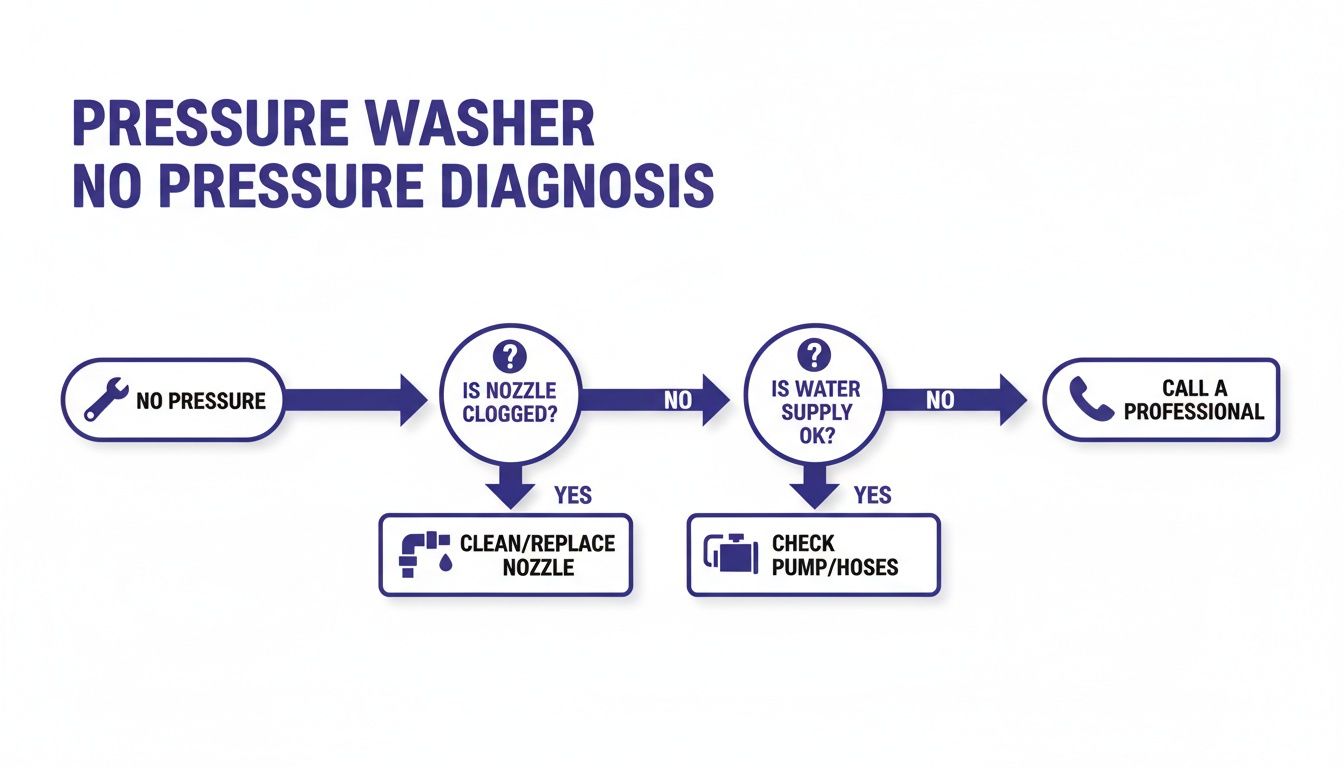

This flowchart breaks down the diagnostic process for the most common issue we see: a total loss of pressure.

As you can see, simple checks like inspecting the nozzle and confirming a solid water supply should always come first. Only after ruling those out should you start suspecting a bigger problem with the pump or hoses that requires a pro.

Quick DIY Diagnostics vs When to Call A Professional

Not sure if your issue is a five-minute fix or something more serious? This table should help you figure out your next move.

Symptom | Potential DIY Fix | When to Call a Pro |

|---|---|---|

No or Low Pressure | Check water supply, clear clogged nozzle, inspect for kinked hoses. | If basics are clear and pressure is still low, the pump unloader or internal seals may have failed. |

Pulsating Spray | Purge air from the system, clean the inlet filter, check for nozzle blockages. | If pulsing continues, it could be a sign of worn pump valves or a failing unloader valve. |

Engine Won't Start | Check fuel level, ensure choke is set correctly, inspect spark plug and air filter. | If the engine has spark and fuel but won't turn over or makes grinding noises, there might be internal damage. |

Water in Pump Oil | STOP USE IMMEDIATELY. | This is a clear sign of failed internal seals. Continued use will destroy the pump. |

Loud Knocking/Grinding | STOP USE IMMEDIATELY. | This indicates a serious internal engine or pump problem, like a broken connecting rod or bearing failure. |

If you've run through the DIY fixes and you're still stuck—or if you see a major red flag like water in the oil—it's time to stop and call in an expert.

When to Seek Professional Repair Service

Pushing a machine that’s clearly struggling is a recipe for disaster. What starts as a small issue can quickly snowball into a catastrophic failure, costing you far more in the long run. This is especially true when it comes to the guts of the pump or engine.

If you spot milky, grey oil in the pump or hear a loud, metallic knocking from the engine, shut it down immediately. Those are tell-tale signs of internal failure that need a professional's touch before the whole system gives out.

At Contractor's Maintenance Service, we're an authorized service center for the brands you rely on, including Graco, Titan, and Honda. That means we have the factory training to get to the root of the problem and, just as importantly, we have access to the genuine OEM parts needed to make a repair that lasts.

For a deeper dive into what you can handle yourself, check out our guide on troubleshooting pressure washer problems to see if a quick fix is all you need. Going with a local, authorized expert ensures your gear is fixed right, protecting your warranty and your investment.

What Goes Wrong With Pressure Washers?

Knowing what's happening inside your machine is the first step toward a quick and effective fix. In our San Luis Obispo shop, we’ve seen it all—from simple clogs to catastrophic breakdowns. Once you understand the common culprits, you'll have a much clearer picture of what to expect when you bring your machine in for repair.

The heart of any pressure washer is its pump, and it’s also the component that takes the most abuse. The constant high pressure and flow of water eventually wear down critical internal parts, leading to the most frequent repairs we handle.

Unpacking Pump Problems

The pump is a complex assembly of seals, pistons, and valves, all working in tight harmony. When just one of these parts fails, the machine’s performance drops off a cliff.

Here are a few of the most common pump failures we diagnose:

Worn Seals and Packings: These are the workhorses that prevent water from leaking, both inside and out. Over time, they just wear out. The classic symptoms are a loss of pressure or finding water mixed in with your pump oil.

Cracked Ceramic Pistons: High pressure and sudden temperature changes can cause these precision parts to crack. A cracked piston will immediately cause a significant drop in performance and can lead to more internal damage if you keep running it.

Unloader Valve Malfunctions: This valve is what regulates your pressure. When it sticks or fails, you might get erratic pressure spikes, a total loss of pressure, or a machine that just won't build pressure at all.

One of the sneakiest pump killers? Using the wrong nozzle. It can seriously overwork the pump and lead to premature failure. If you're not sure about your setup, take a moment to learn how to choose the right pressure washer nozzle and save yourself a lot of headaches.

Engine Troubles in Gas-Powered Units

When it comes to gas-powered machines, especially those running reliable Honda engines, the problems are almost always related to fuel or ignition. These engines are tough, but they aren't immune to issues, particularly under the demanding conditions of a construction site or a big painting job.

Old or contaminated fuel is public enemy number one. The ethanol in modern gasoline can gum up the tiny jets and passages inside a carburetor in just a few weeks. That leads to a machine that's hard to start, runs rough, or won't stay running.

Another frequent flyer is a failed ignition coil. After countless hours of operation and heat cycles, the coil can weaken and produce a spark that's too weak to ignite the fuel mixture consistently. This often shows up as an engine that runs fine for a bit, then dies once it gets hot.

The pressure washer market is projected to hit USD 4.03 billion by 2030, but a huge pain point for owners is still maintenance and repair. In fact, statistics show engine failures affect 25% of portable Honda-powered models within two years. Expert service makes a real difference—professional maintenance can extend equipment life by 2-3 times, seriously cutting down your long-term costs. You can find more details on these industry trends by reading the full market analysis on Grandview Research.

What to Expect from Our Repair Process

When your equipment is down, you need a repair process that’s clear, fast, and transparent. No surprises, no runaround. At Contractor's Maintenance Service, we’ve designed our entire system to get you back on the job with minimal downtime. We’re proud to serve professionals across the Central Coast, including San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, and Santa Maria.

The moment your pressure washer hits our shop, our technicians get straight to work on the intake and diagnostic phase. This isn't just a quick glance; we conduct a thorough inspection to pinpoint the exact root cause of the problem.

Shortly after, we'll give you a detailed quote and a realistic repair timeline. The quote breaks everything down—parts costs, estimated labor, and a plain-English explanation of the work needed. We believe in total transparency so you can make an informed decision without any pressure.

Timelines and Turnaround

We get it. Every hour your machine is out of commission is money out of your pocket. That’s why we’re obsessed with efficient turnaround times.

Common Repairs: For straightforward fixes like seal replacements, unloader valve adjustments, or carburetor cleanings, we can often get the work done in 24 to 48 hours. Having a massive in-house inventory of genuine parts for brands like Graco, Wagner/Titan, and Multiquip helps us move fast.

Complex Overhauls: More serious issues, like a complete pump rebuild or significant engine work, will naturally take a bit longer. For these jobs, we’ll provide a specific timeline based on the complexity and whether any special-order parts are needed.

Warranty Work: As an authorized service center, we handle warranty claims from start to finish. This process sometimes involves extra steps for manufacturer approval, but we manage all the communication to make it as painless as possible for you.

Our commitment is to provide a clear path forward. We communicate every step of the way, ensuring you're never left wondering about the status of your repair. Your project planning depends on reliable information, and we deliver it.

Understanding Repair Costs

The cost of any pressure washer repair boils down to two things: the price of the parts and the labor involved. As an authorized dealer, we strictly use genuine OEM parts. Why? Because they guarantee a perfect fit and lasting performance.

While aftermarket parts might look cheaper on the invoice, they often lead to premature failure and can cause even more expensive damage down the road.

Investing in a professional repair with the right components protects your equipment and ensures it runs to factory specs. It's simply the most cost-effective solution in the long run. Many shops now offer convenient online booking to get your equipment assessed quickly, and you can easily directly schedule your repair with us. Getting an expert eye on it is the first step toward a fast and reliable fix.

Why An Authorized Service Center Matters

When your gear goes down on a job site here in San Luis Obispo County, you're faced with a choice. It can be tempting to just find the nearest mechanic, but not all repair shops are created equal. Trust me, going with a general shop over an authorized service center can cause some serious headaches for your tools—and your wallet—down the road.

The single biggest reason to stick with an authorized center is our direct line to the manufacturers. We’re the trusted local partner for major brands like Graco and Honda. What does that mean for you? We handle the entire warranty claim from start to finish. We navigate all the paperwork and back-and-forth so your repair gets covered without you wasting time or money. A generic shop just can't do that for you.

The Critical Role of Genuine OEM Parts

Here’s another huge difference: we have exclusive access to genuine Original Equipment Manufacturer (OEM) parts. These aren't just "good enough" parts; they are engineered to the exact specs of your machine. This guarantees a perfect fit, which means your equipment runs exactly how it was designed to.

Sure, you might save a few bucks upfront with aftermarket parts, but it's a gamble. We see the fallout all the time. Those slight differences in fit and quality can lead to a whole host of problems:

Poor Performance: The machine just won't run at peak efficiency, and that costs you time on the job.

Early Breakdowns: An ill-fitting part puts stress on other components, setting you up for another failure.

Voided Warranties: The moment you install a non-OEM part, you can kiss your manufacturer's warranty goodbye.

Choosing genuine parts from an authorized dealer isn't just about the immediate fix. It's about protecting the long-term value, safety, and reliability of your equipment.

The pressure washer repair industry is growing fast—it's projected to hit USD 7.10 billion by 2030. With demand this high, especially for the heavy-duty mobile units that dominate the market, downtime is incredibly expensive. A single breakdown can easily cost a contractor $500 to $2000 per day in lost work. Authorized centers help you avoid that pain by using the right parts and offering preventive maintenance that can slash failure rates by up to 60%, keeping you safe and compliant on the job site. You can dig deeper into these market trends over on Mordor Intelligence.

Specialized Services You Won't Find Elsewhere

Our work goes well beyond simple repairs. For instance, we regularly have industrial clients come in needing a custom hydraulic hose built for a very specific, high-pressure application. That’s a specialized service that requires the right equipment and know-how—something your average repair shop just isn't set up for.

When you bring your equipment to Contractor's Maintenance Service, you’re really investing in peace of mind. Our factory-trained technicians here in San Luis Obispo deliver expert service that makes your equipment safer and more reliable, ensuring you stay productive and profitable.

Practical Maintenance to Avoid Future Breakdowns

The best way to deal with a breakdown is to make sure it never happens in the first place. You’ve heard it before, but it's true: consistent, proactive maintenance is the single best thing you can do to extend the life of your pressure washer. It keeps it running reliably on every job and, most importantly, saves you money in the long run.

For busy contractors here in San Luis Obispo and the surrounding areas like Paso Robles, Arroyo Grande, and Santa Maria, a simple routine is your best defense against unexpected downtime that kills your schedule and your profits. It doesn't have to be complicated. Breaking it down into quick daily, weekly, and seasonal checks is the key to catching small issues before they snowball into project-halting, expensive repairs.

Daily and Weekly Maintenance Checks

Think of these as the quick walk-around you do before starting a demanding job. These checks take just a few minutes but can save you hours of headaches later.

Before Every Single Use: * Check Oil Levels: This is non-negotiable. Just like your truck, both the engine and pump oil are vital. Running on low oil is a fast track to catastrophic failure. * Inspect Hoses: Give them a quick once-over. You're looking for obvious cracks, bulges, or scuffs. A burst hose isn't just a work-stopper; it's a serious safety hazard. * Clean Nozzles and Inlet Filter: Make sure the nozzle tip is clear of debris and the water inlet screen is clean. This prevents clogs that tank your pressure and make you work harder for worse results.

Once a Week: * Look for Leaks: Fire up the machine and do a quick visual inspection of all connections, hoses, and the pump body for any water or oil drips. * Clean the Machine: Wiping down grease and grime isn't just for looks. It helps you spot potential leaks early and keeps the cooling fins clear so the engine doesn't overheat.

A disciplined maintenance schedule isn’t optional for professional equipment. It’s the difference between a tool that lasts for years and one that’s constantly in the shop, costing you time and money.

Essential Seasonal and Long-Term Care

Beyond the daily grind, a few seasonal tasks are absolutely critical for the long-term health of your machine—especially when winter rolls around.

One of the most destructive (and entirely preventable) failures we see is freeze damage. If you're working in an area that gets freezing temperatures, like parts of Paso Robles or Atascadero in the winter, winterizing your pressure washer is mandatory. Any water left in the pump will expand when it freezes, cracking the manifold and destroying internal components. It's a repair that often runs into the hundreds of dollars.

To prevent this, you have to run a pump antifreeze solution through the system until you see it coming out of the spray wand. This simple step pushes all the water out, protecting your pump from a fatal freeze. If you want a more detailed walkthrough, you can master pressure washer pump maintenance with our essential tips. Trust me, this small bit of effort will save you a massive repair bill.

The global pressure washer market is projected to hit USD 4.03 billion by 2030, but high maintenance costs are still a major headache for users. While mobile units make up 62.1% of sales, their heavy use leads to more frequent breakdowns. The good news? Following a solid preventive maintenance plan can extend your equipment's life by up to 50%, which drastically cuts repair bills for contractors who depend on their gear day in and day out. You can learn more about these pressure washer market trends.

Got Questions About Repairs in San Luis Obispo? We Have Answers.

When a crucial piece of equipment goes down, you've got questions. Getting straight answers fast is the key to managing your projects, your crew, and your budget without skipping a beat. We've pulled together the most common questions we hear from pros searching for "pressure washer repair near me" to give you the info you need right from the start.

This isn't generic advice. It’s practical info for contractors and maintenance managers across the San Luis Obispo area, covering everything from service schedules to the specific brands we know inside and out.

How Often Should My Commercial Equipment Be Serviced?

For a commercial-grade pressure washer, being proactive is everything. Forget the calendar—the best service interval is all about hours on the job.

A solid rule of thumb is to bring your machine in for a professional tune-up every 200-250 operating hours.

But, if your work environment is particularly rough—say, you're spraying abrasive materials or kicking up a lot of dust—you'll want to tighten that up to every 150 hours. Catching small wear-and-tear issues then is what prevents a catastrophic failure later.

Is It Better to Repair or Replace My Pressure Washer?

This is the classic dilemma, and it really comes down to a simple cost-benefit check. We live by the 50% rule: if the total repair cost is less than half the price of a comparable new machine, repairing it is almost always the smarter financial move.

Of course, you have to consider the machine's history, too. A five-year-old unit that’s been meticulously maintained is a prime candidate for repair. An older, beat-up machine that's seen better days? It might be time to let it go. We’ll always give you a detailed diagnostic and a clear quote to help you make that call with confidence.

Which Brands Do You Specialize In?

Our techs have deep, factory-level training on the top brands that professionals rely on every day. We’re an authorized service and warranty center for the industry's most trusted names.

We're experts in:

Graco

Wagner/Titan

Multiquip

Honda Engines

By focusing on these brands, we keep a massive inventory of genuine OEM parts on hand. That means we can get your repairs done faster and more reliably than anyone else.

As an authorized center, our deep knowledge of these specific systems means we diagnose issues faster and fix them correctly the first time, getting you back to work with minimal disruption.

Do You Serve Areas Outside of San Luis Obispo?

Absolutely. While our shop is right here in San Luis Obispo, our service area stretches across the entire Central Coast. We're the go-to repair facility for contractors, painters, and public works departments throughout the region.

And for local businesses looking to expand their own reach, understanding how customers find you is key. Smart online strategies, including a professional power washer website design, can make all the difference in connecting with clients across the area.

We proudly provide pressure washer repair for customers in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Santa Maria

Nipomo

Grover Beach & Pismo Beach

Morro Bay & Cambria

And all surrounding communities.

Comments