Troubleshooting pressure washer problems: Quick fixes to get you back in action

- DLL Studios

- Dec 5, 2025

- 16 min read

When your pressure washer suddenly quits on you, it's easy to assume the worst. But more often than not, the fix is simpler than you think. Most pressure washer problems boil down to a handful of common culprits, like a clogged nozzle, a kinked hose, or just an insufficient water supply. Checking these first can save you a ton of time and keep you from tearing into the machine unnecessarily.

Quickly Diagnosing Common Pressure Washer Problems

Before you start pulling things apart, a quick diagnostic check is the best way to get pointed in the right direction. The goal is to systematically rule out the easy stuff first. You'd be surprised how often the solution is as simple as clearing a tiny piece of grit from the nozzle tip or making sure the spigot is turned on all the way.

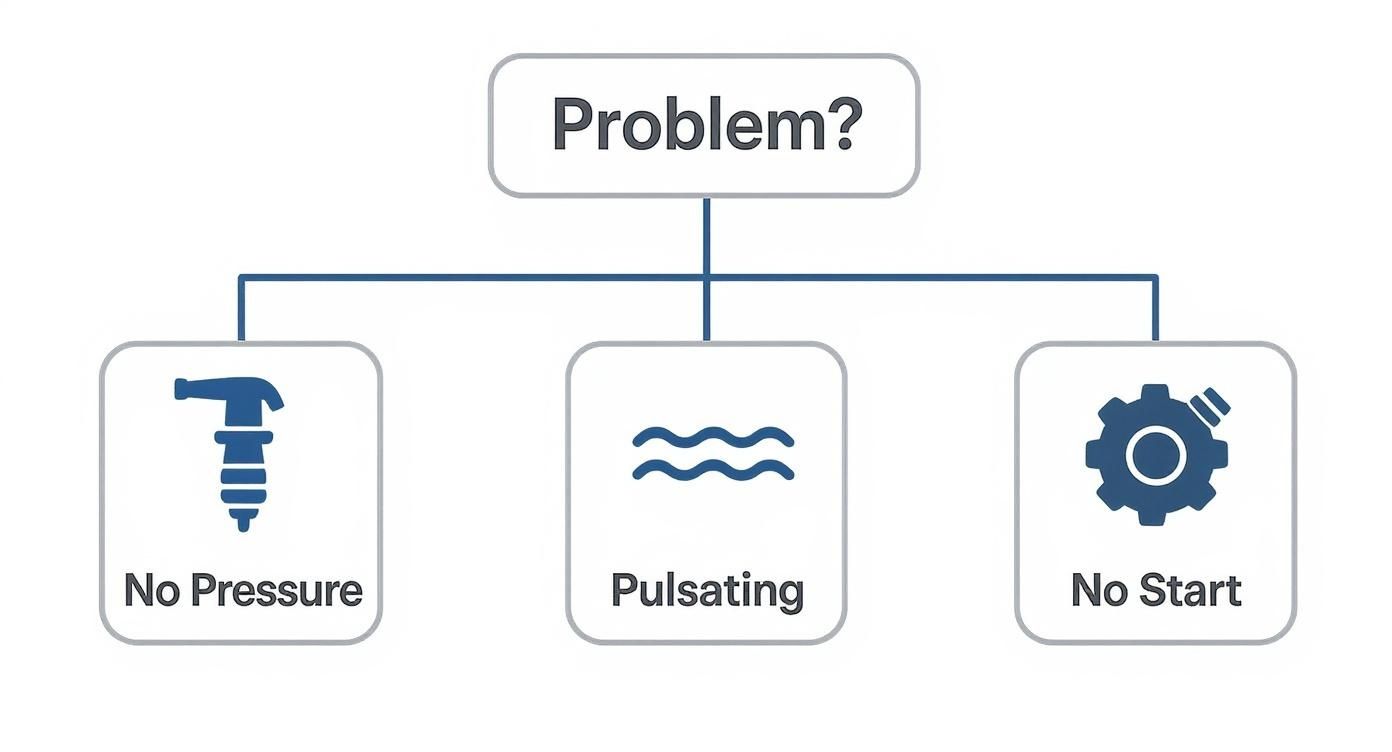

This flowchart gives you a clear visual path for troubleshooting, helping you quickly narrow down the cause of the issue.

By breaking down the diagnostics into the three most common symptoms—no pressure, pulsating spray, and failure to start—this guide streamlines the whole process.

To make things even easier, here's a quick reference table. Just find the symptom your machine is showing to see the most common cause and what you should check first.

Pressure Washer Problem and Solution Quick Guide

Symptom | Most Likely Cause | First Thing to Check |

|---|---|---|

Low or No Pressure | Blockage in the system | Nozzle tip for clogs |

Pulsating or Surging Spray | Air in the pump or water line | Garden hose for kinks or leaks |

Engine Won't Start (Gas) | Fuel or spark issue | Fuel level and spark plug connection |

Motor Won't Start (Electric) | Power supply issue | GFCI outlet and power cord connections |

Water Leaking from Pump | Worn seals or O-rings | All hose connections for tightness |

This table isn't exhaustive, but it covers the most frequent issues we see and gives you a solid starting point for your diagnosis.

Where to Start Your Inspection

Your eyes and ears are your best diagnostic tools. Start with a simple walk-around. Look for anything that seems out of place.

Are there any obvious leaks?

Is the high-pressure hose screwed on tight at both the pump and the spray gun?

Is your garden hose kinked up anywhere?

Sometimes, just untwisting a hose is all it takes to solve the problem.

Next, listen to the machine. If you have a gas engine, does it sound like it's struggling to turn over, or is it running rough? For an electric model, do you hear a low hum that tells you it's getting power, or is it dead silent? These initial clues are incredibly valuable.

Identifying the Most Common Issues

By far, the most widespread complaint is low or no water pressure, which accounts for roughly 35–40% of all troubleshooting calls we get. The funny thing is, the problem is often traced back to something incredibly simple. A blocked nozzle tip is responsible for around 30% of these low-pressure cases alone. Other usual suspects include a clogged inlet water filter or a tangled garden hose. You can dig into more pressure washer market insights from industry reports to see the trends.

Here on the Central Coast, from San Luis Obispo and Paso Robles to Arroyo Grande and Atascadero, we see these exact problems every single day. Our hands-on experience helps folks in Pismo Beach, Grover Beach, Morro Bay, and Templeton get their equipment back up and running fast.

A systematic approach is your best tool. Always start with the simplest potential cause and work your way toward more complex ones. Check the water source, then the hoses, then the nozzle, before you even think about opening up the pump or engine.

This methodical process is the key to avoiding wasted time. By focusing on the most likely culprits first, you can often solve the problem in minutes and get right back to work.

How to Restore Lost Water Pressure

It's one of the most frustrating things that can happen with a pressure washer: you fire it up, and all you get is a weak, disappointing spray. Low pressure is the number one complaint we hear from customers, but here's the good news—the fix is often surprisingly simple. Before you jump to conclusions about a costly pump repair, let's walk through a few common culprits to get your machine back to full power.

This process of elimination starts with the easiest and most frequently overlooked issues. More often than not, a simple check or a quick clean is all it takes to solve your troubleshooting pressure washer problems and bring back that powerful blast.

Start at the Water Source

Before you even think about touching the pressure washer itself, go check your water supply. It sounds almost too basic, but you'd be surprised how often the problem starts right here. A pressure washer can only put out what you put in, so a restricted supply means a weak output. Every time.

First, is the spigot turned on all the way? A partially opened valve is a classic reason for pressure loss.

Next, take a look at your garden hose. Kinks are a huge offender. Walk the entire length of the hose and straighten out any sharp bends that are choking off the water flow. Also, the hose itself matters—using one that's too long (over 50 feet) or too narrow (less than a 3/4-inch diameter) can starve the pump of the water it needs to build proper pressure.

The Number One Culprit: The Nozzle Tip

If your water supply checks out, the next place to look is the very end of the line: the spray nozzle tip. This is probably the most common cause of low pressure we see. Tiny bits of debris like sand, sediment, or mineral buildup can easily get stuck in that tiny orifice, blocking the flow. In fact, a clogged nozzle is responsible for around 30% of all low-pressure issues.

To check it, first disconnect the spark plug wire or unplug the machine. Safety first. Then, pop the nozzle tip off the end of your spray wand.

Look through it: Hold the nozzle up to a light source. Can you see clearly through the small hole, or does it look blocked?

Clear it out: Use a dedicated nozzle cleaning tool or even a straightened paperclip to gently poke out any debris. Be careful not to scratch or widen the hole, as this will permanently ruin the spray pattern.

Flush it: Once you've dislodged the blockage, run water backward through the nozzle to flush out any leftover particles.

The nozzle you use is also critical for performance. For a complete breakdown of how different tips create different spray patterns and pressures, take a look at our guide on how to choose the right pressure washer nozzle.

Inspect the Inlet Water Filter

Nozzle is clean but the pressure is still weak? Your next stop is the water inlet filter. This little screen is your pump's last line of defense, catching junk from your water source before it can cause internal damage. Over time, it's guaranteed to get clogged with sediment, rust flakes, and hard water deposits.

You'll find this filter right where your garden hose connects to the pressure washer.

Unscrew the garden hose from the machine.

Peer inside the inlet fitting. You should see a small, cone-shaped screen.

Carefully pry it out with a small flathead screwdriver or a pair of needle-nose pliers.

Once it's out, rinse the screen under a faucet until it's clean. If it's caked with white mineral buildup, let it soak in some vinegar for about 30 minutes, then give it a light scrub with an old toothbrush. A clean filter is absolutely essential for good water flow.

Local Insight: For our clients here in San Luis Obispo and the surrounding areas like Paso Robles and Atascadero, hard water mineral buildup is a constant battle. We regularly pull inlet filters that are completely choked with calcium deposits—a textbook cause for a gradual drop in pressure. Cleaning this filter should be part of your regular maintenance routine.

By methodically checking these three areas—the water source, the nozzle, and the inlet filter—you can solve the vast majority of low-pressure problems on your own. If you've gone through these steps and are still stuck with a weak spray, the problem might be more complex, possibly involving the pump's unloader valve or worn internal seals. When you've exhausted these DIY fixes, that's the time to bring it to the pros at Contractor's Maintenance Service for an expert diagnosis, whether you're in Morro Bay, Pismo Beach, or right here in SLO.

What to Do When Your Engine Won't Start

You pull the starter cord, and... nothing. Just dead silence. A pressure washer that refuses to start can stop a project in its tracks, but don't throw in the towel just yet. The fix is often simpler than you think, and running through a logical checklist is the best way to get back to work, whether you've got a gas engine or an electric motor.

The diagnostic path you'll take depends entirely on your power source. For a gas engine, it's all about chasing the classic trio: fuel, air, and spark. With an electric model, your attention shifts to the power supply and its built-in safety circuits.

Diagnosing a Gas Engine No-Start

When a gas-powered pressure washer won't fire up, it almost always comes down to one of three things. Think of it as the engine's lifeblood—it needs fuel to burn, air to mix with that fuel, and a spark to get the party started. If any one of those is missing, you're going nowhere.

Before you start tearing things apart, do a quick sanity check. Is the engine switch in the "ON" position? Is the choke set correctly for a cold start? We've all been there; these simple oversights happen to the best of us.

Essential Gas Engine Checks:

Fuel Quality and Level: First, is there gas in the tank? More importantly, is it fresh? Gasoline can start to go bad in as little as 30 days, leaving behind gummy deposits that will clog up a carburetor in no time. If that fuel has been sitting for months, drain it and refill with fresh gas.

Air Filter Inspection: An engine has to breathe. A clogged air filter is like trying to run a marathon while breathing through a straw—it just won't work. Pop the cover off, pull the filter out, and hold it up to the light. If it's caked with dirt, it’s time for a new one.

Spark Plug Health: The spark plug is what ignites the whole process. Carefully disconnect the spark plug wire and use a spark plug socket to remove the plug. Look for heavy carbon buildup, oil, or any signs of damage on the electrode. A fouled plug can't create a strong enough spark.

You might be able to get it going with a quick clean from a wire brush, but spark plugs are cheap. If it looks even slightly questionable, replacing it is your best bet.

Troubleshooting an Electric Pressure Washer

If your electric pressure washer is giving you the silent treatment, the game plan is totally different. Forget fuel and spark plugs. Your entire focus needs to be on the electrical path from the outlet to the motor. The problem is almost always a break in that chain.

Start with the most obvious culprit: the wall outlet. Plug a lamp or your phone charger into it to make sure it's hot. If not, you’ve probably just tripped a circuit breaker. A quick trip to your home's main panel should solve it.

Once you know the outlet is good, look at the GFCI plug on your power cord.

The Ground Fault Circuit Interrupter (GFCI) is that little box on your power cord with "Test" and "Reset" buttons. Its job is to save you from electrical shock by instantly cutting power if it detects a problem. It's a very common reason for a no-start issue.

Press the "Reset" button firmly. You should hear or feel a little click. If it trips again right away, there could be a short in the machine or the cord. At that point, it’s best to stop and get it looked at by a pro. While you're at it, give the entire power cord a quick inspection for any cuts or damage.

For our customers in San Luis Obispo and nearby towns like Paso Robles or Arroyo Grande, finding the right part is easy. At Contractor's Maintenance Service, we keep everything from spark plugs to switches for brands like Honda in stock, so folks in Atascadero, Pismo Beach, and Morro Bay can get what they need. If you're tackling a bigger job, check out our DIY guide on how to repair a pressure washer for more detailed instructions.

Understanding the Thermal Overload Switch

There's one more safety feature on electric models that can cause a shutdown: the thermal overload switch. This is an internal component that automatically kills power to the motor if it starts to overheat, protecting it from permanent damage.

If your machine was running fine and then suddenly quit and won't restart, this is the likely cause. The solution here is simple: just wait.

You have to let the motor cool down completely, which usually takes around 15-20 minutes. Once it's cool, it should fire right back up. If it keeps tripping, you might be using an extension cord that's too long or too thin, causing a voltage drop that makes the motor work too hard and overheat.

Fixing Leaks and Pulsating Sprays

A pressure washer that’s dripping water or surging erratically isn't just a minor headache. These are tell-tale signs of a problem that’s actively hurting your machine's performance and efficiency. Even a small, steady leak robs you of precious output pressure, while a pulsating spray makes getting a clean, uniform finish next to impossible.

Catching these issues early is key. It prevents them from snowballing into bigger, more expensive pump or engine trouble. Let's walk through how to methodically hunt down the source of leaks and tame that unpredictable spray by focusing on the small parts that make a massive difference.

Pinpointing and Sealing Water Leaks

Finding a water leak seems simple, but the source can be surprisingly tricky to nail down. Water has a knack for traveling along a hose or fitting before it drips, so the wettest spot isn't always the real culprit. A systematic check is the only way to be sure.

Start with the machine off. Connect your garden hose, turn on the water, but don't start the engine yet. This simple step pressurizes the low-pressure side of the system, and you'll often spot leaks at the garden hose connection or inlet fitting right away.

Garden Hose Connection: Seeing water drip from where your hose screws onto the machine? The issue is almost always a worn-out or missing rubber washer inside the hose fitting. It’s a cheap part that solves an incredibly common problem.

High-Pressure Hose Fittings: Now, inspect both ends of your high-pressure hose—where it connects to the pump and where it meets the spray gun. These connections depend on small rubber O-rings to maintain a perfect seal under all that force.

Spray Wand Connections: Don't overlook where the spray wand connects to the trigger gun. This is another spot that sees a lot of wear, and the O-rings here can easily fail.

O-rings are the unsung heroes of any pressure washer, but they break down over time from pressure, friction, and simple exposure. All it takes is a tiny crack or a flattened spot to cause a leak. For a deeper dive into these critical components, check out our guide covering everything you need to know about high-pressure hoses.

Replacing a Worn O-Ring

If you've traced a leak to a specific connection point, swapping out the O-ring is a quick fix. Just grab a small flathead screwdriver or a pick tool and carefully pry the old black rubber ring out of its groove.

Go easy—you don't want to scratch the metal fitting. Once the old one is out, find a matching replacement and pop it into the groove. Make sure it's seated evenly all the way around. This simple move fixes over 80% of all connection-related leaks.

Expert Tip: Before you install a new O-ring, put a dab of silicone or plumber's grease on it. This helps it slide into place without getting twisted or torn, and it creates a much better, longer-lasting seal.

Curing a Pulsating or Surging Spray

When your pressure washer spray starts pulsing—jumping between high and low pressure—it’s a classic sign the pump isn't getting what it needs. Usually, this means air is getting into the system or something is restricting the water flow.

Trapped air is the most frequent offender. Air compresses, and water doesn't, which makes the pump struggle and causes that erratic output. The first thing you should always do is purge the air.

It’s easy. Turn the machine off and disconnect the high-pressure hose from the pump outlet. With your garden hose on, just squeeze the trigger on your spray gun and let water run freely through it for a solid two minutes. This will push any trapped air right out of the system. Reconnect everything, fire it up, and you’ll often find the problem is gone.

If purging the air doesn't do the trick, it's time to check for blockages:

The Nozzle Tip: A partially clogged nozzle is the number one cause of pulsation. Debris creates a bottleneck, making pressure build up and release unevenly. Give it a thorough cleaning.

The Inlet Filter: A dirty water inlet filter will starve the pump for water, causing it to surge. Make sure that little screen is spotless.

Kinked Hoses: A sharp bend or kink in your garden hose can cause the exact same water starvation problem. Straighten it out.

For our local customers in San Luis Obispo and nearby areas like Paso Robles and Arroyo Grande, we know that hard water can cause mineral deposits to build up inside fittings. This can lead to both leaks and flow restrictions. If you’ve tried these fixes and are still dealing with leaks or pulsation, the issue might be deeper inside the pump—perhaps with the unloader valve or internal seals. For anyone in Atascadero, Morro Bay, or Pismo Beach, bringing your machine to Contractor's Maintenance Service for a professional diagnosis is your best bet.

Your San Luis Obispo Pressure Washer Experts

Sometimes, you do everything right and the machine still won't cooperate. You’ve methodically checked for clogs, confirmed your water supply is solid, and purged every last bit of air from the system, but you're still stuck. When that happens, it’s a clear sign the problem runs deeper than a simple DIY fix can handle.

This is especially true when you suspect a serious engine or pump issue.

If you're dealing with stubbornly low pressure, signs of an internal leak, or an engine that just won't play ball, forcing it is one of the worst things you can do. Pushing a machine with a bad pump seal or a faulty unloader valve can quickly turn a repairable problem into a catastrophic failure. Before you know it, you're looking at a full replacement instead of a fix.

Your Local Repair Authority on the Central Coast

For anyone in San Luis Obispo and the nearby communities, Contractor's Maintenance Service is the go-to authority for professional pressure washer repair. We’ve been helping contractors and homeowners across the county get their equipment back in top shape for years.

We proudly serve the entire area, including:

San Luis Obispo

Arroyo Grande

Atascadero

Paso Robles

Grover Beach

Pismo Beach

Morro Bay

Templeton

Our technicians have the specialized diagnostic tools and the hands-on experience needed to pinpoint tough problems fast. We handle it all—from tricky unloader valve replacements and carburetor rebuilds to complete pump overhauls—giving your equipment the exact care it needs to perform.

Don't let a stubborn machine derail your project or weekend plans. When DIY troubleshooting pressure washer problems hits a wall, bringing it to an expert not only saves you time but also ensures the repair is done right with genuine, high-quality parts.

Instead of wasting another frustrating hour on guesswork, let our team get your pressure washer running like new again. We provide dependable service and stock the genuine parts required to restore your machine's power and reliability, getting you back on the job with confidence.

A Few More Common Questions

Even after going through the usual troubleshooting steps, some questions pop up again and again. Here are the answers to a few of the most common issues we hear about from customers all over the Central Coast, from Paso Robles to Pismo Beach.

Why Does My Pressure Washer Keep Shutting Off?

It's one of the most frustrating things that can happen: you're in the middle of a job, and the machine just dies. What's going on usually comes down to whether you're running a gas or electric model.

If you have an electric pressure washer, the problem is almost always the thermal overload switch. Think of it as a built-in safety net that kills the motor to stop it from overheating. Let it sit and cool down for at least 15-20 minutes before you even think about starting it up again. The biggest cause of this? Using a cheap, thin extension cord or one that's way too long. It creates a voltage drop, forcing the motor to work harder and get hot.

On a gas engine, the first thing to check is the low-oil sensor. It does exactly what it sounds like—it shuts the engine down if the oil gets dangerously low, saving you from a seized motor. Pop the cap, check the dipstick, and top it off. Another, less common cause is a majorly restricted water supply. If the pump is starving for water, it has to work overtime, and some models will shut down to protect themselves.

Can I Use Dish Soap in My Pressure Washer?

Let me make this simple: absolutely not. You should only ever run detergents that are specifically made for pressure washers. It might seem like a harmless shortcut, but putting something like dish soap in your machine is a recipe for trouble.

For one, household soaps are often way too thick. They'll gum up the works, clogging the detergent injector, the siphon tube, and the nozzle. You’ll spend more time cleaning out your machine than cleaning your driveway.

Even worse, many of those cleaners contain chemicals like bleach or ammonia. These are incredibly corrosive and will eat away at the pump's internal components, especially the seals and O-rings. Before you know it, you'll have a leaking, failing pump and a repair bill that costs far more than a bottle of proper pressure washer soap.

Do yourself—and your machine—a favor. Stick with pressure-washer-safe soaps. They're formulated to work with your machine's system and won't destroy the pump from the inside out.

How Do I Winterize My Pressure Washer?

If you live anywhere that gets cold enough to freeze, winterizing isn't just a good idea—it's essential. Any water left inside the pump will expand as it turns to ice, and that expansion can easily crack the pump housing or wreck the internal parts. It's a costly mistake to make.

The good news is, the process is pretty straightforward:

First, drain all the water. Disconnect every hose and give the engine a quick pull or two (or a quick run if electric) to push out as much water as possible.

Next, run antifreeze through it. Get a bottle of pump antifreeze, often sold as "Pump Saver," and connect it right to the water inlet.

Circulate the fluid. Turn the unit on just long enough for the antifreeze to come out of the high-pressure outlet. That tells you all the water is gone.

For gas models, prep the engine. Pour a good fuel stabilizer into the gas tank and run the engine for a minute to get it through the carburetor.

Finally, store it somewhere safe. A dry, protected spot like a garage or shed where it won't freeze is perfect.

Taking these few steps now will save you from a massive headache (and an empty wallet) in the spring.

What Does the Unloader Valve Do?

The unloader valve is one of the most important parts of your pressure washer, handling both safety and performance. When you let go of the trigger on the spray gun, the unloader's job is to redirect the flow of water into a bypass loop inside the pump. Without it, the pressure would instantly build to dangerous levels, which could destroy the pump or even burst a hose.

You can usually tell when your unloader is on its way out. The tell-tale signs of a bad unloader are:

A huge, sudden loss of pressure while you're spraying.

The pressure is surging or pulsating like crazy.

The engine bogs down or nearly stalls when you release the trigger.

Because adjusting or replacing an unloader valve requires special tools and a deep understanding of pump mechanics, this is one job that's really best left to a pro. For our customers in San Luis Obispo, Arroyo Grande, Atascadero, and nearby, this is a repair we handle all the time at Contractor's Maintenance Service. Trying to fix it yourself without the right know-how can easily lead to more damage or create an unsafe machine.

If you've tried everything you can or you're dealing with a bigger problem, don't hesitate to get in touch. The team at Contractor's Maintenance Service has seen it all and can get any pressure washer issue diagnosed and fixed right, getting you back to work fast. Visit us online to learn more about our repair services.

Comments