Hydraulic Hose Repair Service A San Luis Obispo Contractor's Guide

- DLL Studios

- 2 days ago

- 13 min read

When a hydraulic hose lets go, it brings the whole job to a screeching halt. One minute you're moving earth, the next you're dealing with a busted piece of equipment and a serious safety hazard. Those first few moments after a hose bursts are absolutely critical—not just for minimizing equipment damage, but for preventing a high-pressure fluid injury.

Every contractor and maintenance pro needs to know exactly what to do.

Your First Steps After A Hydraulic Hose Fails

Whether you're working a site in San Luis Obispo or Paso Robles, a ruptured hose demands a fast, methodical response. We're talking about pressures that often shoot past 2,000 PSI, which can turn what looks like a simple leak into a major incident in a split second.

Your first thought should always be safety. Once the scene is secure, you can start assessing the damage and get ready for a professional repair. Handling this right from the start stabilizes the situation and gets you that much closer to being operational again.

Secure The Equipment Immediately

The very first thing you do is kill the power. Shut the machine down completely. This is the only way to depressurize the hydraulic system and stop the flow, which is non-negotiable for preventing high-pressure fluid injection injuries. Those injuries are nasty and often look harmless at first.

With the equipment off, make sure it's secured and won't move, especially if you're on a grade.

Next, you need to isolate the area. Get everyone clear of the machine until the system has had a chance to fully depressurize and cool down. A burst hose can spray hot hydraulic fluid everywhere, creating a nasty slip and burn hazard. This is where your lockout/tagout procedures come into play—follow them to the letter.

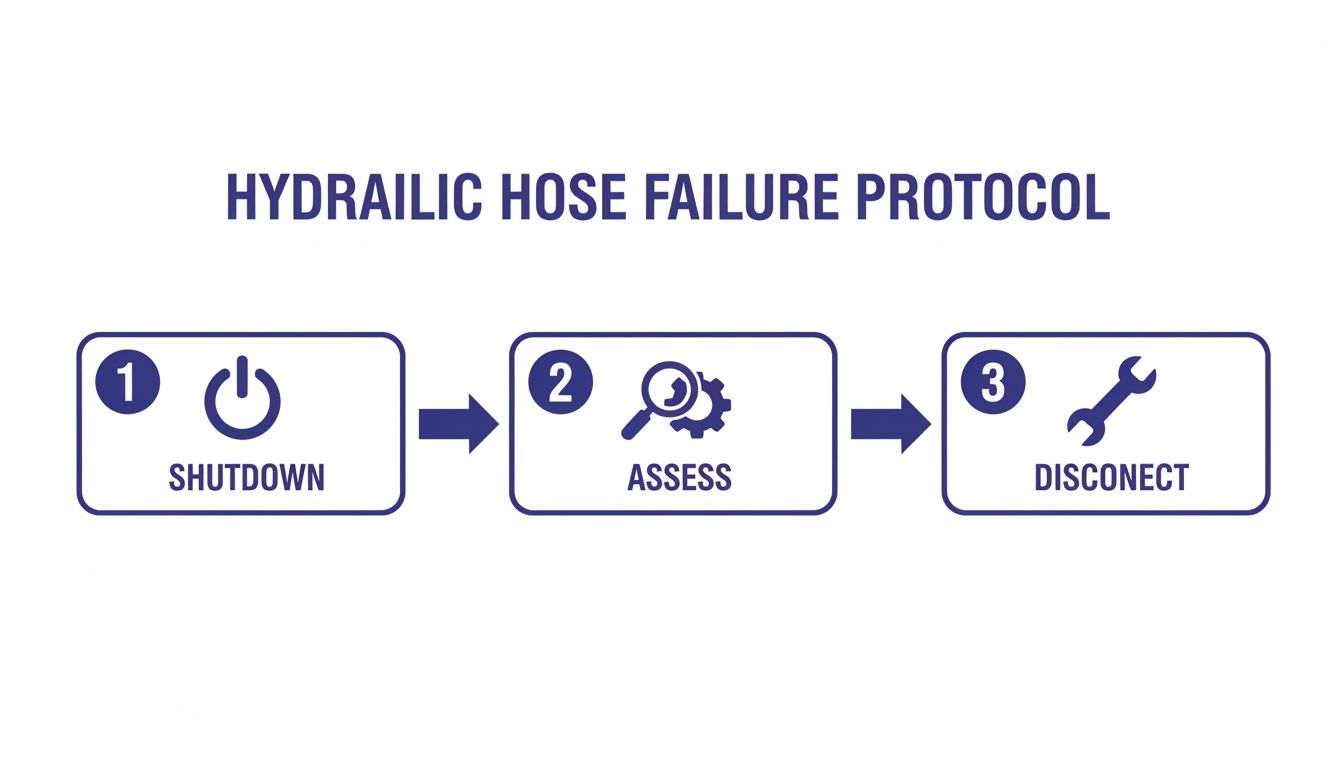

This protocol breaks down the essential steps for safely handling a hydraulic hose failure on-site.

Stick to this simple Shutdown, Assess, and Disconnect process. It keeps everyone safe and preps the equipment for a quick, effective repair.

Assess And Prepare For Repair

Once the machinery is safe and secure, it's time for some field triage. Take a careful look at the failed hose—without touching it—to see if you're dealing with a small pinhole leak or a total rupture. Look for any markings printed on the hose jacket. Those numbers and letters tell you its size, pressure rating, and type, all vital info for getting an exact replacement.

If you can do so safely, go ahead and disconnect the hose using the right tools. Be sure to place a clean container underneath to catch any leftover fluid and keep it from contaminating the ground.

Key Takeaway: Never, ever use your hand to check for hydraulic leaks, even if you're wearing gloves. A pinhole leak can shoot fluid right through your skin, causing severe tissue damage that requires immediate medical help.

For a deeper dive into safety protocols, check out our guide on ensuring reliable operations in industrial settings. With the hose disconnected, you're ready to bring it to our shop in San Luis Obispo for a fast, precise replacement.

Deciding Between Onsite And In-Shop Repairs

Once you've got the equipment safely shut down, you've hit a fork in the road. Do you bring the busted hose to our shop in San Luis Obispo, or do you need our mobile hydraulic hose repair service to roll out to your job site? Making the right call here can genuinely save you a ton of time and money, getting you back up and running way faster.

A few things will steer this decision, from how big your machine is to how complex the failure seems. Thinking it through upfront makes the whole repair process smoother, whether you're working in Paso Robles, Arroyo Grande, or right here in SLO.

When An In-Shop Visit Makes Sense

Honestly, bringing the damaged hose straight to our service counter is often the quickest and most budget-friendly move—if you can safely get it off the machine yourself. This is the perfect route for smaller, more portable equipment or when you have your own maintenance crew who can handle the disconnect.

Consider swinging by our shop when:

The hose is easy to get to. You can pull the component off without a major teardown.

You need a custom assembly. Our shop is stocked with a massive inventory of hoses and fittings, which means we can build you a precise, factory-grade replacement while you wait.

Cost is your main driver. Cutting out the service call fee makes an in-shop repair the most economical choice, hands down.

Choosing Our Onsite Mobile Service

For the big stuff—excavators, agricultural harvesters, anything that’s not going anywhere—an onsite repair isn't just a nice-to-have, it's a necessity. Our mobile service literally brings the workshop to you, fully equipped to diagnose the problem, fabricate a new hose, and install it right there on your job site.

Onsite service is your best bet if:

The equipment is immobile. Hauling heavy machinery is a logistical nightmare and costs a fortune.

You need an expert diagnosis. If you're not sure why the hose failed, our technicians can inspect the whole system on-site to pinpoint the root cause before it happens again.

Every minute of downtime costs you money. Getting a technician out to your site in Atascadero or Grover Beach is the fastest way to get that machine earning its keep again.

The financial hit from equipment downtime can be jaw-dropping. The global hydraulic hose market is booming, largely thanks to the construction sector. For contractors, a single failed hose on a critical machine can lead to downtime losses that climb past $50,000 per day. Choosing the right expert repair service can slash those potential costs. You can dig into the numbers in the full research on hydraulic hose and fittings.

Here's a quick comparison to help you decide the best repair option for your situation.

Factor | In-Shop Repair (At Contractor's Maintenance Service) | Onsite Service |

|---|---|---|

Urgency | Good for non-critical failures or if you have a spare. | Best for emergency situations where downtime is critical. |

Cost | More economical; avoids service call-out and travel fees. | Higher initial cost but saves money by reducing downtime. |

Convenience | Requires you to remove and transport the hose yourself. | We come to you, handling removal, fabrication, and installation. |

Diagnostics | Limited to the component you bring in. | Full system diagnosis to find root causes of failure. |

Best For | Smaller equipment, accessible hoses, and budget-focused repairs. | Large, immobile machinery and urgent, complex failures. |

At the end of the day, both options are on the table for a reason.

A Quick Guide: If you can safely get the hose in your truck, bring it to us. If the machine is too big to move or the problem is more complex than just the hose, give us a call, and we’ll come to you.

We're set up to serve the diverse needs of contractors and agricultural operations across San Luis Obispo County and all the surrounding communities, no matter which path you choose.

A Look Inside Custom Hose Fabrication

Sometimes, an off-the-shelf hose from a big-box store just won’t cut it. You run into this all the time with older machinery, specialized equipment, or even just tricky routing challenges. When that happens, a custom-fabricated hose assembly isn't just a nice-to-have—it's the only way to guarantee a perfect, safe fit.

This is where the hands-on expertise at our San Luis Obispo shop really makes a difference. We’re not just matching a part number; we're building a component designed to meet or even exceed the original factory specs. It's a careful mix of precision measurement, material science, and expert craftsmanship, all to make sure the final product can handle the intense pressures your machinery throws at it. Think of it as the difference between a temporary patch and a long-term solution.

Matching The Right Hose And Fittings

The whole process kicks off with a detailed look at your old hose or the equipment's specific needs. We start by identifying the right type of hose, which means digging into factors like pressure rating (PSI), temperature resistance, and what kind of fluid it’ll be carrying. A hose for a high-pressure excavator is worlds apart from one used on a chemical sprayer. The material matters. A lot.

From there, we dive into our extensive inventory to find the perfect fittings. With hundreds of options—from JIC and NPT to flat-face O-rings—getting the thread type and size exactly right is non-negotiable for a leak-proof connection. We meticulously measure the required length, always accounting for proper routing to prevent kinks and abrasion down the road.

Expert Insight: The most common point of failure on a hydraulic hose is right at the connection between the hose and the fitting. A professionally crimped seal is the single most important factor in creating a durable, reliable assembly that prevents catastrophic blowouts.

The Critical Crimping Process

Once the hose and fittings are selected, we move to the most crucial step: the crimp. Our technicians use a precision hydraulic crimper that’s calibrated to specific manufacturer settings. This isn't something you can eyeball. The machine applies an immense, perfectly even pressure to the fitting's collar, securely locking it onto the hose.

This creates a permanent, 360-degree seal that’s absolutely essential for safety and performance. An improper crimp, whether it's too loose or too tight, is a ticking time bomb—it will fail under pressure, guaranteed. Our process ensures every single custom hose that leaves our shop is built for the real world. This hands-on, detail-oriented approach is why our hydraulic hose repair service is so effective at preventing costly downtime.

Unplanned downtime from a blown hydraulic hose can cost industrial operations up to $260,000 per hour. The most common braided and rubber hoses often fail due to simple abrasion or improper fittings—exactly the kinds of issues that custom fabrication is designed to solve. To get a better sense of the market, you can discover more insights about global hydraulic hose trends on market.us.

From Paso Robles to Arroyo Grande, our custom solutions are all about getting your equipment back in service with confidence. Whether it's for a pressure washer or a heavy-duty earthmover, a professionally made hose provides a level of longevity that standard replacements just can’t touch. For a deeper dive into the technical side, check out our guide on what you need to know about high-pressure hoses.

Your Post-Repair Installation Checklist

Getting a professional repair or a custom-fabricated hose is a huge step, but the job’s not over until it’s installed correctly. A sloppy installation can make a brand-new hose fail in no time, putting you right back where you started. This final checklist is all about reassembling your equipment for maximum safety and performance.

Following these steps with care is just as critical as the quality of the hose itself. It’s what separates a quick fix from a solution that lasts, whether you're working on a job site in Atascadero or doing routine maintenance in Arroyo Grande.

Proper Routing And Fitting Tightness

First things first: let's talk about routing the new hose. Your main goal here is to avoid sharp bends, twists, or any spots where it might rub against something. Never try to force a hose into a tight space or route it too close to hot engine parts.

A good rule of thumb is to leave just enough slack for the hose to flex naturally as the machine moves, but not so much that it kinks or gets snagged.

Next up is tightening the fittings—and this is where a lot of people go wrong. Overtightening is one of the most common mistakes we see. It can easily wreck the threads or crush an O-ring, which is a guaranteed recipe for a leak. The trick is to tighten the fitting until it feels snug, then give it just an extra quarter-turn with your wrench. You’ll develop a "feel" for the right torque over time.

Pro Tip: Always use two wrenches when tightening fittings. One holds the hose or adapter steady, and the other turns the nut. This simple technique prevents the whole hose assembly from twisting, which can mess up its internal structure and lead to a premature failure.

System Testing And Final Checks

With the hose properly installed, it’s time to safely test your work. Before you even think about starting the engine, do a final walkthrough. Double-check that all your connections are secure and the hose is routed clear of any hazards.

Now, start the machine and let the hydraulic system run at low pressure for a few minutes.

This is your chance to be a detective. Meticulously inspect every connection point for leaks—even the smallest drip or bit of weeping fluid is a red flag. Once you're confident the system is sealed tight, you can start cycling the equipment’s functions slowly. Let the hose move through its full range of motion while you keep a close eye out for any signs of kinking, rubbing, or binding.

This final check is what ensures our hydraulic hose repair service delivers reliable results for our clients across the Central Coast. From Paso Robles to Santa Maria, we always stress that a quality installation is the last, essential piece of any successful repair. A job isn't done until it's been tested and proven safe.

Proactive Maintenance To Prevent Future Failures

The best hydraulic hose repair service is the one you never have to call. Seriously. Shifting from a reactive, "fix-it-when-it-breaks" mindset to a proactive one is the single most effective way to keep your equipment running and avoid those project-halting failures. It’s all about catching the small stuff before it becomes a catastrophic blowout.

Giving your team a simple, regular inspection schedule can save you thousands in the long run. When they know what to look for, you can schedule replacements during planned downtime—not in the middle of a critical job in Paso Robles or Arroyo Grande.

Building Your Inspection Routine

A visual check doesn't have to be complicated or take hours. Your operators and maintenance crew just need to be trained to spot the early warning signs of a hose that’s nearing the end of its road.

During daily walk-arounds, keep an eye out for:

Cracks and Abrasions: Any visible damage to the outer cover is a huge red flag. It means the hose's integrity is compromised.

Blisters or Bulges: These are clear signs the inner tube has failed, letting pressurized fluid seep into the reinforcement layers. It's a ticking time bomb.

Weeping or Leaking Fittings: A damp or grimy fitting means the seal is shot. It needs immediate attention before it gets worse.

This same principle of proactive checks applies everywhere. Just like with hydraulics, routine checks are crucial for preventing future failures, a concept also seen in guides to top-quality commercial door repairs and maintenance services. Ignoring these little signals is a gamble that almost never pays off.

The True Cost Of Neglect

Let's talk numbers. Hydraulic hoses are notorious failure points, accounting for a staggering 40-50% of all hydraulic system breakdowns. For contractors and equipment rental yards, ignoring routine hose checks can easily balloon repair bills by 200% or more.

On the flip side, a solid preventive maintenance program can slash hose failures by up to 60%, which is a massive boost for your uptime and job site safety.

A Maintenance Mindset: Treat your hydraulic system's cleanliness as non-negotiable. Contaminated fluid is like sand in an engine—it grinds away at pumps, valves, and cylinders, leading to expensive system-wide failures that all started with one neglected component.

From San Luis Obispo to Atascadero and Santa Maria, our goal is to help you stay ahead of breakdowns. For more detailed strategies, check out our guide on the top 10 preventive maintenance best practices for 2025. Taking these small, consistent steps is what keeps your machinery productive and your job sites safe.

Common Questions About Hydraulic Hose Repair

When a hose blows, your equipment grinds to a halt, and you need answers—fast. We get a lot of calls at our San Luis Obispo shop, especially from contractors and maintenance pros on a tight schedule. Here are some straight-shooting answers to the questions we hear the most.

How Long Does a Hydraulic Hose Repair Actually Take?

For most straightforward jobs, if you bring the busted hose to us, we can build you a brand-new, custom assembly while you wait. We're talking 15 to 30 minutes, and you're out the door. It’s the perfect fix for folks in San Luis Obispo or nearby towns like Arroyo Grande and Atascadero who can pop over to the shop.

Now, not every job is that simple. If we need to drive out to your job site to figure out what’s wrong, or if your machine uses some rare, old-school fittings we have to order, it’ll take a bit longer. But we’re always upfront about it. You'll get a clear, honest time estimate before we start any work, so you know exactly what to expect.

What Areas Do You Cover for Mobile and In-Shop Repairs?

Our shop is the heart of our operation, serving as the go-to spot for hydraulic services here on the Central Coast. We're proud to be the trusted partner for contractors, farmers, and industrial crews all over the region.

Our mobile service trucks cover all of San Luis Obispo County and the surrounding communities. You'll see us working with clients every day in:

San Luis Obispo (our home base)

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

And while our mobile trucks are dedicated to these local spots, our reach doesn't stop there. We also custom-build and ship hose assemblies, parts, and fittings to businesses all across the country.

Our Local Commitment: We know what it takes to work here—from the vineyards near Paso Robles to the construction sites popping up in Santa Maria. Being local means we're more than just a parts supplier; we're invested in keeping your operation running smoothly.

What Info Should I Have Ready When I Call?

To get you the right fix as quickly as possible, a little bit of info from your end goes a long way. The more you can tell us, the better prepared we'll be to solve your problem, whether you’re coming to us or we're coming to you.

Before you call, try to grab these details:

What machine is it? Let us know if the hose is from a Graco paint sprayer, a Multiquip compactor, an excavator, or something else.

What are the hose dimensions? The inside diameter and the total length you need are the two most important measurements.

What kind of fittings are on the ends? Take a look at the connectors on each end of the hose assembly.

If you're not sure about any of that, don't worry. Bringing the old hose with you is always the best bet. If you can't, sending us a few clear pictures of the whole hose, with close-ups of the fittings and any writing on the side, works wonders.

Is It Better to Repair a Hose or Just Replace It?

We get this one all the time, and our answer always comes down to safety and reliability. For any high-pressure hydraulic hose, we always recommend replacing the entire assembly. Trying to patch a hose or reuse fittings from an old, failed hose is a recipe for disaster.

A patch creates a weak spot that’s almost guaranteed to blow under pressure, and the results can be catastrophic. Old fittings can have stress fractures or damage you can't even see. When we say we "repair" a hose, what we're really doing is building you a brand-new, complete hose assembly with top-quality hose and perfectly matched, new fittings.

It's the only way to ensure the part is safe, durable, and will perform like it’s supposed to. The small cost difference for a complete new assembly is nothing compared to the massive expense—and safety risk—of another failure on the job.

When you need a hydraulic hose repair service that gets how urgent your work is, you can count on the local experts. For fast service at our shop or emergency help on-site in San Luis Obispo and beyond, give Contractor's Maintenance Service a call today. We’ll help you cut downtime and keep your project moving.

Visit us online to learn more: https://www.contractorsmaintenanceservice.com

Comments