A Contractor's Guide to Pressure Washer Pump Repair Cost

- Jan 8

- 13 min read

When your pressure washer pump gives up the ghost, the first thing on your mind is always the same: "How much is this going to cost me?" It's a tough spot to be in. A minor fix, like a simple seal kit, might set you back around $150 at a pro shop, but a complete pump rebuild can easily climb past $400.

What you end up paying really boils down to the specific problem and, just as importantly, the type of pump you're running.

Understanding Pressure Washer Pump Repair Costs

For any contractor, a dead pressure washer pump means instant downtime—and that means lost money. Getting a handle on potential repair costs is the first step toward making a smart decision that gets you back on the job fast. The pump is the heart of your machine, and when it stops, so does your cash flow.

There's a good reason the cost to fix one can vary so wildly. The simple axial pump on a smaller, homeowner-grade unit is a world away from the heavy-duty triplex pump built for the daily grind of commercial work. That difference in engineering and complexity hits you in both the price of the parts and the time a technician has to spend on the bench.

Common Repair Cost Scenarios

Let's look at a few numbers to get a better idea of what you can expect. Most of the time, you'll be dealing with wear-and-tear items that just need routine replacement. To help you budget, here’s a quick overview of what you might be looking at.

Estimated Pressure Washer Pump Repair Costs At a Glance

This table breaks down some typical repair jobs, giving you a ballpark idea of the costs involved. It's a good starting point for weighing your options.

Repair Type | Typical Parts Cost | Estimated Professional Labor Cost | Total Estimated Cost Range |

|---|---|---|---|

Seal & O-Ring Kit | $20 - $75 | $100 - $150 | $120 - $225 |

Unloader Valve | $40 - $120 | $100 - $150 | $140 - $270 |

Check Valves (Set) | $30 - $90 | $120 - $180 | $150 - $270 |

Minor Rebuild | $100 - $200 | $150 - $250 | $250 - $450 |

Keep in mind these are just estimates. The final bill will always depend on your specific pump model, the shop's labor rate, and the extent of the damage.

Major Repairs vs. Full Replacement

What about more serious problems? Things like a cracked manifold or internal damage from running the pump dry (cavitation) are a whole different ballgame.

While the parts for a minor fix might only be $20–$50, the professional labor is what drives the final invoice up to that $150–$300 range. When the damage is too severe for a rebuild, you're looking at a full replacement. That could be anywhere from $200–$400 for a standard commercial model to well over $1,000 for a big industrial pump.

It's not just about the repair bill, either. These costs are a big part of your overall business expenses. In fact, if you look at the total cost of pressure washing services, you'll find equipment maintenance eats up a significant slice of the budget.

Here's something to think about: pump repair is often the single largest maintenance expense over the life of a machine, making up a whopping 35–50% of what you'll spend.

Key Factors Driving Your Final Repair Bill

Ever wonder why one pump repair quote is a couple hundred bucks and the next is a small fortune? It all boils down to a few key things. Just like with a car engine, not all pumps are created equal, and the specific failure dictates what it’ll take to get it running again. That final number on your invoice is a mix of the pump’s design, the parts you go with, and just how bad the damage really is.

A minor leak might be a quick, simple fix. But if you’ve got serious internal damage, that’s a whole different story—it requires a much deeper dive, pushing up both the labor and parts costs. Knowing what drives these costs helps you look at a repair quote and know exactly what you’re paying for.

Axial vs. Triplex Pumps: The Cost Equation

The single biggest factor in your repair bill is the kind of pump humming away in your machine. Most pressure washers you’ll run into use one of two designs: axial or triplex.

Axial Pumps: These are what you'll find in most light-duty, homeowner-grade machines. They’re simpler, have fewer moving parts, and are cheaper to make. The catch? They aren't really designed to be rebuilt. A major failure usually means a full replacement is the only path that makes financial sense.

Triplex Pumps: These are the workhorses built for the daily grind of commercial jobs. They're more robust and complex, with heavy-duty components like ceramic plungers and beefy seals. Their initial cost is higher, but their secret weapon is rebuildability. A good technician can tear down a triplex pump and replace individual worn-out parts, often giving it a whole new lease on life.

This is a fundamental difference. Dropping $400 on a rebuild for a high-end triplex pump is often a smart investment. Spending even $200 to patch up a basic axial pump? You're probably better off putting that money toward a new one.

OEM vs. Aftermarket Parts

Your next big decision is where the replacement parts come from. This choice hits your wallet upfront and determines how reliable the repair will be down the road.

OEM (Original Equipment Manufacturer) parts are straight from the brand that built your pump. They guarantee a perfect fit and are made to the original performance specs. Sure, they cost more, but you're paying for peace of mind and, often, a warranty.

Aftermarket parts, on the other hand, are made by third-party companies. They're usually cheaper, but the quality can be all over the map. A poorly made valve or seal might fail in a month, landing you right back in the shop and costing you more in downtime than you saved.

Problem Complexity and Local Service

Finally, the nature of the damage itself plays a huge role. Swapping out an unloader valve is a pretty quick job. But diagnosing and fixing internal damage from cavitation—when tiny air bubbles collapse violently inside the pump—takes serious time and expertise. A cracked manifold is another one of those complex, labor-intensive repairs that will definitely drive up the bill.

If you want to get ahead of these issues, our guide on pressure washer pump troubleshooting is a great resource for spotting problems early.

Here at Contractor's Maintenance Service, we're the go-to for expert diagnostics for pros across San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, and the surrounding Central Coast communities. Our experience means we get straight to the root cause, saving you from paying for guesswork and getting you back on the job fast.

Repair or Replace: Deciding the Smartest Financial Path

Every contractor hits this crossroads eventually. Your pressure washer pump is failing, and you have to make the call: fix it, or scrap it for a new one? Get this wrong, and it costs you more than just the invoice. It means more downtime, more headaches, and lost revenue down the road. You need to look at the numbers and think about the long-term game.

A great rule of thumb I’ve always used is the 40% Rule. If the repair quote is more than 40% of what it would cost to buy a new, comparable pump, it’s almost always smarter to just replace it. This benchmark keeps you from throwing good money after bad on a machine that’s already on its last legs.

More Than Just the Initial Quote

While that 40% rule is a solid starting point, the raw numbers don't paint the full picture. You've got to consider the hidden costs that come with a repair.

Downtime: What's an hour of downtime worth to you? How about a full day? A complex repair could bench your machine for days, whereas swapping in a new pump might have you back on the job by lunchtime.

Age and Efficiency: An old pump is still an old pump, even with a few new parts. A new model might run more efficiently, push higher pressure, or have features that make your crew more productive. That's a return on investment that goes way beyond the initial cost.

Warranty: A new pump comes with a fresh manufacturer’s warranty and that peace of mind is priceless. A repair might have a 90-day guarantee on the work, but it won’t cover the other old parts that are waiting to fail next.

Applying the Rule in the Real World

Industry data backs this up. Minor fixes like replacing seals or valves make perfect sense when they fall under that 30-40% threshold. For example, spending $150 on a valve job for a pump that costs $450 new? That's a good move.

But when you're looking at major damage like a cracked manifold, most service centers will tell you to just replace the whole unit. Those kinds of repairs can get expensive and complicated fast. If you want to dive deeper into equipment trends, check out the analysis from the global pressure washer market.

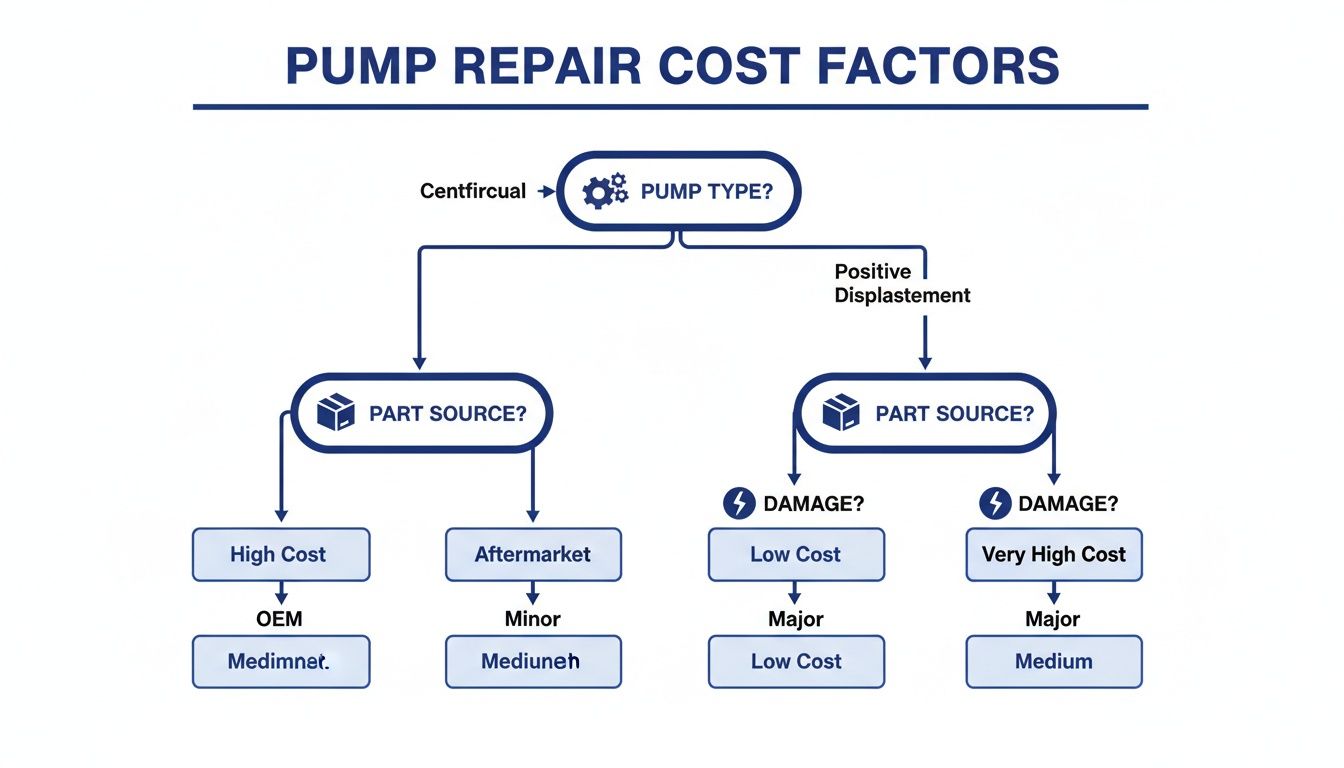

This decision tree gives you a quick visual on how to weigh the factors.

As you can see, the type of pump, where you get your parts, and how bad the damage is are the three big drivers. They'll tell you whether a repair is a smart investment or if it's time to move on.

Should You Repair Your Pressure Washer Pump Yourself or Call a Pro?

It's tempting to think you can save a few bucks by tackling a pressure washer pump repair on your own. For a straightforward job, like swapping out some old O-rings or seals, you absolutely can. If you're comfortable with a wrench and know your way around an engine, it's a great way to get your machine running again without the labor cost.

But here’s where a lot of DIY jobs go sideways. The biggest pitfall is misdiagnosing the problem. That worn-out seal you spotted might not be the root cause—it could just be a symptom of a much deeper issue, like a cracked plunger or a busted unloader valve. Ordering the wrong parts is another classic headache that wastes both time and money.

What's Your Time Really Worth?

For any professional contractor, time is money. Plain and simple. Every hour you spend tinkering in the garage is an hour you’re not out on a job, earning. That’s where the true cost of a DIY repair starts to creep in.

You have to weigh the potential snags:

Specialty Tools: Many pump repairs demand tools you probably don't have lying around, like seal pullers or a torque wrench that’s calibrated for very specific settings. Buying those for a one-time fix can easily cost more than just paying a pro to do the job right.

Unexpected Downtime: What looks like a two-hour fix can quickly spiral into a multi-day project when a part is seized or you realize you ordered the wrong thing. A professional shop, like ours right here in San Luis Obispo, has the parts and experience to get you back in business fast.

The "Oops" Factor: One wrong move—like over-tightening a bolt and cracking the manifold—can turn a $150 repair into a $500+ replacement in the blink of an eye. That's a high-stakes gamble most contractors can't afford.

Now, if you're set on handling your own maintenance, we want you to do it right. That's why we put together a DIY guide on how to repair a pressure washer to walk you through the basics.

The Real Value of Calling a Pro on the Central Coast

At the end of the day, hiring a professional isn't just about paying for parts and labor—it's an investment in certainty and speed. When you bring your gear to a dedicated service center, you're buying diagnostic expertise, access to the right tools, and the confidence that comes with a warranty.

Think of it this way: a professional repair minimizes your downtime, and downtime is the single most expensive part of any breakdown. Getting back to work just one or two days sooner often pays for the entire repair bill.

For all the contractors out there in Paso Robles, Atascadero, Arroyo Grande, Pismo Beach, and across SLO County, our job is to crush that downtime. We get the diagnosis right the first time and use quality OEM parts to make sure the fix holds, protecting your schedule and your profit.

Proactive Maintenance to Reduce Long-Term Pump Costs

Let's be honest—the cheapest repair is the one you never have to make. Instead of waiting for a breakdown to derail your workday, a solid maintenance plan is the best way to control your pressure washer pump repair cost and get the most out of your equipment. Think of it as an investment in uptime, protecting your pump from surprise failures and keeping your business profitable.

You don't need complex overhauls. Simple, consistent habits make all the difference. A quick inspection before each job, sticking to an oil change schedule, and proper winterization aren't just suggestions in a manual; they are the bedrock of a reliable machine. Taking these small steps can head off the kind of catastrophic damage that leads to those budget-breaking repair bills.

Your Contractor Focused Maintenance Playbook

For professionals on the Central Coast, from San Luis Obispo to Paso Robles, a machine that's out of commission means a canceled job and lost revenue. Generic advice just doesn’t cut it. Here’s a playbook built for contractors to keep your pump in prime condition.

Install an Inlet Filter: This is your pump's best friend, hands down. An inexpensive screen filter on your water inlet hose stops sand, sediment, and other debris from getting into the pump where it can score pistons, plungers, and valves.

Prevent Cavitation at All Costs: Cavitation happens when the pump is starved for water, which creates tiny, destructive air bubbles that act like microscopic jackhammers on internal parts. Always make sure your water supply is sufficient and your hoses are completely unkinked before you fire up the engine.

Master Proper Winterization: In areas like Atascadero or Arroyo Grande where temperatures can dip, winterizing your pump is non-negotiable. Running antifreeze through the system stops water from freezing, expanding, and cracking the manifold—a costly and totally preventable repair.

Stick to an Oil Schedule: Just like the engine in your truck, your pump's oil is there to lubricate and cool critical components. Check the oil level every day and change it according to the manufacturer's recommended hours to fend off premature wear.

A well-maintained pump doesn't just last longer; it performs better. Consistent maintenance ensures you get maximum pressure and flow on every job, which translates to faster work and happier clients.

The Growing Market for Repairs

The global demand for pressure washers is climbing, with the market expected to jump from $3.28 billion to $4.73 billion by 2033. At the same time, the pump repair services industry is projected to see nearly 60% growth. This tells us one thing: more and more money is being spent on repairs. Understanding this trend really drives home the financial importance of good maintenance.

Knowing how to operate your equipment correctly is just as important as maintaining it. You can learn more about safe pressure washer techniques to protect both your gear and the surfaces you clean. Following these simple maintenance steps is the most effective strategy you have to lower your operating expenses in the long run.

Expert Pump Repair Services in San Luis Obispo County

For any professional contractor working on California's Central Coast, a busted pressure washer isn't just an annoyance—it's a direct hit to your bottom line. When your gear goes down, you need a local crew that gets the urgency and has the know-how to get you back on the job, fast. That’s what we’re here for.

At Contractor's Maintenance Service, we're your go-to for expert pressure washer pump diagnostics and repair. We aren't just a parts counter. We’re a full-service repair center laser-focused on cutting your downtime and keeping your business profitable.

Your Local Authorized Service Center

We're proud to serve the hardworking pros all over San Luis Obispo County. It doesn't matter if your job site is in San Luis Obispo, Paso Robles, Atascadero, or Arroyo Grande—we've got you covered. We also handle service for the coastal towns from Pismo Beach and Grover Beach all the way down to Nipomo.

As an authorized service center for top-tier brands like Graco and Multiquip, our technicians have the factory training and direct access to OEM parts that a solid, lasting repair demands. This official status means we're also equipped to handle tricky warranty claims, saving you the headache of fighting with manufacturers.

Choosing an authorized service center ensures your repair meets factory specifications, protecting your equipment's performance and often preserving its warranty. It's the difference between a temporary patch and a professional solution.

We get that the right pressure washer pump repair cost is about more than just the invoice; it includes a fast turnaround and work you can count on. Our team zeroes in on accurate diagnostics to fix the root cause of the problem, stopping those repeat failures that bleed you dry over time.

If you're looking for reliable service in the area, check out our guide on finding pressure washer repair near you in San Luis Obispo County.

From routine maintenance to full-blown pump rebuilds, our mission is simple: keep your equipment in the field and making money for your business.

Got Pump Problems? Here Are Some Quick Answers

When a pressure washer pump goes down on a job site, you don't have time for guesswork. You need clear, straightforward answers to get back up and running. We've pulled together the most common questions our technicians hear from contractors right here in San Luis Obispo to give you the information you need, fast.

Whether you're working a job in Paso Robles or finishing up in Pismo Beach, these insights can help you figure out what's wrong and what to do next.

How Often Should I Be Servicing My Pump?

For a machine that's getting regular commercial use, a good rule of thumb is to check the pump oil every 50-100 hours of operation. Plan on a full oil change every 200-300 hours, or at least once a season. You'll also want to give the seals and valves a solid inspection once a year.

Think of it this way: proactive maintenance is the cheapest insurance you can buy against a catastrophic failure. Staying on top of a simple schedule like this prevents the vast majority of major breakdowns and keeps your long-term pressure washer pump repair cost way down.

Is It Okay to Use Aftermarket Parts for a Repair?

While you might save a few bucks upfront with aftermarket parts, OEM (Original Equipment Manufacturer) parts are really the only way to go for professional equipment. They’re built to the exact specs of your pump, which means a perfect fit, reliable performance, and a longer lifespan.

Using a non-OEM part can be a real gamble. It might cause the repair to fail prematurely or even void your machine's warranty. For our professional clients from Arroyo Grande to Atascadero, we stick to OEM parts exclusively. It's the only way we can guarantee the quality of our work and protect your investment.

Using the right parts isn't about spending more; it's about spending smart. OEM components are an investment in reliability and uptime, ensuring the repair holds up under the daily demands of professional work.

What Are the Signs My Pump Is About to Fail?

A pump will almost always give you a few warning signs before it completely gives out. If you see, hear, or feel any of these, it’s time to shut the machine down and get it looked at.

Pulsating or surging pressure that feels inconsistent.

Water leaking from the pump casing itself.

Milky or gray oil in the sight glass—a dead giveaway that water has gotten inside.

Strange grinding or knocking sounds coming from the pump during operation.

Catching these symptoms early can be the difference between a minor repair and a full pump replacement. If you spot any of them, bring your machine in for a proper diagnosis before the problem gets worse.

For expert diagnostics and reliable repairs on the Central Coast, trust the team at Contractor's Maintenance Service. We keep your equipment running, so you can keep your business moving. Visit our website or stop by our shop in San Luis Obispo today.

Comments