Airless Sprayer Repair Near Me Your Contractor Guide in San Luis Obispo

- DLL Studios

- Dec 30, 2025

- 13 min read

When your airless sprayer quits mid-job, you're not just losing time—you're losing money. For professional painters and contractors on the Central Coast looking for airless sprayer repair near me, Contractor's Maintenance Service is the dedicated, authorized service center you can count on. We get your most important tool back on the job, fast.

Your Local Solution for Airless Sprayer Repair in San Luis Obispo County

Nothing kills a project's momentum like equipment failure. A sputtering motor, a sudden drop in pressure, or a rig that won't even turn on can bring a profitable day to a dead stop. For a pro, this isn't just an annoyance; it’s a direct threat to your deadlines, labor costs, and your reputation. Finding a qualified repair shop that gets the urgency is non-negotiable.

That’s where we step in. Contractor's Maintenance Service is the trusted partner for painting professionals all over San Luis Obispo County. We’re not a generic, one-size-fits-all shop; we specialize in the high-performance equipment that is the engine of your business.

Serving the Entire Central Coast

We’re proud to be the go-to service hub for contractors working in every corner of our local communities. Whether you’re on a job site in downtown SLO or a smaller town nearby, we are your local fix. Our main service areas include:

San Luis Obispo (SLO)

Paso Robles

Atascadero

Arroyo Grande

Templeton

Grover Beach

Pismo Beach

Morro Bay

Cayucos

Cambria

And all surrounding San Luis Obispo County communities

Our technicians are factory-trained and fully authorized to service the top-tier brands you rely on, including Graco and Titan. Being authorized means we have direct access to genuine OEM parts, we follow the manufacturer's exact standards, and we can handle any warranty claims for you without a hassle.

Your sprayer is the lifeblood of your operation. Choosing an authorized service center ensures that your investment is protected, its performance is maintained, and its lifespan is maximized. It's the difference between a quick fix and a lasting, reliable repair.

We know you can't afford to wait weeks for a repair. Our goal is swift diagnostics and a fast turnaround, often getting your sprayer back in your hands within 24 to 48 hours for common issues. While we live and breathe sprayer tech, our expertise also covers other essential job site tools. For tips on keeping your other gear running, check out our guide to finding a dependable pressure washer repair service in San Luis Obispo County. Our aim is to be your single source for keeping all your equipment in peak condition.

Diagnosing Common Sprayer Problems on the Job Site

When your airless sprayer sputters to a halt mid-job, the clock starts ticking. Every minute of downtime is a direct hit to your schedule and your wallet. But before you start searching for "airless sprayer repair near me," a quick on-site diagnosis can often tell you if you’re dealing with a minor hiccup or a major mechanical failure.

Think of yourself as a detective at a crime scene—the clues are right there if you know what to look for. Is the motor humming but putting out zero pressure? Is the spray pattern creating ugly "tails" and leaving uneven coverage? Each symptom points to a different culprit.

Often, the problem is way simpler than you think. Something as small as a clogged filter or a worn-out tip can easily mimic the signs of a serious pump issue. Before you assume the worst, rule out these common, easy-to-fix problems. This quick check can save you a trip to the shop and get you back to work in minutes, not hours.

Identifying the Root Cause

The most common headaches painters run into can usually be traced back to a handful of key areas. An inconsistent spray pattern, for instance, is a classic sign that something’s off with either the tip or the pressure regulation.

Uneven Spray Pattern (Tailing): This almost always means the pressure is too low for the material you're spraying, or the spray tip is worn out. A worn tip just can’t atomize paint properly, leaving those heavy edges on your spray fan. You can learn more about how the right tip impacts your finish in our guide on choosing the right tip size for airless sprayer finishes.

No Pressure or Fluctuating Pressure: This one can point to a few things, from a simple clogged inlet filter to a more serious internal pump seal failure or a busted pressure control system.

Motor Runs but Won't Prime: Nine times out of ten, this is caused by a stuck inlet valve ball, which loves to happen if the sprayer wasn't cleaned thoroughly after the last job. A few gentle taps on the fluid section can sometimes be enough to knock it loose.

We've put together a quick reference table to help you diagnose these issues right on the spot.

Quick On-Site Sprayer Troubleshooting Guide

Use this table to quickly diagnose common airless sprayer issues you encounter on the job.

Symptom | Likely Cause | Quick Fix to Try | When to Call a Pro |

|---|---|---|---|

Sprayer won't prime | Stuck inlet or outlet valve ball | Gently tap the fluid section with a hammer or mallet to dislodge the ball. | If tapping doesn't work or the issue persists after cleaning. |

Uneven spray pattern ("tails") | Worn spray tip or pressure is set too low | Replace the spray tip. Increase the pressure setting gradually. | If a new tip and correct pressure don't solve it. |

Low or no pressure | Clogged filters (gun, manifold, or inlet) | Clean or replace all filters. | If filters are clean and pressure issues remain. |

Motor stops unexpectedly | Overheating or electrical issue | Let the motor cool down. Check the power source and extension cord. | If it won't restart after cooling or trips breakers repeatedly. |

Fluid leaking from pump | Worn packings or seals | Tighten packing nut slightly. | If tightening doesn't stop the leak or if it's a major leak. |

This table should get you through the most common field fixes, but it's just as important to know when to throw in the towel.

Knowing how to run these quick field diagnostics is a crucial skill. It lets you handle the small stuff yourself, saving you precious time, and helps you give a technician clear, accurate info when a professional repair is the only answer.

When to Stop and Call for Help

While you can fix a lot of issues on your own, some symptoms are red flags for bigger problems that need a pro. Trying to fix complex internal parts without the right training or tools can turn a simple repair into a ruined machine.

If your sprayer shuts off out of nowhere, starts making grinding noises, or you see fluid leaking from the motor housing, stop what you're doing. These are clear signs that it’s time to bring your equipment to a professional for a safe and effective repair.

Making the Call: Repair or Replace Your Sprayer?

Sooner or later, every contractor faces this question. Your trusted airless sprayer is on the fritz again, and you have to make a tough business decision: do you sink more money into another repair, or is it time to cut your losses and invest in a new machine?

This isn't just about the immediate repair bill. It's about the total cost of ownership and, more importantly, protecting your crew's productivity on the job site.

Think of it like an old work truck. A flat tire? That's a simple fix, no question. But when the transmission goes out for the third time this year, you start wondering if the constant downtime and bleeding wallet are worth it. An aging sprayer that demands constant attention does the same thing, slowly draining your profits through lost labor hours and frustrating project delays.

A Practical Cost-Benefit Analysis

A major repair—say, a full pump overhaul on an older Graco rig—can easily run you a good chunk of what a brand-new sprayer costs. If your machine is over five years old and has a history of breaking down, that repair bill is probably just a band-aid.

You have to weigh the short-term savings of a repair against the long-term value a new model brings. Newer sprayers aren't just fresh out of the box; they come with real efficiency gains. They often apply coatings more evenly, use less material, and are built for easier maintenance. All of that translates directly into lower labor costs and better margins on every job.

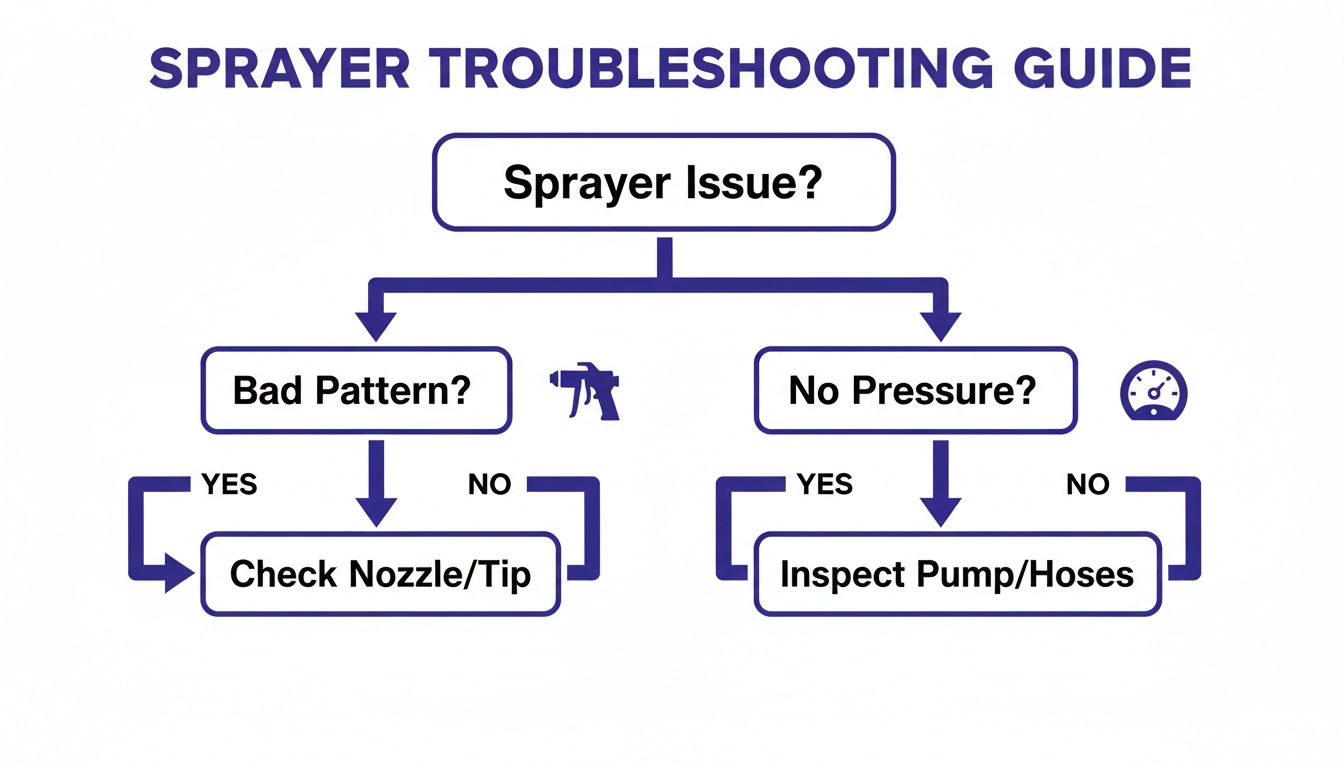

This flowchart gives you a quick visual for those initial diagnostic steps, whether you're dealing with a bad spray pattern or a total loss of pressure.

The big takeaway here? Always check the simple, user-serviceable stuff first, like tips and filters. Don't assume it's a catastrophic failure that needs a pro until you've ruled out the easy fixes.

Calculating the True Cost of Downtime

To really make the right call, you need to look beyond the repair quote and calculate the true cost of holding onto an unreliable sprayer.

Ask yourself these questions:

Frequency of Repairs: How many times has this machine been in the shop in the last 12 months?

Lost Labor: How many crew hours have you paid for while guys were standing around waiting on a working sprayer?

Project Delays: Have equipment problems thrown off your schedule and pushed back deadlines?

When you actually run the numbers, you might find that the cost of lost productivity from just one or two major breakdowns already exceeds the investment in a new, warrantied machine. Making a strategic replacement can be one of the most profitable decisions you make all year.

The Advantage of Using an Authorized Service Center

When you’re Googling "airless sprayer repair near me," you’ll quickly find that not all repair shops are the same. Deciding where to take your equipment is a business decision, plain and simple. It’s one that directly impacts your wallet, your efficiency on the job site, and how long your expensive tools will last.

The gap between an authorized service center and a generic repair shop can be huge—often the difference between a permanent fix and a problem that keeps coming back.

It’s a lot like taking a high-performance truck to the dealership versus a general mechanic. The local guy might be able to get it running, but the dealership has factory-trained specialists, proprietary diagnostic tools, and the exact parts engineered for your model. An authorized service center is the dealership for your professional sprayers.

What Being Authorized Really Means

That word "authorized" isn’t just marketing fluff. It's a stamp of approval straight from the manufacturer, a sign that a shop meets their tough standards. For big names like Graco, Titan, and Wagner, it’s your guarantee of quality work.

When you bring your equipment to us at Contractor's Maintenance Service, you’re getting:

Factory-Trained Technicians: Our team doesn't just watch YouTube videos. They’re trained directly by the people who made your sprayer, so they know every model inside and out and follow approved repair protocols.

Genuine OEM Parts: We only use Original Equipment Manufacturer (OEM) parts. These aren't knock-offs; they’re engineered to the exact specs of your sprayer, ensuring it runs like it just came out of the box.

Seamless Warranty Processing: If your rig is still under warranty, we handle everything. We’ll manage the diagnostics, the paperwork, and all the back-and-forth with the manufacturer. No headaches for you.

The Hidden Risks of Unauthorized Repairs

Going to a generic shop might look like a way to save a few bucks upfront, but those savings often disappear thanks to hidden costs. The biggest gamble is their use of aftermarket parts. They might look the same, but they rarely have the durability or precision fit of genuine components. This can lead to a quick failure that might even damage other parts of your sprayer.

Using aftermarket parts can immediately void your manufacturer's warranty. That small saving on one repair could end up costing you thousands by invalidating your coverage when a major issue pops up later.

The numbers don't lie. Accessories and parts can make up 60% of repair costs for contractors, showing just how crucial the right components are. And with downtime from worn parts sidelining 25% of jobsites monthly in North America, using genuine parts is the smartest way to protect your investment. You can discover more insights about the airless sprayer market's growth and its impact on maintenance needs.

Bottom line? Choosing an authorized service center is about protecting your investment. It guarantees your equipment is fixed right the first time, keeps its warranty intact, and gets you back to work with a reliable machine you can count on.

Getting Your Sprayer Ready for a Fast Repair

When you're ready to drop off your equipment for an airless sprayer repair near me, a little prep work on your end can make a world of difference in how fast we get it back to you. Think of it like a chef prepping ingredients before service—it helps our technicians dive right into diagnostics instead of spending time on cleanup.

Taking a few minutes to get your sprayer ready ensures a smoother, speedier service experience. It means we can pinpoint the real issue faster, and you can get your machine back on the job site where it belongs.

Pre-Repair Checklist for Contractors

Before you bring your sprayer to our shop in San Luis Obispo, running through this quick checklist gives us the critical info we need to get started right away.

Flush the System: If you can, flush your sprayer with the right cleaning solvent for whatever material you last ran through it. A clean machine is much easier and safer for our team to inspect and work on.

Document the Problem: Make a few notes—mental or written—about the specific symptoms. Is it losing pressure? Making a weird noise? Refusing to prime? The more detail you give us, the faster we can find the root cause.

Locate Model & Serial Number: Have the model and serial numbers handy. We'll need this to order the correct OEM parts and process any warranty claims you might have.

Think of your sprayer's symptoms as clues for our technicians. Details like "it started losing pressure after 20 minutes of use" are far more helpful than "it's broken," and lead to a much quicker solution.

Our repair process is built on transparency. Once you drop off your rig, we'll run an initial diagnostic to figure out what’s wrong. From there, we’ll give you a detailed estimate for your approval before we touch a single part—no surprises. After the repair, we do a final test run to make sure the machine is back to factory specs.

This straightforward approach takes the guesswork out of the service journey. Whether you're working in Paso Robles, Arroyo Grande, or Atascadero, our goal is to be your go-to partner for keeping your gear in top shape. For more insights into sprayer tech, check out our guide for professional painters on portable airless sprayers.

Get Your Equipment Serviced Today

When a critical piece of equipment goes down, your search for "airless sprayer repair near me" needs to end fast. At Contractor's Maintenance Service, we get it. We’re here to slash your downtime and get your professional-grade tools back on the job, where they belong. Our authorized service center is the go-to hub for painting contractors across the Central Coast.

We proudly serve pros throughout San Luis Obispo County and the surrounding communities. Whether your job is in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, or anywhere nearby, think of us as your local partner for expert repairs and maintenance. We're your one-stop shop for everything from emergency service to stocking up on essential parts.

More Than Just a Repair Shop

Our expertise doesn't stop at airless sprayers. We know you rely on a whole range of tools to get the job done, and we provide sales, service, and parts for many of the top brands to keep all your equipment in peak condition.

Our other services include:

Genuine Parts on Hand: We keep a huge inventory of OEM parts stocked and ready for quick access.

Custom Hydraulic Hoses: Need a specific hose? We’ll fabricate it to your exact specs while you wait.

Small Engine & Equipment Repair: We also service generators, pressure washers, and other job site essentials.

The airless paint sprayer market is growing, but here's a stat that hits home: unplanned equipment failures can eat up to 40% of a construction firm's maintenance budget. As an authorized center, we fight that by stocking the parts you need and offering turnarounds that shrink repair times from weeks to just a few days, saving you serious money. You can learn more about findings in the airless sprayer market here.

Don’t let a broken sprayer derail your project and hurt your bottom line. We’re here to provide the expert service you need, right when you need it, ensuring your business keeps moving forward.

Ready to get started? We make it simple. For any service business, making sure every customer call is handled smoothly is key; exploring the top call management solutions can be a game-changer for streamlining appointments and inquiries.

Contact us today to schedule your repair.

Frequently Asked Questions

When your sprayer goes down, you've got questions and you need answers—fast. We get it. To help you figure out the best next step for your business, here are the straight-up answers to the questions we hear most from painting contractors.

How Long Does a Typical Airless Sprayer Repair Take?

This always comes down to what's wrong with the machine and if we have the parts on hand. Our goal is to get you back on the job ASAP, which is why we keep a deep inventory of common Graco and Titan parts.

For most standard fixes, like fluid section repacks or simple filter swaps, we can usually turn the repair around in 24 to 48 hours. We’ll diagnose it, give you a clear timeline with your estimate, and if we need to special-order something, you'll know upfront. No surprises.

Can You Handle Warranty Repairs for Graco and Titan?

Absolutely. We're a fully authorized service center for the big names like Graco and Titan, which means we can manage the entire warranty process for you. That's one of the biggest perks of working with a certified shop—we handle the headaches and paperwork so you don't have to.

Just bring your sprayer and proof of purchase to our San Luis Obispo shop, and we'll take it from there. We diagnose the issue, talk directly to the manufacturer, do the repairs with genuine OEM parts, and file all the documentation. It's completely hands-off for you.

Choosing an authorized repair center ensures your warranty remains valid and your equipment is serviced to the manufacturer's exact specifications, protecting your investment.

What Does a Common Sprayer Repair Cost?

Repair costs can be all over the map. A routine service like replacing worn packings in the fluid section is going to be a lot less than a major overhaul that requires a new motor or pump. We believe in being completely transparent with pricing.

That's why we always provide a detailed, itemized estimate for you to approve before we touch anything. This way, you know exactly what you're looking at and can make a smart business decision about whether the repair makes financial sense.

What Other Contractor Equipment Do You Service?

While airless paint sprayers are our specialty, we know you rely on a lot more than one tool to get the job done. Our shop is set up to be a one-stop service partner for local contractors. Our services also cover:

Pressure Washers

Generators

Small Engines (from brands like Honda and Multiquip)

Custom Hydraulic Hose Fabrication

We're here to be the go-to service hub for contractors in San Luis Obispo, Paso Robles, Atascadero, and Arroyo Grande, keeping all the gear that powers your business in top shape.

Don't let a broken machine slow you down. For expert diagnostics, quick turnarounds, and service you can count on, trust Contractor's Maintenance Service. Visit our website or give our shop a call today to get your equipment back to work.

Comments