Essential Power Washer Replacement Tips for Peak Performance

- DLL Studios

- 6 days ago

- 13 min read

Getting your power washer replacement tips right starts with picking the correct nozzle for the job. This decision is huge—it directly impacts your cleaning power and, more importantly, the safety of the surface you're working on. A mismatched nozzle can either blast away more than you intended, causing permanent damage, or just waste your time by not cleaning effectively.

The secret is understanding the standard color-coding system and making sure the nozzle's orifice size is a match for your machine's PSI and GPM ratings. Get that right, and you'll get optimal performance every time.

Choosing The Right Nozzle For Any Cleaning Job

Think of your power washer nozzles like specialized tools in a toolbox. Each one is engineered for a specific task. Using the right one is the key to a fast, effective, and damage-free cleaning job.

The most common way to identify a nozzle's function is by its color, which tells you the angle of the water spray it produces. A narrower angle concentrates the pressure on a small area, giving you maximum force. A wider angle distributes that same pressure over a larger area for gentler, broader cleaning.

This choice is more critical than most people think. Grab a nozzle that’s too aggressive—like using a narrow-angle yellow tip on your car's paint—and you can cause irreversible damage in seconds. On the flip side, using a wide-angle white tip on stubborn, oil-stained concrete will just move water around without cleaning a thing. Finding that balance is the first step to mastering your equipment.

Decoding The Color System

That universal color-coding system is your best friend here. It's a straightforward guide to the pressure and coverage you can expect from each tip. Each color represents a specific spray angle, measured in degrees.

Here's a quick rundown of what each color means and where to use it.

Power Washer Nozzle Color and Application Guide

This table is a handy cheat sheet. It breaks down the standard nozzle colors, their spray angles, and what kind of jobs they're built for. Keep it in mind before you pull the trigger.

Nozzle Color | Spray Angle (Degrees) | Pressure Intensity | Best For |

|---|---|---|---|

Red | 0° | Maximum (Pinpoint) | Removing caked-on mud from equipment, wasp nests, stubborn, isolated stains. |

Yellow | 15° | High (Stripping) | Surface prep on hard materials, removing loose paint, heavy mildew, rust. |

Green | 25° | Medium (General) | The go-to for most jobs: siding, decks, driveways, outdoor furniture. |

White | 40° | Low (Gentle) | Delicate surfaces like windows, blinds, vehicles, and light rinsing. |

Black | Soap/Low-Pressure | Very Low (Applying) | Pulling detergent from the soap tank to apply it before cleaning. |

Think of this table as your starting point. Always test a small, inconspicuous area first, especially if you're unsure.

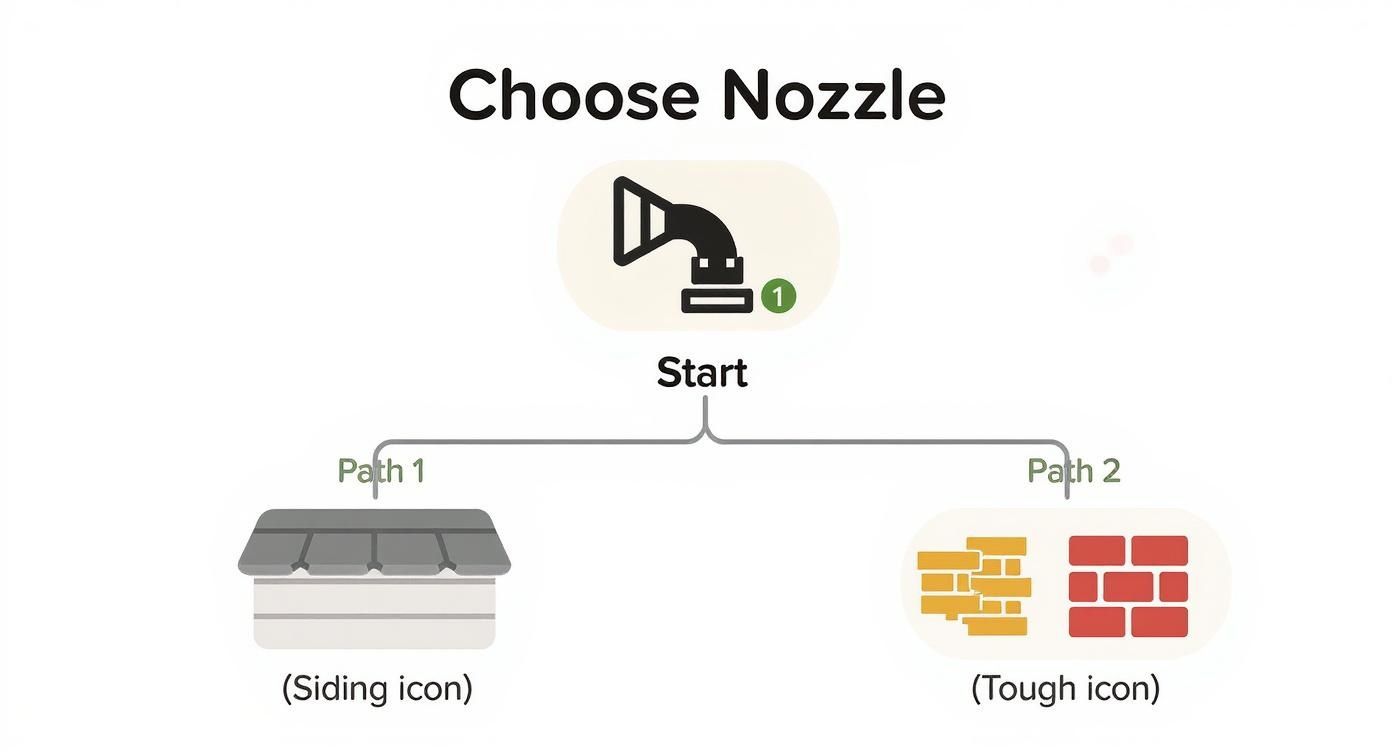

Here’s a great visual that helps simplify the decision-making process.

As the diagram shows, you'll lean toward the gentler green or white nozzles for most home surfaces, saving the more powerful yellow or red tips for tough, durable materials that can handle the force.

Beyond The Colors

The demand for power washers is growing in both residential and commercial sectors, which is exactly why knowing how to use them properly is so important. The global pressure washer market is projected to hit USD 7.10 billion by 2030, all thanks to people looking for more efficient ways to clean. You can learn more about the pressure washer market trends and see what's driving this growth.

For those of us providing services here in San Luis Obispo and the surrounding areas—from Paso Robles and Atascadero to Arroyo Grande, Pismo Beach, and Nipomo—using the right equipment safely isn't just a goal, it's our top priority. Our expertise ensures that whether you're in the heart of SLO or the nearby communities, your power washing job gets done right, without any collateral damage.

How to Safely Replace Your Power Washer Nozzle

Swapping out a power washer nozzle should be a quick, routine task. But "routine" doesn't mean you can skip the safety steps. We're dealing with extreme pressure, and even when the machine is off, that stored energy demands respect. The whole process takes less than a minute, but doing it right is what keeps it safe.

Before you even touch the wand, you have to neutralize the machine. This isn't optional.

Gas Engines: Shut it down and, just to be sure, disconnect the spark plug wire. This makes an accidental startup impossible.

Electric Motors: Turn off the motor and physically unplug the power cord from the wall.

Once the power source is cut, you still have pressure trapped in the hose and wand. Get rid of it. Point the spray gun in a safe direction—away from people, windows, or anything fragile—and squeeze the trigger. You'll get a final blast of water, then a trickle. Hold it until the flow stops completely. Now you're safe to proceed.

The Mechanics of a Quick Change

With the system fully depressurized, you can get to work on the nozzle itself. Most modern power washers feature a quick-connect collar right at the end of the wand. It's a spring-loaded sleeve designed for fast, tool-free swaps.

To pop the old nozzle out, grab the collar with one hand and pull it back towards the trigger. This retracts the ball bearings holding the tip in place, allowing the nozzle to come loose. Use your other hand to simply pull it out. If it feels stuck, don't try to pry it out with a screwdriver. There's likely some grit or debris in the collar that needs to be cleaned out first.

Don't Forget the O-Ring

Here’s a step pros never skip but beginners often miss: check the O-ring. Look inside the quick-connect fitting, and you'll see a small black rubber ring. That tiny, inexpensive part is responsible for creating a perfect seal, and it’s the #1 cause of annoying leaks at the wand tip.

Pro Tip: A leaky O-ring isn't just a drip. It signifies a pressure loss, which makes your pump work harder and can cause premature wear on much more expensive parts down the line.

Give it a quick inspection. Look for any cracks, nicks, or signs that it's been flattened over time. If it looks worn, use a small pick or a tiny flathead screwdriver to carefully pry it out and pop in a new one. Knowing how to spot these small problems can save you from bigger headaches. For more on troubleshooting different parts, our complete guide to pressure washer parts and repair is a great resource.

Installing the new nozzle is the reverse of removal. Pull back the collar, push the new tip in firmly until you feel it seat, and release the collar. You should hear a satisfying "click" as it locks in. Always give the nozzle a little tug to make sure it's secure before you fire up the machine. Proper replacement is just one part of the safety equation; for a broader overview, check out this guide on safe pressure washer operation and nozzle selection.

Matching Nozzles to Your Machine's PSI and GPM

It’s easy to think a nozzle is just a nozzle. You grab one that fits, and you’re good to go, right? That’s a common mistake we see all the time, and it’s one that can lead to disappointing results or, worse, serious damage to your equipment.

While the color-coding on nozzles tells you the spray angle, the real secret to getting the performance you paid for lies in a tiny, often-overlooked detail: the orifice size.

True power washing performance comes from creating a perfect partnership between your machine and its tip. Every pressure washer is engineered for a specific PSI (Pounds per Square Inch) and GPM (Gallons Per Minute). To hit that sweet spot, the nozzle’s orifice size has to be matched precisely to those ratings.

Think of it like putting your thumb over a garden hose. A smaller opening forces the water out with more power. A pressure washer nozzle does the same thing—a smaller orifice creates higher pressure from a given flow of water.

Why The Wrong Size Is a Big Problem

Using the wrong nozzle size is a recipe for frustration. If you pick an orifice that’s too small for your machine's GPM rating, you’re basically choking the water flow. This causes a dangerous spike in pressure that puts a ton of strain on your pump and engine. It can trip the unloader valve or even lead to catastrophic failure.

On the flip side, a nozzle with an orifice that's too big will never let the system build up to its rated pressure. You end up with a weak, wimpy stream that can’t blast away tough grime, no matter how powerful your machine is supposed to be. This is the #1 reason people come to us complaining about a sudden loss of pressure after buying new tips.

Mismatching your nozzle's orifice size to your machine's specs is like putting the wrong fuel in a car. It might seem to work for a moment, but you're risking significant internal damage and will never get the performance it was designed for.

Universal vs. Proprietary Fittings

The good news is that most modern power washers use a universal quick-connect system. This standard fitting makes it incredibly easy to swap between different tips and is what you’ll find on most equipment used by pros and homeowners.

However, some brands like to do their own thing. It's always a good idea to keep an eye out for proprietary fittings, especially on certain models from popular manufacturers:

Kärcher: Often uses a bayonet-style or "twist-and-lock" fitting, particularly on their K-series electric models.

Simpson: While most of their lineup uses standard quick-connects, some units, especially older ones, might have threaded connections.

BE Pressure: They typically stick to the industry standard, but it never hurts to double-check your specific model before buying replacements.

For our clients here in San Luis Obispo and the surrounding areas like Paso Robles, Arroyo Grande, and Atascadero, the easiest way to get it right is to just bring your old nozzle or wand into the shop. That way, we can guarantee you walk out with the perfect power washer replacement tips for your machine, whether you're working on a job in Morro Bay, Pismo Beach, or Nipomo.

For a deeper dive into overall pressure washing techniques, including how to select the right nozzles for different surfaces, check out this a complete guide on how to pressure wash a house.

Simple Maintenance to Extend Nozzle Life

Your power washer nozzles are precision tools, but they won't last forever without a little TLC. Even tiny specks of dirt, sand, or mineral buildup from hard water can clog the orifice. The result? Erratic spray patterns and a frustrating drop in pressure.

A few simple maintenance habits can make a huge difference in how long your nozzles last and how well they perform.

Clearing Clogs and Buildup

The most common culprit behind a sputtering nozzle is a simple blockage. If your spray pattern suddenly becomes uneven or weak, it’s the first sign that something is stuck in the tip. Ignoring it just makes your pump work harder, which can lead to premature wear on more critical—and expensive—components.

For more details on keeping the heart of your machine healthy, check out our guide on essential pressure washer pump maintenance.

Clearing a blockage is usually pretty straightforward if you have the right tool. Most new power washers include a small wire nozzle cleaning tool designed specifically for this job. Just insert the wire into the nozzle's opening and gently work it back and forth to break up and dislodge whatever is stuck in there.

Can't find your tool? A straightened paperclip will do the trick in a pinch. Just be careful not to be too aggressive—you don't want to scratch or widen the orifice, as that would permanently change the nozzle's pressure and flow rating.

For those of us working in San Luis Obispo and surrounding areas like Paso Robles or Arroyo Grande, hard water is a constant battle. Mineral deposits can build up inside the nozzle over time, slowly choking off the water flow even if there's no visible debris.

Pro Tip: To dissolve these stubborn deposits, try soaking your nozzles in a 50/50 solution of white vinegar and water for about an hour. After the soak, give them a good rinse with clean water and use your cleaning tool to clear out any loosened scale.

Smart Storage Habits

How you store your nozzles is just as important as how you clean them. Whatever you do, don't leave a nozzle attached to the wand when you're done for the day. This is a perfect way to trap moisture, inviting corrosion and allowing debris to build up inside the quick-connect fitting.

A simple organizer or a dedicated holder is a great, cheap investment. Keeping your tips in a case prevents them from getting lost, stepped on, or banged up while rolling around in a toolbox. This is especially true now that pressure washers are so common. Electric pressure washers have become a huge market segment, valued at around USD 2.9 billion in 2023 and still growing. You can discover more insights about the electric pressure washer market on alliedmarketresearch.com.

These small habits protect your investment and ensure your equipment is always ready for the next job.

Professional Power Washer Service in San Luis Obispo

Sometimes, simply swapping out a nozzle isn't going to cut it. If you've already tried a few different power washer replacement tips and you’re still dealing with a pulsing pump, weak pressure, or an engine that just won’t cooperate, you’re looking at a bigger issue.

Those symptoms are classic signs of a problem buried deeper in the machine—think pump issues, a faulty unloader valve, or engine trouble. These aren't simple fixes; they're the kind of problems that need a professional eye and a skilled hand. For anyone running a business or maintaining property on California's Central Coast, this is where you call in the experts.

Your Local Experts on The Central Coast

At Contractor's Maintenance Service, we're the go-to resource for those complex power washer repairs. Our service area covers all of San Luis Obispo County, so you’re never far from professional help.

We're proud to serve communities all over the area, including:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Pismo Beach

Grover Beach

Nipomo

Morro Bay

If your equipment is giving you a headache, don't waste time and money playing a guessing game. Our technicians have the diagnostic tools and hands-on experience with top brands like Kärcher and Mi-T-M to pinpoint the problem and get your machine back in fighting shape. From diagnostics to parts, we are your source for top-quality pressure washer nozzles in San Luis Obispo, CA and full-service repairs.

When to DIY vs Call for Service

Knowing when to put down the wrench and pick up the phone can save you from a much bigger, more expensive headache down the road. It's great that portable pressure washers are so common now—the market is expected to hit USD 3.24 billion by 2032—but it also means more people are trying to tackle repairs that are way over their heads.

So, how do you know when you've hit your limit? This table breaks it down.

Symptom | Potential DIY Fix | When to Call Contractor's Maintenance Service |

|---|---|---|

Weak or No Pressure | Check for a clogged nozzle, kinked hose, or incorrect water supply. | If you've tried all the simple fixes and pressure is still low, it could be the pump seals or unloader valve. |

Pulsing or Surging | Make sure all air is purged from the system; check for clogs in the nozzle or inlet filter. | Persistent pulsing often points to a worn-out pump valve or a failing unloader. |

Engine Won't Start | Check the fuel level, spark plug, and air filter. Ensure the choke is set correctly. | If the engine sputters, backfires, or won't turn over after basic checks, it's time for an engine expert. |

Water or Oil Leaks | Tighten loose fittings. Replace worn O-rings on hoses and connections. | Leaks coming directly from the pump body or engine casing are a serious red flag. |

Ultimately, if you're not comfortable with the repair or the problem seems to be internal, it's always smarter and safer to call for service. Continuing to run a machine with a serious issue can quickly turn a repair job into a replacement job.

Bottom line: If you hear grinding or knocking from the pump, see oil or water leaking from the machine's body, or the engine is struggling, stop what you’re doing. That’s your machine telling you it's time to call in a pro before a small problem becomes a total failure.

Frequently Asked Questions About Power Washer Nozzles

Even after you get the hang of nozzle types and charts, questions always come up in the field. From strange pressure drops to leaky fittings, knowing how to troubleshoot on the spot can save you a ton of frustration. We get these questions all the time from our customers, so let's walk through some of the most common ones.

Whether you're a pro working in Paso Robles, a homeowner in Arroyo Grande, or managing properties over in Atascadero, these are the issues that pop up for everyone.

What Happens If I Use the Wrong Size Nozzle?

This is easily the most important question we get, and for a good reason. Running your machine with the wrong nozzle orifice size can cause serious problems for your equipment and ruin your cleaning results. Getting this right is fundamental.

If the Orifice is Too Small: You're essentially choking the water flow. This creates a massive pressure spike inside the pump, forcing it to work way harder than it's designed to. The engine will strain, the unloader valve might start cycling erratically, and you risk overheating and destroying your pump seals and valves.

If the Orifice is Too Large: The system can't build up enough backpressure to hit its rated PSI. You'll end up with a weak, mushy stream that won't strip away tough grime, no matter how powerful your machine is supposed to be. This is the #1 cause of a sudden, unexplained loss of pressure.

The bottom line is simple: your nozzle's orifice size must be a perfect match for your machine’s PSI and GPM ratings. It’s not something you can guess on—it’s critical for performance and protecting your investment.

Why Is My Nozzle Leaking at the Connection?

That constant drip from your quick-connect fitting isn't just annoying; it's a pressure leak that’s robbing your machine of its full power. In 99% of cases, the problem is a tiny, cheap part: the O-ring.

Inside the female quick-connect coupler on your wand, there's a small rubber O-ring that creates the seal. Over time, that ring gets flattened, cracked, or nicked. When it can no longer create a tight seal, water will find its way out. This is a super common issue for our customers in coastal towns like Pismo Beach, Grover Beach, and Morro Bay, where fine sand and grit just chew these seals up.

Luckily, it’s a quick fix. Grab a small pick or a tiny flathead screwdriver, carefully pry out the old O-ring, and press a new one into its place. It’s a 30-second repair that will instantly stop the leak and restore your seal.

Can I Use One Brand’s Nozzles on Another Brand’s Machine?

For the most part, yes. The industry has thankfully standardized around the 1/4-inch quick-connect fitting for most professional and prosumer machines. This means a nozzle from a brand like Simpson will almost always snap right onto a wand from Mi-T-M or BE Pressure without any issues. This standardization makes finding power washer replacement tips a whole lot simpler.

The main exception is with some consumer-grade electric models. Certain brands, most notably Kärcher, often use their own proprietary bayonet or twist-lock connectors that won't work with the standard quick-connect system. Before buying new nozzles, always double-check the fitting type on your specific machine to avoid a frustrating mismatch.

How Often Should I Replace My Nozzles?

There's no magic number here. Nozzle lifespan depends entirely on how much you use them and what you're spraying. A contractor in Nipomo running their machine 40 hours a week might burn through a set of nozzles in a season. A homeowner using theirs a few weekends a year could get years out of the same set.

Instead of watching the calendar, watch for the signs of a worn-out nozzle:

The spray pattern looks erratic, uneven, or "blown out."

You notice a significant drop in pressure, even though you know you have the right orifice size.

You can physically see that the orifice hole looks wider or damaged.

Once you spot these signs, it's time for a new nozzle. Pushing a worn-out tip is just wasting time, fuel, and putting extra strain on your pump for poor results.

If you have other questions or need help finding the right parts for your pressure washer, we’ve got you covered. Contractor's Maintenance Service is the local expert for everything from simple nozzle replacements to complete engine rebuilds. Visit us online to see how we can keep your gear running like new.

Comments