Airless Sprayer vs HVLP Which Is Right for Your Next Job

- DLL Studios

- Jan 20

- 15 min read

For any professional painter, the choice between an airless sprayer vs HVLP system isn't about which one is better overall. It’s about picking the right tool for the job in front of you. Airless rigs are built for speed on big projects, while HVLP systems give you the precision needed for fine-finish work. Getting this choice right directly impacts your speed, the quality of your finish, and ultimately, your bottom line.

Choosing the Right Sprayer for Your Project

The whole airless vs. HVLP debate boils down to one simple trade-off: speed versus control.

An airless sprayer is a powerhouse. It uses a high-pressure pump to force thick coatings through a tiny tip, atomizing the material without any compressed air. Think of it as your broadest brush—perfect for knocking out huge surfaces like commercial building exteriors or priming an entire new construction project quickly and efficiently.

On the other hand, an HVLP (High Volume, Low Pressure) system does the opposite. It uses a large volume of low-pressure air to create a soft, highly controlled spray. This gives you fantastic transfer efficiency and a flawless, almost factory-like finish, making it the go-to for detailed work. It’s the fine-tipped pen you need for cabinetry, architectural trim, and custom furniture where every detail counts.

Quick Decision Matrix Airless vs HVLP

To help contractors in San Luis Obispo, Paso Robles, Atascadero, Santa Maria, Arroyo Grande, and the surrounding Central Coast areas make a quick call, here’s a table that cuts straight to the core differences.

Key Factor | Airless Sprayer | HVLP Sprayer |

|---|---|---|

Best For | Large surface areas, exteriors, new construction | Fine finishing, cabinetry, trim, detailed work |

Speed | Very fast; covers large areas quickly | Slower; designed for precision and control |

Finish Quality | Good to very good; can leave a stipple pattern | Excellent; produces a smooth, "factory" finish |

Overspray | High; requires extensive masking and prep | Very low; minimizes wasted material and cleanup |

Material Use | Handles thick, unthinned paints like latex | Best with thinner materials; may require thinning |

This quick comparison makes it clear: each sprayer has its place. The decision depends entirely on the demands of the project at hand.

For local pros, owning both systems is a real strategic advantage. An airless lets you bid competitively on large residential and commercial jobs. Meanwhile, an HVLP sprayer opens the door to high-margin, fine-finish projects that discerning clients are more than willing to pay for.

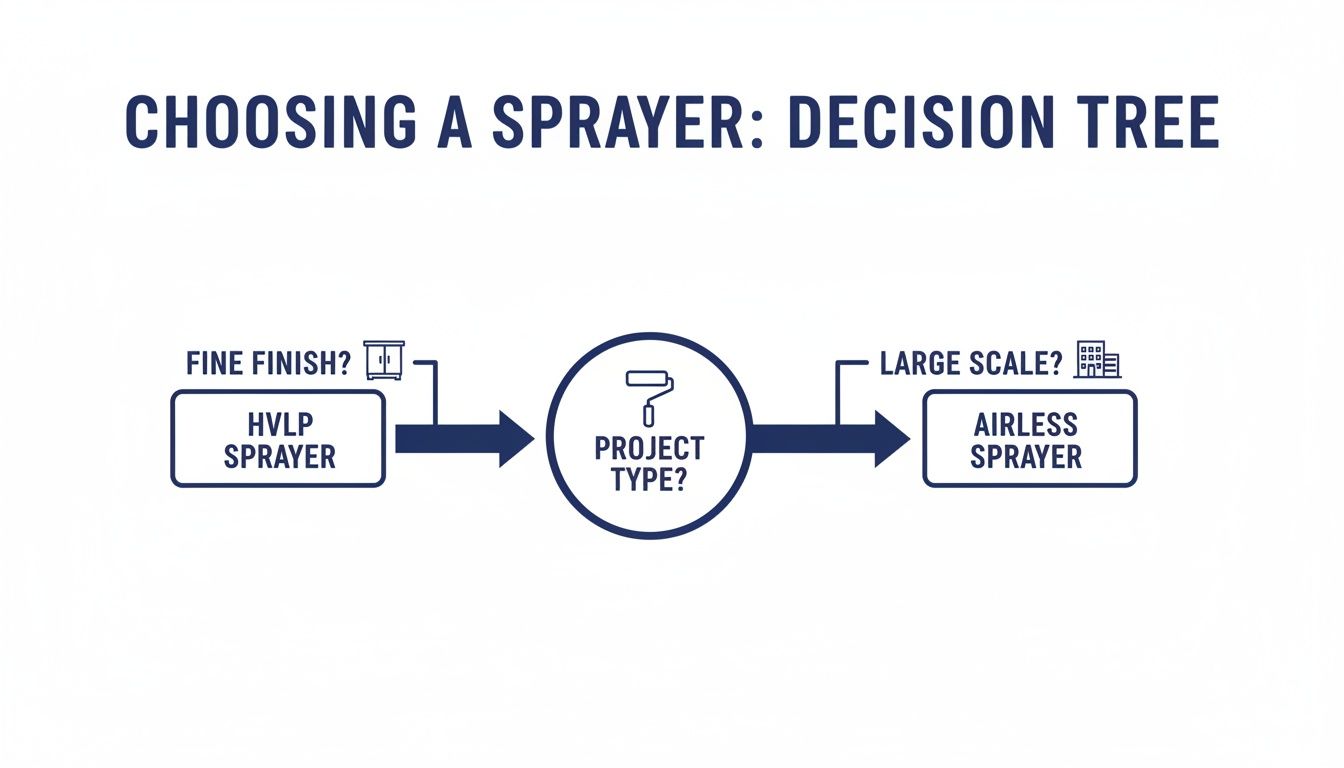

This decision tree gives you a simple visual for choosing your sprayer based on the type of project you're tackling.

The graphic reinforces the core idea: match the tool's strength—whether it's raw speed or pinpoint precision—to what the job needs most. Making this simple choice correctly is the foundation of an efficient and profitable painting business.

Understanding the Core Technology Behind Each System

To really settle the airless sprayer vs. HVLP debate for your own shop, you have to get a handle on how these machines actually work. While both tools atomize paint, they get there in completely different ways. One is all about brute force, and the other is about controlled finesse.

That core difference is what dictates everything—from speed and finish quality to the kinds of materials you can run through them.

Think of an airless sprayer as a hydraulic powerhouse. It uses a high-pressure pump to force fluid coatings—often at pressures over 3,000 PSI—through a tiny hole in the spray tip. The material atomizes from the massive pressure drop as it hits the open air. No compressed air is involved at all.

This method is incredibly fast and efficient for blasting through large areas. Since there's no air mixing with the paint, it can easily handle thick, unthinned materials like latex and even heavy elastomeric coatings.

The Power of High-Pressure Atomization

The sheer force of an airless sprayer makes it the undisputed champ for productivity on big jobs, like the ones we see all over San Luis Obispo County, including Paso Robles, Atascadero, and the coastal towns of Morro Bay and Cambria. Here’s how that power translates to performance on-site:

Raw Speed: The high fluid flow lets you lay down gallons of paint in minutes, not hours.

Thick Material Capability: Its muscle means you don't have to thin most architectural paints, which saves time and keeps the coating performing as intended.

Long Hose Lengths: That intense pressure can push material through hundreds of feet of hose, letting you cover a multi-story building without hauling the sprayer around.

At its core, an airless sprayer is a production machine. It atomizes paint by forcing it through a small opening at extreme pressure, making it ideal for covering vast surfaces like new construction drywall or commercial exteriors with incredible speed.

This brute-force approach is exactly what you need when coverage and speed are the name of the game. But all that power comes at a cost—you get more overspray and a less refined finish than you would with its counterpart.

The Finesse of High-Volume, Low-Pressure Air

In sharp contrast, an HVLP (High Volume, Low Pressure) system is all about precision. Instead of high fluid pressure, it relies on a large volume of air at very low pressure—typically under 10 PSI at the spray tip—to atomize the paint. This creates a soft, gentle spray that seems to "wrap" around surfaces with very little bounce-back.

You’ll find two main kinds of HVLP systems: turbine units and conversion guns. Turbine systems are all-in-one units that use a multi-stage turbine to generate warm, dry airflow. Conversion guns, on the other hand, hook up to a standard air compressor. If you’re leaning toward a conversion setup, take a look at our guide on choosing a compressor for painting to make sure you’ve got the right airflow.

This low-pressure delivery is the secret to HVLP's signature benefits. It’s no wonder the market is growing, with projections showing HVLP volumes climbing past 1.5 million units in 2023. Operating at just 10-15 PSI, HVLP systems boast an impressive 80% transfer efficiency. For a professional contractor, that means drastically less overspray and paint waste, which hits the bottom line directly.

Comparing Performance: Speed, Finish, and Efficiency

When you're weighing an airless sprayer vs HVLP, the real decision comes down to the daily trade-offs between speed, finish quality, and material efficiency. These are the metrics that make or break your timeline, the final look, and your bottom line. Figuring out how to balance these three is what separates the pros.

We'll get into the weeds on these three performance areas, focusing on what matters to contractors working here in San Luis Obispo and up and down the Central Coast. Getting these nuances right is how you make money on every single project.

Speed and Productivity: The Unmatched Power of Airless

Let’s be blunt: when the clock is ticking and you've got a massive surface to cover, the airless sprayer is king. It was built for one thing—laying down a ton of material as fast as humanly possible. That raw power is a total game-changer on large-scale jobs.

Picture yourself priming the entire interior of a new custom home out in Paso Robles. With an airless rig that can push over a gallon of paint per minute, you could knock that out in a day. Try that with an HVLP sprayer, and you'd be there for several days, killing your bid and throwing the whole project schedule off track.

That incredible speed comes from the high-pressure pump, which can atomize thick coatings without you having to thin them. Not only does that save a ton of prep time, but it also ensures the material works just like the manufacturer said it would. For painting commercial exteriors in Atascadero or spraying industrial coatings in Santa Maria, this isn't just a nice-to-have; it's a must.

A seasoned painter can work up to 10 times faster with an airless sprayer compared to a traditional brush and roller. On big jobs, that’s not just an efficiency boost—it’s the difference between making a profit and losing your shirt.

This speed advantage is exactly why airless technology is all over the professional market. In fact, airless spray painting machines are projected to hold a 41.2% revenue share of the global market by 2025. Their ability to blast thick paints at high pressure and cover huge areas quickly makes them perfect for any job site where time is money.

Finish Quality and Control: The Precision of HVLP

While airless systems win the race on speed, HVLP sprayers absolutely own the category of finish quality. The whole "High Volume, Low Pressure" concept creates a soft, fine mist that gently lays paint onto a surface. The result is a glass-smooth finish with almost zero texture—a level of control that's just not possible with a high-pressure airless.

Think about a kitchen cabinet refinishing project in a Santa Maria or Arroyo Grande home. The homeowner expects a perfect, factory-like finish. An airless sprayer, even with the finest tip, is probably going to leave a slight stipple or "orange peel" texture. The HVLP system, on the other hand, delivers that mirror-like sheen every time. It’s the only real choice for that kind of high-stakes work.

That precision is also crucial for detailed jobs like staining custom trim, coating metal railings, or finishing built-ins. The low pressure drastically cuts down on bounce-back, letting you coat complex shapes evenly without blowing half your material into the air.

Airless Finish: Best for walls, ceilings, and exteriors where a minimal texture is perfectly fine. The quality here really comes down to your technique and picking the right tip. You can learn more about choosing the right tip size for airless sprayer finishes in our detailed guide.

HVLP Finish: Delivers an automotive-grade, ultra-smooth finish that’s ideal for cabinetry, doors, trim, and furniture. It’s at its best when spraying fine-finish materials like lacquers, varnishes, and thinned enamels.

Transfer Efficiency and Material Costs

Transfer efficiency is all about how much of your paint actually sticks to the target versus getting lost as overspray. This is where the airless sprayer vs HVLP debate really hits your wallet.

HVLP systems are famous for their high transfer efficiency, often hitting 65% to 80%. That means most of your expensive coating is going right where you want it. The low pressure creates a gentle spray that "wraps" around what you're painting with very little airborne mist, making it perfect for indoor jobs or working near finished surfaces.

Airless sprayers are a different story. Their efficiency is much lower, typically hanging around 40% to 50%. The high pressure atomizes the paint so forcefully that a huge amount of it becomes overspray, floating away and settling as dust on everything in sight. This means a lot more time spent on masking and prep, which adds to your labor costs.

For a contractor in Nipomo or Los Osos spraying a pricey epoxy on industrial equipment, the material savings from using an HVLP could easily add up to hundreds of dollars on just one job. Factor in the reduced cleanup time, and the project becomes that much more profitable.

So, while an airless gets the work done faster, the hidden cost of wasted material can eat into your profits, especially when you're using premium coatings. It's a trade-off you have to consider. If the material is cheap and speed is everything (like priming new drywall), airless is the obvious choice. But if the coating is expensive and the finish needs to be flawless, the HVLP's efficiency gives you a clear financial edge.

Matching the Sprayer to the Job Application Scenarios

Choosing the right tool is more than half the battle in the painting trade; it’s the difference between a profitable job and a frustrating one. The whole airless sprayer vs HVLP debate ends the second you step onto a job site. Out here, what matters is the task at hand, and that dictates which machine comes out of the truck.

Each sprayer is built to own a completely different environment. Knowing when to use which one eliminates guesswork and helps you deliver the quality and speed your clients expect. For contractors here on the Central Coast, from the new developments in Arroyo Grande to the established homes in Nipomo and Morro Bay, this knowledge is key to bidding jobs correctly and getting them done right.

When to Deploy an Airless Sprayer

Think of the airless sprayer as your workhorse. It’s built for big jobs where speed and coverage are everything. Its power to push thick, unthinned coatings through long hoses at high pressure makes it the undisputed champ of production painting.

An airless rig is the only logical choice in scenarios like these:

Large Residential Exteriors: Got a two-story home with stucco or siding in San Luis Obispo? An airless lets you push material through 100+ feet of hose, so you can work around the entire perimeter without dragging equipment everywhere. A job that would take a week can be knocked out in a couple of days.

New Construction Priming: You’re staring at hundreds of square feet of fresh drywall in a custom home in Templeton. The high fluid delivery of an airless sprayer lays down a consistent coat of primer on walls and ceilings in a fraction of the time it would take with any other method.

Applying Heavy Industrial Coatings: We’re talking about elastomeric coatings on a commercial roof in Grover Beach or block filler on a concrete warehouse. An HVLP system can't even begin to atomize these heavy-bodied materials. You need the raw power of an airless sprayer to handle that viscosity and get the right film thickness.

Our team at Contractor's Maintenance Service is constantly helping contractors in the greater San Luis Obispo County area pick the right Graco or Titan model. It almost always comes down to their typical job mix—a painter doing large commercial repaints needs a totally different machine than someone specializing in residential exteriors.

Where an HVLP System Excels

If the airless sprayer is brute force, the HVLP system is surgical precision. It delivers a soft, low-pressure spray that creates an exceptionally smooth finish with minimal overspray. This makes it the go-to tool for any high-visibility, detailed work.

Here’s where an HVLP system really shines:

Fine-Finish Cabinetry and Built-ins: When a client in Pismo Beach or Cayucos demands a flawless, factory-like finish on their kitchen cabinets, an HVLP sprayer is the only way to go. It atomizes thin coatings like lacquers and enamels into a fine mist, leaving a glass-smooth surface an airless just can't touch.

Architectural Trim and Doors: Spraying intricate crown molding, window casings, or multi-panel doors requires total control to prevent runs and drips. An HVLP gun lets you put the paint exactly where you want it, saving you hours in cleanup and wasted material.

Automotive and Equipment Refinishing: The auto industry is all about perfection, and HVLP systems dominate here. They keep overspray to a minimum, which is critical when you're working with expensive, multi-stage automotive paints to get a perfect finish on panels and parts.

The global market backs this up. While the airless paint sprayers market is growing, HVLP systems have carved out a solid niche in precision work. In fact, automotive applications make up a 37.8% share of the HVLP market, where controlling overspray is essential for both results and cost. You can dig deeper into these numbers in this comprehensive market report.

Making the Right Choice On-Site

Ultimately, the choice between an airless sprayer vs HVLP is a strategic one you make on every single job. A smart painting business owns both, ready to tackle any project with the ideal tool. By matching the sprayer’s strengths to the demands of the surface, you guarantee better efficiency, superior quality, and more profit in your pocket.

Managing Uptime Through Smart Maintenance

A sprayer's real value isn't found on the price tag—it’s measured in uptime. The daily grind of setup, cleaning, and maintenance is where the airless sprayer vs HVLP debate really hits home, and it's where you either lock in your profits or watch them drain away with every minute of downtime.

The differences in day-to-day upkeep are night and day. An airless sprayer, with its high-pressure system and long hoses, requires a serious commitment to flushing everything out. If you don't meticulously clean the pump, filters, and sometimes 100 feet of hose, you're asking for stubborn clogs and expensive component failures. For a no-nonsense walkthrough, our guide on how to clean an airless paint sprayer breaks down the process for professional contractors.

On the flip side, an HVLP system is all about a quick turnaround. Cleanup is usually limited to the fluid cup, the nozzle set, and the gun itself. This is a much faster process that uses way less solvent—a huge plus when you're switching colors frequently or knocking out small-batch jobs.

Critical Maintenance Tasks for Peak Performance

Daily cleaning is just the start. If you want to keep your equipment on the job and out of the shop, you have to be proactive with maintenance. Each system has a unique checklist of wear parts and service intervals you just can’t afford to ignore. Whether you're working in San Luis Obispo or Paso Robles, downtime on the Central Coast is money lost.

With an airless sprayer, you're focused on the high-pressure parts:

Pump Packings: These seals are the workhorses of the fluid section and will wear out. Inspect them regularly and replace them to prevent pressure drops and messy leaks.

Piston Rod: A scratched or worn piston rod will chew through new packings in no time. Give it a periodic check to make sure it's smooth and undamaged.

Filters: Clogged manifold and gun filters are the number one cause of tip clogs. Keep them clean to maintain a perfect spray pattern.

For an HVLP system, it's all about protecting the air-delivery components:

Turbine Filters: If the intake and output filters on your turbine get clogged, the unit will overheat and lose pressure. This can burn out the motor fast.

Needle and Nozzle Sets: These are precision components. They have to be spotless and free of any nicks or damage to atomize material correctly and give you pattern control.

Gaskets and Seals: O-rings and other seals in the gun can dry out, crack, or wear down, leading to air leaks that will ruin your spray pattern.

A single day of unexpected downtime can easily cost a contractor more than a year's worth of preventive maintenance parts. Proactive care isn't an expense; it's an investment in reliability.

Authorized Service and Support on the Central Coast

When a sprayer finally does go down, you need an expert, and you need them fast. As an authorized service center for industry leaders like Graco and Titan, we handle the specialized repairs, warranty support, and genuine parts that keep pros in business. Our job is to get your equipment running at 100% and minimize your downtime so you can stay productive.

For painting contractors in San Luis Obispo, Atascadero, Santa Maria, Arroyo Grande, Paso Robles, Morro Bay, Nipomo, and the surrounding San Luis Obispo County areas, having a local partner for service and repair is a game-changer. We know the demands of your job and are here to deliver the fast, reliable support you need to keep your projects moving and profitable.

Choosing the Right Sprayer for Your Business

When it comes to the airless vs. HVLP debate, it’s best to see them not as competitors but as two essential tools in a pro’s arsenal. The most successful painting businesses I know own both. Why? Because it lets them bid on any job that comes their way, from high-volume production work to the high-margin, detailed finishes clients love.

Having both systems in your truck transforms your business. You're no longer just a painter; you're a versatile finishing contractor who can handle anything.

So, when you’re ready to make your next purchase, take a step back and think about what really drives your business day-to-day. Answering a few honest questions will tell you exactly where to put your money first, or which rig to add to your fleet next.

Your Strategic Equipment Checklist

To figure out what you need, ask yourself these three questions:

What kind of jobs do I do most? Are you primarily tackling large residential exteriors and commercial interiors, or is your focus on fine-finish work like cabinets and custom trim?

What materials am I spraying all the time? Is your bread and butter unthinned latex and heavy-bodied coatings? Or are you working more with lacquers, stains, and enamels that need to be thinned?

What do my clients really want? Are your customers on tight deadlines where speed is everything? Or are they demanding a flawless, factory-like finish and are willing to pay a premium for it?

Your gear should be making you money, period. Investing in a tool that doesn’t align with your main source of income is a costly mistake. Focus on the sprayer that will generate the most revenue for you right now.

For contractors working in San Luis Obispo, Cambria, Morro Bay, Paso Robles, Atascadero, and all across the Central Coast, making the right call is critical. We can help you sort through your needs and pick the perfect equipment for the jobs you're actually doing. Get in touch with us for expert advice, sales, and authorized service to make sure your next investment moves your business forward.

Frequently Asked Questions

When you're trying to decide between an airless sprayer and an HVLP system, a few practical questions always come up. Getting straight answers is crucial for any contractor in San Luis Obispo and the surrounding areas who wants to pick the right tool for the job, maximize efficiency, and deliver a flawless finish.

Can I Spray Unthinned Latex with an HVLP Sprayer?

You can, but I wouldn't recommend it. HVLP systems are built for thin-viscosity materials like lacquers and stains. To get latex through one, you have to thin it down significantly—often by 20% or more—and that can seriously mess with the paint's coverage and durability.

For the unthinned latex jobs we see all the time in Paso Robles and Atascadero, an airless sprayer is the only way to go. Its high pressure atomizes that thick material with no problem.

Which Sprayer Is Better for a New Contractor?

It really depends on what kind of work you're chasing. If you're a new painter focusing on residential repaints in Santa Maria, an airless sprayer will get you uniform coverage on big surfaces like walls and exteriors much faster. It’s a workhorse.

But if your business plan is all about fine-finish work—think cabinets, built-ins, and custom trim—an HVLP system is your best bet. The control and minimal overspray make it a much more forgiving tool to learn on for detailed jobs.

The biggest difference comes down to transfer efficiency. An HVLP puts 65-80% of the material on the surface, while an airless is typically in the 40-50% range. That means you could be wasting 30-40% more paint with an airless just from overspray.

Do All HVLP Systems Require a Compressor?

Nope, there are two different animals here. Turbine HVLP systems are all-in-one units with a built-in turbine that generates the airflow. They’re portable and self-contained.

Then you have conversion HVLP guns. These are designed to hook up to a standard shop air compressor, taking its high pressure and converting it into the low-pressure, high-volume flow the gun needs.

For expert advice on choosing the right sprayer for your jobs in San Luis Obispo, Morro Bay, Paso Robles, or Cambria, trust the team at Contractor's Maintenance Service. Visit us online to explore our full range of Graco and Titan sprayers and get the authorized service you need to stay productive. https://www.contractorsmaintenanceservice.com

Comments