The Ultimate Guide to Intake Air Filter Compressors

- DLL Studios

- Jan 18

- 13 min read

Think of the intake air filter as the lungs of your compressor. It's the very first line of defense, a critical component designed to block harmful dust, moisture, and debris from ever reaching the sensitive guts of your machine. Letting this simple part slide can lead to catastrophic failure and expensive downtime.

Your Compressor's First Line of Defense

Your air compressor is basically a giant vacuum, constantly sucking in the surrounding air to pressurize it. That intake air filter is the only thing making sure that air is pristine before it hits the compression chamber. Without a good filter, every spec of dust, grit, and moisture from the job site gets pulled right inside.

That contamination doesn't just vanish. It builds up, creating a nasty chain reaction of problems that, for contractors and maintenance teams, translates directly into operational headaches and hits to the wallet.

Why a Clean Filter Matters

A dirty or failing filter forces your compressor to work way harder to pull in air, kind of like trying to breathe through a clogged straw. That strain has immediate and long-term consequences that show up on your bottom line.

Increased Energy Bills: A clogged filter can spike your energy use by as much as 15-20% as the motor struggles to make up for the restricted airflow.

Premature Component Wear: Those tiny contaminants act like sandpaper inside your machine, scoring cylinder walls, damaging valves, and chewing up critical seals. This drastically shortens your equipment's lifespan.

Compromised Project Quality: If you're a painter, any debris that gets past the filter can contaminate your air lines. The result? Imperfections and a lousy final finish on your project.

Proper maintenance isn't just a suggestion—it's a core business practice. In fact, studies show that a regular filter replacement schedule can slash equipment downtime by a whopping 30%, helping you keep your projects on track and on budget. You can find more insights about compressor filter performance on marketsandmarkets.com.

A clean intake air filter is more than just a part; it's the gatekeeper that protects your entire compressed air system from self-destruction. Ignoring it is like inviting sand into your engine—the damage is inevitable.

For professionals working in San Luis Obispo County, having a reliable local source for parts and expertise is crucial. We proudly serve contractors throughout the region, including San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Grover Beach, Pismo Beach, Morro Bay, and surrounding areas, making sure you get the right parts to keep your equipment running smoothly.

How a Clean Filter Protects Your Bottom Line

A quality intake air filter compressor isn't just a part that blocks dust—it's a direct line of defense for your equipment investment and your budget. Think of it like a high-tech screen designed to catch microscopic bits of dirt, debris, and moisture before they ever get a chance to wreak havoc on your compressor's internals. For a contractor, the impact of this simple component is huge.

This first filtration step is what stops abrasive grit from scratching up cylinder walls, a classic cause of premature wear that leads to expensive repairs. It also keeps your delicate pneumatic tools from getting clogged or damaged by contaminants pushed down the line. And if you're a painting contractor? Clean air is everything. Even one tiny particle can completely ruin a perfect finish.

The Hidden Cost of Pressure Drop

Beyond just protecting your gear, a clean filter is a must for keeping your energy costs in check. The idea of "pressure drop" paints a perfect picture. Imagine trying to breathe through a clogged-up straw—you have to work a lot harder just to get the air you need. A dirty intake filter makes your compressor’s motor do the exact same thing.

All that extra effort isn't free. The motor has to pull significantly more electricity to fight against the resistance, which shows up as a surprisingly big jump in your power bill. Over time, that constant strain can also lead to motor burnout and downtime you didn’t plan for.

A clogged filter can force a compressor to expend substantially more energy just to pull in air. This inefficiency translates directly into higher operating costs, turning a simple maintenance task into a significant financial issue if neglected.

This is a core principle of smart equipment management. When you look at the bigger picture of a preventive vs. reactive maintenance cost analysis, the financial argument for keeping your filters clean becomes crystal clear.

Your Local Partner in Equipment Health

For businesses working in San Luis Obispo County, proactive maintenance is how you stay ahead of the competition. We're here to provide expert service and the right parts to contractors in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Grover Beach, Pismo Beach, Morro Bay, and the surrounding areas.

Making sure your compressor has a clean intake filter is one of the easiest and most effective ways to protect your bottom line. Building this check into your regular routine is a fundamental step, and our team is here to help you create a solid plan. For more tips on setting up a schedule, take a look at your equipment preventative maintenance checklist to keep all your gear in top shape.

By focusing on this one critical component, you'll lower your energy bills, extend the life of your equipment, and deliver better results on every single job.

Selecting the Right Intake Air Filter for Your Job

Picking the right intake air filter compressor is a lot more than just finding one that fits. It’s a calculated decision that lines up the filter’s specs with your compressor, your tools, and the very real conditions of your job site. Get this match wrong, and you’re looking at poor performance, accelerated wear, and possibly even a voided warranty.

Every compressor manufacturer, from Graco to Titan, lays out specific recommendations for a reason. These aren't just suggestions; they’re engineered to keep your machine running at its best. Key specs like CFM rating, micron rating, and physical size are non-negotiable.

Matching the Filter to the Environment

The world your compressor lives in is the biggest factor in choosing the right filter. A filter that works great in a clean shop will fail, and fail spectacularly, on a dusty construction site. Each material is built for a different kind of fight.

Here’s a look at the common filter media you’ll run into, along with where each one really shines.

Compressor Intake Filter Media Comparison

Filter Media | Best For | Filtration Level (Microns) | Pros | Cons |

|---|---|---|---|---|

Paper | Clean, indoor environments like workshops or garages | 5-10 microns | Excellent fine particle filtration, low initial cost. | Clogs quickly in dusty areas, easily damaged by moisture. |

Polyester/Synthetic | Outdoor construction sites, high-humidity, industrial jobs | 10-25 microns | Durable, handles moisture and heavy dust loads well. | Higher upfront cost than paper filters. |

Foam | Smaller compressors, environments with larger debris | 25+ microns | Good airflow, often washable and reusable. | Doesn't capture the finest particles effectively. |

Choosing the right material from this list is your first line of defense against contaminants. Once you’ve matched the media to your environment, the next step is staying on top of maintenance.

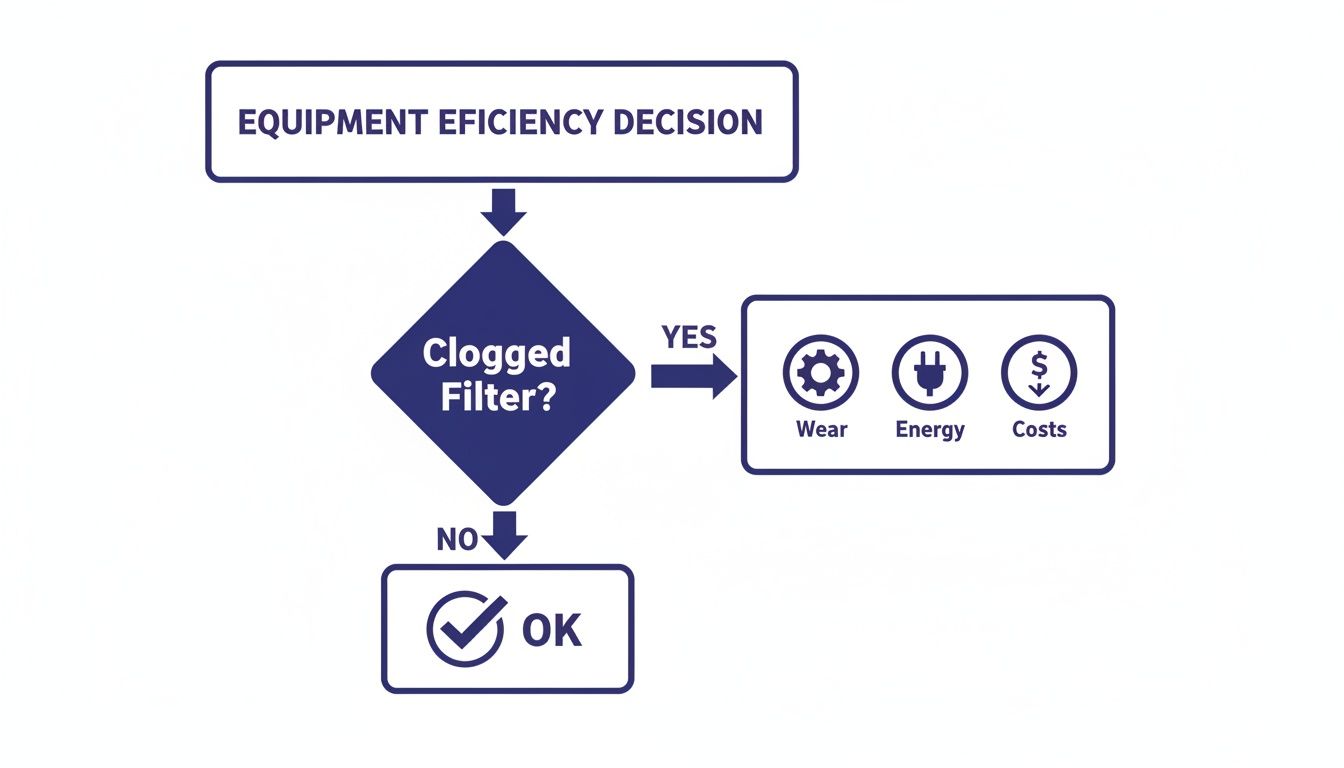

The flowchart below shows exactly what happens when a filter gets clogged. It’s not a small issue—it directly hits your equipment's health, your energy bills, and your bottom line.

As you can see, a clogged filter is a one-way ticket to higher operating costs and unnecessary stress on your machine. A clean filter, on the other hand, keeps everything running just the way it should.

Why OEM Parts Matter

It’s tempting to grab an aftermarket filter to save a few bucks, but that’s almost always a costly mistake in the long run.

Manufacturers design their filters and housings to work together, with specific seals and gaskets engineered for the exact pressure differentials of their machines. A generic filter might not create that perfect seal, which lets unfiltered air sneak right past the filter media.

"The money you save by purchasing generic parts is often the most expensive money you will ever save."

That unfiltered air pumps contaminants straight into your compressor, defeating the whole purpose of having a filter in the first place. It causes the exact kind of internal damage you were trying to prevent. Sticking with OEM parts guarantees the right fit, the right performance, and the protection your investment deserves.

For contractors working in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, and across the Central Coast, we stock the genuine OEM parts you need. Our team knows the local conditions inside and out and can help you select the perfect intake air filter for your specific job, whether you’re on a coastal project in Morro Bay or a dusty inland site. We also serve Grover Beach, Pismo Beach, and the surrounding communities.

A Practical Guide to Filter Maintenance and Replacement

Knowing when and how to swap out your intake air filter compressor is one of those fundamental skills that keeps your gear running and your projects on schedule. Forget just sticking to a generic calendar reminder—getting your hands on the filter and actually looking at it is always the best way to go.

First things first: safety. Before you even think about touching the filter housing, power the compressor down completely and unplug it. Then, bleed all the pressure out of the system. You don't want any surprises from stored energy.

Step-by-Step Filter Inspection and Replacement

Once the machine is safe, you can get to work. The process is pretty simple, but paying close attention to the details will save you from headaches like performance-robbing air leaks down the road.

Locate the Filter Housing: Find the intake filter assembly on your compressor. It’s usually a plastic or metal canister right where the machine pulls air in.

Remove the Housing Cover: Pop the clips, unscrew the bolts, or unlatch the cover to get to the old filter. Make a mental note of how it comes apart so you can put it back together just as easily.

Inspect the Old Filter: Pull the old filter out and give it a good look. Is it just dusty, or do you see any moisture or an oily sheen? Oil is a red flag that could point to a bigger issue upstream, so it's a valuable clue. If you're curious about how different fluids can impact your machine, our guide on synthetic oil for air compressors is a great resource.

Clean and Prep: Before you pop in the new filter, take a second to wipe down the inside of the housing. Get rid of any built-up dust and grime. While you're at it, check the housing's seal or gasket for any cracks or wear—replace it if it looks shot.

Install the New Filter: Seat the new, correct-sized filter firmly in place. You want to make sure it creates a perfect seal. A sloppy fit will let dirty air sneak right past the filter, making it useless.

Secure the Housing: Put the cover back on and tighten down all the latches or screws. Give it a final check to make sure everything is snug and sealed up right.

Setting Realistic Replacement Intervals

Most manufacturers suggest changing the filter every 1,000-2,000 hours, which is a solid starting point. But your job site conditions should be the real driver of your maintenance schedule.

For job sites with a ton of airborne junk—think construction, drywall, or industrial painting—you need to be checking that filter weekly. In those dusty environments, you might be replacing it as often as every 500 hours to keep your compressor from choking and prevent internal damage.

For contractors working anywhere in San Luis Obispo County, whether it's the dusty inland sites in Paso Robles and Atascadero or coastal projects in Pismo Beach, Grover Beach, and Morro Bay, tweaking your maintenance for the local environment is non-negotiable. Being proactive doesn't just keep your equipment humming; it keeps your business running. And remember, filters are just one part of the equation—a solid plan for preventative maintenance for vehicle air systems is just as crucial for keeping your whole operation safe and reliable.

Troubleshooting Common Intake Filter Problems

Even if you stick to a perfect maintenance schedule, your intake air filter can still signal deeper issues with your compressor setup. Think of your filter as a diagnostic tool—it tells a story. This section will help you play detective, figure out the root cause of common filter headaches, and get back to work fast.

A filter that clogs way too quickly is a classic symptom. It's usually a mismatch between the filter media and the job site environment. If you’re running a standard paper filter on a dusty demolition site in Paso Robles, it’s going to get overwhelmed in no time. The fix is often as simple as swapping it out for a more robust polyester or synthetic media built for those tough conditions.

Another frequent culprit is just plain bad placement. If you set up your compressor right next to a cutting station or an unpaved road, it’s going to suck in a ton of extra contaminants. You'll be changing filters far more often than you should.

Diagnosing Moisture and Physical Damage

Finding moisture in your filter housing is a major red flag. This almost always points to high humidity in the intake air, a common headache for anyone working in coastal spots like Morro Bay or Pismo Beach. Make sure your compressor has plenty of ventilation and isn't stuck in a damp, enclosed corner. Sometimes, adding a water separator or an air dryer upstream of the compressor is the only way to solve the problem for good.

If you find physical damage—like tears in the filter or collapsed pleats—it typically means one of two things happened.

Incorrect Installation: The filter wasn't seated correctly in its housing, which allowed high-pressure air to bypass the media and tear it apart.

Extreme Pressure Differential: The filter got so clogged with dirt that the sheer suction force from the compressor literally ripped it to shreds.

Neglecting filter issues is a costly gamble. A compromised intake filter lets in 70-90% more contaminants, which can slash compressor efficiency by 10-15% and cut the equipment's lifespan in half. Valves can gum up in just six months instead of lasting for years.

For contractors working in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Grover Beach, Pismo Beach, Morro Bay, and all surrounding areas, catching these symptoms early is the key to avoiding expensive downtime. Sticking to proactive filter service intervals is proven to head off a huge portion of downstream equipment failures. You can find more data about the impact of proactive filter service in a detailed air compressor filters market report. By digging in and fixing the root cause, you turn a small annoyance into a smart operational improvement, stopping minor issues before they blow up into project-stopping repairs.

Your San Luis Obispo County Source for Compressor Parts

When your equipment goes down, downtime isn't just an inconvenience—it's lost money. Having a local expert who gets it makes all the difference. For contractors across San Luis Obispo County, getting the right part for your intake air filter compressor quickly means getting back to work and protecting your gear from unnecessary wear.

Here at Contractor's Maintenance Service, we're the go-to provider for pros all over the Central Coast. We keep a deep inventory of the parts you need and offer real advice that’s tailored to our local conditions, whether you're dealing with dusty inland job sites or the damp, salty air along the coast.

Local Pros with a Nationwide Reach

Our job is simple: keep you up and running with as little delay as possible. We’re proud to serve our local communities, giving you fast, direct access to the parts and service you need.

San Luis Obispo: The heart of our service area, where we support a ton of local construction and painting contractors.

Paso Robles & Atascadero: We know how hot and dusty it gets inland. That's why we stock heavy-duty filters built to handle the extra load.

Arroyo Grande & Grover Beach: Our team provides solid solutions that stand up to the unique demands of these busy commercial and residential hubs.

Pismo Beach & Morro Bay: We’ve got the parts and know-how to fight the corrosive salt air and moisture that are a constant battle in our coastal towns.

And All Surrounding Areas: Our service extends throughout the county to ensure every contractor has the support they need.

As an authorized service center for top-tier brands like Graco and Honda, we have both the expertise and the genuine OEM parts to get the job done right. We understand the intense demands of your work and are here to provide solutions you can actually rely on.

Finding the right component is more than just a transaction. It's about making sure your equipment runs efficiently and safely, job after job. Think of us as your partners in keeping everything at peak performance.

While we're deeply rooted here in San Luis Obispo, our reach extends well beyond the Central Coast. We offer nationwide shipping, making sure that anyone can access our massive inventory and expertise. So, whether you need a standard replacement or a hard-to-find part, we're here to help. For instance, if you're hunting down a specific part like a primary element for an MTX 70 tamper, we can get it to you fast. Our goal is to be the one reliable source you need for all your compressor maintenance.

Compressor Filter FAQs: Your Questions Answered

When you're out in the field, you need straight answers, not complicated jargon. Getting the facts about your intake air filter compressor can save you a ton of time, money, and project-stopping headaches. Here are a few of the most common questions we hear from contractors and the clear-cut solutions you need.

How Often Should I Actually Change My Compressor's Intake Filter?

As a general guideline, you should plan on a new filter every 1,000 to 2,000 operating hours. But let's be realistic—the real answer depends entirely on your job site.

If you're on a dusty construction project in Paso Robles or in the middle of a heavy renovation in Atascadero, you’ll want to inspect that filter weekly. In those conditions, don't be surprised if it needs changing as often as every 500 hours to keep your equipment safe. When in doubt, always pull out the compressor’s manual for the manufacturer's specific recommendations.

Can I Just Blow Out the Filter and Reuse It?

For almost all filters, the answer is a hard no. While some specific foam filters are designed to be washed and reused, the standard paper and synthetic filters most of us use are strictly disposable.

Trying to clean them with compressed air is a bad move. It can create microscopic tears in the filter media, essentially opening a direct path for grit and dust to enter your compressor’s most sensitive parts. For guaranteed protection, a brand-new, manufacturer-approved filter is the only way to go.

Trying to reuse a disposable filter is like leaving the front door to your compressor wide open for dirt and debris. The few bucks you might save aren't worth the risk of a catastrophic internal failure down the road.

What Happens If I Use the Wrong Size Intake Filter?

Using the wrong size filter is just asking for trouble. It's a surprisingly common mistake that can lead to some serious problems.

A filter that’s too small will choke the airflow, forcing the compressor to work harder, burn more energy, and run hot. On the flip side, a filter that’s too big or doesn't seal properly will let contaminated air sneak right past the filter element. This completely defeats the purpose and exposes your internal components to the exact damage you were trying to prevent.

For contractors working anywhere from San Luis Obispo and Arroyo Grande to Paso Robles, Atascadero, Grover Beach, Pismo Beach, Morro Bay, and all surrounding areas, getting the right part isn't just a suggestion—it's essential.

When you need the right parts and expert advice from a local team that understands your equipment and the conditions you work in, give us a call. For all your compressor needs, contact Contractor's Maintenance Service today. Learn more at https://www.contractorsmaintenanceservice.com.

Comments