Air Compressor Maintenance Schedule: Keep Your Equipment Running Smoothly

- DLL Studios

- 3 days ago

- 16 min read

An effective air compressor maintenance schedule is what separates consistent, reliable uptime from the kind of costly, unexpected breakdowns that throw a wrench in your entire operation. It’s all about a planned series of checks—daily, weekly, monthly, and annually—to make sure every component is working as it should. This isn't just about ticking boxes; it's about catching minor issues before they spiral into major, budget-busting repairs.

Why a Proactive Maintenance Schedule Is Your Best Investment

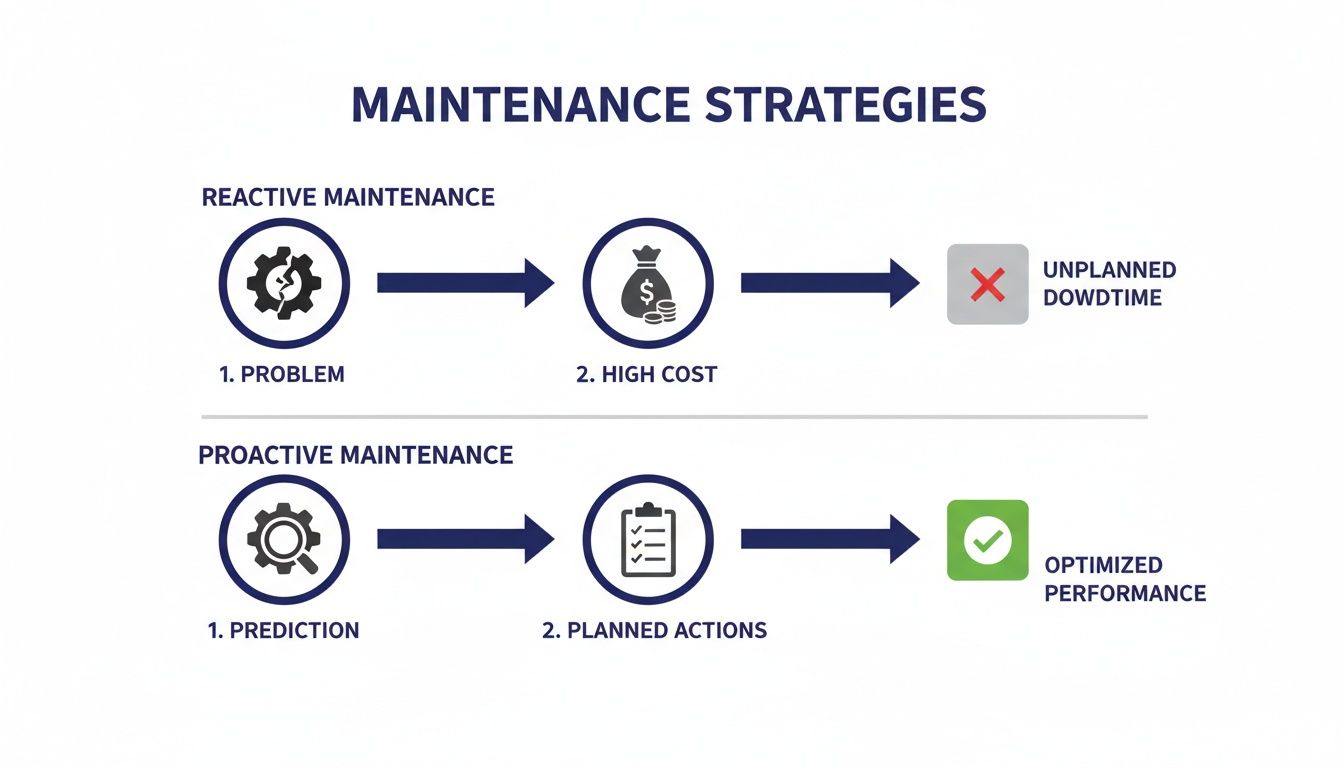

Letting your air compressor run until it fails isn't just a minor risk—it’s a direct threat to your bottom line. Too many businesses get stuck in a reactive repair cycle, only calling for help when a machine is already down. Frankly, that "if it ain't broke, don't fix it" mindset is one of the most expensive mistakes you can make. A proactive air compressor maintenance schedule completely flips the script, shifting your focus from fixing breakdowns to preventing them from ever happening.

Picture a painting contractor in Paso Robles on a tight deadline for a big commercial repaint. Out of nowhere, their airless sprayer gives up the ghost because of a clogged, neglected compressor. The project grinds to a halt, deadlines get missed, and the contractor's reputation takes a serious hit. Or think about a manufacturing line in Santa Maria where every pneumatic tool runs on compressed air. A sudden compressor failure can shut down the entire production floor, costing thousands in lost output and idle labor.

These aren't far-fetched scenarios; they're the everyday reality for businesses that neglect their equipment. A proactive schedule turns maintenance from a chore into a powerful tool for profitability.

The Financial Case for Planned Upkeep

The numbers don't lie. The financial hit from ignoring maintenance is staggering, with some industry analyses showing that preventive maintenance can deliver a jaw-dropping 545% return on investment.

Companies that stick to a scheduled maintenance program see 96% less downtime compared to those that only fix things when they break. The cost difference is just as stark: planned upkeep averages around $720 a year, while a single reactive repair bill can easily top $1,400.

A well-maintained compressor doesn't just run better; it runs cheaper. By catching wear and tear early, you avoid the premium costs of emergency repairs, overnight parts shipping, and operational downtime.

Your Local Maintenance Partner on the Central Coast

For businesses in San Luis Obispo, Atascadero, Arroyo Grande, Paso Robles, Santa Maria, and the surrounding areas of SLO County, managing this schedule doesn’t have to fall entirely on your shoulders.

Partnering with a local expert like Contractor's Maintenance Service can turn upkeep from a burden into a real competitive advantage. We know the demands of Central Coast industries and build maintenance programs designed to get the most life and reliability out of your equipment. Instead of waiting for a failure to disrupt your workflow, our team makes sure your compressors are always ready to work when you are.

By adopting a structured plan, you protect your investment, keep your workplace safe, and maintain a predictable budget. A great first step is to use a preventive maintenance schedule template to get organized. It’s a simple move that lays the foundation for a more resilient and profitable operation, ensuring your most critical equipment never lets you down.

An effective air compressor maintenance schedule is all about consistency. It's no different than your truck—you wouldn't skip an oil change or ignore a tire pressure light. Your compressor needs that same rhythm of daily, weekly, and monthly checks to run reliably and avoid turning a minor hiccup into a major shutdown.

Think of these routines as your first line of defense. A quick walk-around can spot a loose fitting that takes seconds to tighten. A weekly check might catch a fraying belt before it snaps mid-job. It's these small, consistent actions that prevent the quiet wear and tear that kills performance and leads to expensive, premature failures.

The goal is to move from reactive repairs—fixing things after they break—to a proactive plan that keeps your equipment in top shape from the start.

As you can see, a proactive schedule catches problems early, saving you from the high costs and lost time that come with emergency repairs.

To make this easier to manage, here's a quick look at the core tasks for each maintenance interval.

Air Compressor Maintenance At-a-Glance

Frequency | Core Task | Primary Benefit |

|---|---|---|

Daily | Visual inspection and draining tanks | Prevents moisture damage and catches obvious issues immediately. |

Weekly | Cleaning and safety valve check | Ensures efficient airflow and confirms safety systems are functional. |

Monthly | Belt inspection and tensioning | Maintains power transfer efficiency and prevents bearing strain. |

This table gives you a simple framework, but let's break down exactly what to look for at each stage.

Your Daily Maintenance Walk-Through

The daily check is the simplest yet most powerful part of your entire maintenance routine. It only takes a few minutes, but it gives you an immediate pulse on your compressor's health. You're just establishing a baseline of what "normal" looks and sounds like, so you can spot trouble the second it starts.

Drain Condensate from Receiver Tanks: This is non-negotiable. Compressed air creates moisture, and that water collects in the tank. If you let it sit, it causes internal rust that flakes off, clogs your air lines, and wrecks your pneumatic tools. If you're in a humid area like San Luis Obispo or Arroyo Grande, this is even more critical.

Check the Oil Level: For any oil-lubricated unit, a quick glance at the sight glass is all it takes. Running a compressor on low oil is one of the fastest ways to cause a catastrophic, wallet-draining failure.

Listen for Odd Noises or Vibrations: You know how your compressor should sound. Is there a new rattle, a high-pitched whine, or a vibration you didn't feel yesterday? These are often the first warnings of a loose bolt, a worn bearing, or a belt that's about to go.

Scan for Leaks: Do a quick visual sweep of all hoses, fittings, and seals. Any sign of oil or a faint hissing sound is a red flag. That hiss is an air leak, which means your compressor is working harder and wasting energy just to keep up.

Weekly Inspection Tasks

Building on your daily checks, the weekly inspection goes a bit deeper. These tasks make sure the core components are in good shape and the whole system is running efficiently.

Clean the Intake Vents: Dust and debris are your compressor's worst enemy. When intake vents get clogged, they restrict airflow and force the motor to run hotter and harder, which drastically shortens its lifespan. A quick wipe-down or a blast of compressed air is all you need.

Inspect Air Filters: You probably won't need to replace them every week, but a visual check is a must. A dirty filter is like trying to breathe through a straw—it suffocates your compressor. If it looks grimy, it's time for a cleaning or a replacement. We cover this in more detail in our guide on compressor air filter maintenance.

Verify Safety Valve Operation: Give the ring on the pressure relief valve a quick pull. You just want to make sure it moves freely and isn't seized. A stuck safety valve is a serious hazard that could lead to the tank becoming over-pressurized.

A consistent schedule turns abstract maintenance goals into concrete actions. By creating a tiered approach—combining daily monitoring, weekly checks, and monthly deep dives—you build a safety net that prevents silent, internal degradation within your system.

The Monthly Maintenance Deep Dive

Once a month, it's time for a more thorough look. This is when you focus on the parts that wear down more gradually over time.

A key focus here is the drive belts. Proper belt tension is critical for efficiently transferring power from the motor to the pump. If a belt is too loose, it will slip and wear out fast. If it's too tight, it puts a ton of strain on the motor and pump bearings, leading to premature failure.

Inspect for Wear: Look for any cracks, fraying, or a glazed, shiny appearance on the belt's surface.

Check Tension: A good rule of thumb is to press down on the belt at its midpoint. You should feel about a half-inch of play.

Adjust if Necessary: If the tension is off, just loosen the motor mounting bolts, slide the motor to get the right tension, and then tighten everything back down.

For anyone working in places like Paso Robles or Atascadero, where dust from agriculture and construction is a constant battle, you need to be extra vigilant about belts and filters. All that airborne grit acts like sandpaper, accelerating wear on these parts.

This rhythm of daily, weekly, and monthly checks is the foundation of a solid maintenance plan. After every 1,000 to 3,000 hours of operation, more intensive service like a full filter replacement becomes necessary. By staying on top of these simple routines, you ensure your equipment stays in peak condition, ready to work when you are.

Advanced Quarterly and Annual Service Insights

Your daily and weekly checks are the bedrock of a good maintenance plan, but the quarterly and annual services are where the real work happens. This is where we get into the nitty-gritty, replacing high-wear components that directly affect your compressor's performance, efficiency, and how long it's going to last. Think of it as proactive care that stops the kind of slow, creeping damage that can quietly take down your equipment.

These deeper services go way beyond simple visual checks and require a bit more technical know-how. For many businesses here in San Luis Obispo and across the Central Coast, this is the point where calling in a professional really pays off.

The Critical Role of Oil Changes and Analysis

Just like the engine in your work truck, the oil in your compressor is its lifeblood. It breaks down over time, gets contaminated with moisture and grime, and eventually loses its ability to cool and lubricate properly. Putting off an oil change is one of the quickest tickets to catastrophic failure.

An annual or semi-annual oil change should be a non-negotiable part of your schedule. How often you do it depends on your machine's hours and its working environment. A compressor on a dusty construction site in Paso Robles is going to need fresh oil a lot sooner than one in a clean, climate-controlled shop in Arroyo Grande.

But don't just stop at changing the fluid. An oil analysis gives you an incredible look inside your compressor's health. This simple test can spot microscopic metal fragments, signaling premature wear on bearings or other critical parts long before you’d ever hear a strange noise.

Mastering Filter Replacements

You're already inspecting and cleaning filters in your weekly routine, but quarterly and annual service means it's time for a full replacement. Clogged filters are the number one cause of differential pressure—the pressure difference between two points in your system. When a filter gets dirty, your compressor has to work much harder to force air through it, which tanks your efficiency and sends your energy bills soaring.

Here are the key filters you need to stay on top of:

Air Intake Filters: This is your first line of defense, stopping dust and debris from ever getting inside. A clogged intake filter is like trying to make your compressor breathe through a straw.

Oil Filters: These trap contaminants in the lubrication system, protecting all those vital internal components from abrasive wear and tear.

Air/Oil Separators: For rotary screw compressors, this is a make-or-break component. It strips oil out of the compressed air before it heads down your lines. A failing separator leads to oil carryover, which will ruin pneumatic tools and contaminate your final product.

Keeping an eye on differential pressure is crucial. For a typical oil-flooded rotary compressor, a total pressure drop of 9-16 psi is normal. If you see those numbers creeping up, it’s a blaring signal that your filters or separators are choked out and need to be replaced now.

Drive Belt Inspection and Tensioning

The drive belts are what transfer power from the motor to the pump. Over time, they stretch, crack, and wear out. A loose belt will slip, generating excess heat and killing efficiency. On the flip side, a belt that’s too tight puts immense stress on motor and pump bearings, leading to expensive, premature failures.

During your quarterly or annual service, a quick visual check isn't enough. You need to dig deeper.

Inspect Thoroughly: Look for any signs of cracking, glazing (that shiny, worn-out look), or fraying.

Check Tension: Use a belt tension gauge to get an accurate reading. The old "rule of thumb" check is okay for monthly glances, but your annual service demands precision.

Verify Alignment: Make sure the pulleys are perfectly aligned. Even slight misalignment will shred a brand-new belt in no time.

The Case for Professional Service on the Central Coast

While some in-house teams are equipped to handle these bigger tasks, there are solid reasons to bring in professionals like Contractor's Maintenance Service, especially for businesses in San Luis Obispo, Santa Maria, Atascadero, Paso Robles, Arroyo Grande, and other communities throughout SLO county.

First off, safety is paramount. We're talking about high-pressure systems and electrical components that carry serious risks. Our technicians are trained to handle these jobs safely and correctly, every time.

Second, warranty compliance often hinges on service being done by an authorized center. Trying to tackle a major repair yourself could easily void your warranty, leaving you on the hook for any future failures.

Finally, we have the specialized tools and diagnostic equipment to do the job right. We can spot subtle issues an untrained eye would miss, making sure your compressor runs at its absolute best. Our expertise covers everything from reciprocating to rotary screw models, so we know the unique quirks of your specific machine. If you're looking for guidance on lubrication, check out our article on the benefits of using synthetic oil in your air compressor for better performance.

Compressed air systems are becoming more critical than ever. The global air compressor market is projected to grow from $20.1 billion in 2025 to $30.2 billion by 2035. This trend just underscores how vital these machines are across countless industries, reinforcing the value of specialized maintenance to protect these essential assets. You can discover more insights about the growth of the industrial air compressor market on factmr.com. This is why a detailed quarterly and annual service plan is a vital part of any serious air compressor maintenance schedule.

Recognizing Warning Signs and Troubleshooting Common Issues

Even if you follow the perfect maintenance schedule, your air compressor will eventually act up. It's just a fact of life for any hard-working machine. The trick is to catch the warning signs early and know what they mean. A compressor rarely just dies without giving you a heads-up first. Learning to read those signs is the difference between a five-minute fix and a full-blown production shutdown.

Think of this guide as your first line of defense. We'll walk through the most common headaches I see in the field, from a machine that won't kick on to one that can’t seem to build pressure, and give you clear steps to get to the bottom of it.

Compressor Fails to Start

You flip the switch and hear… nothing. It’s a sinking feeling, but don't jump to the worst-case scenario just yet. More often than not, the culprit is something surprisingly simple.

Before you start pricing new motors, run through this quick checklist:

Power Supply: This sounds obvious, but you’d be surprised. Is it actually plugged in? Did someone trip a breaker in the main panel? Always check the easy stuff first.

Pressure Switch: Your compressor has a built-in safety to prevent it from over-pressurizing. If the tank is already full, the pressure switch won't let it start. A quick glance at the tank gauge will tell you if it's at or above its cut-out pressure. If so, it's just doing its job.

Oil Level: Many modern units have a low-oil cutoff sensor. It’s a great feature that prevents the machine from destroying itself, but it can be confusing if you don't know it's there. If the oil is low, it simply won't start.

Constantly Low Air Pressure

Is your compressor running nonstop but your tools feel sluggish? This is one of the most frequent complaints, and it’s a huge red flag. Not only is it frustrating, but it's also burning through electricity and putting unnecessary strain on the motor.

An air leak is the silent killer of system efficiency. Even a tiny leak, just 1/16th of an inch at 100 psi, can waste nearly $1,000 in electricity over a year.

Your first move should be to go on a leak hunt. Grab a spray bottle with some soapy water and hit every single hose, fitting, and connection you can find. See bubbles? You've found a leak. Snug up that fitting or swap out the hose.

If your system is airtight, the next likely suspect is a clogged intake filter. A dirty filter is like trying to breathe through a straw—it chokes the compressor and kills its output. Pull the filter out and take a look. If it's caked with dust, a new one will make a world of difference.

Excessive Oil in the Air Lines

If your pneumatic tools are spitting out a fine, oily mist, you’ve got a problem called "oil carryover." This is a serious issue. That oil contamination will absolutely wreck sensitive tools, ruin a paint job, or contaminate any product it touches.

There are a few reasons this happens:

Worn Piston Rings: On a reciprocating (piston) compressor, worn-out rings let oil sneak past the piston and into the compressed air.

Failing Air/Oil Separator: This is the usual suspect for rotary screw compressors. When the separator gets saturated or fails, oil blows right through into your lines.

Overfilling with Oil: It's tempting to top it off, but too much oil can cause it to foam up and get carried into the air stream. Always fill to the recommended level.

When to Call a Professional on the Central Coast

Look, I'm all for DIY fixes, but some things are best left to the pros. Trying to tackle certain problems without the right tools and training can be dangerous, and you could easily turn a small issue into a catastrophic failure.

If you are in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Santa Maria, or anywhere in the surrounding areas, it's time to put down the wrench and call us at Contractor's Maintenance Service if you notice any of these:

Repeatedly Tripping Breakers: This isn't a fluke. It points to a serious electrical fault, like a short in the motor or a bad starting capacitor. Don't mess with it.

Loud, Mechanical Noises: Grinding, banging, or knocking are the sounds of expensive parts failing. This could be anything from a broken connecting rod to a shot bearing. Shut it down immediately.

The Problem Persists: If you’ve gone through the basic checklist and you’re still stumped, stop guessing. When diagnosing complex or recurring issues, understanding principles of efficient equipment operation is key; therefore, familiarizing yourself with methodologies like Root Cause Analysis Engineering can be very helpful for a deeper understanding. Our technicians have seen it all and have the diagnostic gear to find the real problem fast, saving you time, money, and a whole lot of frustration.

Your Expert Partner for San Luis Obispo Compressor Service

If you run a business anywhere on California's Central Coast—whether it’s a winery in Paso Robles or a construction site in Santa Maria—you know that reliable equipment isn't just nice to have. It's the absolute backbone of your operation. When a critical tool like an air compressor goes down, it doesn't just pause a task; it can halt productivity entirely and throw deadlines into chaos. This is exactly why having a local, expert partner is so crucial for managing your equipment and sticking to a proper air compressor maintenance schedule.

At Contractor's Maintenance Service, we provide specialized support for businesses throughout San Luis Obispo county, including San Luis Obispo, Atascadero, Arroyo Grande, Paso Robles, Santa Maria, and all the surrounding communities. We do a lot more than just fix what's broken. Our real goal is to become your trusted partner in proactive equipment care, making sure your machinery is always ready to get the job done.

More Than Just a Repair Shop

We get it. Downtime costs you money. That’s why we’ve built our services to address every single pain point a contractor or facility manager faces. We don't just react to problems—we help you get ahead of them with maintenance programs designed for the unique demands of our local industries.

Here’s how we make a difference:

Warranty Management: As an authorized service center for top brands like Graco and Wagner/Titan, we handle all warranty claims for you. That means you can skip the headache of navigating complex paperwork and get your equipment back to work faster.

Massive Local Parts Inventory: Waiting for a part to be shipped can derail an entire project. We keep a huge inventory of essential components right here in San Luis Obispo, which drastically cuts down on delays and ensures a quick turnaround.

Custom Hydraulic Hose Fabrication: A burst hose can bring any job to a screeching halt. We can fabricate custom hydraulic hoses on-site, often while you wait, giving you a fast solution to a common and frustrating problem.

A Real-World Central Coast Scenario

Picture this: a painting contractor has a major commercial project in downtown San Luis Obispo. Their airless sprayer starts acting up, threatening to push their tight schedule back by days. Instead of panicking, they bring it to us.

Thanks to their scheduled maintenance plan with us, we had already flagged a key component for potential wear. Because we had the part in stock, our technician was able to complete the service in just a few hours—not days. The contractor picked up their sprayer the same afternoon and got right back on schedule. That's the difference proactive, local service makes. A potential crisis becomes a minor inconvenience.

Your equipment is your livelihood, and protecting that investment is our top priority. We're not just a vendor; we're a dedicated partner committed to your operational success.

For a deeper look into how our local services can benefit your business, learn about our comprehensive maintenance services in San Luis Obispo and see how we keep the Central Coast working.

Common Questions About Air Compressor Maintenance

Even with a solid maintenance plan, you're bound to run into questions. Here are some of the most common ones we hear from equipment owners around San Luis Obispo, with straightforward answers to keep you on track.

How Often Should I Change Compressor Oil?

This is probably the number one question we get, and for good reason—it’s critical. Your manufacturer's manual is always the final word, but a solid rule of thumb for most industrial compressors is an oil change every 1,000 to 2,000 operating hours.

But don't just set it and forget it. The environment your compressor lives in matters a lot. A machine running on a dusty construction site in Paso Robles will chew through oil much faster than one in a sterile, climate-controlled facility in Arroyo Grande. Throw in high heat or humidity, and that oil will break down even quicker, so you'll need to keep a close eye on it.

Rotary Screw vs. Reciprocating Compressor Maintenance

So, what’s the real difference in upkeep between these two workhorses? While they both need regular attention, where you focus that attention is quite different.

Reciprocating Compressors: Think mechanical wear and tear. You’ll spend more time checking components like valves, piston rings, and the cylinder itself. These parts are under a ton of stress and need frequent inspection.

Rotary Screw Compressors: It's all about the lubrication system. Your checklist will be heavy on monitoring oil coolers, filters, and especially the air/oil separator. That separator is the unsung hero preventing oil from contaminating your air lines.

What Maintenance Records Should I Keep?

If you’re not keeping a detailed log, you’re flying blind. Good records are your best defense for troubleshooting issues, making warranty claims, and planning your service schedule.

Your logbook should tell the complete story of your machine's life. It's the proof you need to show you’ve followed maintenance protocols, which is often a requirement to keep your manufacturer's warranty valid.

Your records don't have to be complicated, but they should include:

Service Dates: Exactly when was each task done?

Operating Hours: Log the hours on the meter at every service.

Tasks Completed: Get specific. "Oil change" is good, but "Changed oil and replaced oil filter" is better. Note things like belt tensioning, too.

Parts Replaced: List the exact parts you used for any repair.

This simple habit turns into an invaluable resource over time. It helps you spot trends before they become problems and gives you the data to justify every maintenance decision, keeping your equipment running strong for years.

When your maintenance schedule demands more than a quick check-up, Contractor's Maintenance Service is the partner businesses trust across the Central Coast. We handle expert repairs, warranty service, and keep a huge local parts inventory to slash your downtime. Protect your investment by visiting us at https://www.contractorsmaintenanceservice.com.

Comments