Your Equipment Preventative Maintenance Checklist

- DLL Studios

- Dec 3, 2025

- 15 min read

An effective equipment preventative maintenance checklist is a simple, structured guide that operators and technicians use for routine inspections and service. It’s all about shifting from costly, reactive repairs to a proactive strategy. The goal? Catching small issues before they turn into major failures and expensive downtime.

Why Your Business Needs a Maintenance Checklist

Downtime isn't just an inconvenience; it's a direct and often massive hit to your bottom line. Every minute a piece of equipment sits idle because of an unexpected failure, your project schedule slips, labor costs pile up, and profitability takes a nosedive.

Moving from a reactive "fix-it-when-it-breaks" approach to a proactive one is the single most powerful thing you can do to protect your assets and budget. The cornerstone of this strategy is a well-designed equipment preventative maintenance checklist.

From Reactive Chaos to Proactive Control

Think about a scene that plays out all too often on job sites from San Luis Obispo to Paso Robles: a key excavator goes down mid-dig because of a burst hydraulic hose. The whole crew is at a standstill, the project stalls, and you're scrambling to get a mobile repair service on-site. That’s the reality of a reactive approach.

Now, imagine this instead: during a routine daily walk-around guided by a checklist, the operator spots a tiny, weeping crack in that same hose. It gets flagged immediately. At the end of the day, a technician from Contractor's Maintenance Service swaps it out during planned downtime. The cost is minimal, and the project never skips a beat. That's the power of a checklist—it brings consistency and takes the guesswork out of the equation.

A checklist ensures that nothing gets missed, no matter who is doing the inspection. It standardizes the whole process, creating a reliable baseline for equipment health and a vital historical record for predicting future problems.

The Financial and Operational Impact

The argument for preventative maintenance isn't just talk; it's backed by hard numbers. Equipment failure is a primary cause of operational headaches, accounting for 42% of unplanned downtime costs worldwide. Those costs go way beyond the repair bill, factoring in lost productivity and even safety risks.

Implementing a checklist-driven PM program can extend the life of your equipment by 20% to 40%, letting you put off major capital investments for years.

For businesses working in Atascadero, Arroyo Grande, or Morro Bay, this means you can put in better project bids, keep clients happier, and boost your bottom line. A structured program brings a few key advantages to the table:

Reduces Human Error: A checklist ensures every critical point is checked, every single time.

Ensures Consistency: The same checks are done across all shifts and by all operators, period.

Creates a Data Trail: Documented checks give you invaluable insight into wear patterns and recurring issues.

Fosters a Culture of Ownership: It empowers operators to take real responsibility for the health of their machines.

At the end of the day, a maintenance checklist isn't just more paperwork. It's a strategic tool that turns maintenance into a predictable, controlled process that safeguards your most valuable assets. To see how this fits into a bigger strategy, check out our guide on preventive maintenance best practices for 2025.

Your Daily Pre-Operation Inspection

Those first ten minutes of a shift can make or break the entire day. A quick, solid pre-operation inspection is the single best way to catch a problem before it turns into a breakdown that grinds your whole project to a halt. This isn't about adding another task to the list; it's about giving your operators the power to be the first line of defense for your equipment.

This daily walk-around is the cornerstone of any good equipment preventative maintenance checklist. It turns operators from people who just run the machine into people who are invested in its health. When your team knows what to look for, they can spot a potential failure when it's still just a small, cheap fix.

The Power of the Walk-Around

A daily inspection is a lot more than just kicking the tires. It’s a systematic check—both visual and functional—designed to catch the obvious and not-so-obvious signs of trouble before the machine is put under any real stress. For crews working anywhere from Paso Robles to Grover Beach, a simple check can be the difference between a productive day and a costly delay waiting for a mobile repair truck to show up.

The goal here is to make this a non-negotiable habit, as routine as grabbing a hard hat. A good daily checklist really just boils down to a few core areas:

Fluids and Leaks: Are the engine oil, hydraulic fluid, and coolant levels where they should be? Even more importantly, do you see any drips, puddles, or suspicious wet spots on or under the machine?

Hoses and Belts: Get your eyes on the hydraulic and coolant hoses. Look for cracks, bulges, scuffs, or any weeping from the fittings. Give the serpentine and V-belts a once-over for fraying, glazing, or too much slack.

Undercarriage and Tires: On wheeled equipment, check the tire pressure and look for cuts or heavy wear. For tracked machines, inspect for loose pads, broken grousers, and make sure the track tension looks right.

Safety Features: Do the lights work? How about the horn and backup alarm? Is the fire extinguisher charged and easy to get to? Are all the safety guards and shields in place?

From Strategy to the Job Site

Everyone agrees that preventive maintenance is a smart strategy. A revealing 2025 report surveyed over 1,300 maintenance professionals and found that 71% of maintenance leaders consider it a core part of their strategy. But here's the kicker: the report also showed that less than 35% actually spend the majority of their maintenance time on it. That's a huge disconnect, especially when you learn that our fixed industrial assets now average 24 years old—the highest since 1947. You can dig into more of these findings in the 2025 State of Industrial Maintenance Report on getmaintainx.com.

A simple daily pre-operation checklist is the perfect way to close that gap. It takes almost no time but delivers a massive impact, turning a high-level plan into a daily, hands-on practice.

Empowering your operators with a clear, simple checklist isn't just about finding problems. It’s about building a proactive mindset where everyone on site feels responsible for the equipment's condition and operational readiness.

For businesses all over San Luis Obispo County, whether on coastal projects in Pismo Beach or agricultural jobs inland, this daily discipline is what separates the most efficient operations from everyone else.

To make this dead simple, we've put together a quick table outlining the absolute must-check items. Think of this as your starting point for a fast but thorough daily review.

Essential Daily Pre-Shift Inspection Points

System Category | Key Inspection Point | What to Look For |

|---|---|---|

Engine & Fluids | Check Engine Oil & Coolant | Proper levels on dipstick/sight glass. No signs of milky or contaminated fluid. |

Hydraulics | Inspect Hoses & Cylinders | No visible leaks, drips, cracks, or abrasions. Cylinder rods are clean and free of damage. |

Undercarriage | Examine Tires or Tracks | Proper inflation on tires. No missing bolts, excessive wear, or damage on tracks. |

Safety Systems | Test Alarms, Lights, & Horn | Ensure backup alarm, horn, and all work lights are fully functional. |

Attachments | Check Bucket/Blade/Forks | Look for cracks, broken welds, or excessive wear on cutting edges and teeth. |

This table is a great foundation, but a truly effective checklist is always tailored to the specific machine—whether it’s a paint sprayer in Atascadero or a compacting plate down in Arroyo Grande. By making these checks a mandatory part of the daily routine, you systematically stamp out the small problems before they grow into catastrophic, budget-killing failures. It’s the simplest and most cost-effective insurance policy you can have for your fleet.

Building Checklists for Scheduled Service Intervals

Daily checks are your first line of defense, but a truly effective maintenance program goes deeper. It’s all about scheduled service based on hard data—like operational hours or calendar dates. This is where you graduate from quick visual inspections to the nitty-gritty tasks that prevent catastrophic, long-term wear and tear.

This proactive approach means you’re servicing equipment before major components fail, not after.

Whether you're running a big construction site in San Luis Obispo or managing farm equipment out in Paso Robles, this level of planning is non-negotiable. Otherwise, you're just guessing when vital services are due, which almost always ends in expensive downtime. A solid scheduled maintenance plan can actually boost equipment life by 20% to 40%. That’s a huge return on a small investment of your time.

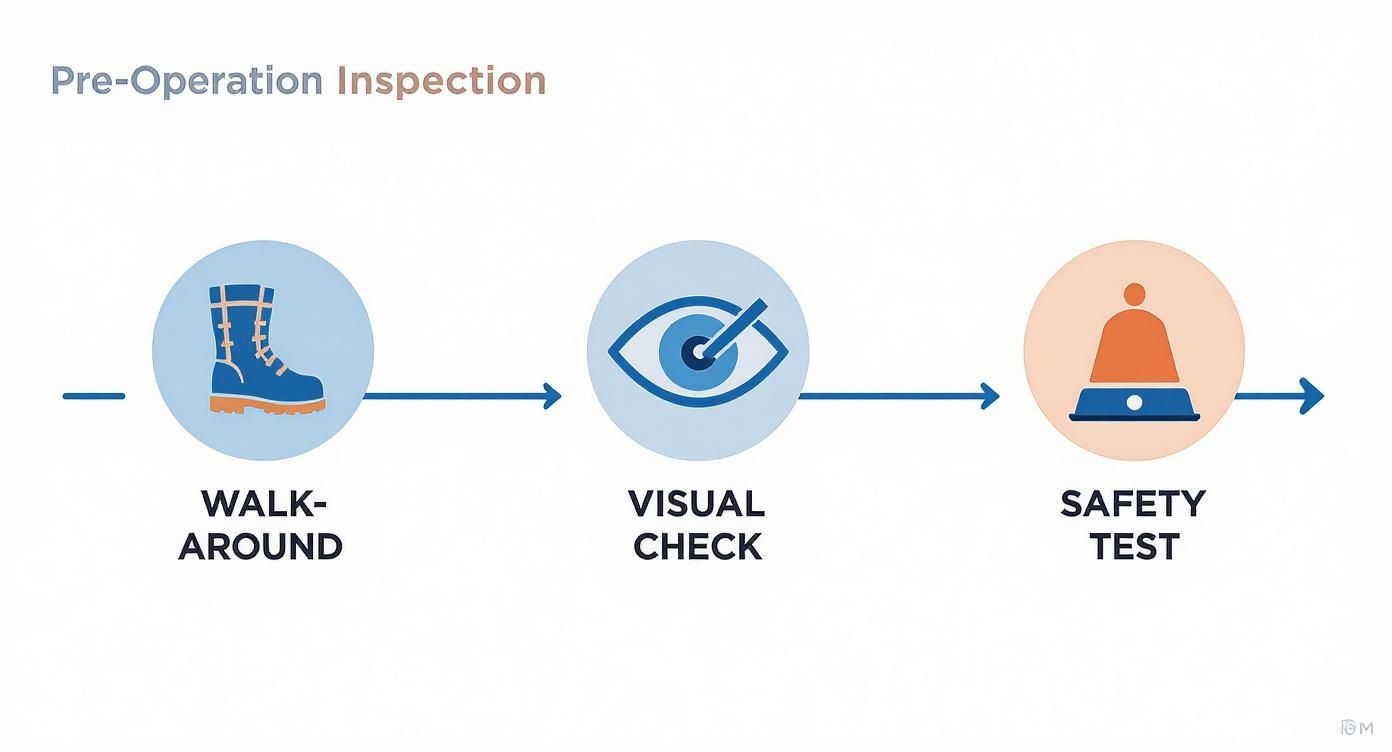

This diagram shows how those simple daily checks are the foundation for a much bigger, more detailed maintenance strategy.

Think of the daily walk-around, visual check, and safety test as the starting point. Now, let’s build on that with more in-depth service intervals.

Establishing Service Milestones

Your equipment's operator manual is always the first place you should look. Manufacturers lay out detailed service intervals based on run-time hours, usually at key milestones like 250, 500, and 1,000 hours. These aren't just random numbers; they’re based on tons of testing and data about the lifespan of fluids, filters, and other high-wear parts.

Your own checklists should be built around these intervals. A 250-hour service is typically a minor check-up, while a 1,000-hour service is a major overhaul involving more complex work.

Let's walk through a practical example. Imagine an excavator working on a job site in Atascadero. Here’s what its service checklist might look like.

Sample Excavator Service Checklist Framework

250-Hour Service (Minor Interval)

This is your most frequent scheduled check, zeroing in on fluids and critical grease points.

Engine: Change the engine oil and swap out the oil filter.

Fuel System: Replace the primary fuel filter and the water separator element.

Hydraulics: Check the hydraulic fluid level and top it off. It’s also smart to take a fluid sample for analysis to catch contamination or wear early.

Grease Points: Lube up all boom, arm, and bucket pivot points according to the manual. Don't skip the swing bearing and turntable.

500-Hour Service (Intermediate Interval)

Here, you'll do everything from the 250-hour service plus some additional filter changes and more thorough inspections.

All 250-Hour Tasks: First, complete every item from the previous checklist.

Fuel System: Now, replace the final, secondary fuel filter.

Hydraulic System: Replace the hydraulic tank return filter. This is a must-do to protect your sensitive pumps and valves.

Cooling System: Check the radiator and oil cooler for dirt and debris. Clean the fins to prevent overheating and check your coolant concentration.

Creating a structured schedule is fundamental to proactive maintenance. For more guidance on organizing these tasks, our preventive maintenance schedule template guide offers an excellent framework to get you started.

1,000-Hour Service (Major Interval)

This is a much more comprehensive service that tackles fluids and components with a longer lifespan.

All 250 & 500-Hour Tasks: You guessed it. Start by doing all the tasks from the previous intervals.

Hydraulic System: This is usually when you’ll completely change the hydraulic fluid and replace the suction filter inside the tank.

Swing Drive & Final Drives: Change the gear oil in both the swing drive machinery and the final drives.

Engine: Check and adjust the engine valve clearance based on the manufacturer's specs.

Cooling System: Time to drain, flush, and replace the engine coolant entirely.

Adapting Checklists for Your Fleet

This excavator example gives you a solid blueprint, but the real magic happens when you customize it for your specific equipment and job sites. A compactor kicking up dust on a hot inland site near Santa Margarita is going to need its air filters checked way more often than a machine working in the mild coastal air of Morro Bay or Pismo Beach.

When you build your own checklists, always keep these things in mind:

Manufacturer Recommendations: This is your baseline. Don't ignore it.

Operating Environment: Is it dusty, muddy, salty, or scorching hot? Adjust your service frequency to match.

Machine Age and History: An older machine with a known issue might need more frequent eyes on that specific system.

For businesses all over San Luis Obispo County, from Grover Beach to Arroyo Grande, having a local expert to call is a game-changer. While these checklists empower your crew to handle routine PM, you’ll eventually run into complex jobs or unexpected problems. That's where we come in. At Contractor's Maintenance Service, we can help with everything from advanced diagnostics and warranty repairs to custom hydraulic hose fabrication, making sure your maintenance program keeps your fleet humming.

Mastering Your Maintenance Records and Data

A preventative maintenance checklist is a fantastic tool, but it's only half the battle. If that completed checklist just gets tossed in a pile, you're missing out on its real power. Proper record-keeping is what turns a simple daily task into a goldmine of information about your fleet.

Think of your maintenance logs—whether they're in a binder or a digital system—as the complete history of each machine. This history lets you move from just reacting to problems to actually predicting and preventing them. It’s how you shift your maintenance program from a necessary expense to a strategic tool for managing your assets.

What Your Maintenance Logs Must Capture

Consistency is everything. To make your data useful down the road, every log entry needs to capture the same core information, no matter who is doing the work.

Make sure your records always include these key details:

Date of Service: The exact day the work was done.

Hour Meter Reading: This is non-negotiable for tracking usage and scheduling future maintenance.

Technician Name: Essential for accountability and asking follow-up questions if needed.

Tasks Performed: A clear description of what was done, from topping off fluids to swapping out a filter.

Parts and Fluids Used: Get specific with part numbers and fluid types. This makes reordering a breeze.

Technician Notes: This is often where the most valuable insights are found. Notes on a strange noise, an unusual sign of wear, or a tricky repair can be an early warning of a much bigger problem.

Turning Raw Data into Actionable Insights

Once you start logging this information consistently, you can start connecting the dots.

Are you replacing the same hydraulic hose on a specific loader every three months? That’s not just bad luck. That’s a data point telling you something is wrong—maybe the hose is routed incorrectly and rubbing, or perhaps you need a tougher, higher-grade hose for that application.

This is the kind of insight that helps you:

Spot Recurring Problems: Pinpoint repeat failures on certain machines before they become chronic headaches.

Predict Component Failures: If your records show a bearing tends to fail around the 1,500-hour mark, you can schedule its replacement at 1,450 hours and avoid the downtime.

Optimize Your Maintenance Schedule: The manufacturer's manual provides a good baseline, but your data shows the reality. Maybe your dusty job sites around Paso Robles mean you need to change air filters more often than recommended.

By analyzing your own maintenance history, you can fine-tune your equipment preventative maintenance checklist and service intervals based on how your machines actually perform in your environment, not just on generic guidelines.

This isn't just a theory; it's where the entire industrial maintenance field is heading. Companies that get serious about their data have seen up to an 80% reduction in unplanned downtime and a 60% boost in maintenance efficiency. It’s all about using real-world information to find the root cause of problems and keep your equipment running better, longer. If you want to dig deeper into these trends, oxmaint.com offers some great insights on modern maintenance strategies.

For any business in San Luis Obispo county, from Arroyo Grande to Atascadero, keeping detailed records is a game-changer. It gives you the hard proof you need to make smarter purchasing decisions, justify your maintenance budget, and ultimately, run a more profitable operation.

Expert Repair Services in San Luis Obispo County

Even the most dedicated preventative maintenance program has its limits. Daily checks and scheduled services are fantastic for catching the small stuff, but sooner or later, a problem will pop up that calls for a professional. Think complex diagnostics, major component failures, or specialized jobs that demand tools and expertise beyond your in-house shop.

This is where having a trusted local partner makes all the difference. Knowing when to put down the wrench and call in an expert is just as critical as your daily walk-around. Trying to patch up a tricky hydraulic issue or dive into an engine rebuild without the right training can quickly turn a small problem into a massive headache, leading to more damage and costly downtime.

Your Local Partner from Paso Robles to Pismo Beach

Here at Contractor's Maintenance Service, we're deeply rooted in the Central Coast community. We're proud to serve businesses all over San Luis Obispo County, delivering fast, reliable support to keep your operation running. Whether you're on a job site in San Luis Obispo, running a farm in Paso Robles, or managing a municipal project in Atascadero, our team is just a call away.

Our service area covers the entire region, including:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Nipomo

Los Osos

Templeton

Santa Margarita

And all the surrounding communities

We get it. When a critical piece of equipment goes down, you need help now. Our expert technicians are ready to tackle the jobs that go beyond your standard PM checklist, cutting down your downtime and getting you back to work fast. Think of us as the professional backup you need for a complete maintenance strategy.

When to Call a Professional vs DIY Maintenance

Knowing what your crew can handle versus what needs a specialist is the key to managing your fleet effectively. Some jobs are perfect for your team's routine PM, but others are best left to the pros to avoid bigger problems down the road. This table breaks down common scenarios to help you make the right call.

Maintenance Task | Recommended for In-House PM | When to Call Contractor's Maintenance Service |

|---|---|---|

Fluid & Filter Changes | Yes - Ideal for your team's scheduled maintenance intervals. | When you discover metal shavings or heavy contamination in the fluids. |

Greasing & Lubrication | Yes - A core part of any daily or weekly checklist. | If a grease point refuses to take grease, indicating a blockage or failed bearing. |

Visual Hose Inspection | Yes - Operators should check for cracks, leaks, or abrasion daily. | When a hose fails or you need a custom-fabricated hydraulic hose replacement. |

Major Component Repair | No - Engine, transmission, or final drive overhauls require specialized tools. | For any internal engine work, transmission diagnostics, or hydraulic pump rebuilds. |

Warranty Claims | No - These must be handled by an authorized service center. | As an authorized service center for top brands, we manage warranty repairs for you. |

A strong maintenance program isn’t just about routine checks. It's about building a reliable system to handle every possible scenario—including having a trusted expert on call for those inevitable, complex issues.

Ultimately, our team is an extension of yours. While you focus on the daily and weekly tasks that keep your machines running smoothly, we’re here to provide the heavy-lifting and deep technical expertise for major repairs. And just like your heavy equipment, other assets need care, too. You can learn more about our professional pressure washing in San Luis Obispo, CA and see how we help businesses maintain their property's value and appearance across the county.

Answering Common Questions About Maintenance Checklists

Even with the best plan on paper, questions always pop up when you start putting an equipment preventative maintenance checklist into action. Tackling these common concerns from the get-go is the best way to make sure your strategy is practical, effective, and actually gets used by your team. Here are a few of the most frequent questions we hear from businesses across San Luis Obispo County.

How Often Should I Actually Do Preventative Maintenance?

There's no single right answer here. The ideal frequency is a careful balance between the manufacturer's guidelines, the machine's age, and the real-world conditions it operates in. Always start with the operator’s manual—it gives you a solid baseline schedule based on service hours, like every 250, 500, or 1,000 hours.

But you can't stop there. You have to adapt that schedule to your reality. For instance, equipment baking in the dusty, hot conditions around Paso Robles is going to need more frequent filter changes than a machine working in the cooler, coastal air of Morro Bay.

The most effective approach is usually a tiered system. This means daily visual checks by the operators, more detailed weekly inspections, and the heavy-duty services performed right on schedule with the hour-meter.

What Are the Most Overlooked Checklist Items?

Everyone remembers to check the engine and hydraulics. It's the small, seemingly insignificant stuff that gets missed—and eventually causes massive headaches. Time and again, technicians find that these components are completely ignored until they fail.

Here are some of the usual suspects:

Battery Terminals: A little corrosion is all it takes to cause starting issues. Checking and cleaning them is a quick job that prevents a lot of frustration.

Safety Decals and Labels: Are they still readable? This is a critical safety and compliance check that often gets forgotten.

Backup Alarms and Lights: These are essential for job site safety, but it's easy to skip a function test when you're in a hurry.

Radiator and Cooler Fins: Clogged fins are a leading cause of overheating, especially in our demanding local environments. Blowing them out is non-negotiable.

Operator Cab Safety: This is more than just a clean cab. Are the windows clear for good visibility? Does the seatbelt work? Is the fire extinguisher charged and easy to grab?

Adding these specific points to your maintenance checklist makes it truly comprehensive.

How Do I Get My Crew to Actually Use the Checklists?

This is the big one. Without your team's buy-in, even the most perfect checklist is just a piece of paper. The secret is to make the process collaborative and dead simple.

First, get your operators and technicians involved in creating the checklists. They're the ones on the front lines, and their insights on what works (and what doesn't) are invaluable.

Next, make it easy. Use clear, simple language. Think about using digital checklist apps that work on a phone or tablet right at the machine. Most importantly, train your team on why these checks matter. When you can connect a quick inspection to better safety and less downtime, people are far more likely to get on board.

What’s the Difference Between Preventative and Predictive Maintenance?

People often use these terms interchangeably, but they’re two different approaches. Understanding the difference is key to leveling up your maintenance strategy.

Preventative Maintenance (PM) is all about the schedule. It's time-based or usage-based, meaning you perform a service at a set interval—like changing the engine oil every 500 hours, no matter what the oil actually looks like. It’s a proactive strategy designed to stop failures before they happen.

Predictive Maintenance (PdM), on the other hand, is condition-based. It uses technology like oil analysis, thermal imaging, or vibration sensors to monitor a component's real-time condition. With PdM, you only change the oil when the analysis shows it’s starting to break down.

For businesses here on the Central Coast, from Atascadero to Arroyo Grande, mastering a solid preventative maintenance program is the most important first step. It builds the discipline you need to explore more advanced strategies later on.

When your checklist uncovers an issue that goes beyond routine service, you need a partner you can trust. At Contractor's Maintenance Service, we provide expert diagnostics, major repairs, and custom hose fabrication to keep your fleet running at its best. Visit us online to learn how we can support your maintenance program.

Comments