Soap injector for pressure washers: A Practical Guide to Clean Results

- DLL Studios

- Dec 10, 2025

- 14 min read

Ever wonder how professional cleaners get surfaces so spotless? It’s not just about the raw power of the pressure washer. The real secret weapon is the soap injector. This simple but essential accessory is what transforms your machine from a powerful water hose into a legitimate, deep-cleaning tool.

It works using something called the Venturi effect. In simple terms, as high-pressure water flows through the injector, it creates a low-pressure zone that siphons soap from a container and mixes it into the water stream. The magic happens after the soap has passed through your pump—a method we call downstream injection. This is absolutely key to protecting your equipment.

Why a Soap Injector Is a Pressure Washing Game Changer

Let's be real: high-pressure water alone is great for blasting off loose dirt, but it’s not going to touch stubborn grime, oil, or organic stains. A soap injector for pressure washers is what bridges that gap. It elevates your machine from a rinsing tool to a true cleaning system.

This one accessory lets you apply powerful cleaning agents that chemically break down tough residues before you rinse them away. It's the difference between pushing dirt around and actually lifting it off the surface for a professional finish.

The Power of Downstream Injection

The biggest advantage of a quality injector is how it works. Professional-grade models use downstream injection, pulling soap into the water stream after it’s already gone through your high-pressure pump. This is a massive improvement over older, less common upstream models that fed chemicals right through the pump itself.

So, why is this such a big deal?

It Protects Your Pump: Harsh chemicals like degreasers and bleach are corrosive. They will eat away at the seals and pistons inside your pressure washer pump in no time. Downstreaming completely bypasses the pump, saving you from costly repairs and protecting your investment.

It’s Way More Efficient: If you're tackling a big job like washing a house in San Luis Obispo or cleaning a fleet of trucks in Paso Robles, applying soap with an injector is dramatically faster than messing with a separate pump sprayer.

You Get Consistent Results: The injector ensures a perfectly uniform mix of soap and water. This prevents the streaky, blotchy results you get from inconsistent manual application and stops you from wasting expensive chemicals.

For any serious pro or DIYer in our local areas like Atascadero and Arroyo Grande, a downstream soap injector isn’t a nice-to-have accessory—it's a foundational tool for getting the job done safely, efficiently, and with far better results.

It’s no surprise that the demand for these tools is growing right alongside the pressure washer market itself. Globally, the market is on track to hit USD 3.0 billion by 2032, which tells you that more and more people are figuring out the value of smart attachments. You can read more on this market growth to see where the industry is heading.

From Pismo Beach to Morro Bay, our clients know that the right tools make all the difference. When it comes to pressure washing, the soap injector is at the top of that list.

Choosing the Right Soap Injector for Your Machine

Picking the right soap injector for your pressure washer isn't just about finding one that fits. It's about matching the tool to the machine to get flawless, repeatable results every single time. A poorly matched injector is a recipe for frustration, causing everything from weak soap draw to a sudden, mysterious drop in pressure. Getting this right from the jump saves you time, money, and a whole lot of headaches on the job.

The entire pressure washer accessory market is built on this idea of customization and efficiency. Valued at around USD 345 million in 2021, this segment is booming because pros and homeowners alike know how much the right specialized tools matter. That growth, projected at a 5.8% CAGR according to insights from kbvresearch.com, shows just how critical a reliable soap injector for pressure washers is for upping your game.

Match GPM and PSI Ratings

First things first: you absolutely have to match the injector's specs to your pressure washer's output. Every injector is rated for a specific range of Gallons Per Minute (GPM) and Pounds per Square Inch (PSI). If your machine is a beast that pushes 4 GPM at 4000 PSI, you need an injector built to handle that exact flow and pressure.

Trying to run that powerful machine through an injector rated for a lower GPM will choke the water flow, forcing your pump to work overtime and risking serious damage. On the flip side, using an oversized injector on a smaller machine won't create enough vacuum to pull soap effectively. Always check your machine's specs and buy an injector that lists those numbers clearly within its operational range.

Fixed vs. Adjustable Injectors

Once you've nailed down the GPM and PSI, your next choice is between a fixed or an adjustable injector. Each has its place, and the right one for you really depends on the kind of work you do day in and day out.

Fixed Injectors: These are the simple, bulletproof workhorses of the industry. They're cost-effective and typically pull at a set draw rate, often somewhere between 10:1 to 20:1. This is perfect for bread-and-butter jobs like house washing or cleaning concrete where you just need a consistent, reliable soap mix.

Adjustable Injectors: These models give you control. With a simple knob or collar, you can dial in the precise chemical-to-water ratio you need. This is a must-have for more delicate work like wood restoration, where too much chemical can scorch the surface, or for switching between different cleaners without having to swap out your hardware.

For a clearer picture, let's break down where each type shines.

Injector Type Comparison for Common Cleaning Tasks

Feature | Fixed Injector | Adjustable Injector |

|---|---|---|

Best For | Routine, high-volume tasks (house washing, concrete) | Specialized jobs, delicate surfaces, multi-chemical use |

Draw Rate | Pre-set (e.g., 20:1), consistent and reliable | Variable, allows for fine-tuning on the fly |

Complexity | Simple, plug-and-play | Requires calibration for specific chemicals |

Cost | More economical | Higher initial investment |

Ideal User | Professionals focused on efficiency for standard jobs | Detail-oriented pros needing maximum versatility |

An adjustable injector really proves its worth when versatility is key.

Imagine you’re cleaning a delicate cedar fence in Atascadero that needs a gentle touch. Minutes later, you’re tackling a grimy, oil-stained driveway that requires a much stronger mix. An adjustable injector makes that transition seamless.

Ultimately, the choice comes down to the control and flexibility your jobs demand.

Materials and Connection Types

Finally, don't overlook the injector's build quality. Brass is the industry standard for a reason—it's tough, durable, and holds up well against corrosion from common cleaning chemicals. If you’re regularly running highly aggressive or acidic solutions, it might be worth investing in a stainless steel model for superior longevity, though they do come with a higher price tag.

You also need to double-check the connection types. Most professional-grade setups use 3/8" quick-connect fittings, which make it incredibly easy to snap the injector in place between the pump and the high-pressure hose. Make sure your new injector has the correct male and female fittings to avoid an unplanned trip to the hardware store.

While you're at it, upgrading your injector is a great time to give your whole system a once-over. To keep everything running smoothly, take a look at our selection of high-performance Graco pumps and parts.

How to Install and Set Up Your Injector Correctly

Forget those confusing diagrams and overly technical manuals. Getting your soap injector hooked up and running is actually pretty simple once you know the basics.

The number one rule, followed by pretty much every pro out there, is to place the injector downstream. That means it goes after your pump but before your high-pressure hose. This isn't just a suggestion—it's the only way to protect your pump from getting chewed up by harsh chemicals.

Physically connecting it is usually just a matter of snapping a few quick-connect fittings together. The injector plugs right into the outlet port on your pressure washer, and your main high-pressure hose connects to the other end. It's a solid, simple setup that takes less than a minute.

The All-Important Flow Arrow

Before you click anything into place, grab the injector and look closely at the metal body. You'll see a small arrow stamped into it. This little arrow is your most important guide—it tells you which way the water needs to flow.

If you hook it up backward, it just won't work. Simple as that. The guts of the injector, a tiny ball and spring, need the high-pressure water pushing in the right direction to create the suction that pulls the soap.

So, always make sure that arrow is pointing away from your pump and toward your spray gun.

Connecting and Submerging the Siphon Tube

Once the injector is facing the right way and connected, it's time for the siphon tube. Push the clear vinyl tube onto the small hose barb on the injector. Make sure it has a good, snug fit. Air leaks here are a super common reason why an injector won't draw soap.

Now, drop the weighted filter on the other end of the tube into your bucket of cleaning mix. You want that filter to be fully submerged and sitting flat on the bottom. That little screen keeps gunk from clogging up the injector, and the weight stops the hose from curling up and popping out of your bucket.

The Secret Weapon: The Black Soap Nozzle

Alright, this is the part that trips up almost every beginner. You can have everything else hooked up perfectly, but if you're using a standard high-pressure nozzle (like your white, green, or yellow tips), your injector won't pull a single drop of soap. This isn't a defect; it's how the system is designed to work.

To pull soap, the injector needs a significant drop in pressure. You create that pressure drop by switching to the low-pressure black soap nozzle. This special tip has a much larger hole, or orifice, which lets water rush through freely and causes the pressure inside the hose to plummet.

This pressure drop is what triggers the Venturi effect inside the injector. It creates a vacuum that literally siphons the soap up the tube and mixes it into the water stream. Switching to the black nozzle is like flipping the "on" switch for your injector.

If your injector isn't drawing soap, the very first thing to check is the nozzle on your wand. In 90% of cases, swapping to the black soap tip fixes the problem instantly.

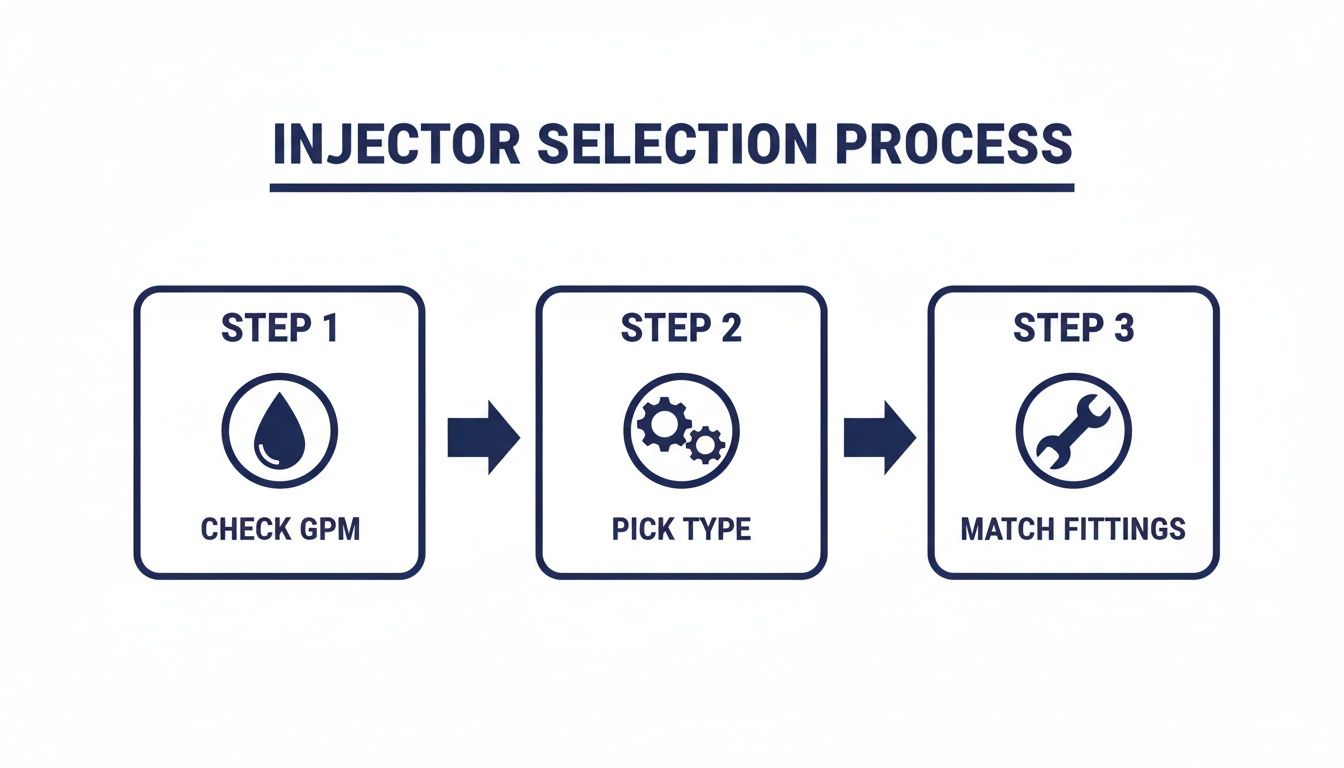

Before you even get to installation, though, picking the right injector is half the battle. This quick visual breaks down the process.

As you can see, matching your machine's GPM, choosing the right injector type, and making sure your fittings are compatible from the get-go are the real keys. Nail these steps first, and the actual hookup will be a breeze.

Calibrating Your Injector for the Perfect Mix

Getting your chemical-to-water ratio dialed in isn't just a suggestion—it's what separates a professional job from a costly mistake. A good soap injector for pressure washers gives you that control, but only if you know how to calibrate it for your specific machine.

Most injectors come stamped with a ratio like 10:1 or 20:1. That sounds simple, right? It means for every 10 or 20 gallons of water zipping through the hose, it should pull one gallon of chemical. But here's the catch: that's just a starting point. Your machine's actual GPM, the length of your hose, and even the thickness of your soap can throw that number way off.

Finding Your True Draw Rate

Don't just guess and hope for the best. You can nail down your injector's actual draw rate with a quick, hands-on test. All you need is a measuring cup and the timer on your phone. This simple process gives you the hard data you need to mix your solutions perfectly every single time.

Grab a measuring cup and fill it with exactly 16 ounces of water.

Stick your injector’s siphon tube right into the cup.

Fire up your pressure washer with the black soap nozzle attached. Start spraying and time how long it takes to suck the cup dry.

Let's say it took 30 seconds. That means your injector is drawing 32 ounces per minute.

Armed with that number, you can now calculate precisely how much chemical you’re laying down. If you're running a 4 GPM pressure washer and drawing 32 ounces (0.25 gallons) of soap per minute, you’re getting a final mix of 16:1 at the nozzle.

This simple test is the most important five minutes you can spend setting up your equipment. It moves you from hoping for the right mix to knowing you have it—a crucial step for any professional who needs consistent, repeatable results.

Adjusting Your Mix for Different Jobs

Once you know your injector's real-world draw rate, you can start customizing your chemical mix for specific jobs. After all, not every surface needs the same chemical strength.

For instance, a routine vinyl siding wash in San Luis Obispo might only need a gentle 1% solution hitting the wall. But tackling a grimy, neglected concrete driveway in Paso Robles could demand a much stronger 3-4% mix. You can hit these different strengths simply by adjusting the concentration of the chemical in your draw bucket.

The financial upside of a properly calibrated soap injector is huge, making it an essential tool for any small business owner. When you're just starting a pressure washing business, the initial investment for a quality setup can be around $3,000 to $4,000. Controlling your chemical usage with a calibrated injector is one of the fastest ways to slash your operational costs and boost your bottom line.

Troubleshooting Common Soap Injector Problems

It’s a moment every pressure washer operator dreads: you pull the trigger, and nothing happens. The soap just isn't flowing. A working soap injector for pressure washers is non-negotiable, and when it acts up, your job grinds to a halt.

Luckily, you can diagnose most injector issues in just a few minutes right on the job site. This isn't the time for a full teardown—it's about getting back to work.

Injector Not Drawing Soap

This is the big one. The engine's running, water is spraying, but the chemical level in your bucket isn't budging. Before you start thinking the injector is toast, walk through these quick checks. I've seen these simple things solve the problem 9 out of 10 times.

Nozzle Check: Are you using the low-pressure black soap nozzle? A high-pressure tip (white, green, yellow) won't create the pressure drop needed for the injector to pull chemical. It’s the most common oversight by far.

Siphon Tube Inspection: Give that clear vinyl tube a quick look. Even a tiny crack or split can introduce air and kill the suction. Make sure it's pushed on tight to the hose barb for an airtight seal.

Filter Clog: That little weighted filter at the end of the siphon tube loves to get clogged with gunk from the bottom of a soap bucket. Pull it out and give it a good rinse.

If you’ve tried all that and you're still getting nothing, the culprit might be internal. Dried soap residue can easily cause the small ball bearing and spring inside the injector to get stuck. Usually, a good soak in hot water is enough to free them up.

For other equipment headaches, our guide on troubleshooting pressure washer problems has a ton of other quick fixes to get you running again.

Injector Won't Stop Siphoning Soap

Just as frustrating is the opposite problem—you switch back to a high-pressure nozzle for rinsing, but the injector keeps trickling soap into the line. This is almost always a sign that the internal check valve is stuck open.

Inside your injector, a tiny ball and spring are supposed to block the siphon tube as soon as you switch back to high pressure. When they get gummed up with old soap or debris, the ball can't seat properly, and you get a continuous, weak soap draw.

The fix is usually pretty simple. Disconnect the injector and try flushing it with clean water from both ends. Sometimes a firm tap on a hard surface is all it takes to dislodge a stuck ball. If that doesn’t work, you'll need to disassemble it for a proper cleaning. This is why keeping your injector clean is the best preventive maintenance you can do.

Professional Pressure Washing in San Luis Obispo County

While grabbing your own soap injector for pressure washers and tackling a project yourself can feel incredibly satisfying, some jobs just demand a professional touch.

Think large-scale commercial buildings, stubborn, set-in stains, or delicate historic surfaces where one wrong move could cause permanent damage. In those situations, calling in an experienced crew isn't just easier—it's the smartest and safest choice. Our team rolls up with commercial-grade equipment, perfectly calibrated to deliver flawless results, whether we're cleaning a storefront in downtown San Luis Obispo or washing down heavy equipment at a Paso Robles vineyard.

We're proud to serve homeowners and businesses all over the Central Coast. Being local means we know firsthand the unique cleaning challenges our communities face, from coastal salt spray to inland dust and grime.

Our Service Areas

We provide expert cleaning solutions across SLO County and its surrounding communities. You'll find our team working in:

San Luis Obispo and the Edna Valley

North County cities, including Paso Robles, Atascadero, and Templeton

The Five Cities area: Arroyo Grande, Pismo Beach, Grover Beach, Nipomo, and Oceano

Coastal communities like Morro Bay, Los Osos, and Cambria

For other pros in the business, remember that top-notch cleaning is only half the battle. Using efficient job and cost tracking tools can make a huge difference in keeping your operations running smoothly.

If you're in the area and want a guaranteed, professional clean without lifting a finger, check out our trusted professional pressure washing in San Luis Obispo, CA services. Let us handle the tough stuff for you.

Got Questions About Soap Injectors? We Have Answers

Here in San Luis Obispo, we field a lot of questions about getting the most out of a soap injector for pressure washers. Let's clear up some of the most common ones with answers that come from years of hands-on experience.

Can I Use Just Any Soap with My Injector?

Definitely not. This is a mistake we see all the time. Using regular household soaps like dish soap is a fast track to problems. They're often way too thick to be drawn through the injector properly, and worse, they can damage the seals inside your pump or leave a nasty film on the surface you're trying to clean.

You absolutely need to use detergents formulated specifically for pressure washing. Always match the soap to the job—whether it's a dedicated house wash, a potent concrete cleaner, or a gentle deck wash.

My Soap Injector Just Stopped Working. What Gives?

Nine times out of ten, the culprit is a simple clog. It's the first thing you should check.

Start by looking at the small filter on the end of your chemical pickup tube. It doesn't take much debris to block it completely. If that looks clean, the issue is likely inside the injector itself. The small internal ball and spring mechanism can easily get gummed up with dried soap residue.

A quick soak in a bucket of hot water or carefully cleaning out the injector's internals with a small pick usually does the trick. Also, double-check that you're using the low-pressure black soap nozzle. High-pressure tips won't create the suction needed to pull soap.

What’s the Difference Between Upstream and Downstream Injectors?

This is a really important question for both safety and the longevity of your equipment. A downstream injector, which is the industry standard for a reason, pulls soap into the water stream after it has already passed through the pump. This is critical because it protects your pump's delicate internal components from corrosive chemicals.

An upstream injector, on the other hand, adds the soap before the pump. This should only ever be done with pumps specifically built to handle harsh chemicals. Using an upstream injector with a standard pressure washer pump will destroy it in short order. For any job you're tackling, from Paso Robles to Arroyo Grande, downstream is the only way to go.

Does the Length of My Hose Really Affect the Injector?

Yes, it has a massive impact on performance. Most standard, off-the-shelf injectors start to struggle once you go beyond 100-150 feet of hose.

The extra distance adds a ton of friction, which weakens the Venturi effect—the suction that pulls the chemical into the line. If you're on a job site in Atascadero and need to run a longer hose, you'll have to upgrade to a higher-quality injector specifically designed to handle the increased distance.

For no-nonsense advice and the high-performance parts you need—including the right soap injector for your pressure washer—you can always count on the team at Contractor's Maintenance Service. We're here to keep your gear running strong. Find your solution at https://www.contractorsmaintenanceservice.com.