Graco Airless Sprayer Comparison: graco airless sprayer comparison guide

- DLL Studios

- 4 days ago

- 17 min read

Picking the right Graco airless sprayer isn't just a purchase; it's a core business decision. The best machine for you is the one that's a perfect match for the kind of work you do day in and day out—whether that’s detailed fine-finish jobs or slinging heavy industrial coatings. This Graco airless sprayer comparison cuts through the noise and focuses on real-world performance to help you land on a rig that will actually make you more productive and profitable.

Choosing Your Next Graco Airless Sprayer

For a professional contractor, a sprayer is more than just a tool. It's the engine driving your business. Choosing the wrong one can stall projects, ruin your finish quality, and ultimately cost you money. This guide goes beyond the basic spec sheets to give you a straight-up comparison based on what you’ll actually face on the job site.

We’re going to zero in on the metrics that really matter to your bottom line. We’ll break down the key performance specs so you can make a smart choice that lines up with how you work.

Key Performance Metrics for Comparison

Getting a feel for how each Graco model stacks up in these areas is the first step toward a smart investment. You need to look at:

Pump Technology: This is the heart of the sprayer. It determines how tough the machine is and what kinds of materials it can handle without bogging down.

Flow Rate (GPM): Gallons Per Minute tells you how fast you can lay down material, which has a direct impact on how quickly you can wrap up a job.

Pressure (PSI): Maximum Pounds per Square Inch is all about the sprayer’s power to atomize thicker coatings and push paint through longer hose runs.

Tip Support: The max tip size a machine can support dictates the range of coatings you can spray effectively. A bigger tip means thicker material.

This comparison will frame our recommendations around real-world scenarios, making sure you get the right machine for the work you do. If you need a broader overview first, our guide to finding the best airless paint sprayer for contractors is a great place to start.

As the Central Coast's authorized Graco service center, we don't just help you choose the right sprayer—we provide the long-term support to protect that valuable investment.

Local Expertise You Can Trust

Working with a local expert gives you a huge advantage. Here at Contractor's Maintenance Service, we're proud to serve professional contractors throughout San Luis Obispo and all the surrounding communities. Our service area includes:

San Luis Obispo

Paso Robles

Atascadero

Templeton

Morro Bay

Arroyo Grande

Pismo Beach

Grover Beach

Nipomo

Santa Maria

When you partner with us, you get instant access to genuine parts, practical advice from technicians who know these machines inside and out, and way faster repair times to keep your downtime to a minimum.

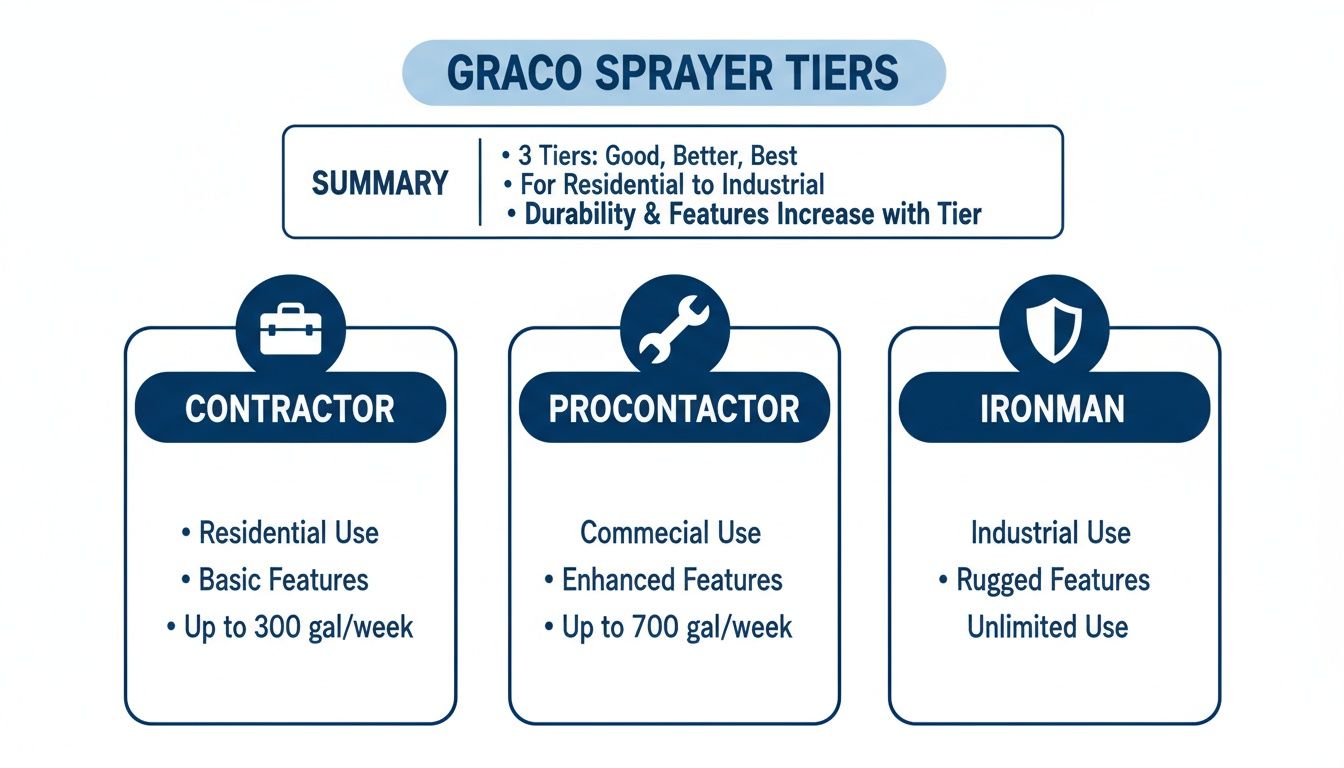

Breaking Down Graco's Sprayer Series

When you see Graco's series names—Contractor, ProContractor, and IronMan—don't just think of them as labels. They're a clear roadmap to the sprayer's durability, features, and the kind of work it's built for. Getting a handle on these tiers is the first step in making a smart investment, whether you're doing daily repaints or tackling massive industrial jobs. It's a key part of any solid Graco airless sprayer comparison.

Each series is engineered for a specific intensity and job site. You can think of it like this: are you buying a reliable work truck, a high-performance utility vehicle packed with tech, or an armored rig that can handle anything you throw at it? Choosing the right one means you won't overpay for features you'll never use or, worse, end up with a machine that can't keep up with your work.

For pros here in San Luis Obispo County, matching the sprayer to the job is everything. A contractor working on new construction out in Atascadero has totally different demands than someone doing delicate, fine-finish work on a historic home in Morro Bay.

Contractor Series: The Professional Standard

The Contractor series is the trusted workhorse of the Graco family. These are the machines you see on job sites day in and day out, built for professionals who need consistent, reliable performance without any fuss. They are the go-to choice for a huge number of residential and light commercial painters for a reason.

Built for durability and simple operation, the Contractor series skips the complex digital bells and whistles and focuses on core performance. This straightforward design makes them easier to use and maintain on the fly, offering a fantastic balance of power and value. They're the perfect fit for painters spraying standard architectural coatings like latex, enamels, and stains.

ProContractor Series: Advanced Features For High-Volume Work

When you step up to the ProContractor series, you're getting a suite of smart technologies aimed at maximizing efficiency and keeping you on the job. These models are built for high-volume painters who know that downtime is lost money.

The biggest upgrades you'll find in the ProContractor series are:

ProConnect System: This is a huge deal. It lets you swap out a worn pump right on the job site in just a few minutes, with no special tools. It basically eliminates pump failures as a reason to pack up for the day.

Digital Displays: These models feature SmartControl technology with a digital screen, giving you dead-on pressure control and helpful diagnostics. You can track gallons sprayed and get real-time status updates on your machine.

Enhanced Durability: You'll typically find more robust components, like long-lasting brushless motors that require less maintenance than their brushed counterparts.

The ProContractor series is for the serious professional whose entire business model relies on speed and reliability. Being able to change a pump in under a minute is a total game-changer for productivity.

IronMan Series: Built For The Harshest Environments

At the very top of the durability mountain sits the IronMan series. The name says it all—these sprayers are built to survive the most punishing and unforgiving job sites imaginable. They are the undisputed choice for heavy industrial work, infrastructure projects, and any environment where equipment gets abused.

IronMan models are loaded with components designed for maximum toughness. We're talking reinforced, heavy-duty frames that shield the engine and pump from hard impacts, flat-proof tires that roll over anything, and the most powerful motors Graco puts in a sprayer. When you're spraying thick coatings in a challenging environment, the IronMan series delivers unmatched resilience. It’s the top-tier choice for contractors handling large-scale agricultural or industrial coating projects from Santa Maria to Nipomo.

Graco Airless Sprayer Model Specifications

When you're doing a real Graco airless sprayer comparison, you have to look past the series names and get down to the hard numbers. The specs—Max GPM, Max PSI, and pump technology—are what really tell you how a machine is going to perform on the job site. These numbers dictate everything from how fast you can lay down paint to the kinds of materials you can even run through the pump.

This section gets into a side-by-side look at some of Graco's most popular professional models. We'll break down the nimble Ultra Max II 490, the workhorse 695, the high-production 1095, and a heavy-hitting gas-powered GH series sprayer. This is about matching a sprayer’s real-world capabilities to your daily grind, whether you're a painter in San Luis Obispo or a coatings contractor up in Santa Maria.

To get the lay of the land, it helps to know how Graco tiers its sprayers for different levels of professional use. Each series—Contractor, ProContractor, and IronMan—strikes a specific balance of features, durability, and price.

This chart is a great visual guide. It shows how Graco builds its lineup from the standard Contractor models, which are absolute workhorses, up to the feature-packed ProContractor and the nearly indestructible IronMan series. It helps you decide where your investment should land based on how hard you run your gear.

For a clearer picture, this matrix lines up the key specs of each model we're discussing. It's a quick way to see how they stack up against each other and align their performance with the kind of work you do most.

Graco Airless Sprayer Model Specification Matrix

Model | Max GPM | Max PSI | Max Tip Size | Motor Type | Pump Technology | Ideal Application |

|---|---|---|---|---|---|---|

Ultra Max II 490 | 0.54 | 3300 | .023" | Electric | Endurance Piston | Residential Repaints, Small Commercial |

Ultra Max II 695 | 0.95 | 3300 | .031" | Electric | MaxLife Endurance Piston | Commercial, New Construction, Light Texture |

Ultra Max II 1095 | 1.20 | 3300 | .035" | Electric | MaxLife Extreme-Duty | High-Production, Elastomerics, Multi-Gun |

GH Series (Gas) | 2.0+ | 3600-7250 | .047"+ | Gas (Honda) | Xtreme Piston | Industrial Coatings, Roofs, No Power Access |

This table cuts through the noise, giving you a straightforward look at what each machine is built for. As you can see, the jump in GPM and pump durability is what separates a residential rig from a high-production or industrial sprayer.

The Graco Ultra Max II 490: A Residential Powerhouse

The Graco Ultra Max II 490 is often the first serious sprayer a professional painter buys, and there's a good reason for that. It’s a huge leap in durability and features from the smaller, big-box store units. It's an electric sprayer that’s known for being both portable and dead reliable.

Max GPM (Gallons Per Minute): 0.54 GPM

Max PSI (Pounds per Square Inch): 3300 PSI

Pump Technology: Endurance Piston Pump with ProConnect

With a flow rate of 0.54 GPM, the 490 is dialed in for spraying standard architectural coatings like latex paints, primers, and stains. Its 3300 PSI gives you excellent atomization for getting those fine finishes on trim, doors, and walls. It’s a favorite for residential repaint specialists in communities like Arroyo Grande and Pismo Beach. The ProConnect system is also a lifesaver, letting you swap out the pump on-site in minutes to kill downtime.

The Graco Ultra Max II 695: The Commercial All-Rounder

When your jobs get bigger and you need more versatility, the Ultra Max II 695 is the rig you step up to. This model is a staple for commercial painters who need one machine that can handle a wider range of materials and larger-scale work.

The performance jump from the 490 is immediately noticeable. It can comfortably run larger tip sizes and longer hose lengths without a major pressure drop, making it perfect for multi-story commercial buildings or big new construction projects.

Max GPM: 0.95 GPM

Max PSI: 3300 PSI

Pump Technology: MaxLife Endurance Piston Pump

The 695 nearly doubles the flow rate of the 490, pushing 0.95 GPM. That boost in output is what makes you money on bigger projects. While the max pressure stays at 3300 PSI, the higher GPM means it can handle slightly thicker materials and sustain a bigger tip, turning it into a versatile workhorse for contractors in Atascadero and Paso Robles.

The Graco Ultra Max II 1095: High-Production Specialist

For high-volume residential and commercial work, the Ultra Max II 1095 brings some serious muscle. This machine is built for contractors who are regularly spraying heavier coatings or need to run two guns at once. This is the point where electric sprayers start encroaching on territory once held exclusively by gas rigs.

The real difference with the 1095 isn’t just raw power; it’s the ability to maintain that power all day long. Its beefy motor and pump can handle the strain of spraying thicker materials without overheating or bogging down.

This model is a game-changer when you're applying block fillers, elastomeric coatings, and other tough materials.

Max GPM: 1.2 GPM

Max PSI: 3300 PSI

Pump Technology: MaxLife Extreme-Duty Piston Pump

At 1.2 GPM, the 1095 can keep up with the fastest painters out there and easily support two guns to maximize efficiency. Its Extreme-Duty pump is built to take the abuse of abrasive coatings, giving it a longer service life and better reliability on tough jobs from Templeton to Grover Beach.

Choosing a brand with a strong foothold in the market is also a smart move. By the mid-2020s, Graco had become a dominant global player, often the one everyone else is measured against. Research shows Graco holds about 24% of the global unit market share in airless sprayers, cementing its top-tier status. This is happening in a market that's projected to grow from USD 1.31 billion in 2022 to USD 1.75 billion by 2028. For a pro, this matters. Market share usually means better parts availability and a stronger service network—critical for guys who can’t afford downtime and rely on shops like Contractor’s Maintenance Service. You can read the full research on airless sprayer trends to learn more about these market dynamics.

The Graco GH Series: Unmatched Gas-Powered Performance

When you're on a job site in the rural parts of San Luis Obispo County with no reliable power, or the job calls for spraying the heaviest materials around, a gas-powered rig like a Graco GH model is the only answer. These machines give you total freedom and incredible power.

Fitted with bulletproof Honda engines, the GH series is built for the most extreme applications. They’ll chew through everything from architectural coatings to industrial-grade epoxies, roof coatings, and mastics without breaking a sweat.

Max GPM: Ranges from 2.0 to 4.0+ GPM (depending on model)

Max PSI: Ranges from 3600 to 7250 PSI

Pump Technology: Xtreme Piston Pump with ProConnect

The raw power of these units is their biggest selling point. With flow rates starting at 2.0 GPM and pressure that can top 7000 PSI, they are made for the most demanding industrial and infrastructure jobs. For any contractor in Morro Bay or Nipomo tackling large-scale projects, the GH series delivers performance that electric models just can't touch.

Matching Sprayers to Real-World Applications

A spec sheet gives you the "what," but the job site tells you the "why." Moving beyond a simple Graco airless sprayer comparison, let's talk about how these machines solve actual problems for professional contractors. Making the right choice is about more than just numbers; it's about matching the tool to the task to protect your bottom line.

For pros working everywhere from the coastal homes in Morro Bay to the big agricultural properties out in Paso Robles, the right sprayer makes all the difference. Here are three common scenarios we see every day, and the Graco models that are perfect for each job.

The Residential Repaint Specialist

This is the painter who’s in and out of people’s homes every day, tackling everything from single-room touch-ups to full exterior repaints. Their job is all about working cleanly in furnished spaces, moving efficiently, and leaving behind a finish that gets people talking. For them, portability and precision are everything.

The go-to sprayer for this work is the Graco Ultra 395 PC or the Ultra Max II 490 PC.

Portability: These rigs are light and compact. That means they’re easy to haul up a flight of stairs, navigate around furniture, and load into the van at the end of the day. That kind of agility is a must when you're working in occupied homes in neighborhoods like Arroyo Grande or Pismo Beach.

Fine Finish Capability: They have more than enough power to properly atomize your standard architectural coatings—latex paints, enamels, you name it. The result is a smooth, even coat on walls, ceilings, and trim.

Quiet Operation: Being electric, they're worlds quieter than gas models. That keeps the noise down for the homeowners, which is a huge part of maintaining a professional reputation.

The key for a residential specialist is finesse over brute force. The Ultra 395 and 490 give you the precise pressure control you need to minimize overspray indoors and get that perfect finish without blowing through material.

The Commercial Property Manager

Versatility is the name of the game here. One day you might be spraying hundreds of apartment walls with latex in San Luis Obispo, and the next you’re putting a thick elastomeric coating on a commercial building in Santa Maria. You need one machine that won't back down from either job.

For this kind of work, you step up to the Graco Ultra Max II 695 or 795.

These models are a serious upgrade in both power and durability. The higher flow rate on the 695 (0.95 GPM) means it can support larger tip sizes and longer hoses, which is crucial for tackling big projects and multi-story buildings without constantly moving the rig. It can handle a much wider range of materials, from thin interior paints to heavy exterior coatings, without putting a strain on the pump. Of course, with more power comes the need for more knowledge—choosing the right tip size for airless sprayer finishes becomes critical with these bigger machines.

The Industrial Coatings Contractor

This is the pro working in the toughest environments. They're applying heavy-duty, protective coatings that demand extreme pressure and serious volume. Their job sites—industrial plants, agricultural facilities, or major infrastructure projects—often don't have a reliable power source.

For these jobs, a gas-powered beast like the Graco GH 5040 is the only real answer.

Immense Power: With a burly Honda engine, these sprayers generate the raw pressure needed to atomize the thickest materials out there—epoxies, roof coatings, and block fillers.

Total Autonomy: Because they're gas-powered, you aren't tethered to a power cord. This gives you complete freedom on remote or undeveloped job sites from Templeton to Nipomo.

High-Volume Output: Pushing a flow rate that often tops 2.0 GPM, these machines are built for pure production. They can run multiple guns or hundreds of feet of hose to cover huge surfaces in a hurry.

The decision to go with a GH series sprayer comes down to the material and the location. When the coating is thick and the power is scarce, no electric sprayer can touch the performance of a gas rig. As you can see, a meaningful Graco airless sprayer comparison has to go beyond the spec sheet and get into the reality of the work you do every day.

Keeping Your Graco Running: Uptime, Service, And Repairs

A professional Graco sprayer is a serious piece of equipment, and its real value isn't just in how well it lays down paint—it's in its uptime. When your rig is down for repairs, you're not making money. Simple as that. That's why any smart Graco airless sprayer comparison has to look past the sticker price and consider the total cost of ownership, where good maintenance and reliable service are everything.

More often than not, it’s the small, replaceable wear parts that lead to major downtime. Staying on top of routine maintenance is the absolute best way to keep a minor issue from turning into a catastrophic failure that benches your whole operation.

Know Your Wear Parts, Master Your Maintenance

Getting familiar with the lifecycle of your sprayer’s key components is the first step to keeping it running job after job. A few minutes of routine checks and simple parts swaps can save you from expensive, time-sucking repairs later.

Keep a close eye on these parts:

Spray Tips: A blown-out tip doesn't just create an ugly, uneven spray pattern; it wastes a ton of paint and makes your pump work way harder than it should. The moment you see "tailing," it's time for a new one.

Packings: These seals are the heart and soul of your fluid section. Once they start to wear, you'll lose pressure, and eventually, the pump will give out.

Filters: When your manifold and gun filters get clogged, material flow gets choked off, putting a massive strain on your motor and pump. Cleaning and replacing them regularly isn't optional—it's essential.

Good maintenance doesn't just prevent breakdowns; it guarantees you're putting down a quality finish every single time. For a full breakdown of the process, check out our guide on how to clean an airless paint sprayer like a pro contractor.

Your Authorized Graco Service Partner On The Central Coast

When a real problem pops up, you need a partner who knows these machines inside and out and can get you back on the job fast. As the authorized Graco service and warranty center for San Luis Obispo and the surrounding areas, we've got the diagnostic tools, genuine parts, and expert repair skills your investment deserves. Our years of hands-on experience with Graco systems mean we can pinpoint problems quickly, saving you both time and money.

We’re proud to be the go-to service center for professional contractors all over the Central Coast, including:

San Luis Obispo

Paso Robles

Atascadero

Templeton

Morro Bay

Arroyo Grande

Pismo Beach

Grover Beach

Nipomo

Santa Maria

There’s a huge advantage to having a local, factory-authorized service center. It means faster repair turnarounds, immediate access to the right parts, and practical advice from guys who actually work on this equipment—something you just can't get from a website.

The Growing Importance Of Parts And Accessories

These days, any solid Graco airless sprayer comparison has to factor in the total cost of ownership, which is heavily tied to how easy it is to get parts and accessories. The global market for airless sprayer accessories is projected to jump from USD 908.3 million in 2025 to a massive USD 1,611.3 million by 2035.

That kind of growth tells you one thing: a sprayer platform with strong aftermarket support is a much better long-term investment than a cheaper machine that’s a nightmare to service. For a deeper dive into this market trend, you can discover more insights about the airless accessories market.

Your Local Graco Support On The Central Coast

Picking out the right Graco sprayer is a great start, but it's only half the battle. To really protect your investment and keep your jobs running smoothly, you need a local partner who knows these machines inside and out. That's where we come in. Contractor's Maintenance Service is the go-to Graco authority in San Luis Obispo, serving professional contractors up and down the Central Coast.

When your equipment is your livelihood, you can't afford to mess around with long shipping times for parts or waste hours on the phone with a support line that's never actually seen your sprayer. Working with a local expert means you get immediate access to a full stock of genuine Graco parts, right here in SLO.

Full Service For The Central Coast

Our shop might be in San Luis Obispo, but our service area covers the entire region. We're the trusted service and repair center for pros working in communities all over the Central Coast.

Our dedicated service area includes:

San Luis Obispo

Paso Robles

Atascadero

Templeton

Morro Bay

Arroyo Grande

Pismo Beach

Grover Beach

Nipomo

Santa Maria

Having us nearby means that whether you're on a job in North County or down in the Five Cities, expert help is just a short drive away.

Choosing a local, authorized dealer gives you more than just convenience. It’s peace of mind. You get hands-on advice from technicians with real-world experience and faster repair turnarounds, which means less downtime for you.

We encourage local contractors to swing by our shop. Let's talk about the kinds of jobs you're running and take a look at our inventory firsthand. Our team can give you practical advice on choosing the right sprayer, the best accessories, and a maintenance plan that makes sense for you. Come see for yourself why we're the top partner for professional painting and industrial equipment support throughout San Luis Obispo County. Your uptime is our business.

Frequently Asked Questions About Graco Sprayers

When you're comparing Graco airless sprayers, a few key questions always seem to pop up. Let's tackle some of the most common ones we hear from contractors to clear things up so you can choose your gear and get to work.

What's The Difference Between a Piston Pump and a Diaphragm Pump?

All of Graco’s professional-grade airless sprayers are built with piston pumps, and for good reason—they're the industry standard when it comes to power and durability. They muscle through thicker materials at high pressure, which is exactly what a pro needs on the job. A huge plus is that they’re designed to be serviced, with replaceable parts like packings that keep the machine running for years.

Diaphragm pumps, which you might find in other brands or lower-end models, just can't keep up. They typically run at lower pressures and struggle with heavy-bodied coatings. They're also a headache to service in the field. For any serious contractor in San Luis Obispo and nearby areas, Graco's piston pump is the only way to go for true reliability.

How Do I Know When To Replace My Sprayer Tip?

A worn-out sprayer tip is a silent profit killer. It wastes paint, slows you down, and destroys the quality of your finish. The biggest giveaway is a failing spray pattern. A fresh tip gives you a crisp, clean fan of material with defined edges.

Once a tip starts to wear, the pattern gets rounded and you'll see heavy bands of paint on the edges—a classic sign of "tailing." This forces you to overlap more, lay down too much material, and deal with a ton of overspray. Tip life varies based on what you're spraying (latex is way more abrasive than stain), but you should swap it out the second you see the pattern degrade. Keeping your pressure at the lowest functional setting for the job will also help your tips last much longer.

A worn tip can easily double your paint usage on a big job. Swapping out a small, inexpensive part is a no-brainer to protect your bottom line and your reputation.

Can I Use a Longer Hose On My Graco Sprayer?

You can, but you have to know your machine’s limits. Every Graco sprayer has a maximum supported hose length, and ignoring it is asking for trouble. Exceeding that length causes a serious pressure drop from the pump to the gun, which means poor atomization and a blotchy, unprofessional finish.

Even worse, it puts a massive strain on the sprayer's motor and pump, leading to burnout and premature failure. Before you hook up another section of hose for a job in Atascadero or Paso Robles, crack open the manual or give our team a call. For jobs that require long runs, you absolutely need a sprayer with enough guts—like a Graco Ultra Max II 695 or bigger—to push paint that far and still maintain perfect pressure at the gun.

For expert advice tailored to your specific needs, or for fast, reliable service on your existing equipment, trust the professionals at Contractor's Maintenance Service. We keep contractors on the Central Coast working. Find the parts and support you need at https://www.contractorsmaintenanceservice.com.

Comments