Finding the Best Airless Paint Sprayer for Contractors

- Dec 20, 2025

- 16 min read

Picking the right airless paint sprayer isn't about finding a single “best” model—it’s about matching the machine to the work you do every day. For a pro contractor, the right rig is the difference between a profitable job and a frustrating one, directly impacting your speed, finish quality, and bottom line.

The best airless paint sprayer for a residential repaint specialist is a world away from what a commercial contractor needs for a massive new construction project.

Finding the Right Airless Sprayer for Your Business

Think of your paint sprayer like you would any other mission-critical piece of equipment. It’s not just a tool; it's the engine of your painting operation. You wouldn't use a half-ton pickup to haul a 10,000-pound excavator, and the same logic applies here. The world of airless sprayers is divided into different classes, each built for a specific scale and type of work.

Choosing the wrong machine will cost you time and money, plain and simple. A sprayer that's too small for the job will constantly clog and struggle to atomize thicker coatings, leaving you with a subpar finish and a ticked-off client. Go too big, and you're just wasting material. Using a high-production monster for intricate trim work means massive overspray and throwing dollars in the trash. Getting this right from the start is non-negotiable.

If you’re focused on smaller, high-detail jobs, our professional painter’s guide to portable airless sprayers is a great place to dig into compact but mighty options.

Your Local Central Coast Partner

As a professional painter, downtime is the enemy. When a machine goes down, the whole job grinds to a halt. That’s why having a local partner you can count on for sales, service, and parts isn’t a luxury—it’s essential to keeping your business profitable. We’re proud to be that partner for painting and construction pros across the Central Coast.

We’ve got the expert advice and deep inventory of sprayers, parts, and accessories to keep you running, whether you're in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach & Pismo Beach

Morro Bay

Santa Maria

Or any of the surrounding towns

This guide is designed to cut through the noise and give you the practical knowledge you need. We'll start with a quick look at the main sprayer categories to help you zero in on the right class of machine for your business. From there, we’ll get into the nitty-gritty of technical specs, job-specific setups, and the must-have accessories that separate the pros from the amateurs.

Choosing a sprayer is an investment in your productivity. The goal is to find the machine that provides the best return by perfectly aligning with the demands of your typical projects, ensuring speed, quality, and reliability every time you pull the trigger.

How to Decode GPM, PSI, and Tip Size

When you’re ready to step up to a professional airless sprayer, it’s time to look past the brand name and get into the specs. At first glance, numbers like GPM, PSI, and tip sizes can feel like a foreign language. But these three specs are the most critical clues to a sprayer's real-world performance—they tell you exactly what that machine can do on the job site.

Think of these numbers as the vital signs of your sprayer. Once you understand them, you can match the rig's capabilities to the material you're spraying and the finish quality you need. Getting this right is the secret to flawless results, maximum efficiency, and avoiding those frustrating clogs that bring a whole job to a dead stop.

GPM: The Engine of Your Sprayer

Gallons Per Minute (GPM) is probably the single most important number to look at when you’re choosing an airless sprayer. It’s a simple measurement of how much fluid the pump can move in one minute. A higher GPM is just like having a bigger engine in your truck; it gives you more raw power and capability.

That power translates directly to two things: speed and the ability to handle thicker materials. A sprayer with a high GPM can support a larger spray tip, letting you lay down a wider, heavier coat of paint much faster. For big commercial jobs—think tilt-up warehouses or multi-family exteriors—a high GPM is non-negotiable if you want to be productive.

Thicker coatings like block fillers, elastomeric paints, and certain industrial primers also need more muscle to get them through the pump and hose. A small machine with a low GPM (like 0.3 GPM) will struggle or just quit, while a high-production unit (1.0 GPM or more) will push that mud without breaking a sweat.

PSI: The Key to a Flawless Finish

If GPM is the sprayer's horsepower, then Pounds per Square Inch (PSI) is its atomization power. This number tells you the maximum pressure the sprayer can build up to force paint through the tip. It’s this pressure that shatters the solid stream of paint into a fine, controllable mist—a process we call atomization.

Higher PSI is essential for getting a glass-smooth finish, especially with thinner materials or on fine-finish work like cabinets, trim, and doors. The incredible pressure (often up to 3,300 PSI) creates tiny paint droplets that land more evenly on the surface and level out beautifully.

For contractors working in San Luis Obispo and surrounding areas like Atascadero or Arroyo Grande, residential repaints demand top-tier finishes. Having a sprayer with enough PSI is a must. Without enough pressure, your paint won't atomize correctly, and you’ll get an uneven pattern with "tails" or "fingers"—those ugly streaks of heavy paint on the edges of your fan that can ruin a job.

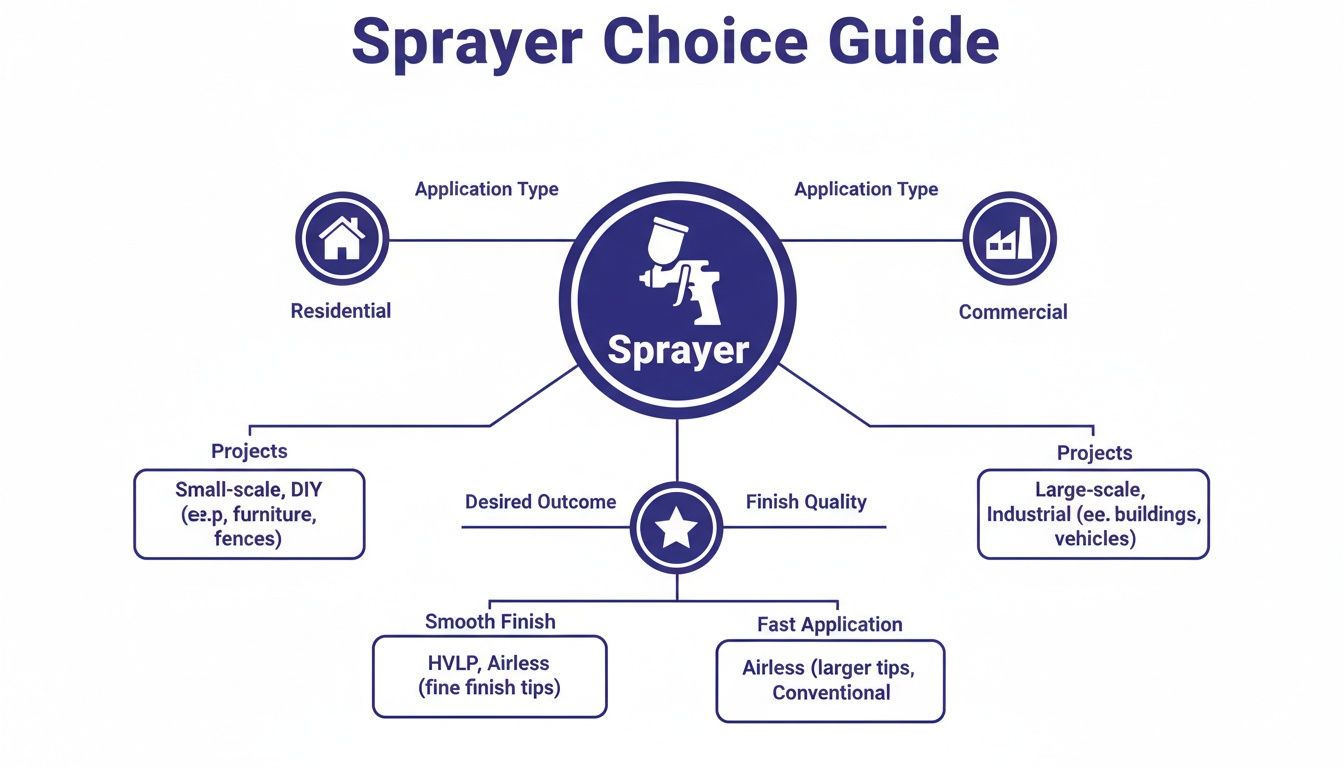

This concept map helps you see how different sprayer specs line up with residential, commercial, and fine-finish work.

As you can see, the path to the right sprayer starts with knowing your primary type of work and what you want the final product to look like.

Tip Size: The Final Piece of the Puzzle

The spray tip is where all that power from your pump finally goes to work. It controls two things: the fan width of your spray pattern and how much material flows through it. Tip sizes are represented by a three-digit number, like a 517.

The First Digit (5): Multiply this number by two, and you get the fan width in inches when you’re spraying about 12 inches from the wall. So, a '5' gives you a 10-inch fan.

The Last Two Digits (17): This is the size of the hole, or orifice, in thousandths of an inch (.017"). This number determines how much paint flows out. Thicker paints need a bigger orifice.

Key Takeaway: You have to match the tip size to your sprayer's max GPM rating and the paint manufacturer's recommendation for the material you're spraying. Slap a tip on that's too big for your rig, and your pressure will drop, leaving you with a lousy spray pattern.

For a deeper dive, check out our complete guide on choosing the right tip size for airless sprayer finishes. Nailing this relationship is fundamental to mastering your equipment.

Ultimately, GPM, PSI, and tip size have to work together in a delicate balance. A high GPM sprayer gives you the potential to crush big jobs, but you need enough PSI to atomize the material cleanly and the right tip size to control the flow and pattern. Dialing in this combination for each specific job is what separates the pros from everyone else.

Matching Your Sprayer to the Contracting Job

Knowing the specs of an airless sprayer is one thing, but putting that knowledge to work on the job site is where it really counts. The truth is, the best airless paint sprayer isn't a specific model—it’s the one that’s a perfect match for the kind of work you do day in and day out. A sprayer that’s a star on a residential repaint could easily get bogged down on a massive commercial project, and the reverse is just as true.

Picking the right rig means connecting its features—GPM, pump design, even its frame—to the realities of your daily grind. Let’s break down the ideal setups for different contracting jobs, so you can invest in a machine that actually makes you more productive and delivers the finish your clients expect.

To make things even simpler, here's a quick reference table matching sprayer specs to common jobs. It's a great starting point for narrowing down your options.

Recommended Sprayer Specs by Job Type

Contracting Job | Recommended GPM | Recommended Max Tip Size | Key Feature Focus |

|---|---|---|---|

Residential Repaint | 0.5 – 0.75 GPM | .023” | Portability, consistent pressure, easy cleanup |

Commercial & Industrial | 1.0 – 2.0+ GPM | .035”+ | High output, durability, gas engine option |

Fine-Finish & Cabinets | 0.3 – 0.5 GPM | .012” | Precise pressure control, FFLP tip support, hopper |

Property Management | 0.5 – 0.9 GPM | .027” | Versatility, durability, easy transport |

This table gives you a solid baseline. Now, let’s dig a little deeper into what these recommendations mean in the real world.

For the Residential Repaint Specialist

Residential work is all about being versatile and mobile. One day you’re spraying an exterior in Paso Robles, the next you’re inside an occupied home in Arroyo Grande doing walls and ceilings. Your sprayer has to be a jack-of-all-trades: light enough for one person to haul around but powerful enough for common architectural coatings.

For this kind of work, a mid-range electric sprayer usually hits the sweet spot.

Portability: You absolutely need a unit on a wheeled cart or a compact stand. It makes navigating through homes and up stairs so much easier.

Consistent Pressure: Look for a quality pump with electronic pressure control. This will give you a smooth, uniform finish on walls without needing to constantly fiddle with the settings.

Moderate GPM: A rig in the 0.5 to 0.75 GPM range is perfect. It can handle most latex paints and stains and will support a tip up to .023”, which is ideal for getting great coverage on walls efficiently.

A sprayer in this category gives you the perfect balance. It’s tough enough for a demanding schedule but nimble enough that it won’t be a headache on residential sites where space is often tight.

The demand for this kind of equipment is booming. The global electric airless paint sprayer market was valued at around USD 2.5 billion in 2025. The cordless segment is growing even faster, showing just how much pros value portable solutions for residential and light commercial jobs.

For the Commercial and Industrial Painter

When you move into commercial and industrial jobs, the rules change completely. On these sites, production is king. You’re dealing with massive surfaces, heavy-duty coatings, and schedules that leave no room for error. Your sprayer isn't just a tool—it’s a workhorse that has to run all day, every day, without quitting.

These jobs call for high-GPM machines, often gas-powered because you can't always count on having electricity on site. The whole point is to move as much material as you can, as fast as you can. The right sprayer for a commercial pro can run multiple guns and handle thick coatings like block fillers and elastomerics without needing to be thinned.

High GPM Output: You should be looking for sprayers with at least 1.0 GPM, and for big jobs, rigs that push 2.0 GPM or more. This lets you run multiple spray guns or use massive tip sizes (.035” and up).

Durable Pump Design: A tough piston pump with long-life packings is non-negotiable for handling abrasive industrial coatings.

Robust Frame: The rig needs a heavy-duty steel frame that can take a beating on a chaotic construction site.

It's also crucial to think about the entire work environment. For specialized jobs in enclosed spaces, you might need additional gear like safe compressed air lifts for paint rooms and dangerous areas to keep things running safely and efficiently.

For the Fine-Finish and Cabinet Specialist

If you’re doing fine-finish work, precision is everything. Whether it’s cabinets, trim, or custom built-ins, your goal is a flawless, glass-smooth surface. For this kind of specialty, the best sprayer is one that gives you absolute control over atomization.

Fine-finish sprayers are built to work at lower pressures while still perfectly atomizing thinner materials like lacquers and urethanes. They’re often used with special Fine Finish Low Pressure (FFLP) tips to get that signature look.

Precise Pressure Control: Being able to dial the PSI way down without losing a consistent fan pattern is critical. This is how you minimize overspray and get a perfect finish.

Smaller Tip Support: The machine has to be able to run small orifice tips (think .008” to .012”) for detailed work.

Hopper Feed System: For spraying small amounts of expensive finishing materials, a small hopper is way better than a standard suction tube. It reduces waste and makes cleanup faster.

These specialized rigs make sure every drop of material is turned into a fine mist, giving you a factory-quality finish that you could never get with a brush or roller. For contractors in places like San Luis Obispo or Atascadero who specialize in high-end custom projects, having a dedicated fine-finish sprayer is a very smart move.

Essential Sprayer Accessories and Consumables

A powerful sprayer is a great start, but it's only half the battle. Even the best airless paint sprayer is just a hunk of metal without the right gear to back it up. Don't think of accessories and consumables as extra costs—they're mission-critical investments that directly boost your speed, finish quality, and daily profits.

The numbers don't lie. The global market for airless sprayer accessories is on track to grow from USD 908.3 million in 2025 to over USD 1.6 billion by 2035. With the construction industry making up nearly 40% of that spending, it's clear these components are what separate the pros from the amateurs.

Decoding the Spray Tip

The spray tip is the single most important part you'll ever buy for your rig. It's where the magic happens—where paint atomizes into a perfect fan. It controls everything from the width of your spray pattern to how much material you're putting down. Getting this right is non-negotiable.

Just as a quick refresher, a tip number like "517" gives you two critical pieces of info:

The "5" tells you the fan width is 10 inches (you just multiply that first digit by two).

The "17" refers to the orifice size, which is .017".

Always match the tip to the material you’re spraying and your pump’s maximum GPM rating. Throwing on the wrong tip is a recipe for disaster. You'll get poor atomization, waste a ton of paint, and end up with a finish that could get you kicked off a job site.

The Impact of Hoses and Filters

Your paint hose is more than just a tube connecting your pump to your gun. Its length and diameter are huge factors in how much pressure actually makes it to the tip. A longer or thinner hose introduces more friction, causing a pressure drop that can starve your gun. For big jobs where you're stretching out, make sure your hose is sized correctly to keep that pressure consistent.

A clean, well-maintained filter system is your best defense against clogs and downtime. Proper filtration—from straining the paint before it enters the machine to using the correct manifold and gun filters—is non-negotiable for professional results.

Filters are the unsung heroes of every professional setup. Nothing stops a job dead in its tracks faster than a clogged tip. By using the right mesh size for your manifold and gun filters, you stop junk from ever reaching the tip in the first place. That saves you hours of headaches and cleanup. For a deeper dive into getting this right, check out our ultimate guide to the perfect paint sprayer hose.

Must-Have Job Site Accessories

Beyond the basics, a few key accessories can completely change your workflow and save your back. These tools are all about working smarter, not harder.

Tip Extensions: These rigid poles, ranging from 6 inches to 6 feet, let you hit tall ceilings, soffits, and high walls without climbing a ladder. It's a massive time-saver and a huge safety improvement.

Pressure Rollers: If a job requires back-rolling, this is your new best friend. It feeds paint directly to a roller cover from the sprayer, so you never have to bend over and dip a roller in a tray again. You can work up to four times faster.

Gun Swivels: It’s a simple little piece of hardware, but it makes a world of difference. A swivel lets your hose rotate freely at the gun, which stops it from kinking up and takes a ton of strain off your wrist during those long days of spraying.

And of course, don’t forget the most important accessory: you. Staying safe on the job is paramount, so always be familiar with the latest Australian Personal Protective Equipment (PPE) requirements to ensure you're using the right masks, gloves, and eye protection. Investing in the right gear makes your sprayer more capable and your business more profitable.

Local Sprayer Service and Support on the Central Coast

Picking the right airless paint sprayer is about more than just comparing GPM and PSI—it’s an investment in a tool that’s supposed to keep your business running and making money. For any professional contractor, downtime is the enemy. It's a direct line to lost revenue and blown project deadlines.

That’s why having a reliable local partner for service and support isn't just a nice-to-have; it's a core part of your business strategy. When your main rig goes down on a job site, you can't afford to wait for parts to ship from halfway across the country. You need someone who gets the urgency and has what it takes to get you back to spraying, fast.

Your Partner on the Central Coast

This is where local expertise really pays off, giving you a safety net that protects your bottom line. We’re here to provide that essential support for painting pros all over the Central Coast. Our entire focus is on keeping your operation running smoothly with a full range of services built for the working contractor.

We’re proud to serve contractors in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach & Pismo Beach

Morro Bay

Santa Maria

And all surrounding communities

Our support doesn't stop once you've made a purchase. We're here for expert advice to make sure you get the right machine in the first place, on-site troubleshooting when things go wrong, and hassle-free warranty processing. With a fully stocked shop of essential parts and consumables, you can get exactly what you need, right when you need it.

The Value of Local Expertise

When you partner with a local dealer, you get an accessible team that knows the specific challenges of working in this region. The demand for professional-grade equipment here is no joke. Industry analysis projects the global airless paint sprayer market to hit roughly USD 1.19 billion by 2025, and North America makes up about 32.2% of that.

That’s a market valued at over USD 382 million, driven by professional contractors who rely on dependable, high-performance tools to make a living. You can dig deeper into these trends in this detailed report on airless paint sprayer revenue.

For a contractor, time is money. A local service center that can diagnose a problem, hand you the right part, and offer solid advice in a single visit is an invaluable asset. It directly boosts your efficiency and profitability.

Ultimately, buying the best airless sprayer is also an investment in the support system behind it. By working with a dedicated local provider, you’re ensuring your equipment stays a productive asset, not a potential liability. It’s your assurance that you’ve got the backup you need, exactly when you need it, keeping your projects on schedule and your business moving forward.

Got Questions About Your Airless Sprayer? We've Got Answers.

No matter how long you've been in the game, questions are going to pop up on the job site. When your sprayer acts up or you're not sure about a maintenance schedule, getting a straight answer fast can save you a ton of time, money, and headaches. Here are some of the most common questions we get from painting contractors here in San Luis Obispo and all over the Central Coast.

Think of this as your field guide for keeping your machine dialed in. Getting these details right means your sprayer will run like a top for years, giving you that perfect finish your clients expect, every single time.

How Often Should I Repack My Pump?

This is the big one, and the honest answer is: it depends. There’s no magic number on the calendar, but your sprayer will tell you when it’s time. How you use it and what you're spraying through it are the biggest factors.

As a rough guideline, a pro using their rig daily with standard latex paints will likely need a repack every 3 to 6 months. If you prefer to track by volume, a good benchmark is to schedule a service after every 400-500 gallons. But forget the numbers for a second—the real signal is a drop in performance.

Keep an eye out for these tell-tale signs:

Pressure Drop: If your sprayer just can't seem to hold its PSI like it used to, the packings are probably shot.

Leaks: See any paint or fluid dripping from the wet end? That’s a dead giveaway the seals are gone.

A "Fluttering" Fan: If your spray pattern is inconsistent and you've already tried a new tip and adjusted the pressure, the problem is likely deeper inside the pump.

Your owner's manual will have the manufacturer's official recommendation, but let the machine's performance be your guide. Trust me, proactive maintenance is always cheaper than a breakdown mid-job.

Can I Really Use One Sprayer for Everything?

It’s the dream, right? One sprayer that can blast a commercial exterior and then lay down a glass-smooth finish on trim. The short answer is yes, but there's a catch. For a sprayer to be a true do-it-all machine, it needs one crucial feature: excellent, fine-tunable pressure control.

This is what lets you adapt the sprayer to completely different jobs.

For Siding and Exteriors: You’ll crank the pressure way up, throw on a big tip (like a .017” to .021”), and just fly.

For Trim and Doors: You’ll do the exact opposite. Dial the pressure way down and switch to a small Fine Finish Low Pressure (FFLP) tip (think a .010” or .012”). This gives you a beautifully atomized spray with minimal overspray—perfect for that buttery smooth finish.

While one versatile sprayer can definitely get the job done, most high-volume contractors eventually add a second, specialized unit to their fleet. Having a dedicated fine-finish rig and a separate production workhorse means no more switching things around and guarantees you have the absolute best airless paint sprayer for the task at hand.

What's the Number One Cause of Clogs?

Nine times out of ten, the culprit behind a frustrating clog is simple: skipping the filter. It’s so tempting to pour and go when you're in a hurry, but that's a mistake. Taking an extra minute to strain your paint will save you from an hour of troubleshooting on a ladder.

Pro Tip: Never, ever assume paint is clean right out of the can. Even a brand-new bucket can have little factory gunk or dried bits floating around. Straining every single gallon is the best insurance policy you can have against clogs.

Proper filtering is a two-step process. First, always pour your paint through a mesh strainer bag into your bucket. That’s your first line of defense. Second, make sure the filters in your machine and your gun are clean and are the right mesh size. A 60-mesh filter is your go-to for latex paints, but for thinner stuff like stains or lacquers, you’ll want to switch to a finer 100-mesh filter.

Gas or Electric: Which Sprayer Is Better for My Business?

The gas vs. electric debate comes down to one thing: where you do most of your work. Each has clear advantages for different job sites, which is why you'll see plenty of established painters in Paso Robles and Atascadero with both in their trucks.

Electric Sprayers:

Best For: Interior work and residential repaints.

The Good: They’re quiet, lighter, and produce zero fumes, making them the only real choice for working inside an occupied home. They also offer fantastic control for fine-finish applications.

The Bad: You’re leashed to a power cord. You'll always need an outlet or a generator nearby.

Gas-Powered Sprayers:

Best For: Big exterior jobs, new construction, and any site without reliable power.

The Good: Total freedom. They go anywhere and usually pack a bigger punch (higher GPM), letting you run larger tips or even two guns at once for maximum speed.

The Bad: They're loud, heavy, and the exhaust fumes make them a non-starter for almost any indoor project.

Think about the jobs you do 80% of the time. If you're mainly doing residential repaints, an electric sprayer is a no-brainer. If you're tackling big, new commercial buildings where power is anyone's guess, a gas rig is the clear winner.

No matter what question you have, the team at Contractor's Maintenance Service has seen it before. From helping you choose the best airless paint sprayer to providing lightning-fast service and parts, we’re your go-to partner on the Central Coast.

Comments