A Contractor’s Guide to Copper Crush Washers

- DLL Studios

- 3 days ago

- 13 min read

Ever wonder what a copper crush washer actually is? It's a special, single-use gasket built to create a perfect, leak-proof seal, especially in connections dealing with high-pressure fluid or gas. Unlike a standard washer that just spreads out the load from a bolt, a copper crush washer is designed to deform under pressure. It literally crushes into place, filling in microscopic gaps between two surfaces. This unique quality makes them non-negotiable for stopping costly and dangerous leaks in your most critical equipment.

Why Copper Crush Washers Are Your Equipment’s Best Friend

Think of a copper crush washer as the unsung hero of your high-pressure gear. It's a small, simple ring, but it's often the only thing standing between you and a catastrophic failure in the hydraulic lines of your Graco sprayer or the engine of your Honda-powered compactor. For any contractor, getting to know this little component is a complete game-changer for your maintenance routine.

The Science of the Seal

Picture trying to join two perfectly flat, hard steel surfaces. They might look flawless, but on a microscopic level, they’re covered in tiny imperfections, like little hills and valleys. A standard flat washer just sits on top of these gaps, leaving a clear path for fluid to escape under pressure.

This is where copper’s unique properties save the day. As you tighten a bolt or fitting, the soft copper washer "crushes" and flows into every single one of those tiny voids, creating a barrier that fluid simply can't get past. It essentially becomes a custom-molded gasket, shaped perfectly for that one specific connection at that exact moment.

A properly installed copper crush washer doesn't just block a leak; it creates a hermetic seal capable of withstandaing extreme pressure and temperature cycles, ensuring your equipment runs safely and efficiently.

To give you a quick snapshot, here’s a breakdown of what makes these washers so essential on the job site.

Copper Crush Washer At a Glance

Key Feature | Primary Benefit | Common Equipment Application |

|---|---|---|

Malleable Copper Construction | Deforms under torque to create a perfect, custom seal. | Hydraulic fittings on paint sprayers (Graco, Wagner) |

Single-Use Design | Guarantees a fresh, reliable seal every time. | Engine drain plugs on generators and compactors |

High-Pressure Resistance | Withstands extreme fluid and gas pressures without failing. | Brake line banjo bolts and fuel line connections |

Excellent Heat Conductivity | Helps dissipate heat, protecting the connection. | High-temperature engine and exhaust components |

This table sums it up: these aren't just generic hardware. They are precision components designed for reliability where it matters most.

A Critical Part of Your Maintenance Strategy

Ignoring this tiny part can have massive consequences. We're talking costly downtime, messy fluid spills on job sites, and premature wear on your most valuable tools. Adding crush washer inspection and replacement to your service schedule is a simple, low-cost way to protect your investment. To get your plan dialed in, check out our guide on building an effective equipment preventative maintenance checklist.

The demand for these seals speaks for itself. The global market for banjo bolts and crush washers has exploded into a USD 1.36 billion industry, largely because of their necessity in machinery and construction. This growth is all thanks to the washers' ability to create leak-proof seals under intense pressures, sometimes up to 10,000 PSI, preventing downtime in equipment from brands like Graco and Wagner/Titan. Learn more about the market drivers for sealing components from Dataintelo. We see this firsthand every day, serving pros like you in San Luis Obispo, Paso Robles, Atascadero, and all the surrounding areas.

Choosing the Right Washer Material and Type

Not all washers are the same, and grabbing the wrong one for a high-pressure job is a recipe for instant failure. When you're working with equipment like pressure washer pumps or Multiquip compactors, the washer's material is every bit as critical as its size. It all comes down to one thing: creating a perfect, single-use seal that can handle extreme punishment.

This is exactly why copper is the go-to for professional applications. It hits that sweet spot between being soft enough to conform to tiny surface imperfections but strong enough not to get obliterated under high torque. That malleability is what gives you a truly leak-proof connection, time and time again.

Plain vs. Annealed Copper Washers

Once you're in the world of copper crush washers, you'll run into two main players: plain (also called work-hardened) and annealed (softened). They're both copper, sure, but their performance couldn't be more different. For sealing, an annealed washer is always the superior choice.

The annealing process involves heating the copper up and then letting it cool slowly. This makes the metal incredibly soft and pliable. Think of it like this: a plain copper washer is like cold, hard clay. An annealed washer is like warm, soft clay that's ready to mold into any shape you need.

When you tighten down a fitting with an annealed copper washer, that softened metal flows into every microscopic groove and pit, creating an absolutely impeccable seal. This is a one-shot deal; once crushed, the copper work-hardens and you can't reuse it for another critical seal.

How Copper Stacks Up Against Other Materials

You'll see other materials out there, but they just don't cut it in the high-stakes world of industrial equipment repair. For our clients on the Central Coast, from Paso Robles to Santa Maria, here’s a quick rundown of why copper consistently comes out on top.

Aluminum: It’s softer and lighter than copper, but it can’t take the heat. It’s also much more likely to corrode, especially when you pair it with steel or brass fittings—a terrible choice for the kind of durable repairs needed to survive San Luis Obispo's working conditions.

Nylon: Fine for low-pressure, low-temperature situations, especially if you need electrical insulation. But throw it into an engine or hydraulic system, and the high heat and chemicals will make it degrade and fail in no time.

Steel: Way too hard. A steel washer can’t conform to create a seal. They're designed to spread a load, not stop a leak. Using a steel washer where a crush washer belongs is a surefire way to end up with a persistent, annoying drip.

For any contractor working in Arroyo Grande or Atascadero, equipment reliability is everything. The unmatched heat resistance and sealing power of annealed copper crush washers make them the only real professional choice for keeping your gear running leak-free.

How to Measure and Select the Perfect Size

Picking the right size copper crush washer isn’t just a minor detail—it’s the difference between a rock-solid, leak-proof seal and a frustrating drip that brings a job to a screeching halt. A washer that’s too small won’t seat correctly on the fitting. Go too big, and it can interfere with other parts or just fail to seal at all. For any contractor, getting this right the first time is non-negotiable. Downtime isn't an option.

The good news is you don’t have to guess. With a simple tool like a set of digital calipers, you can measure any washer with total confidence. It all comes down to nailing three critical dimensions.

The Three Core Measurements

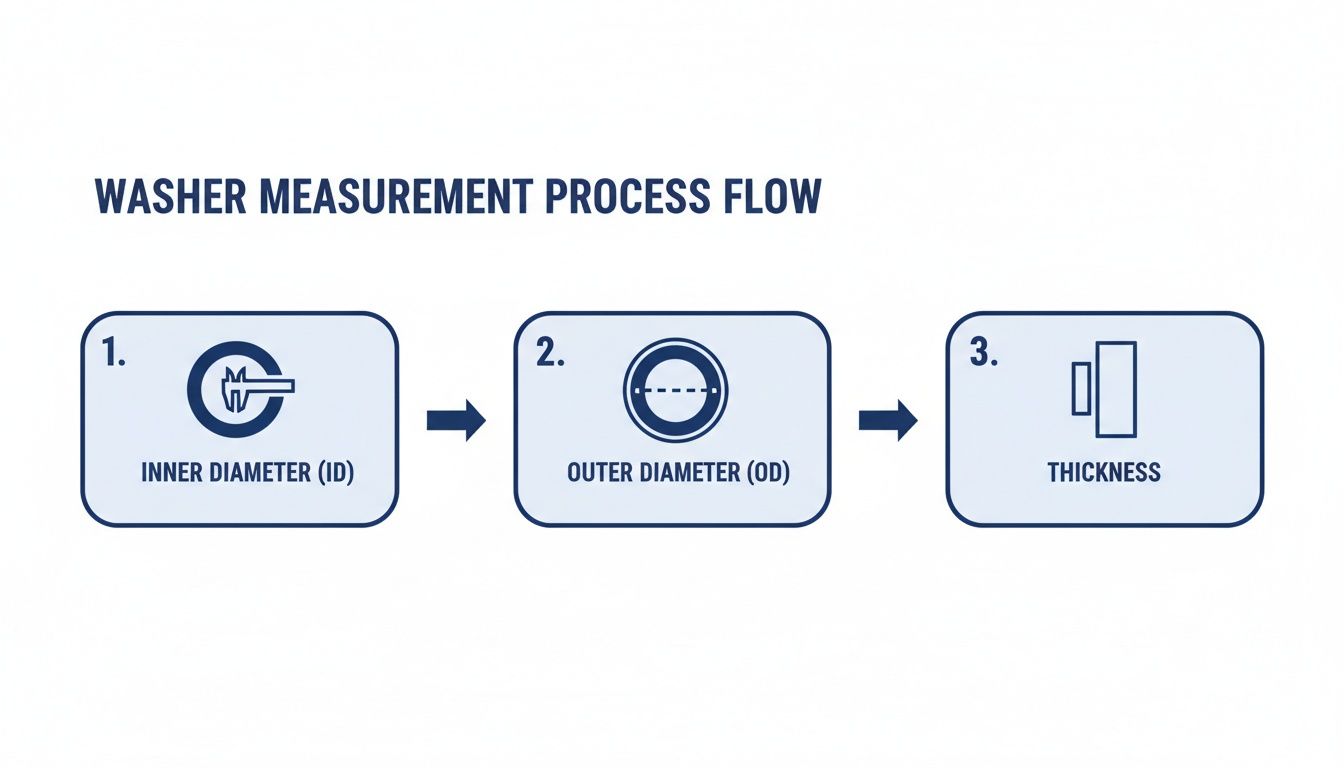

To size any crush washer properly, you need to know its Inner Diameter (ID), Outer Diameter (OD), and thickness.

Inner Diameter (ID): This is your most important number. The ID needs to be just a hair larger than the bolt or fitting’s shaft, enough to slide on smoothly without being sloppy. For an accurate reading, use the small jaws at the top of your calipers.

Outer Diameter (OD): The OD determines how the washer sits on the sealing surface. You need it to be big enough to completely cover the mating area, but not so big that it hangs over the edge or gets pinched by other components when you tighten everything down. Use the main jaws of the calipers for this measurement.

Thickness: A crush washer’s thickness dictates how much it can deform to create that perfect seal. If it’s too thick, you might not be able to tighten the fitting correctly. Too thin, and there won’t be enough material to crush down and fill the gap, leaving you with a leak.

Common Washer Sizes for Your Equipment

For technicians and contractors working around San Luis Obispo County, you start to see the same sizes pop up over and over. Here’s a quick reference for the common applications you'll run into on job sites from Paso Robles to Arroyo Grande.

Application | Common ID Sizes (Metric) | Common ID Sizes (Imperial) |

|---|---|---|

Oil Drain Plugs | M12, M14, M16 | 1/2", 9/16" |

Banjo Bolts (Brake/Fuel) | M10, M12 | 3/8", 7/16" |

Hydraulic Fittings | M14, M16, M18 | 1/2", 5/8" |

This chart is a great starting point, but remember: always measure to be sure.

But what if the old washer is gone or completely mangled? First, carefully measure the bolt or fitting shaft to get the ID. Next, measure the flat sealing surface it presses against to figure out a suitable OD. If you’re ever in a bind, our team at Contractor’s Maintenance Service is here to help. We serve professionals across the Central Coast—including Atascadero, Pismo Beach, Morro Bay, and Santa Maria—and can get you the exact part you need, fast.

Mastering the Art of Installation and Torque

Proper installation is where the real magic of a copper crush washer happens, and it’s a step you absolutely can’t afford to shortcut. This isn't just about tightening a bolt; it's about precision. Your goal isn't just to make it snug—it's to apply the perfect amount of force to deform that soft copper, creating a flawless, custom-molded seal.

This is the "crush" we've been talking about. The washer is designed to be a one-and-done component for any job that matters. Once it's compressed, it work-hardens and permanently shapes itself to the tiny imperfections of the two surfaces it’s sealing. Trying to reuse one is like trying to use a bent key—it’ll never fit the lock perfectly again, and you’re just asking for a leak.

The Non-Negotiables of a Perfect Seal

Getting a durable, leak-proof seal is about more than just muscle. It’s a methodical process that respects the physics of the connection. Rushing these steps is a recipe for a callback, whether you're working in a San Luis Obispo shop or on a job site out in Paso Robles.

First, you have to know you have the right part. This chart breaks down the three critical dimensions you need to confirm with a pair of calipers: Inner Diameter, Outer Diameter, and Thickness.

This quick visual check is your first line of defense. Once you've confirmed you have the exact washer for the job, there are three hard-and-fast rules before you even think about turning a wrench.

Immaculate Surface Prep: Both mating surfaces have to be perfectly clean and dry. Any lingering dirt, old gasket gunk, or oily residue is going to ruin your seal.

Perfect Alignment: Make sure the washer is sitting completely flat against the surface and is perfectly centered on the bolt or fitting. A crooked washer will crush unevenly, creating a weak spot.

Use a Torque Wrench: Guessing tightness is for amateurs. A torque wrench is the only tool that guarantees you apply the precise clamping force required without wrecking your components.

The Dangers of Improper Torque

The difference between a perfect seal and a catastrophic failure often comes down to just a few foot-pounds of torque. Getting it wrong in either direction—too loose or too tight—has serious consequences.

Under-tightening is an obvious mistake; the washer won’t compress enough to fill the microscopic gaps, guaranteeing a slow drip or a major leak. Over-tightening is far more destructive. It can strip threads, crack fittings, or split the washer itself, turning a simple job into a costly repair.

Think about a common task like changing differential fluid. That little drain plug washer absolutely must be torqued to the manufacturer’s exact spec to prevent leaks. It's no wonder the demand for these seals is so strong; the market for copper washers in gasket applications is projected to hit USD 738 million by 2033.

These little guys excel in banjo bolt assemblies, compressing 15-25% to form an airtight barrier in hydraulic systems. Getting the installation right can slash leak-related repairs by up to 40% in machinery common on job sites from Arroyo Grande to Santa Maria. It’s a small part that makes a huge difference.

Troubleshooting Leaks and Common Sealing Failures

We’ve all been there. You’ve done the work, buttoned everything up, and then you see it: that one persistent drip. A slow weep from a hydraulic fitting or an engine drain plug can stop a job cold, costing you real time and money. When a brand-new copper crush washer fails to seal, it's almost never the washer’s fault—the real problem usually lies in one of a few common slip-ups.

This is your first line of defense. Think of this guide as your go-to for figuring out what went wrong so you can get back to business. Whether you’re working in the shop here in San Luis Obispo or out on a job in Paso Robles, a quick diagnostic check will help you nail down the problem and fix it right the first time.

Your Sealing Failure Diagnostic Checklist

Before you reach for a bigger wrench, take a breath and run through the basics. The fix for that annoying leak is probably hiding in one of these four simple questions.

Were the Mating Surfaces Flawless? Both surfaces need to be perfectly clean, dry, and completely free of old gasket gunk, grease, or deep scratches. Even a tiny speck of dirt can create a path for fluid to escape.

Was the Old Washer Completely Removed? It happens more than you think. An old, flattened washer can stick to a surface and look like it’s part of the fitting. Stacking a new washer on top of an old one is a guaranteed recipe for a leak.

Was the Correct Washer Used? Double-check the inner diameter (ID), outer diameter (OD), and thickness. It has to be an exact match for the application. The right size isn't just a suggestion; it’s a requirement for a solid seal.

Was It Torqued to Spec? Did you grab a torque wrench? Under-tightening means the washer never gets the chance to crush and form a seal. Overtightening is just as bad—you can strip the threads or even split the washer.

When you’ve got a stubborn leak, the gut reaction is to just crank down on the fitting a little more. This is almost always the wrong move. You’re more likely to turn a small problem into a big one by stripping threads or cracking a housing. Always back off, inspect everything, and start fresh with a new washer.

While we're talking leaks, understanding some basic fixes like stopping a leaky faucet can be helpful in a pinch, but for high-pressure equipment, there’s no substitute for a perfect seal from the start.

A solid seal is non-negotiable, especially for gear that takes a beating every day. In dry environments, copper’s corrosion resistance means these washers can last 5-7 years in construction tools, easily beating the 2-3 years you’d get from steel alternatives. That durability saves shop managers thousands in parts and labor. It's why we build assortments for Graco and Titan sprayers, where good preventive maintenance can slash downtime by 35%. Copper is also a champ with heat, tolerating temps up to 500°F, which makes it a must-have for engine parts on compactors where overheating causes 18% of all failures.

Knowing how to fix a bad seal is a key part of keeping your equipment running. To learn more about overall maintenance, check out our complete guide to pressure washer parts and repair. We're here to help professionals in Atascadero, Arroyo Grande, Pismo Beach, Morro Bay, and Santa Maria keep their gear in top-tier condition.

Your Local Source for Parts and Expertise in San Luis Obispo

When your equipment goes down on a job site, waiting for a part to ship is a luxury you can't afford. Every hour of downtime is money lost, which is why having a local partner who gets that urgency makes all the difference. For contractors and service shops across the Central Coast, Contractor's Maintenance Service is that partner—your go-to for immediate access to critical parts like copper crush washers and the know-how to back them up.

We’re here to support the hardworking pros in our community. Our service area covers projects from San Luis Obispo and Paso Robles to Atascadero, and all the way down through Arroyo Grande and Pismo Beach. We also make sure teams in Morro Bay and Santa Maria have a reliable local hub for parts and repairs.

More Than Just a Parts Counter

When you work with a local supplier, you get a lot more than just a component in a bag. You get a team that lives and breathes your equipment.

Real Expertise: We know the ins and outs of Graco sprayers, Titan pumps, and Honda engines. We’ll help you pinpoint the exact copper crush washer or fitting you need, so you can get the job done right the first time.

Parts in Hand, Today: Walk in with a problem, walk out with the solution. We stock our inventory based on what local contractors actually use, cutting out the shipping delays that kill your schedule.

Custom Work on the Spot: Need a hydraulic hose built to spec? We offer fast, custom fabrication services that you just can't get from an online retailer.

Our whole mission is to provide the convenience and expertise that keeps your operation running smoothly. When you need service you can count on, see how we support local businesses through our commitment to professional pressure washing in San Luis Obispo, CA and keep your projects on track.

Your Questions Answered: Copper Crush Washers

Alright, let's wrap this up by tackling the most common questions our team gets from contractors and techs out in the field. Think of this as the quick-and-dirty guide to getting it right every time.

Can I Ever Reuse a Copper Crush Washer?

For anything that matters—we're talking hydraulics, fuel lines, or brake lines—the answer is a hard no. It's just not worth the risk.

These washers are engineered to deform one time to create a perfect, custom seal. That single act of crushing hardens the copper, and it loses its ability to seal properly a second time. Trying to reuse one is basically inviting a leak. Some old-timers might talk about re-annealing them with a torch, but for any professional job where safety and reliability are on the line, always use a fresh washer.

What Happens If I Overtighten the Washer?

This is probably the most common mistake we see, and it can cause some serious headaches. Cranking down too hard can strip the threads on your bolt or fitting, turning a five-minute washer swap into a massive repair job.

Even worse, too much torque will split the washer, buckle it, or just smash it into an useless shape. It completely defeats the purpose and often creates a leak where there wasn't one before. The only way to nail it is with a torque wrench, following the manufacturer's specs to the letter.

The goal is to crush, not destroy. Proper torque lets the washer deform just enough to fill every microscopic gap, creating a perfect seal without wrecking the washer or the parts it’s connecting.

Why Choose Copper Over a Cheaper Alternative?

It comes down to getting the right tool for the job. Copper brings a unique mix of properties that are perfect for the demands of heavy-duty equipment. It's soft enough to mold into slightly imperfect surfaces for a rock-solid seal but tough enough to handle insane pressures without giving up.

Its ability to handle heat is another big one. You'll find copper washers on engines and exhaust systems where a rubber or nylon alternative would melt in a heartbeat. Sure, aluminum is soft too, but it corrodes more easily and can't take the same heat, making copper the clear winner for anything that needs to be reliable for the long haul.

When you need the right copper crush washers and some solid advice without waiting for an online order, we're here for you. Contractor's Maintenance Service is the local go-to for shops in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, Pismo Beach, Morro Bay, and Santa Maria. We’ve got the parts and the know-how to keep your gear running.

See how we can help at https://www.contractorsmaintenanceservice.com.

Comments