The 2 ball valve: A Contractor's Field Guide to Quick Installations

- Dec 23, 2025

- 13 min read

When you hear someone in the trades mention a "2 ball valve," they're almost always talking about its size. Specifically, it's a valve designed to fit a 2-inch diameter pipe. It's a simple but crucial distinction, and getting it right is key for maintenance teams and contractors trying to avoid costly mix-ups and project delays.

Understanding the 2 Inch Ball Valve

Think of a ball valve as a simple gatekeeper for whatever fluid is flowing through a pipe. Inside its housing, there's a sphere with a hole drilled right through the middle. A quick quarter-turn of the handle either lines that hole up with the pipe to let things flow or turns it sideways to block the path completely. It's this straightforward on/off function that makes it such a workhorse in so many different systems.

A 2 inch ball valve is just that same essential component, but built for pipes with a 2-inch nominal diameter. You'll find these things everywhere, from industrial plants to commercial buildings, handling critical jobs day in and day out.

Where You Find Them

Thanks to their reliability and no-fuss operation, these valves are indispensable in a ton of fields. You'll often spot them in applications like:

Main water shutoffs for large commercial or residential buildings.

Irrigation systems where they control water flow to different zones.

HVAC systems for isolating parts of hydronic heating or cooling loops.

Industrial processing lines to manage the flow of chemicals, water, and other fluids.

The demand for these components is massive and still climbing. Industry analysis shows the ball valve market was valued at roughly $14.2 billion in 2024 and is expected to keep expanding over the next ten years. This growth is fueled by heavy use in sectors like oil & gas, water treatment, and power generation. You can find more data about these market trends and detailed projections online.

Local Expertise for the Central Coast

For pros working right here in San Luis Obispo County, getting the right valve quickly is what keeps a job on track. At Contractor's Maintenance Service, we offer specialized support for projects in San Luis Obispo, Paso Robles, Atascadero, Arroyo Grande, and Pismo Beach.

Having a local partner who understands regional requirements—from agricultural needs in Paso Robles to coastal corrosion concerns in Morro Bay—ensures you get a component that performs reliably and meets local codes. We also serve Nipomo and other surrounding communities.

Choosing Your Valve Materials and Designs

Picking the right 2 ball valve goes way beyond just matching the pipe size. Your first big call is the valve's material. This single choice determines its lifespan, cost, and what it can safely handle. It's like choosing tires for a truck—you wouldn't put highway tires on a rig meant for muddy fields.

Each of the common materials has its own sweet spot. Brass is the everyday workhorse, perfect for general plumbing and non-drinking water systems because it’s affordable and resists corrosion well. When you’re dealing with aggressive chemicals or high heat, stainless steel is the undisputed champ. And for low-pressure jobs like irrigation or cold water lines, a lightweight PVC valve is often the smart, rust-proof choice.

Common Materials and Their Uses

Here in San Luis Obispo County, we see it all—from agricultural setups in Paso Robles to the complex commercial plumbing in SLO. That variety makes material selection absolutely critical.

Brass: This is your go-to for most water, oil, and air lines in typical homes and businesses. It's reliable and won't break the bank.

Stainless Steel (304 & 316): You'll find this in food processing plants, chemical facilities, and marine environments like Morro Bay, where salt is always in the air.

PVC (Polyvinyl Chloride): Ideal for low-pressure, cool-temperature uses like sprinkler systems or pool plumbing in places like Atascadero and Arroyo Grande.

Making the right choice upfront means installing a valve that will last for years, not months. This same logic applies to other parts of a system. For example, our guide on choosing your 2 inch discharge hose shows how the right material is key to performance and durability.

To make things a bit clearer, here's a quick rundown of how these materials stack up.

Comparing 2 Inch Ball Valve Materials

Material | Common Applications | Pros | Cons |

|---|---|---|---|

Brass | General plumbing, water, oil, air lines, non-potable water systems | Cost-effective, good corrosion resistance, durable | Can contain lead (check for lead-free certification for potable water), not for highly corrosive fluids |

Stainless Steel | Food processing, chemical transport, marine, high-temp/high-pressure systems | Excellent durability, superior corrosion resistance, handles extreme temperatures | More expensive than brass or PVC |

PVC | Irrigation, pool and spa plumbing, cold water lines, low-pressure applications | Lightweight, rust-proof, inexpensive | Not suitable for high temperatures or high pressure, can become brittle in sunlight over time |

As you can see, the environment and the fluid passing through the valve are what really drive the decision.

Understanding Port and Bore Designs

After you've picked your material, you need to look inside the valve. The internal design—specifically the port and bore—has a huge impact on how it performs.

A valve's port is simply the hole going through the ball. A full port valve (also called full bore) has an opening that’s the same size as the pipe. This means it offers virtually no resistance to flow when it's open. A standard port valve has a slightly smaller opening, which creates a minor pressure drop but often comes in a more compact and budget-friendly package.

The bore design is all about how the ball is held inside the valve.

In a floating ball design, the ball is nestled between two seats, and pressure pushes it against the downstream seat to seal tightly. For bigger or higher-pressure jobs, a trunnion-mounted design adds a bottom stem (the trunnion) to support the ball, preventing it from shifting under heavy loads.

While standard valves handle most jobs, some systems need more specialized gear. For example, innovations in thermostatic shower valve technology show how advanced designs can improve efficiency and save resources.

The demand for these materials isn't random; it follows industrial trends. Steel alloys make up a massive 46.9% of the global market value because they’re essential in high-pressure and high-temperature industries. The 1" to 5" valve size range, which includes our trusty 2 inch ball valve, accounts for about 32% of the market volume, showing just how common it is across countless industrial and utility applications.

A Practical Framework for Valve Selection

Picking the right valve is about more than just matching materials to the fluid inside the pipe. A truly solid, leak-free installation comes from looking at the whole picture: pressure, temperature, how it connects, and what it’s up against chemically. This isn't just a checklist; it's about asking why one valve is the right fit for the job, ensuring everything stays safe and reliable for years.

The first thing to nail down is the system's operating conditions. Every 2 ball valve comes with maximum pressure and temperature ratings, and these are hard limits you can't ignore. Pushing a valve past its specs is a fast track to catastrophic failure, leaks, or even dangerous blowouts. Always double-check that the valve’s ratings for both pounds per square inch (PSI) and temperature are comfortably above what your system will ever demand at its peak.

Aligning Connections with System Needs

Next up, think about how the valve will actually attach to the pipes. The type of end connection you choose is a huge deal, affecting how easy it is to install and whether you can get it out later for maintenance. Each style has its own pros and cons, making them better suited for different jobs.

Threaded Connections (NPT): These are the everyday workhorses. They're common, easy to install, and perfect for lower-pressure systems where you might need to unscrew the valve down the road. You’ll see them all over residential plumbing and general utility lines.

Socket Weld Connections: When you need a stronger, more permanent bond, socket welds are the way to go. The pipe slips into a socket on the valve and is welded in place, creating a very leak-proof seal. This is the preferred method for high-pressure or high-temperature jobs where you don't plan on taking it apart.

Flanged Connections: Held together with bolts, these are the easiest to remove for maintenance or replacement. That makes them the top choice in industrial plants where equipment gets serviced or swapped out regularly.

Getting the connection right from the start means a secure fit and a lot fewer headaches if you ever need to work on the system again.

Ensuring Long-Term Fluid Compatibility

Finally, you have to be absolutely sure that every single part of the valve—from its body down to the little seals inside—can handle the fluid it's controlling. This is the step that prevents the slow, quiet death of a valve from chemical corrosion or a degraded seal. The wrong material can cause a valve to seize up, leak, or just plain fail.

A classic mistake is only worrying about the valve body. Don't forget, the internal seals and seats (usually made of materials like PTFE) are just as vulnerable. If they're not compatible with the fluid, they can swell, crack, or even dissolve completely over time.

While these careful steps are bread-and-butter in industrial settings, they're just as important in homes. The North American residential ball valve market is expected to hit $652.2 million by 2035, a huge jump driven by new builds and plumbing updates. This trend shows a clear shift toward higher-quality, corrosion-resistant materials in our homes. You can read more about the trends in the residential ball valve market to see where things are headed. For contractors here in San Luis Obispo, Pismo Beach, and Arroyo Grande, picking the right valve for our local water conditions means every client gets an installation that’s built to last.

Installation and Maintenance Best Practices

Getting a 2 ball valve installed right is about more than just cranking down on a few fittings. It's about setting that valve up for a long, leak-free life. A solid installation is the foundation for years of reliable service, preventing early failures and making sure the valve works exactly like it's supposed to.

First things first: pipe alignment. Never try to force misaligned pipes to meet the valve. That puts a huge amount of stress on the connections and the valve body itself, which can lead to tiny fractures over time, especially with threaded ends. Always make sure the piping is supported on its own, so the valve isn't carrying the load. The pipe ends should meet squarely and without any strain before you even think about tightening them.

Next up is the seal. If you're working with threaded valves, using the right amount and type of thread sealant or PTFE tape is critical. Too much sealant can get pushed inside the valve and gum up the ball or seats. Just use enough to get a secure, leak-proof seal. Pro tip: always wrap the tape in the direction of the threads so it doesn't unravel as you tighten it.

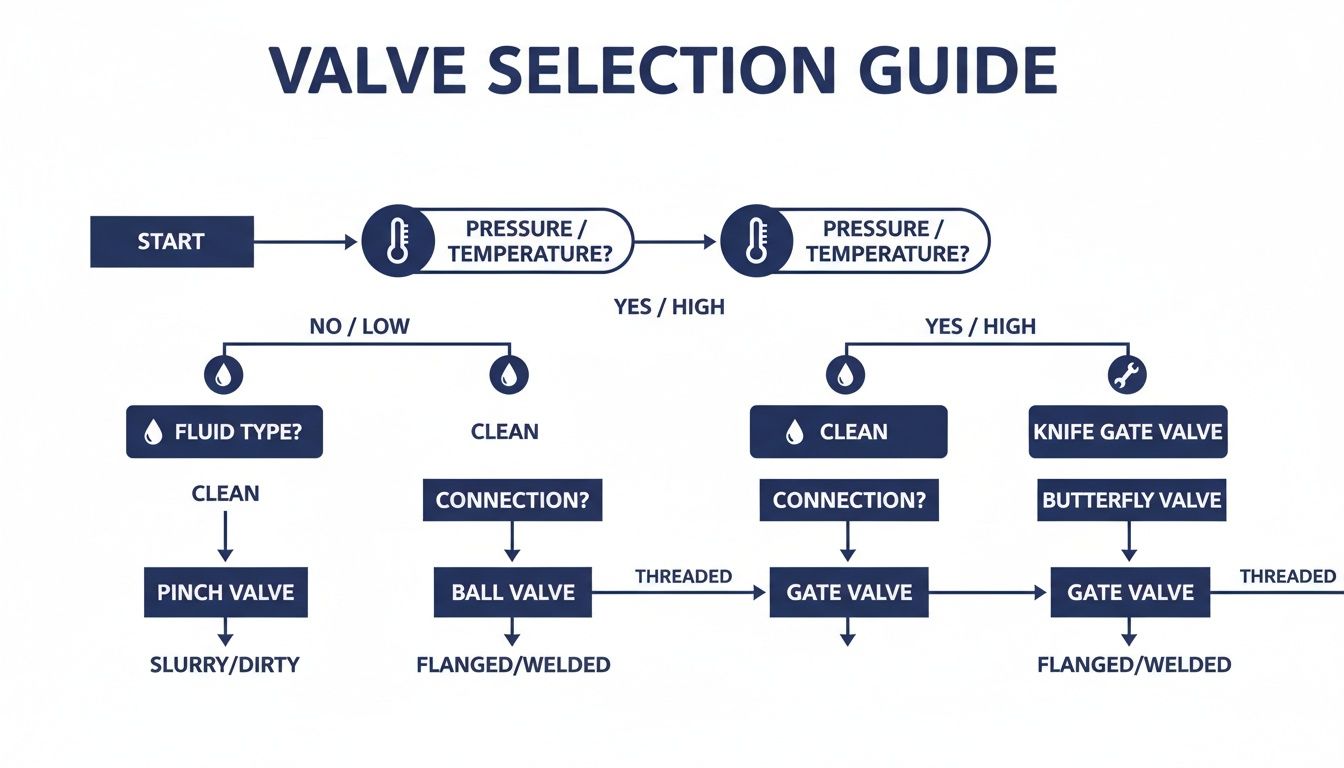

Before you even get to installation, you have to be sure you've picked the right valve for the job. This decision tree is a great visual for walking through the key factors.

Following a logical path like this ensures the valve you're about to install is a perfect match for the system's demands, which helps you sidestep common installation headaches from the very beginning.

A Proactive Maintenance Schedule

Once the valve is in, a little bit of maintenance goes a long way. The single best thing you can do is also the easiest: cycle the valve every so often. Just turning the handle from fully open to fully closed every few months keeps mineral buildup and scale from seizing up the ball.

Any time you're doing maintenance that involves shutting down a line, safety has to be your top priority. That always starts with isolating the system correctly. It's a critical skill for both routine checks and emergencies, so knowing how to properly turn off your water main is essential for protecting the property and the plumbing you're working on.

Preventative maintenance should also include regular visual checks. Keep an eye out for the early warning signs of trouble, like:

A little weeping around the stem: This usually just means the packing nut needs a slight tweak—a quarter-turn is often all it takes.

Corrosion on the body or handle: This could point to a small, slow leak or an issue with the surrounding environment.

A stiff handle: If the handle is hard to turn, it’s a clear sign that something is starting to seize up inside.

Local Service for Central Coast Professionals

For all the contractors out there in San Luis Obispo, Paso Robles, and Atascadero, you know that having quick access to the right parts and expertise is what keeps jobs moving. At Contractor’s Maintenance Service, we stock the components and provide the support you need to get your installations and maintenance done right.

Whether you're dealing with high-pressure systems—which demand specific gear you can learn more about in our guide on what you need to know about high-pressure hoses—or standard plumbing jobs in Arroyo Grande and Pismo Beach, we've got your back. A good maintenance plan minimizes downtime and keeps every system you work on safe and efficient.

Troubleshooting Common Ball Valve Problems

Even the toughest 2 ball valve will eventually hit a snag, especially when it's put to work in a demanding system. When a valve starts acting up, you need to figure out what’s wrong—and fast—to get things flowing again. Knowing the early warning signs and what they mean is the key to preventing a small annoyance from turning into a major shutdown.

The calls we get most often from contractors in the field usually involve a handle that’s seized up, a nagging leak around the stem, or a valve that just won't close all the way. Each of these symptoms points to a different issue, and the fix can be anything from a quick tweak to a full replacement.

Diagnosing Leaks and Seizures

A handle that refuses to turn is usually a sign of a valve that hasn't been used in a while. Minerals and scale can build up between the ball and the seats over time, basically gluing the valve shut. On the other hand, a slow, steady drip from around the handle's stem is almost always the first sign that the packing seal is on its way out.

Here’s a quick rundown on how to tackle these common headaches:

Stiff or Seized Handle: This is the classic sign of internal gunk. You might be able to break it free by applying some gentle, steady pressure with a wrench, but don't go overboard with the force—you could easily snap the stem. If it’s really stuck, replacing the valve is usually the safest bet.

Leak Around the Stem: Before you start unscrewing the whole valve, find the packing nut right under the handle. Often, a simple quarter-turn clockwise is all it takes to tighten the seal and stop the drip. If it keeps leaking, the packing material itself is probably shot.

The decision to repair or replace often boils down to time and money. A quick packing adjustment is a no-brainer. But if a valve is seized solid or the internal seals are shot, the labor to tear it down and rebuild it can easily cost more than just installing a new one.

When to Repair vs. Replace

Knowing when to cut your losses and swap out a bad valve is a critical skill. As a rule of thumb, consider the valve's age, how bad the problem is, and where it’s located. An old valve that's leaking and getting hard to turn is just begging to be replaced.

For professionals working in San Luis Obispo, Paso Robles, or Atascadero, getting a replacement part quickly is non-negotiable. That’s why at Contractor's Maintenance Service, we keep a huge variety of valves in stock. Whether you're on a job in Arroyo Grande or Pismo Beach, we’ll make sure you get what you need without delay. We get it—a fast solution keeps your clients happy and your project moving.

Your Go-To Source on the Central Coast

When you’re in the middle of a job, the last thing you need is a delay. For contractors and maintenance crews, waiting for a critical 2 ball valve to be shipped can grind an entire project to a halt. That’s where having a local partner with deep inventory and real-world expertise makes all the difference.

At Contractor’s Maintenance Service, we're your boots-on-the-ground team here on the Central Coast. We get the unique challenges you face every day, whether it's the specific demands of agricultural irrigation or the complexities of commercial plumbing. Our entire focus is on getting you fast, reliable solutions that fit our local conditions and building codes.

Proudly Serving the Central Coast

We’re not just located here; we’re part of this community. We’ve built our service area to make sure professionals across San Luis Obispo County can get the parts they need without the headache of costly shipping delays.

You can count on us for expert service and parts in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Pismo Beach

Morro Bay

Nipomo

And all the surrounding communities

Choosing a local supplier like us is about more than just getting parts faster. It means you’re working with a team that actually understands the water conditions and regulatory quirks of the Central Coast. We make sure every 2 ball valve we hand you is a perfect fit for the job.

That local familiarity means you walk away with the right component and practical advice that helps keep your project on schedule and up to code. We’re here to provide the kind of responsive, knowledgeable support that builds trust and helps your business thrive.

Frequently Asked Questions

After years in the field, we've noticed a few questions about the 2 inch ball valve pop up time and time again. Getting these right isn't just about doing a good job—it's about making sure your installations are safe and built to last. Let's clear up some of the common ones we hear from pros on the job.

Full Port vs. Standard Port: What's the Real Difference?

Think of it this way: a full port (or full bore) valve is like having a straight shot through a pipeline. The hole in the ball is the same size as the pipe itself—a full 2 inches. This means you get almost zero flow restriction, which is perfect for systems where you can't afford to lose pressure or slow things down.

A standard port valve, on the other hand, has a slightly smaller opening. While it does create a bit of a bottleneck, it’s usually so minor that you wouldn't notice it in most everyday applications. The upside? They’re typically more compact and a little easier on the budget. It all comes down to what the system truly needs.

Can I Use a Brass Ball Valve for Gas Lines?

This is a big one, and the answer is a hard no. You absolutely cannot use a standard brass valve meant for water on a gas line.

Valves designed for natural gas or propane have to meet strict safety standards from organizations like CSA Group or UL. They're built with specific materials and seals that won't break down when exposed to hydrocarbons. Grabbing the wrong valve is a serious gamble that could lead to dangerous leaks down the road.

How Often Should I Operate Shutoff Valves?

It’s easy for a valve to seize up over time from corrosion or mineral buildup, especially if it’s just sitting there. The best way to stop this from happening is to simply work the handle every now and then.

A good rule of thumb is to turn the valve from fully open to fully closed and back again about twice a year. It’s a small step that breaks up any gunk and makes sure the valve actually works when you need it to. Tossing this task into your equipment preventative maintenance checklist is a simple way to prevent a future emergency. For our clients in San Luis Obispo, Paso Robles, and Atascadero, this is one of the easiest ways to get more life out of your plumbing hardware.

When you need straight answers or the right parts for a job on the Central Coast, Contractor's Maintenance Service has your back. We stock the reliable components you need to keep your projects moving forward. Find the parts you need at https://www.contractorsmaintenanceservice.com.

Comments