A Complete Guide to the Pressure Washer Lance

- Dec 11, 2025

- 15 min read

A pressure washer lance, often just called a wand, is the rigid tube that connects your trigger gun to the nozzle. Think of it as the critical link that turns the raw power from your machine into a focused, controllable cleaning tool. It’s what gives you the reach and precision you need to tackle any job, big or small.

Without the right lance, even the strongest pressure washer is just making a lot of noise.

What a Pressure Washer Lance Actually Does

It’s easy to dismiss a lance as just an extension pipe, but it’s so much more than that. If your pressure washer is the engine, the lance is the steering wheel. It’s the component that channels all that high-pressure water into a manageable stream, giving you direct command over your work. The lance dictates your distance from the surface, the angle you can hit, and, ultimately, the quality of your finish.

This single tool is often the difference between an amateur-hour mess and a professional-grade clean. Get it right, and you can clean efficiently without causing costly damage, like stripping paint off a car or carving permanent lines into soft wood siding. For anyone serious about pressure washing, from ambitious homeowners to seasoned pros, understanding the lance is non-negotiable.

For a quick overview of how a lance fits into your pressure washing setup, this table breaks down the essentials.

Pressure Washer Lance At a Glance

Component Aspect | Primary Function | Why It Matters |

|---|---|---|

Body/Tube | Channels high-pressure water from the gun to the nozzle | Determines your reach and the ability to work at a safe distance. |

Fittings | Connects the lance to the trigger gun and the nozzle | Ensures a secure, leak-free connection for consistent pressure. |

Nozzle End | Holds the nozzle in place, directing the spray pattern | Allows for quick changes between different spray patterns for various tasks. |

This simple breakdown shows just how central the lance is to the entire operation. It's not just an accessory; it's a core part of the system.

The Role of a Lance in Professional Cleaning

For those of us in the business, the lance is a non-negotiable tool for both safety and efficiency. It creates that crucial standoff distance needed to protect you from high-pressure spray and the inevitable kickback of dirt and debris. For a contractor, picking the right lance means working faster, staying safer, and delivering a better clean every single time.

A well-chosen lance does more than just extend your reach; it enhances control, improves safety, and maximizes the cleaning power of your machine, turning a challenging job into a streamlined process.

The industry's growth underscores just how important reliable equipment has become. The global pressure washer market was valued at USD 2.10 billion in 2024 and is projected to hit USD 3 billion by 2034. North America is leading the charge, holding a dominant 43% market share. This boom means more demand for quality gear, and the lance is right at the heart of that. To see how the lance works with everything else, check out our complete guide to pressure washer parts and repair.

Serving San Luis Obispo and Surrounding Areas

Here at Contractor's Maintenance Service, we live and breathe this stuff. We understand the unique challenges that professionals and homeowners face on California's Central Coast. We’re proud to supply the parts, service, and real-world expertise needed in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Templeton

Nipomo

Santa Margarita

Cambria

Los Osos

Cayucos

Whether you're restoring a historic building downtown SLO or blasting mud off equipment in the vineyards of Paso Robles, having the right pressure washer lance is fundamental to getting the job done right.

The Anatomy of a High-Performing Lance

If you want to master pressure washing, you've got to know your gear inside and out. A top-tier pressure washer lance isn't just a metal pipe; it's an engineered tool with distinct parts working in harmony to give you control and power. Getting familiar with these components is the first step toward picking the right tool for the job.

Every lance is built around three key parts: the inlet fitting, the tube (or body), and the outlet coupler. Each one is vital to the lance's performance, durability, and how it feels in your hands. When you can spot quality in each of these areas, you'll know right away if a lance is built for professional work.

Think of it this way: the inlet is the handshake with your trigger gun, the tube is the strong arm giving you reach, and the outlet is the skilled hand that aims the nozzle. If any one of them fails, the whole operation falls apart.

Inlet and Outlet Fittings: The Critical Connections

Fittings are the unsung heroes of a solid pressure washing setup. The inlet fitting is where the lance meets your trigger gun, and the outlet coupler is where you snap on your spray nozzle. These connections have to handle thousands of PSI without a single drop, so their design and material are absolutely crucial.

You'll generally run into two types of fittings out in the field:

Threaded Fittings (e.g., M22): These screw-on connectors create an incredibly secure, vibration-proof seal. They're the go-to for heavy-duty jobs where you just can't afford a failure.

Quick-Connect (QC) Fittings: Just like the name says, these let you swap lances and nozzles in seconds without any tools. Their speed and convenience make them a favorite for contractors who need to adapt on the fly.

A quality fitting, whether it's a threaded or QC style, will be machined from solid brass or stainless steel. This prevents corrosion and guarantees a tight seal, job after job.

For professional contractors, especially those working in demanding environments from Paso Robles to Nipomo, a leaking fitting isn't just an annoyance—it's a pressure drop that costs time and money. Secure connections are non-negotiable for job site efficiency.

Lance Body Materials: Durability Meets Ergonomics

The body of the pressure washer lance is where material science really kicks in. The material choice directly affects the lance's weight, how long it'll last, and its ability to stand up to harsh chemicals and hot water.

Here’s a quick rundown of the most common materials:

Material | Key Advantage | Best Use Case |

|---|---|---|

Stainless Steel | Superior durability and rust resistance | Heavy-duty, daily professional use |

Plated Steel | Strong and budget-friendly | General-purpose and frequent use |

Aluminum | Lightweight, reducing user fatigue | Extended-reach or overhead cleaning |

For our professional clients in San Luis Obispo and Atascadero, stainless steel is pretty much the gold standard. It can take the daily abuse and exposure to different cleaning solutions without breaking a sweat.

The integrity of the lance is directly tied to the performance of your entire system, all the way down to the high-pressure hose. To get the full picture on this critical link, check out our guide on what you need to know about high-pressure hoses. This foundational knowledge ensures you build a setup that’s rock-solid from the pump to the nozzle.

Choosing The Right Type of Pressure Washer Lance

Picking the right pressure washer lance is a lot like choosing the right tool for any other job—it’s the difference between fighting your equipment and getting a clean, professional finish efficiently. A lance that’s too short will have you hunched over all day, while one that’s too long is just clumsy and unsafe. It's all about translating your machine's power into precise, effective cleaning.

Think of it like choosing between a paintbrush and a roller. You wouldn’t try to paint a whole house with a tiny detail brush, and you wouldn't do trim work with a giant roller. The same logic applies here. The right lance makes the work flow, while the wrong one turns a simple job into a frustrating mess.

The Workhorse: Fixed-Length Lances

Fixed-length lances are the undisputed workhorses of the pressure washing world. They're simple, durable, and dead reliable, which is why they come standard with most machines. Ranging from 18 to 48 inches, they give you the perfect blend of reach and control for cleaning everyday surfaces like driveways, siding, and equipment.

For contractors working in San Luis Obispo, a standard 36-inch lance is often the go-to for general-purpose cleaning on commercial buildings and residential homes. It’s long enough to keep you clear of splashback but not so long that it becomes hard to handle.

Telescoping Lances for High-Reach Jobs

When you’re staring up at second-story siding, high gables, or the top of a piece of heavy equipment, a telescoping lance is your best friend. These extendable tools can reach up to 24 feet, letting you get the job done safely from the ground instead of messing around with a ladder.

But make no mistake, they demand respect. A fully extended lance with high-pressure water blasting out the end can feel like you’re trying to tame a wild animal. It takes real strength and proper technique to manage, but it’s a game-changer for those high-reach jobs common in areas like Paso Robles or Atascadero. For other specialized tasks, insights from tools like vacuum wand extensions can also offer smart ways to handle long-reach equipment.

Angled Lances and Specialized Tools

Sometimes, the grime is hiding where a straight lance just can’t get. That’s where angled lances come in. They’re designed with a curve, making them perfect for cleaning out gutters, blasting mud from vehicle undercarriages, or hitting the tops of large equipment without awkward stretching.

The right specialized lance doesn't just make a difficult job possible—it makes it easy. Investing in tools like an angled lance or a foam cannon pays for itself in time saved and superior results, especially on detailed jobs.

Beyond just angled wands, a few other specialized tools are worth having in your truck:

Foam Cannons: An absolute must-have for vehicle detailers and house washers. They snap onto the end of your lance and mix soap concentrate with water and air, creating a thick, clinging foam that melts away dirt and grime.

Chemical Injector Lances: These are built for applying detergents or chemicals at low pressure. They let you switch from soaping to rinsing without having to swap out your entire setup.

To help you decide which lance is best for your typical jobs, here’s a quick comparison of the main types.

Comparison of Pressure Washer Lance Types

Lance Type | Best For | Key Advantage | Potential Drawback |

|---|---|---|---|

Fixed-Length | General-purpose cleaning (driveways, siding, decks) | Durable, easy to control, and reliable | Limited reach for high areas |

Telescoping | Second-story siding, high gables, tall vehicles | Safely cleans high areas from the ground | Can be heavy and difficult to control when fully extended |

Angled | Gutters, vehicle undercarriages, hard-to-reach spots | Reaches areas inaccessible to straight lances | Less versatile for general, flat-surface cleaning |

Specialized | Applying soaps (foam cannons) or chemicals (injectors) | Dramatically improves cleaning efficiency and results | Adds another piece of equipment to manage and maintain |

Choosing the right tool from this lineup ensures you're not just working harder, but smarter.

The impact of these tools is clear. Residential users, who make up over 40% of the market, often prefer foam lances that boost cleaning efficiency by 25%. In North America, where vehicle washing is huge, curved lances are proven to reduce back strain by 15-20%. And most importantly, extendable lances are credited with preventing up to 70% of ladder-related accidents by keeping operators on the ground. You can find more pressure washer market trends on arizton.com.

Whether you’re cleaning coastal homes in Pismo Beach or agricultural machinery in Templeton, having the right lances in your arsenal means you’re ready for whatever the job throws at you.

How Lances and Nozzles Work Together

A pressure washer lance is really just a channel for controlled power. On its own, though, it's pretty useless. All that potential force means nothing without the right partner screwed onto the end: the nozzle. The nozzle is what actually shapes the water stream, turning raw pressure into a precision tool for a specific job.

Think of it like this: the lance is a high-powered rifle, and the nozzle is the ammunition. You wouldn't use a sniper round for close-quarters work, and you wouldn't use birdshot for a long-range target. It’s the same idea here. The nozzle you pick determines if you’re blasting old paint off concrete or just giving a dusty car a gentle rinse.

This partnership is the absolute core of effective pressure washing.

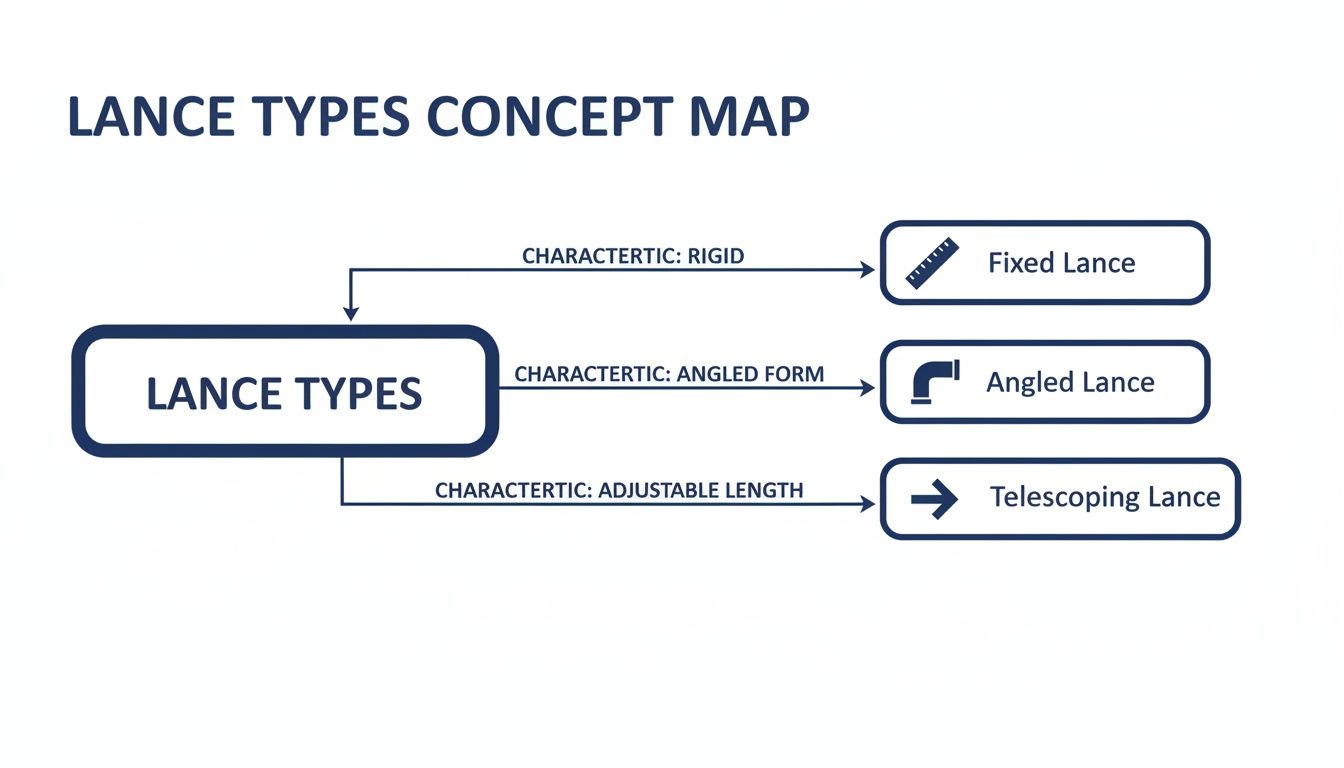

This map breaks down the main types of lances in your arsenal. Seeing them laid out like this helps connect the right tool to the physical demands of the job, from reaching high peaks to hitting awkward angles.

Decoding the Color System

To make nozzle selection dead simple, the industry came up with a universal color-coding system. It’s brilliant, really. Each color corresponds to a specific spray angle, measured in degrees. A smaller degree means a tighter, more powerful stream; a larger degree creates a wider, gentler fan of water.

Here’s the breakdown every pro has memorized:

Red Nozzle (0 degrees): This is the "turbo-blaster" of nozzles. It creates a pinpoint jet of water that can cut into wood or gouge concrete. It’s incredibly powerful and, frankly, dangerous if misused. Only bring this out for the most stubborn, specific tasks, like blowing out old grout.

Yellow Nozzle (15 degrees): This is your heavy-duty stripping and prep tip. It’s perfect for peeling away caked-on grime, mildew, or flaking paint from hard surfaces before you repaint or reseal them.

Green Nozzle (25 degrees): Meet your go-to for general cleaning. The green tip strikes a great balance between power and coverage, making it the workhorse for washing vehicles, cleaning decks, and rinsing siding.

White Nozzle (40 degrees): When you need to be careful, grab the white nozzle. It produces a wider, gentler spray that's ideal for cleaning windows, outdoor furniture, or fragile stucco exteriors without causing damage.

Black Nozzle (Soap): The black nozzle is different. It has the widest opening, which causes the pressure to drop significantly. This pressure drop is the trigger that activates the detergent injector on your machine, pulling soap into the water stream for application.

Understanding this color system isn't just a good idea—it’s non-negotiable for professional work. Slapping a 0-degree nozzle on a wooden deck will cause irreversible damage in seconds. Trying to clean tough concrete stains with a 40-degree nozzle will just waste your time. True mastery is knowing exactly which tool to grab for the job in front of you.

Matching Nozzles to Common Jobs

Let's ground this in the real world with scenarios we see every day across San Luis Obispo County.

Say you’re cleaning a greasy restaurant patio in downtown San Luis Obispo. You'd start with the black soap tip to lay down a good degreaser. After letting it dwell, you’d switch to the yellow or green nozzle to power through the grime. For a homeowner in Paso Robles prepping a wood fence for staining, the white 40-degree nozzle is the only safe choice to clean the surface without scarring the wood grain.

Vehicle washing is another common job, from Atascadero to Arroyo Grande. The green 25-degree nozzle is often the best for rinsing, but only from a safe distance. Get too close, even with a wider-angle nozzle, and you can easily damage a car’s clear coat. This careful selection process is what separates the pros from the amateurs, preventing costly mistakes and ensuring a flawless finish.

You can dive deeper into this relationship in our complete guide to pressure washer spray tips, which breaks down how to optimize your setup for any surface you might encounter.

Need a Pro on the Central Coast?

Look, mastering a pressure washer lance and knowing which nozzle to grab for the job is one thing. But sometimes, you just need to bring in the experts. If you're a property owner or contractor here on California's Central Coast, you already know our environment throws a unique set of challenges at every surface.

We're talking about the salty air that hangs heavy in our coastal towns and the agricultural dust that settles over everything inland. These aren't just your run-of-the-mill cleaning jobs, and that's where having a local crew makes all the difference. We’ve got the right gear and, more importantly, the hands-on experience to tackle exactly what our community's properties are up against.

We've Got San Luis Obispo County Covered

Our mobile teams are ready to roll out to your job site or property, bringing professional-grade equipment and the right techniques to deliver a perfect finish, every single time. We're proud to serve the entire SLO County area and surrounding communities.

You'll find us working in:

San Luis Obispo and the surrounding neighborhoods.

Paso Robles and all across the North County.

Atascadero and its neighboring communities.

The Five Cities area, including Arroyo Grande, Grover Beach, and Pismo Beach.

Coastal spots like Morro Bay, Los Osos, Cayucos and Cambria.

Inland towns from Templeton and Santa Margarita to Nipomo.

No matter where you are on the Central Coast, professional help is just a phone call away.

The Right Approach for Local Properties

A one-size-fits-all approach to pressure washing just doesn't cut it here. You can't treat the stucco on an Arroyo Grande home the same way you'd handle the historic brickwork in downtown SLO—not if you want to avoid costly damage. Cleaning up ag equipment in Templeton is a world away from restoring a weathered wooden deck on the coast in Cambria.

Our goal is simple: protect your investment while making it look its best. We carefully choose the right pressure washer lance, nozzle, and cleaning solutions to safely tackle everything from delicate wood siding to tough-as-nails concrete driveways.

Whether it's a massive commercial building, a simple house wash, or bringing a patio back to life, our team has seen it all. We know how to get rid of stubborn mildew and years of built-up grime, boosting your property's curb appeal and protecting its value. It's about combining the right tools with real local expertise to deliver a clean that lasts.

Lance Maintenance and Critical Safety Practices

Your pressure washer lance is a workhorse, but like any high-performance tool, it needs a little care to keep running strong. Think of it this way: routine maintenance isn't just a suggestion—it's what separates a reliable, long-lasting tool from one that fails you mid-job. A well-maintained lance is a safe lance.

Most common failures are completely preventable with simple, consistent checks. Making it a habit to inspect your gear before you fire up the machine can save you a world of frustration, downtime, and potential hazards.

Keeping Your Lance in Top Condition

Preventive maintenance is quick, easy, and pays for itself a hundred times over. You just need to focus on the key spots where wear and tear hit the hardest. Catching a worn O-ring is a cheap, simple fix; ignoring it can snowball into a much bigger, more expensive repair down the line.

Here are the essential checks to make a regular part of your routine:

Inspect and Clean Nozzles: Pull the nozzle off after every job and make sure it’s clear of debris. Even a tiny clog can cause a sputtering, uneven spray pattern and put a ton of unnecessary strain on your pump.

Check O-Rings and Seals: Those little rubber O-rings at your connection points are the only thing keeping a perfect, leak-free seal. Look for any signs of cracking, flattening, or brittleness. If you see any, replace them immediately to avoid pressure loss.

Examine Fittings for Damage: Give the threads on your inlet fitting and the locking mechanism on your quick-connect coupler a quick once-over. Damaged fittings are a recipe for dangerous, high-pressure leaks.

A sudden drop in pressure or a steady drip from a connection is your lance's way of telling you something's wrong. Pay attention to those little warnings—they're the key to avoiding a catastrophic failure.

Critical Safety Protocols You Cannot Ignore

The same power that blasts away grime makes a pressure washer incredibly dangerous if you don't respect it. The water jet from a lance can easily cause deep cuts or, far worse, high-pressure injection injuries. Those are a serious medical emergency.

Safety isn't optional. Always wear your Personal Protective Equipment (PPE), especially safety glasses to shield your eyes from splashback and flying debris, and sturdy, closed-toe boots. And it should go without saying, but never, ever point a pressure washer lance at another person or an animal.

When it comes to using lances safely, especially on delicate surfaces, there are specific techniques you need to know. For a deeper dive, check out these professional tips for safely cleaning windows with a pressure washer.

The good news is that modern gear is built with safety in mind. Today's industrial lances are engineered to handle burst pressures up to a staggering 12,000 PSI. On top of that, innovations like insulated lances for electric washers have helped cut down on shock-related incidents by 60% since new certifications were rolled out. Safety data from 2023 also showed 15% fewer injuries with quick-disconnect lances, which have become a standard feature for a very good reason.

Common Questions About Pressure Washer Lances

Even the most seasoned pros have questions now and then. Getting straight answers is the difference between a smooth day and a costly problem on the job site. Here are a few of the most common things we get asked by contractors right here on the Central Coast.

These aren't hypotheticals; they're the real-world questions we answer every day, from helping landscapers in Paso Robles to builders in San Luis Obispo.

Can I Use Any Lance with My Pressure Washer?

Absolutely not, and this is one area where you can't afford to guess. Compatibility is everything. First, the fittings—like a common M22 thread or a quick-connect plug—have to be a perfect match for your trigger gun. If they're not, you'll either have a leaky mess or it just won't connect at all.

Even more critical is making sure the pressure washer lance is rated to handle your machine’s maximum PSI and GPM. Putting a 2,500 PSI lance on a 4,000 PSI machine is a recipe for disaster. That kind of failure isn't just a leak; it's a blowout that can cause serious injury. Always, always check the specs on both your washer and the lance before connecting them.

What Is the Difference Between a Lance and a Wand?

In our world, "lance" and "wand" mean the same thing. They both refer to the rigid tube connecting your trigger gun to the spray nozzle. While "lance" might sound a bit more technical, you'll hear both terms used interchangeably out in the field.

Don't get hung up on the terminology. What really matters are the specs that affect how the tool actually performs:

Its overall length, which dictates your reach.

The material it's made from (stainless steel is a pro favorite for a reason).

The pressure and flow rating (PSI/GPM).

The type of fittings on each end.

How Do I Know When to Replace My Lance?

Treating your lance like a lifetime tool is a mistake. It's a consumable part, and regular inspection is a non-negotiable safety habit. You should pull a lance from service immediately if you see any of these red flags:

Visible Damage: Any cracks, deep rust, or major dents are a sign of trouble. If a lance is bent, it's done—its structural integrity is shot.

Persistent Leaks: If you're getting leaks at the connection points and a new O-ring doesn't solve it, the fitting itself is probably worn or damaged.

Compromised Fittings: Look for stripped threads on screw-on connectors. On quick-connects, check for a wobbly or loose fit. That connection needs to be rock-solid.

A pressure washer lance is a consumable part, not a lifetime tool. For our professional clients in Atascadero and Arroyo Grande who use their equipment daily, proactive replacement is key to preventing unexpected downtime and ensuring job site safety.

Whether you're cleaning agricultural equipment in Templeton or a commercial storefront in Morro Bay, a reliable lance is fundamental. Don't wait for it to fail completely—replace your gear at the first sign of serious wear.

For expert advice and access to professional-grade pressure washer parts and accessories, trust the team at Contractor's Maintenance Service. We provide the durable equipment and reliable support that keeps contractors on California's Central Coast running. Visit us online or at our San Luis Obispo shop to find the right solutions for your needs at https://www.contractorsmaintenanceservice.com.