Preventive maintenance vs corrective maintenance: A Practical Guide

- Dec 31, 2025

- 15 min read

When it comes to equipment upkeep, the debate between preventive vs corrective maintenance boils down to one simple question: do you want to be proactive or reactive? Preventive maintenance is all about scheduled care to stop failures before they even start. Corrective maintenance, on the other hand, is fixing equipment after it’s already broken. For businesses in San Luis Obispo and the surrounding areas, this choice directly hits your project timelines, budget, and bottom line.

Defining Your Maintenance Philosophy

Every equipment owner has a maintenance routine, whether they realize it or not. The real question is whether that routine is a planned, proactive strategy or a reactive, run-it-til-it-breaks model. This isn’t a minor decision—it’s one of the most critical choices a contractor or facility manager can make. One path gives you predictable costs and rock-solid reliability; the other is a high-wire act of risk and potentially catastrophic downtime.

For companies that depend on heavy machinery, from construction crews in Paso Robles to agricultural operators in Santa Maria, getting this right is non-negotiable. A smart approach doesn’t just squeeze more life out of your valuable assets; it protects your reputation for being reliable and finishing jobs on time.

Proactive vs Reactive Approaches

A proactive strategy is all about looking ahead. It means scheduling routine inspections, lubrication, and parts replacements based on manufacturer guidelines and how you actually use the equipment. It’s the foundation for keeping unexpected shutdowns to a minimum. Our guide on building a preventive maintenance schedule template is a fantastic place to start mapping this out.

The reactive approach is the exact opposite—you wait for something to go wrong. It might save you a little on upfront labor and parts, but it almost always leads to bigger, more expensive emergency repairs and serious operational losses down the road. This might work for a cheap, easily replaced hand tool, but it’s a massive gamble for your essential equipment. For a service provider in Atascadero or Arroyo Grande, an unexpected equipment failure can bring an entire project to a screeching halt.

The real goal here is to shift from a culture of constant repair to a culture of genuine reliability. The time you spend today preventing a breakdown will save you far more time and money tomorrow when that same failure happens at the worst possible moment.

To make the choice clearer, here’s a straightforward comparison of these two maintenance philosophies. It’s designed to help you weigh the trade-offs and see what makes the most sense for your operation.

Preventive vs Corrective Maintenance At a Glance

Attribute | Preventive Maintenance | Corrective Maintenance |

|---|---|---|

Timing | Proactive & Scheduled | Reactive & Unplanned |

Cost Structure | Predictable, budgeted costs | Unpredictable, high emergency costs |

Downtime | Planned, minimal & controlled | Unplanned, often extensive |

Asset Lifespan | Maximized & extended | Often shortened due to stress |

Risk Profile | Low risk of unexpected failure | High risk of catastrophic failure |

Ideal For | Critical, high-value equipment | Non-critical, redundant assets |

Ultimately, this table shows two very different ways of managing assets. Preventive maintenance is an investment in stability, while corrective maintenance operates on a risk-and-reward basis that often doesn't pay off with critical machinery.

The Financial Impact of Your Maintenance Choice

The real comparison isn't a single repair bill versus a scheduled service fee. It's about the total cost of ownership.

For our clients here in San Luis Obispo and the surrounding areas, this is a daily reality. Picture a painting contractor in Paso Robles whose Graco sprayer gives out mid-job. The cost isn't just the emergency repair. It's the crew you're paying to stand around, the project delays, and the potential penalty clauses in your contract. Corrective maintenance is a high-stakes gamble with your budget.

Preventive maintenance, on the other hand, brings predictability to your finances. By scheduling routine service for your equipment—whether you're in Atascadero, Arroyo Grande, or Santa Maria—you turn volatile repair expenses into a manageable, budgeted cost. It’s a proactive investment in stability, allowing you to forecast expenses and sidestep the financial shock of a catastrophic failure.

Calculating the True Return on Investment

The ROI is where a preventive program really shines. Yes, it requires an upfront investment in parts, labor, and a little bit of planned downtime. But the returns are substantial and well-documented. You aren't just avoiding a single repair; you're heading off the cascade of financial fallout that comes with an unexpected breakdown.

The numbers don't lie. Research shows that companies with solid preventive maintenance programs saved between 12% and 18% compared to those stuck in a reactive cycle. Even better, every dollar you invest in preventive upkeep can generate roughly $5 in avoided future costs, from sky-high emergency labor rates to lost production. You can dive deeper into the economic advantages of proactive maintenance strategies to see how this plays out across different industries.

The most expensive repair is always the one you didn't plan for. Proactive maintenance turns a potential financial crisis into a controlled, predictable line item on your budget, protecting your profitability and reputation.

For businesses on the Central Coast, this means real money saved. A construction firm in Santa Maria that services its Multiquip compactors on schedule avoids the five-figure cost of a complete engine rebuild and the project delays that would follow. This gets to the heart of the financial difference: preventive maintenance puts you in control of your costs, while corrective maintenance lets costs control you.

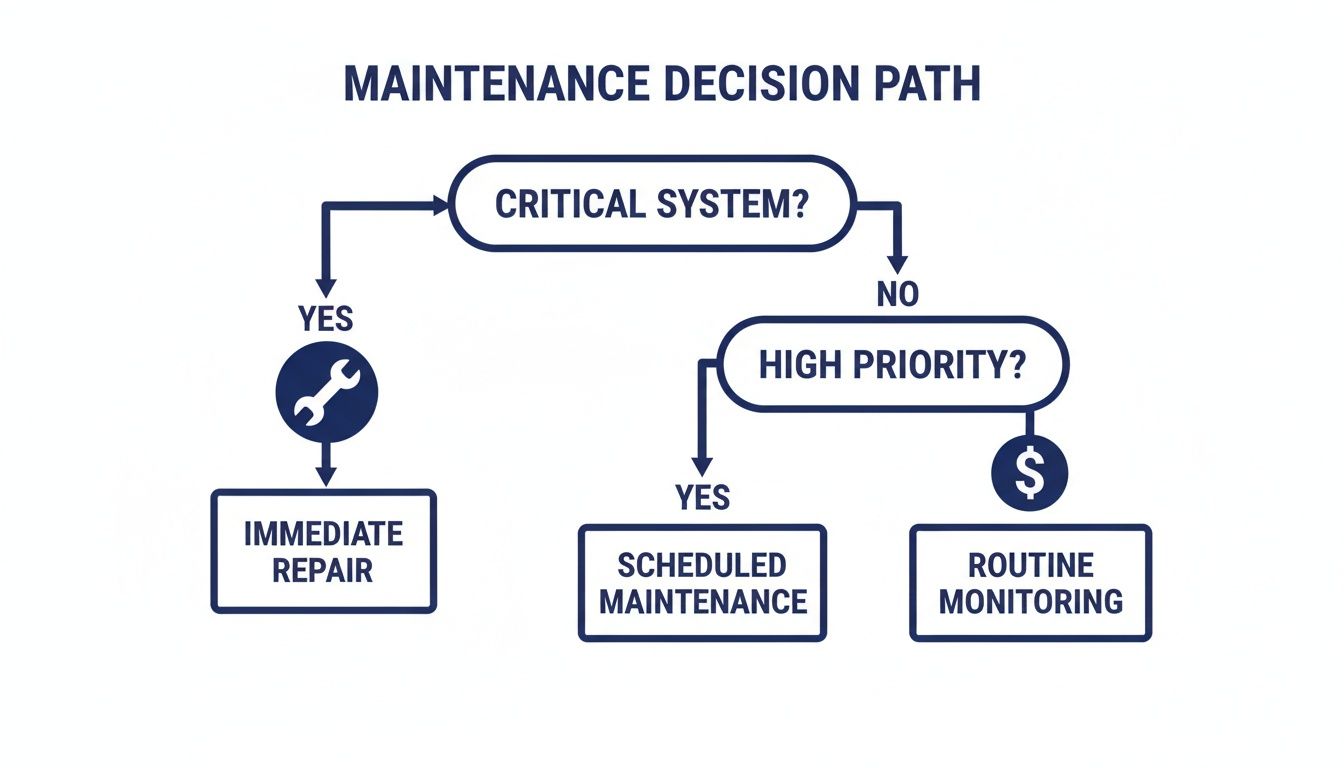

This simple decision tree helps visualize the financial logic. It guides you to consider equipment criticality first, which is the primary driver of financial risk.

As the flowchart shows, the path for critical assets leads straight to planned maintenance to protect your bottom line. Non-critical assets, however, give you more financial flexibility.

The Hidden Costs of Deferred Maintenance

One of the most dangerous financial traps of a reactive approach is deferred maintenance. This is what happens when you knowingly put off necessary upkeep to save a few bucks today. But here's the catch: the delay doesn't eliminate the cost; it multiplies it.

Think of it like a small leak in a hydraulic hose. A quick, scheduled replacement is a minor expense. But if you put it off, that hose will eventually burst under pressure, potentially causing:

Catastrophic component failure: The initial problem can set off a chain reaction, destroying more expensive parts of the system.

Safety incidents: A sudden equipment failure can lead to workplace accidents, injuries, and costly liabilities.

Extended, unplanned downtime: What could have been a 30-minute fix now requires days of complex repairs and scrambling for parts.

Studies show that for every $1 of deferred maintenance, a company can expect to pay $4 in capital renewal costs later. That small, postponed expense grows exponentially, eating into profits and straining resources. It’s a costly lesson many businesses learn only after a major failure brings operations to a screeching halt. A preventive mindset avoids this debt by tackling small issues before they blow up into financial disasters.

How Maintenance Impacts Operational Uptime and Asset Longevity

Your maintenance strategy is the single biggest factor determining how often your equipment runs and how long it lasts. The choice between preventive maintenance vs. corrective maintenance directly shapes your daily productivity and the health of your most critical assets. One approach builds reliability and control; the other invites chaos and unexpected costs.

It really boils down to downtime. Preventive maintenance involves controlled, scheduled downtime that you plan for. Corrective maintenance, on the other hand, leads to chaotic, unpredictable stoppages that always seem to hit at the worst possible moment, bringing your whole operation to a grinding halt.

Fostering Reliability Through Proactive Care

A preventive approach is all about consistency. By sticking to routine inspections and service, you catch small issues before they snowball into catastrophic failures. This consistency is measured with key performance indicators like Overall Equipment Effectiveness (OEE), a metric that combines availability, performance, and quality into one score.

For contractors and facility managers from San Luis Obispo to Paso Robles, reliability isn't just a goal—it's a promise you make to your clients. A proactive maintenance plan ensures your equipment is ready to go when you are, maximizing your operational uptime and protecting your reputation for finishing jobs on time.

The data backs this up. A Deloitte analysis found that planned maintenance strategies typically achieve an OEE of 50%-75%, a huge jump from the less than 50% OEE common with reactive approaches. A comprehensive PWC study also revealed that combining preventive and predictive strategies extends the life of aging assets by 20%, cuts machine downtime by 30%-50%, and reduces safety risks by 14%. For any business managing valuable equipment, those numbers translate directly to better productivity and a safer work environment.

Extending Asset Longevity and Protecting Investments

Your equipment is a major capital investment. A corrective, run-to-failure strategy puts that investment at constant risk. Every major breakdown puts immense stress on your machinery, shortening its effective service life and forcing you into costly replacements sooner than you'd like.

Preventive maintenance, in contrast, is like a long-term care plan for your assets. Simple, routine tasks can dramatically extend the life of your equipment:

Regular lubrication reduces friction and stops premature wear on moving parts.

Fluid analysis and changes keep engines and hydraulic systems clean and cool.

Filter replacements protect critical components from damaging contaminants.

Component inspections identify signs of fatigue before a part fails completely.

Understanding the finer points of different strategies, like mastering enterprise fleet maintenance, can have a huge impact on your company's bottom line. Every service interval you meet is another step toward maximizing your return on that big investment.

A well-maintained machine not only runs better today but also retains more of its value over time. Preventive care is the most effective way to protect your capital and delay the enormous expense of purchasing new equipment.

Real-World Scenarios on the Central Coast

The impact of these maintenance choices is clear in daily operations all over our local communities. Think about a construction crew in Arroyo Grande relying on a hydraulic excavator.

A proactive hydraulic hose inspection, a key part of our recommended equipment preventative maintenance checklist, can spot a worn or cracked hose long before it fails. This scheduled, low-cost replacement prevents a sudden, catastrophic burst that could sideline the machine for days, cause a dangerous fluid spill, and bring the entire project to a standstill. The difference isn't just about a hose; it's about project continuity, workplace safety, and profitability.

When a Run-to-Failure Strategy Makes Sense

While preventive maintenance is the gold standard for your most critical machinery, it’s not always the smartest or most cost-effective play for every single asset you own. The whole debate over preventive maintenance vs corrective maintenance isn't about one being "good" and the other "bad." It’s about being strategic—applying the right approach to the right piece of equipment. Sometimes, letting a machine run until it breaks is the best business decision you can make.

This reactive strategy, a type of corrective maintenance, is an intentional choice. You use an asset until it fails, and only then do you repair or replace it. It's a calculated risk, but one that pays off when the cost and effort of a preventive program would be far greater than the fallout from an actual failure. For businesses in San Luis Obispo and nearby areas like Paso Robles, this approach frees up valuable time and money to focus on what really drives the business forward.

Identifying Low-Risk Assets

The key to a successful run-to-failure strategy is knowing your equipment inside and out. Not everything carries the same weight. Start by sorting your assets based on their impact on safety, production, and project timelines. A run-to-failure model is a perfect fit for items that are non-critical, cheap to replace, or have backups ready to go.

Ask yourself these questions when deciding if an asset is a good candidate for a corrective maintenance plan:

Low Failure Impact: If this piece of equipment fails, will it shut down the whole operation or create a safety hazard? If the answer is no, it's a possibility.

Low Repair Cost: Is the asset inexpensive and easy to fix or replace? The cost of a brand-new unit should be minimal.

Redundancy: Do you have backups sitting on the shelf? If one unit goes down, another can be swapped in with little to no downtime.

Making this strategic choice allows contractors in Atascadero and Arroyo Grande to get the most out of their maintenance budgets. It means directing funds and labor toward the high-value equipment that keeps revenue flowing and ensures your operations don't miss a beat.

Practical Scenarios for Corrective Maintenance

Real-world examples make it obvious where this strategy shines. Picture a commercial painting crew working on a job in Santa Maria. They might have a dozen handheld power tools, like sanders or drills.

It would be a massive waste of time to create a detailed preventive maintenance schedule for every single low-cost sander. The labor spent taking it apart, inspecting it, and servicing it would likely cost more than the tool itself. In this case, a run-to-failure approach is the clear winner. When a sander breaks, it’s quickly and cheaply replaced, and the project moves on without a major hiccup.

A run-to-failure strategy isn’t about neglecting your equipment; it’s about making a conscious, data-driven decision to allocate your maintenance resources where they will deliver the greatest return on investment.

Other common examples where this makes sense include:

Non-essential lighting fixtures in a workshop.

Seldom-used backup pumps that aren't tied to a critical safety system.

Small, non-specialized office equipment like printers or fans.

By adopting a hybrid model—using preventive maintenance for your critical systems and corrective maintenance for low-risk assets—you build a balanced, efficient, and cost-effective operation. It’s a practical mindset that recognizes that not all equipment plays the same role in your day-to-day business.

Building Your Preventive Maintenance Program

Making the jump from a reactive, costly repair cycle to a proactive, cost-saving operational model is one of the smartest moves a contractor can make. The real difference between preventive maintenance vs corrective maintenance comes down to deliberate planning. It’s about taking control of your equipment’s health before a failure wrecks your schedule and budget.

For businesses here on the Central Coast, from Paso Robles down to Santa Maria, that transition starts with one simple but non-negotiable step. You can't maintain what you don't track.

Foundational Steps to Proactive Maintenance

Building a solid PM program doesn't mean you need complex software or a massive overhaul on day one. It all starts with methodical organization and a clear-eyed view of your assets.

Create a Comprehensive Equipment Inventory: Make a list of every single piece of machinery you depend on. Include the important details: manufacturer, model number, serial number, and the date you bought it. This list is the backbone of your entire maintenance strategy.

Prioritize Your Assets: Let's be honest, not all equipment is created equal. Group each item based on how critical it is to your daily operations. A primary air compressor in an Atascadero workshop is way more important than a backup power tool. This helps you put your resources where they’ll make the biggest impact.

Develop Manufacturer-Aligned Checklists: Crack open the owner’s manuals for your high-priority gear. Manufacturers give you detailed service intervals and specific tasks for a reason—they know the machine best. Turn those recommendations into simple, clear checklists for daily, weekly, and monthly inspections.

Getting these first steps right creates the framework you need for a program that actually works. You can get more ideas for structuring these plans by checking out our guide on the top 10 preventive maintenance best practices for 2025.

Setting Up a Practical Scheduling System

Once you have your inventory and checklists, it’s time to get everything on a schedule. This can be as straightforward as a shared digital calendar or even a physical whiteboard in the shop. The key isn't the tool you use; it's consistency and making sure your team can see it.

A smart PM program also means thinking ahead about parts, like making sure you have replacement coils for contactors or other common wear-and-tear items on hand. This kind of foresight stops a scheduled service from turning into an unexpected delay while you're scrambling to find a part.

A maintenance schedule isn't just a to-do list; it's a strategic tool that transforms your operational mindset. It shifts your focus from "What broke today?" to "What can we do today to prevent a breakdown tomorrow?"

Whether you’re working in San Luis Obispo or Arroyo Grande, a dedicated service partner like Contractor's Maintenance Service can help pull this all together. We can help you source the right OEM parts and give you the expert technical support to execute your plan effectively.

Tracking Success and Validating Your Program

So, how do you know if your preventive maintenance program is actually paying off? The proof is in the data. By tracking just a few simple metrics, you can validate your efforts and pinpoint areas to improve.

Mean Time Between Failures (MTBF): This is just the average time your equipment runs between breakdowns. As your PM program takes hold, you should see the MTBF for your critical assets go up. A lot.

Reduction in Emergency Calls: One of the first things you'll notice is a drop in those frantic, unplanned service calls. This directly translates to lower costs and fewer disruptions to your jobs.

Maintenance Cost Analysis: Compare your total maintenance spending over time. While you’ll have planned costs for preventive tasks, your overall expenses on emergency repairs should drop, leading to real net savings.

To help you get started, here's a sample schedule that provides a clear, adaptable template for common contractor equipment.

Sample Preventive Maintenance Schedule for Contractor Equipment

This table outlines a basic maintenance cadence for some of the most common tools of the trade. You can adapt it to fit the specific models and usage levels in your own shop.

Equipment Type | Daily Checks | Weekly Tasks | Monthly Service | Annual Overhaul |

|---|---|---|---|---|

Airless Sprayer | Clean filters, check for leaks | Inspect gun & tip wear | Lubricate packings | Rebuild fluid section |

Pressure Washer | Inspect hoses & connections | Check oil levels | Clean nozzles & inlet filter | Service engine & pump |

Generator | Check fuel & oil levels | Test outlets & breakers | Change oil & air filter | Inspect all electrical components |

Compactor | Clean air filter | Check belt tension | Change engine oil | Full engine & system service |

Remember, a good schedule is a living document. Tweak it as you learn more about your equipment's performance and needs. The goal is to find the sweet spot that maximizes uptime and minimizes surprise costs.

Your Local Maintenance Partner in San Luis Obispo

Knowing the difference between preventive vs. corrective maintenance is one thing. Putting it into practice with a reliable, local expert is another. At Contractor's Maintenance Service, we're that partner for businesses all over San Luis Obispo County. We’re committed to keeping your essential equipment running, whether you need a solid preventive plan or an urgent repair.

We proudly serve San Luis Obispo and the surrounding areas, including Paso Robles, Atascadero, Arroyo Grande, Santa Maria, and the greater Central Coast region. We know the local landscape and the unique demands on your machinery, from heavy agricultural equipment to essential construction tools. Our only goal is to minimize your downtime and keep you productive with fast, effective solutions.

Authorized Service and Specialized Expertise

When your equipment goes down, you need a team that knows your machinery inside and out. As an authorized service center for leading brands like Graco, Wagner/Titan, and Multiquip, we deliver manufacturer-backed repairs and warranty support you can actually trust. Our factory training ensures your equipment is serviced to the highest standard, protecting its performance and lifespan.

We do more than just standard repairs. We specialize in building custom hydraulic hoses to your exact specs while you wait. That unique service is a total game-changer when a failed hose threatens to grind your project to a halt, getting you back to work with almost no delay.

Your equipment's reliability is our top priority. We combine rapid diagnostics with expert repairs and a massive parts inventory to solve your maintenance challenges quickly and effectively, keeping your projects on track and on budget.

Your Go-To for Parts and Repairs

One of the biggest headaches in maintenance is tracking down the right parts. We’ve built our reputation on locating hard-to-find components, saving you the time and frustration of hunting for obscure fittings or engine parts. Thanks to our extensive inventory and supplier network, we can often find what others can’t.

Whether you're building a preventive maintenance program from scratch or you’re in the middle of an unexpected breakdown, our team is here to help. We do more than just sell parts; we provide trusted advice on the right maintenance strategy and execute complex repairs. Think of us as your dedicated maintenance partner.

For businesses on the Central Coast, choosing Contractor's Maintenance Service means choosing reliability. We offer:

Rapid Diagnostics: We get to the root cause of equipment failure quickly, so the repair is done right the first time.

Expert Repairs: Our authorized training means we restore your equipment to peak condition, not just patch the problem.

Customer-First Approach: We're deeply committed to your success. You get the support you need, exactly when you need it.

Contact us today to see how we can support your maintenance needs.

Frequently Asked Questions

Jumping into a formal maintenance strategy can bring up a lot of questions. Below, we’ve tackled some of the most common ones we hear from contractors and facility managers trying to decide between preventive and corrective maintenance.

Think of this as a quick guide to help you make the right call, whether you're running a small crew in San Luis Obispo or a large industrial site in Santa Maria.

What Is the First Step to Starting a Preventive Maintenance Program?

The best place to start is by creating a detailed inventory of your essential equipment. You can't maintain what you don't track. Pinpoint the machinery that's absolutely critical to your operations—the assets that would shut you down if they failed.

Once you have that list, the next step is to work with a service expert. They can help you review the manufacturer’s recommended service intervals and build out a baseline schedule. This simple groundwork is the foundation of a solid, proactive maintenance culture.

Is Corrective Maintenance Always Cheaper Initially?

While a "fix-it-when-it-breaks" approach avoids upfront spending on scheduled service, corrective maintenance is a high-risk gamble. It might look cheaper on paper month-to-month, but that view is dangerously shortsighted.

The cost of just one unexpected breakdown almost always blows past the annual cost of a planned preventive maintenance program. When you start adding up lost productivity, project delays, and premium emergency repair fees, the financial hit can be huge. For businesses in Paso Robles or Atascadero, one major failure can easily wipe out a project's profitability.

The initial savings of skipping maintenance are often an illusion. The true cost of corrective maintenance shows up when a critical asset fails at the worst possible moment, forcing you to pay for emergency repairs, overtime labor, and lost revenue.

How Do I Know If My Preventive Maintenance Program Is Working?

You don't need complicated analytics to see the results. Success can be measured through simple but powerful signs that show your proactive efforts are paying off.

Look for these clear indicators that your program is on the right track:

A noticeable reduction in emergency service calls.

Longer, more consistent operational periods between equipment failures.

A measurable decrease in your overall maintenance and repair spending over time.

These metrics are proof that shifting from a reactive to a proactive mindset is delivering a real return. For operations in Arroyo Grande and across the Central Coast, this means more uptime, better budget control, and a far more stable operation.

For expert guidance on building a maintenance strategy that fits your needs, trust Contractor's Maintenance Service. We provide authorized repairs, hard-to-find parts, and custom solutions to keep your equipment running reliably. Get in touch with us today.

Comments