The Ultimate Hydraulic Fitting Types Chart and Identification Guide

- Jan 10

- 15 min read

When you're faced with a pile of hydraulic fittings, a good hydraulic fitting types chart is your best friend. It’s the quickest way to get a handle on what you’re looking at, whether it's a JIC, NPT, ORFS, or something else entirely. By comparing the sealing method and what the fitting looks like, you can narrow down the options fast, well before you even pull out the calipers. Getting it right from the start is what separates a smooth repair from leaks, damaged equipment, and a whole lot of downtime.

Why a Fitting Identification Chart Is Essential

Being able to correctly identify hydraulic fittings isn’t just a handy skill—it’s absolutely critical for anyone working on machinery. A single wrong component can lead to catastrophic failure, spewing high-pressure fluid that’s both dangerous and messy. With dozens of different standards floating around from North America, Europe, and Asia, a reliable chart is your first line of defense against a costly mistake.

For our customers in San Luis Obispo and the surrounding areas, this is non-negotiable. Whether you’re maintaining vineyard equipment in Paso Robles or running heavy machinery on a Pismo Beach construction site, getting the right parts quickly is everything. When a hose blows on a job in Atascadero, Arroyo Grande, or Nipomo, there’s no time for guesswork. That's why knowing how to read a fitting chart is a foundational skill.

The Foundation of Fitting Identification

Before you get lost in the details of a chart, remember that identifying any fitting comes down to a few basic principles. You just need to know what to look for, understand how it seals, and have an idea of where it’s commonly used.

Visual Inspection: First, just look at it. What’s the overall shape? Do you see a flared end, a flat face with a little O-ring peeking out, or threads that get narrower at the end? This first glance will immediately rule out a bunch of possibilities.

Sealing Method: Next, think about how it stops leaks. Fittings create a seal in different ways. Some rely on the threads mashing together (NPT), others on a precisely angled metal-to-metal surface (JIC), and many modern fittings use a soft seal like an O-ring (ORFS, ORB).

Common Applications: Context is key. Certain fittings are industry standards for specific equipment. JIC fittings, for example, are all over North American mobile equipment, while you'll typically find DIN metric fittings on machines built in Europe.

This simple visual guide breaks down the core steps for identifying any hydraulic fitting by focusing on what you can see, how it seals, and where it’s most likely used.

As the graphic shows, identification is a systematic process. You start with a quick visual check and then drill down into the specifics of its design and purpose. From here, this guide will build on these fundamentals, giving you the detailed charts and knowledge needed to pick the right part with confidence, every single time.

Understanding North American Fitting Standards

When it comes to hydraulic systems, not all fittings are made the same, and your location on the map makes a big difference. For anyone working with equipment in North America, a few core standards are the bread and butter of most domestic machinery. Getting a firm handle on these common types is the first step to identifying them correctly and making leak-free repairs.

These standards weren't picked at random; they were developed to guarantee reliability and make parts interchangeable across a massive range of equipment. Knowing their unique sealing methods is non-negotiable if you’re using a hydraulic fitting types chart to track down the right replacement.

JIC 37° Flare Fittings

The Joint Industry Council (JIC) fitting, officially known as the SAE J514 37° flare, is hands-down the most common fitting you'll find on mobile equipment in the United States. Its popularity comes from a design that’s both simple and incredibly effective.

Sealing Method: JIC fittings rely on a solid metal-to-metal seal created between the 37° flared tip of the male fitting and the matching conical seat inside the female fitting.

Common Applications: You’ll spot these all over high-pressure systems on construction, agricultural, and forestry equipment.

Materials: Most are made from carbon steel, stainless steel, or brass.

A perfect example is the hydraulic cylinder on a Multiquip compactor or the fluid lines on a Graco line striper—they almost always use JIC fittings because they stand up so well to high vibration.

SAE Straight Thread O-Ring Boss

Often just called O-Ring Boss (or ORB), the SAE J1926 fitting is the go-to for a superior, leak-proof connection. It has quickly become the preferred choice for high-pressure jobs where a leak simply isn't an option.

The ORB fitting uses a straight thread and seals with a high-durometer O-ring that gets compressed into a beveled port, which creates an exceptionally tight seal. This design makes it a champion at preventing leaks caused by vibration or sudden pressure spikes. You can easily identify an ORB fitting by its straight threads and the visible O-ring sitting at the base of the male thread.

National Pipe Taper

National Pipe Taper (NPT) and its dry-seal cousin, NPTF, are some of the oldest standards still in heavy rotation today. Unlike JIC or ORB fittings, NPT creates a seal through thread interference.

The male and female threads are both tapered, designed to wedge together and form a seal as they tighten. For a standard NPT fitting, a thread sealant like Teflon tape or pipe dope is almost always required to fill any tiny gaps and stop leaks in their tracks.

NPTF (Dryseal) threads are machined to create a tighter mechanical seal on their own, but using a sealant is still a good idea. You’ll typically find these in lower-pressure fluid power systems and general plumbing applications.

That said, the equipment world is becoming more global. Hydraulic fitting type charts are now drawing sharper distinctions between regional standards as more machinery gets imported from Europe and Asia. While North American charts are still dominated by NPTF, ORB, and JIC, metric and BSPP fittings now account for an estimated 20–30% of connections on mixed OEM fleets. For service shops, this means a single wall chart can easily list 50–100 different fitting families, which is why getting expert support is more critical than ever. Learn more about these global market shifts and their impact on fitting selection.

A Look at International Fitting Standards

As equipment fleets get more and more global, you can't afford to be unfamiliar with international fitting standards. It's not just an option anymore—it's a necessity. Machinery coming in from Europe and Asia has its own set of hydraulic connection standards, and they are completely different from what we're used to in North America. For any maintenance team here in San Luis Obispo County, whether you're servicing equipment in Paso Robles vineyards or on an Arroyo Grande construction site, you have to know these global systems.

Trying to mix and match these fittings with North American types is just asking for leaks and catastrophic failure. It's why any good hydraulic fitting types chart has to break down the British, German, and Japanese standards in detail. At Contractor's Maintenance Service, we make sure to stock a wide variety of these international fittings to keep your jobs moving, whether you're in Atascadero, Pismo Beach, Grover Beach, or Nipomo.

British Standard Pipe Fittings

One of the most common international standards you'll run into is the British Standard Pipe (BSP). It’s a lot like NPT in that it comes in two main flavors, but their sealing methods and thread profiles are totally different.

BSPP (Parallel): British Standard Pipe Parallel fittings have straight, parallel threads. They can't seal by themselves and need a soft seal—usually a bonded seal washer (often called a Dowty seal) or an O-ring that gets compressed against a flat surface to stop leaks.

BSPT (Tapered): British Standard Pipe Tapered fittings use tapered threads to form a seal through thread interference, which sounds similar to NPT. The key difference, however, is the thread angle: BSPT is 55°, while NPT is 60°, making them incompatible.

You absolutely cannot mix BSP and NPT fittings, even if they seem to thread together at first. Those mismatched thread angles will always create a leak path once the system is under pressure.

German DIN Fittings

If you're working on equipment made in Germany or elsewhere in Europe, you're almost guaranteed to find DIN (Deutsches Institut für Normung) fittings. The most common type is the 24° cone series, which is known for its incredible performance in high-pressure situations.

You can spot DIN fittings by their 24° seat angle and metric threads. Their sealing mechanism is a cool bite-type design where a ferrule (or cutting ring) actually bites into the outer surface of the hydraulic tube as you tighten the nut. This creates a really strong, vibration-resistant mechanical seal.

This bite-type connection is extremely reliable, which is why DIN fittings have become a global standard for both mobile and industrial hydraulic systems.

Japanese Industrial Standard Fittings

Japanese equipment, from brands like Komatsu or Honda, uses Japanese Industrial Standard (JIS) fittings. They look a lot like the 37° JIC flare at first glance, but there’s a crucial difference that means you can't swap them.

JIS fittings typically have a 30° flare seating surface. If you try to connect a 37° JIC fitting to a 30° JIS port, you'll end up with a poor seal concentrated on a tiny line of contact, which is a guaranteed leak under pressure. On top of that, some JIS fittings use a 60° cone seat, which you'll often see on hose adapters. Always use a gauge to check the seat angle to make sure you've identified it correctly and avoid expensive mistakes when working on Japanese machinery.

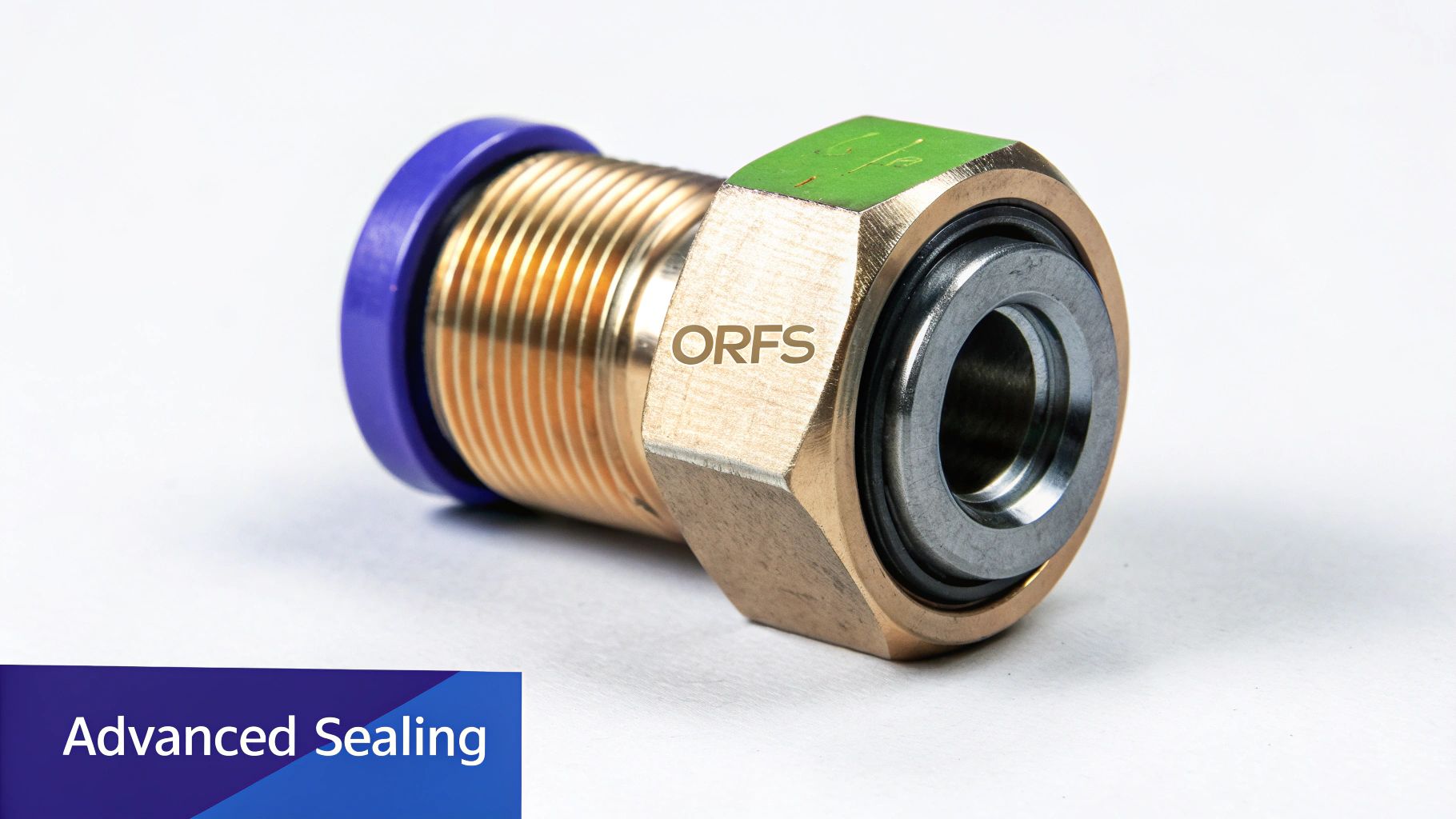

Taking Sealing to the Next Level: Advanced Fittings

When you move beyond standard connections, you'll find a class of fittings built for one specific purpose: zero-leak performance. These are the heavy hitters, engineered for hydraulic systems where even the smallest drip is a massive problem—think safety hazards, expensive fluid loss, or extreme operating pressures. For anyone running modern, high-demand equipment in San Luis Obispo, Paso Robles, or Atascadero, knowing these fittings is non-negotiable.

The star of this category is the O-Ring Face Seal (ORFS) fitting. Its design is a brilliant lesson in reliability. Instead of relying on metal-to-metal contact or thread interference, an ORFS fitting features a flat face with a tough O-ring tucked neatly into a groove. When you tighten it down, that O-ring compresses against the flat face of its mate, creating a seal that’s incredibly tough and fantastic in high-vibration and high-pressure situations.

Compression and Bite-Type Fittings are Taking Over

Right alongside ORFS, you have a whole family of compression-style fittings that have really grabbed a huge piece of the market. The principle is simple but effective: as you tighten the nut, a component—either a ferrule or a cutting ring—is forced to deform onto the hydraulic tubing. This creates a solid mechanical grip and an impressive seal.

Bite-Type Fittings: Very common in DIN metric systems, these use a hardened ferrule that actually "bites" into the tube's outer surface. The result is a rock-solid, leak-proof connection.

Ferrule Fittings: You'll often see these on instrumentation lines. They use one or two ferrules that swage onto the tube, giving you a secure seal without compromising the tube's integrity.

This industry-wide move toward better sealing isn't just a coincidence. If you look at a hydraulic fitting chart from a decade ago, it was dominated by older threaded styles. Today, the game has changed. Industry research now shows that card sleeve (compression) fittings are the dominant category by revenue, simply because they perform better. One report even projects compression fittings to grow at 7.7% CAGR from 2019-2024, and then speed up to 10.3% CAGR by 2030, leaving many older designs in the dust.

When you're dealing with advanced sealing technologies, never underestimate the importance of quality components like replacement O-rings. A single, low-quality O-ring can easily compromise an entire high-pressure connection, leading to leaks and system failure.

For our local contractors in Arroyo Grande, Pismo Beach, and Nipomo, this trend means you're seeing more of these advanced fittings on newer machines where leak-related downtime is incredibly expensive. While O-rings are the sealing heroes in ORFS systems, other fittings use different components to get the job done. For instance, you might find our guide on copper crush washers helpful, as they serve a similar sealing purpose in banjo fittings and other static connections: https://www.contractorsmaintenanceservice.com/post/a-contractor-s-guide-to-copper-crush-washers. Knowing the right component for the job is key to a reliable repair.

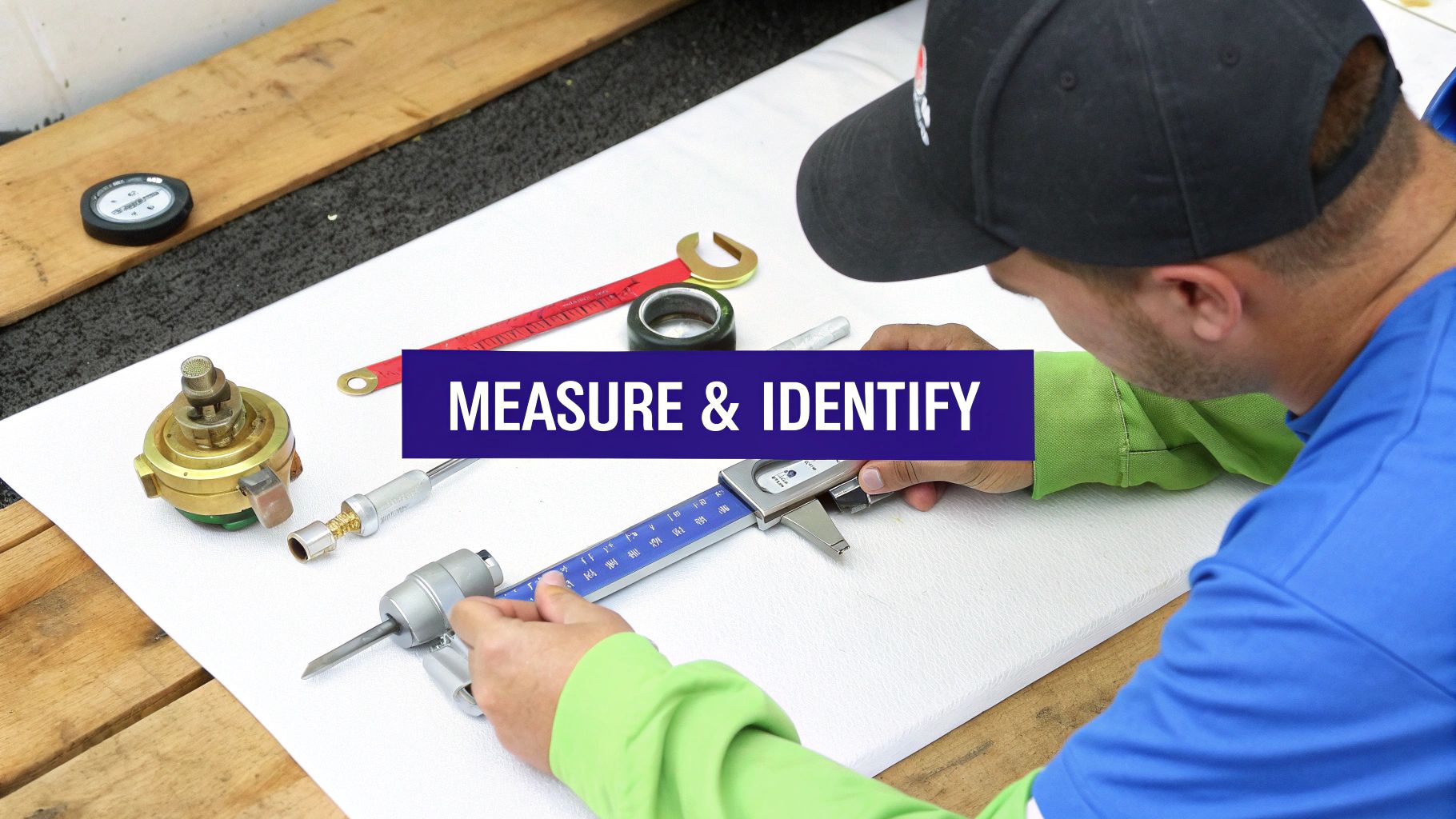

How to Measure and Identify Any Hydraulic Fitting

Even with the best hydraulic fitting types chart in front of you, a proper ID comes down to accurate measurement. Get it wrong by a single millimeter, or mistake the thread pitch, and you’re looking at leaks, damaged equipment, and serious safety hazards. This section gives you a straightforward, step-by-step process to confidently measure and identify any fitting you come across.

Whether you're working on a job in San Luis Obispo, Paso Robles, or Atascadero, having the right tools and a solid method is the key to minimizing downtime. With just a few simple instruments, you can get the exact data needed to find a perfect match for your hydraulic system.

The Essential Tools for Identification

You don't need a full-blown workshop to nail down a fitting's identity, just a couple of key tools. Precision is everything here, and these instruments will give you the accuracy you need.

Calipers: A digital or dial caliper is non-negotiable. You’ll need it to measure the outside diameter (OD) of a male thread and the inside diameter (ID) of a female thread.

Thread Pitch Gauge: Also known as a thread gauge, this tool has a series of blades you’ll use to find the thread pitch. It will tell you the threads per inch (TPI) for imperial fittings or the pitch in millimeters for metric ones.

Seat Angle Gauge: This little tool is a lifesaver for accurately measuring the angle of the sealing surface on flared fittings, like the 37° on a JIC fitting or the 30° on a JIS fitting.

These three tools give you all the raw data you need to cross-reference with any identification chart.

A Four-Step Identification Process

With your tools ready, follow this systematic approach to make sure you capture every critical detail. This method is your best bet for just about any fitting you’ll find in the field.

Inspect the Sealing Surface: First, figure out how the fitting seals. Is it a tapered thread (like NPT/BSPT)? Or maybe it's a flared seat (JIC/JIS)? You might see a flat face with an O-ring (ORFS) or an O-ring on the threads themselves (ORB). This quick visual check is your first major clue.

Measure the Seat Angle: For any flared fittings, grab your seat angle gauge to confirm the angle. This step is crucial for telling apart visually similar types like JIC (37°) and AN (45°).

Measure the Thread Diameter: Now, use your calipers to measure the outside diameter of the male thread or the inside diameter of the female thread. To get a good reading, make sure your caliper is perfectly perpendicular to the threads.

Determine the Thread Pitch: Take your thread pitch gauge and press its blades against the threads until one fits perfectly with no gaps. The blade will be marked with either the TPI or the millimeter pitch.

Once you have these four pieces of info—sealing method, seat angle, diameter, and pitch—you have everything you need to identify the fitting using a dash size conversion chart. Cross-referencing these measurements takes all the guesswork out of the equation.

Getting this process right is especially critical for anyone working with high-pressure hoses. Follow these steps every time, and you can be sure your repairs are safe, secure, and leak-free.

Thread Measurement and Dash Size Conversion Chart

To help you put it all together, here's a quick reference chart. Once you've taken your measurements, you can use this table to find the corresponding dash size and confirm the fitting standard. This is where your caliper and thread gauge readings come in handy.

Standard (e.g., JIC/SAE) | Dash Size | Thread Size (TPI or mm) | Male Thread OD (in/mm) | Female Thread ID (in/mm) |

|---|---|---|---|---|

JIC/SAE | -2 | 5/16"-24 | 0.31 | 0.28 |

JIC/SAE | -4 | 7/16"-20 | 0.44 | 0.40 |

JIC/SAE | -6 | 9/16"-18 | 0.56 | 0.51 |

JIC/SAE | -8 | 3/4"-16 | 0.75 | 0.69 |

JIC/SAE | -12 | 1-1/16"-12 | 1.06 | 0.99 |

ORFS | -4 | 9/16"-18 | 0.56 | 0.51 |

ORFS | -6 | 11/16"-16 | 0.69 | 0.63 |

ORFS | -8 | 13/16"-16 | 0.81 | 0.75 |

BSPP | -4 | 1/4"-19 | 0.52 | 0.48 |

BSPP | -8 | 1/2"-14 | 0.83 | 0.76 |

Metric (24° Cone) | M12x1.5 | 1.5mm | 12.0mm | 10.5mm |

Metric (24° Cone) | M16x1.5 | 1.5mm | 16.0mm | 14.5mm |

NPT | -4 | 1/4"-18 | 0.54 | 0.44 |

NPT | -8 | 1/2"-14 | 0.84 | 0.71 |

Keep in mind that this table covers some of the most common sizes, but there are many others out there. Always double-check your measurements to ensure you're ordering or fabricating the right part for the job.

Local Hydraulic Fitting and Hose Services in San Luis Obispo

Knowing your way around a hydraulic fitting chart is one thing, but that chart can't build the part you need to get back up and running. When a critical piece of equipment goes down, you need more than just knowledge—you need the right parts and expert service, fast. For businesses across the Central Coast, that's where having a local partner makes all the difference.

Here at Contractor's Maintenance Service, we're your hands-on hydraulic specialists right here in San Luis Obispo. We get it—downtime isn't just an inconvenience; it's costing you money by the minute. That's why we focus on providing prompt, reliable services to keep your operation moving.

On-the-Spot Custom Hydraulic Hose Fabrication

One of our most vital services is custom hydraulic hose fabrication while you wait. When a hose blows on the job site, you can't afford to wait days for a replacement to ship. Just bring in your busted hose assembly, and our technicians will build you a new one to exact factory specs.

We stock a huge range of hose types and pressure ratings to match whatever your machinery demands. Our process ensures your new assembly is a perfect fit that meets or exceeds the original's durability and safety standards.

An Extensive Inventory of Fittings and Adapters

Trying to track down a rare European or Asian fitting can bring an entire project to a screeching halt. We've curated our inventory to support the diverse equipment used throughout our local industries, from agriculture to construction. That means we stock a massive variety of fittings and adapters to cover nearly any application you can think of.

Our shelves are loaded with:

North American Standards: JIC, NPT, ORFS, and O-Ring Boss.

European Standards: DIN Metric 24° cone and BSP/BSPP.

Asian Standards: JIS 30° flare and 60° cone fittings.

Having this deep inventory means we can almost always grab the component you need right off the shelf, getting you back to work that much faster. Knowing where to find reliable local service is paramount, especially when planning larger hydraulic system installs or even complex diesel marine conversion projects.

Whether you’re managing a fleet in Paso Robles or running a single machine in Nipomo, having a local parts and service center is a major advantage. We proudly serve the entire San Luis Obispo County area, including Atascadero, Arroyo Grande, Pismo Beach, and Grover Beach.

For those trickier issues, our expert technical support is here to help. We can help you identify that mystery component or troubleshoot a leak that just won’t quit. To see more about how we handle repairs, check out our San Luis Obispo contractor's guide to hydraulic hose repair service. Our goal is to be your go-to source for the parts and expertise you need for a safe, lasting repair every time.

Hydraulic Fittings FAQ: Your Questions Answered

Even with a detailed hydraulic fitting types chart on hand, it's normal for specific questions to pop up in the middle of a repair. Getting the details right can be the difference between a solid fix and costly downtime.

Here are some of the most common questions we hear from customers in San Luis Obispo and nearby areas. Think of this as your quick-reference guide for clearing up confusion and getting the job done right the first time.

What Is the Main Difference Between JIC and NPT Fittings?

It all comes down to how they seal. JIC (Joint Industry Council) fittings rely on a 37-degree flared seating surface to create a tough metal-to-metal seal. This design is a workhorse, making it perfect for high-pressure and high-vibration systems where leaks are not an option.

NPT (National Pipe Taper) fittings, on the other hand, seal by thread interference—the tapered threads literally wedge themselves together. Because of this design, they almost always need a sealant like Teflon tape to create a leak-free connection. You'll typically find them in lower-pressure fluid and pneumatic systems.

Can I Mix Different Types of Hydraulic Fittings?

The short answer is no. You should never mix different hydraulic fitting types, even if the threads seem to connect. Mismatching components, like a JIC 37° flare with an AN 45° flare, creates an improper seal that is guaranteed to fail once pressure is applied.

The same goes for mixing thread standards like metric and imperial; it’s a recipe for leaks and can damage the threads. If you absolutely have to connect two different standards, the only safe way is with a purpose-built adapter designed for that specific conversion.

For our customers in Paso Robles, Atascadero, and Arroyo Grande, the easiest way to get the right adapter is to bring both ends of the connection into our shop. We'll identify them on the spot and pull the exact part you need from our extensive inventory.

How Do I Find the Pressure Rating for a Fitting?

A fitting's pressure rating isn't something you can guess—it's determined by the manufacturer based on its design, material, and size. This critical info is always listed in the manufacturer's catalog or on its technical data sheets.

As a general rule of thumb, more advanced designs like ORFS (O-Ring Face Seal) and DIN 24° cone fittings have very high-pressure ratings for demanding jobs. In contrast, NPT fittings usually have lower pressure ratings. Always double-check that your fitting meets or exceeds your system's maximum operating pressure to prevent a catastrophic failure.

What Is a Dash Size in Hydraulic Fittings?

A "dash size" is simply a standardized way to refer to the nominal hose or tube size in sixteenths of an inch. It's an industry shorthand that provides a universal system for matching hoses and fittings without confusion.

For example, a -04 dash size means 4/16" (or 1/4"), and a -12 dash size translates to 12/16" (or 3/4"). Our measurement chart in the previous section is a great tool for converting your thread measurements to the correct dash size. When in doubt, our team serving Pismo Beach, Grover Beach, and Nipomo is always here to help with identification.

For expert help identifying, sourcing, or fabricating any hydraulic fitting, trust the local specialists. Contractor's Maintenance Service has the parts and expertise to keep your equipment running smoothly. Visit us in San Luis Obispo or explore our services online at https://www.contractorsmaintenanceservice.com.