Top Tips for small engine repair near me in San Luis Obispo

- Jan 4

- 16 min read

When a key piece of your equipment goes down on the job, the frantic search for "small engine repair near me" starts. For professionals across San Luis Obispo County, Contractor's Maintenance Service (CMS) is your local, authorized expert. We're here to cut your downtime and get everything from a stubborn Graco paint sprayer to a non-starting Honda compactor back in the fight.

Your Trusted Small Engine Repair Partner in San Luis Obispo

For a contractor, painter, or facilities manager, a busted engine isn't just an inconvenience—it's a direct blow to your bottom line. Suddenly, project deadlines are at risk, labor costs are climbing, and your reputation is on the line. That’s why picking a local, reliable repair partner is one of the smartest business decisions you can make.

Think of your equipment as the key players on your team. When one is sidelined, the whole team's performance takes a hit. A generic, one-size-fits-all shop might slap on a temporary fix. A specialized, local service center like ours, on the other hand, acts like your team's dedicated medic, providing expert care to get them back to full strength for the long haul.

Serving the Entire Central Coast

We get it. You need a partner who is not only skilled but also close by. Our shop is conveniently located to serve professionals across San Luis Obispo and the surrounding areas. We proudly work with businesses in:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

Because we're right here, you won't waste valuable hours driving all over for a dependable repair. We're your neighbors, and we’re just as invested in the success of local businesses as you are.

Why a Local, Authorized Center Matters

Choosing a shop that’s both local and an authorized service center gives you some serious advantages over shipping your equipment off somewhere or using a non-certified mechanic. Just as understanding local service searches is key for homeowners, finding a trusted local repair expert is a game-changer for business owners staring down equipment failure.

The real value of a local partner isn't just about being close. It's about building a relationship with a team that gets to know your equipment, your business, and the urgency of your work. We don't just fix things—we provide peace of mind.

Being an authorized center means our technicians get factory training and use genuine OEM (Original Equipment Manufacturer) parts. This is huge. It guarantees your repairs are done to the manufacturer's exact standards, which is vital for keeping your gear running right, staying safe, and protecting its warranty. For a deeper dive into what we can handle, you can learn more about our comprehensive industrial repair solutions for your business.

This commitment to quality means that when your Honda compactor or Wagner sprayer leaves our shop, it runs just like it did the day you bought it. You completely avoid the gamble of using aftermarket parts that can fail early or even void your warranty, saving you a ton of money and headaches down the road. Trusting a local, certified expert is a smart investment in the life and reliability of your most important tools.

Why Fix It When You Can Just Replace It? Not So Fast.

When a critical piece of equipment like your Multiquip generator or Wagner paint sprayer suddenly quits, the first thought that pops into your head can be a frustrating one: "Great, do I need a new one?" It’s tempting to think a replacement is the quickest way out, but in reality, it's often a knee-jerk reaction that costs you more in the long run. Opting for a professional repair is almost always the smarter, more strategic move for your business.

Think of your equipment as a key player on your team. If a skilled crew member runs into a problem you know is fixable, you don't just fire them and start the long, expensive process of hiring someone new. You get them the expert help they need to get back to 100%. That's exactly what a professional repair does for your machinery—it gets to the root of the problem instead of just writing off a valuable asset.

This mindset is more critical than ever. The global small engine market is on a steady climb, expected to hit USD 26.7 billion by 2035. That growth is fueled by industries like construction and industrial services, where every minute of downtime is a direct hit to the budget. In fact, keeping up with preventive maintenance can extend an engine's life by 20-30%. When you consider that unplanned downtime in construction can cost an average of $50,000 per hour, choosing expert repair isn't just about fixing a machine—it's a calculated business decision. You can read more about the growing demand for small engine services and market trends.

The True Cost of Downtime

When a machine goes down, the cost is much bigger than just the price tag on a replacement. The ripple effects can quietly sabotage your business in ways that are hard to see on a spreadsheet but hit just as hard.

Lost Productivity: Every hour a machine sits idle is an hour your crew isn't making progress. That’s a direct drain on your profits.

Project Delays: One stalled piece of equipment can derail an entire project schedule, leading to blown deadlines and frustrated clients.

A Damaged Reputation: If you're consistently behind schedule because of equipment problems, your professional reputation takes a hit, making it tougher to land the next job.

Finding a quick and reliable small engine repair near me can turn what looks like a catastrophe into a minor speed bump, getting your team back on track and keeping your projects moving forward.

Extending the Lifespan of Your Assets

A professional repair isn't just a quick fix for what’s broken today; it's an investment in the long-term health of your most important tools. At Contractor's Maintenance Service, our technicians do more than just swap out parts. They dig deep to diagnose the real issue, make precise adjustments, and use genuine OEM parts to bring your equipment back to factory-spec performance.

Investing in a professional repair is like adding years to your equipment's career. It’s a proactive strategy that maximizes the return on your initial investment and keeps your assets generating revenue for as long as possible.

This level of detailed work prevents the same problem from popping up again and helps catch small issues before they snowball into catastrophic failures. Over time, that meticulous attention saves you thousands in replacement costs and ensures your gear—from Honda compactors to Graco sprayers—remains a dependable workhorse in your fleet for years to come. Choosing repair is a powerful move for your bottom line, your efficiency, and your peace of mind.

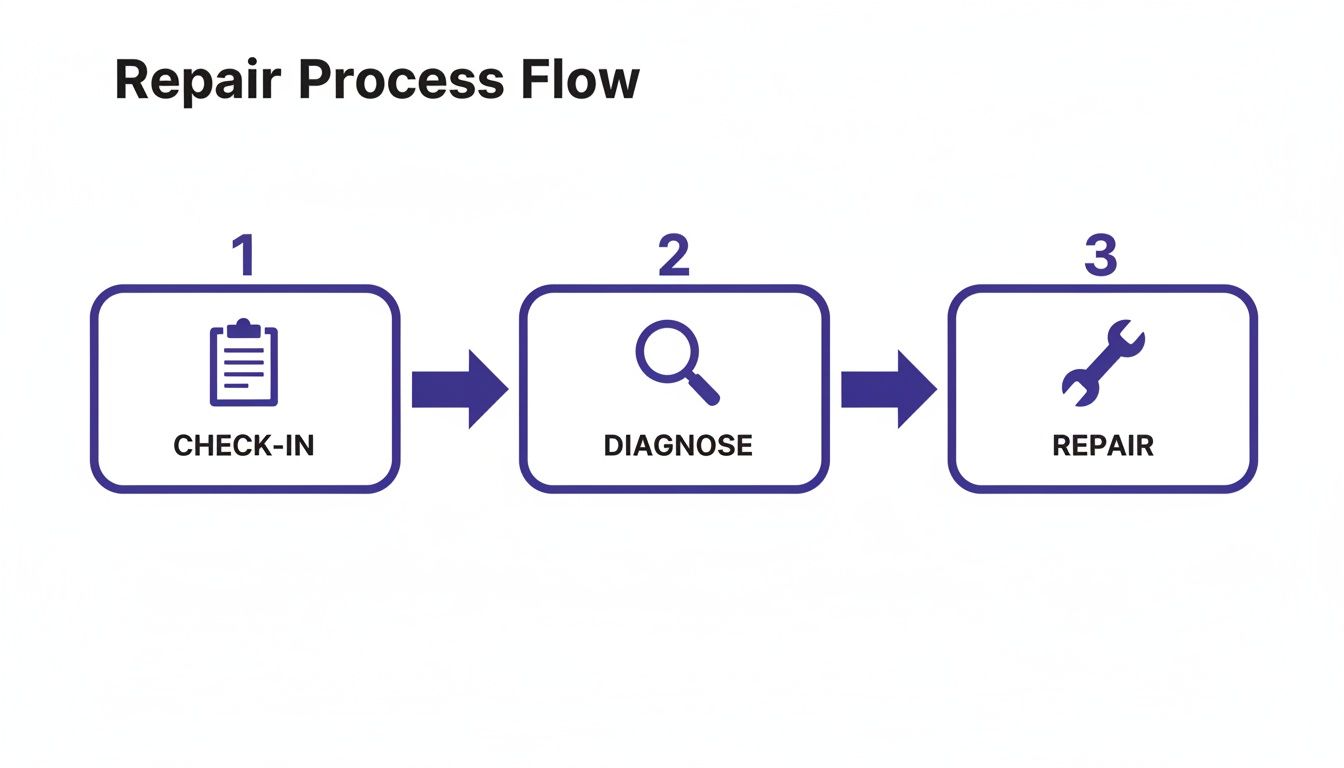

Our Transparent Repair Process From Start to Finish

When you're searching for "small engine repair near me," you’re not just looking for a quick fix. You’re looking for a partner you can trust with the equipment that keeps your business running or your property in top shape. We get it, and that trust is built on clarity and communication from start to finish.

That’s why our repair process is completely straightforward. We've designed it to keep you in the loop and confident in every decision. Think of it like a doctor's visit for your equipment—you wouldn't want a doctor to start a procedure without a thorough exam and a clear diagnosis. We treat your valuable machinery with that exact same level of professional respect. No surprises, no hidden fees, and no work ever gets done without your thumbs-up.

Step 1 Initial Check-In and Intake

It all starts the moment you walk through our doors here in San Luis Obispo. One of our service experts will be there to greet you and, more importantly, to listen. We don't just grab the machine and disappear into the back.

We want to hear the whole story. Tell us about the sputtering engine, the loss of power, or why it just won’t start. Your firsthand account gives our technicians a head start and invaluable clues. We’ll log your equipment's make, model, and serial number, creating a detailed service ticket that stays with it every step of the way.

Step 2 Comprehensive Diagnostic Inspection

Once your equipment is checked in, it heads to our diagnostic bay where our certified technicians take over. This is where our experience really comes into play. We go way beyond just looking at the obvious symptom to uncover the root cause of the problem.

Our diagnostic phase is thorough and might include:

Compression Testing: To check the health of the engine’s cylinders, piston rings, and valves.

Electrical System Analysis: We use multimeters to dig into the ignition coils, spark plugs, and wiring.

Fuel System Evaluation: This involves a close look at fuel lines, filters, and carburetors for any clogs or contamination.

This meticulous approach means we’re fixing the real issue, not just patching a symptom. That saves you from frustrating return trips and future downtime.

Step 3 Clear Communication and Approval

After the diagnostics are done, we hit the brakes. We will never move forward with a repair until you understand exactly what’s going on and give us the green light. Our service advisor will call you and explain our findings in plain English—no confusing technical jargon.

We have a strict "no-surprises" policy. You'll get a detailed, itemized estimate that breaks down the costs for both parts and labor. We’ll walk you through what needs to be done, why it's necessary, and how long it will take. Only after you approve the estimate do we pick up a single tool.

Step 4 Expert Repair and Final Testing

With your approval, our skilled technicians get to work. As an authorized service center for the industry’s top brands, we use genuine OEM (Original Equipment Manufacturer) parts whenever possible. This guarantees a perfect fit and the performance you expect. Our team has the specialized tools and training to do the job right, meeting the highest manufacturer standards.

But our job isn’t finished once the repair is complete. The final, critical step is rigorous testing. We run the equipment under the kind of real-world conditions it will face on the job to make sure it performs flawlessly. This final quality check is our guarantee that when you pick up your machine, it's not just fixed—it's 100% ready to get back to work.

Troubleshooting Common Small Engine Problems Yourself

Let's be honest, not every hiccup with your small engine gear means you have to drop everything and rush to the repair shop. Sometimes, a little bit of know-how can solve the problem in minutes, saving you a whole lot of time and money. Knowing how to run through a few basic checks can be the difference between a minor speed bump and a full-blown workday shutdown.

Before you start loading up your equipment, think of this as first aid for your machinery. A quick diagnostic checklist can often point to a simple fix for the most common issues, which usually boil down to just three things: fuel, spark, and air.

The Engine Refuses to Start

It's the most common and frustrating problem of them all: an engine that just won't turn over. Before you get too worried, take a deep breath and start with the most obvious culprits.

First, the fuel. It sounds almost too simple, but an empty tank or old, stale gas is a top offender. Gasoline can start to go bad in as little as 30 days, leaving behind gummy gunk that clogs up the whole system. If the fuel has been sitting for a while, drain it out and refill with a fresh supply. While you're at it, give the fuel line a quick look for any cracks or blockages.

Next up is the spark plug. If it's dirty, oily, or just plain worn out, it can't create the spark needed to get things going. Carefully pull it out and see what it looks like. A quick scrub with a wire brush might be all it needs, but if it's seen better days, a new spark plug is a cheap and incredibly effective fix.

Finally, check the air filter. A clogged filter is like trying to run a marathon while breathing through a straw—it just won't work. The engine gets starved of the oxygen it needs to run. Pop the filter out and hold it up to a light. If you can't see light passing through, it's time to clean it or swap it for a new one.

If you've run through these checks and are still stuck, that's where our professional process kicks in. We start with a thorough check-in and diagnosis to pinpoint exactly what's going on.

Our approach is designed to get right to the heart of the problem, so we can get your equipment back to you with minimal downtime.

Quick DIY Troubleshooting Checklist

Before bringing your equipment in, run through these common checks for the most frequent small engine issues.

Symptom | Potential Cause | DIY Check / Simple Fix |

|---|---|---|

Engine won't start | Bad fuel, no spark, or no air | Check fuel level and freshness. Inspect and clean/replace the spark plug. Check the air filter for clogs. |

Engine sputters or runs rough | Fuel flow issue or clogged carburetor | Clean the fuel cap vent. Inspect fuel lines. Try a carburetor cleaner for minor clogs. |

Engine starts, then dies | Clogged fuel cap or fuel filter issue | Ensure the fuel cap vent is clear. Check and replace the fuel filter if it's dirty. |

Engine loses power under load | Dirty air filter or clogged exhaust | Clean or replace the air filter. Check the exhaust port/spark arrestor screen for carbon buildup. |

Engine smokes excessively | Oil issues (too much oil, wrong type) | Check the oil level and ensure it's not overfilled. Confirm you're using the correct oil type for your engine. |

Running through this list can often solve the problem right there in your garage. If not, it gives you a much better idea of what might be wrong before you call for help.

The Engine Sputters or Runs Rough

Another classic headache is an engine that starts but then sputters, stalls, or runs like it's about to give up. This almost always points to a problem with either fuel delivery or air intake.

Start with the fuel cap. It's a small part that's easy to overlook, but many are vented to let air into the tank as fuel gets used. If that little vent gets clogged with dirt, it can create a vacuum that messes with the fuel flow and makes the engine sputter. A quick cleaning is often all it takes.

A dirty carburetor is the other usual suspect. Old gas is the enemy here, leaving behind deposits that clog up the tiny jets inside and lead to rough performance. While a full carb rebuild is a job for a pro, a quick spray of carburetor cleaner can sometimes dissolve minor gunk and get things running smoothly again.

Pro Tip: When you're troubleshooting, only change one thing at a time. If you clean the filter, swap the plug, and add fresh gas all at once, you’ll never know what the actual fix was. A step-by-step approach is your best friend here.

When to Call for Professional Help

These DIY tips can handle a lot of the small stuff, but it's just as important to know your limits. If you've tried these checks and the engine is still acting up, it's time to bring it to a professional. Definitely call in the experts if you notice any of these red flags:

Excessive smoke: Blue or white smoke isn't normal and usually points to serious internal engine problems.

Loud knocking or grinding noises: These are bad sounds. They often mean an internal part has failed and is getting ready to cause more damage.

Fluid leaks: Leaking oil or fuel is more than just a mess—it's a safety hazard and a clear sign of a bad seal or gasket.

Trying to tackle complex repairs without the right tools and experience can quickly turn a small problem into a much bigger, more expensive one. By handling the basics yourself and trusting the experts for the heavy lifting, you'll keep your equipment running reliably without breaking the bank.

Authorized Service for The Brands You Trust

Your equipment is a serious investment. When it needs service, you want someone who treats it that way. Typing "small engine repair near me" into a search bar can feel like a roll of the dice, but choosing an authorized service center takes the guesswork out of the equation. At Contractor's Maintenance Service, being authorized isn't just a label—it’s our promise of quality, skill, and reliability.

So, what does "authorized" really mean? It means the manufacturer has given us their official stamp of approval. They’ve recognized us as a trusted partner that meets their demanding standards for technical knowledge, proper tooling, and top-notch customer service. Think of it as our badge of honor and your peace of mind.

The Power of Genuine Parts and Factory Training

Here’s what our authorized status means for you and your equipment: our technicians are trained directly by the manufacturers. They know the ins and outs of brands like Graco, Wagner/Titan, Multiquip, and Honda because they learned from the people who designed them. This specialized knowledge means we can pinpoint problems faster and more accurately.

On top of that, we only use genuine OEM (Original Equipment Manufacturer) parts. These aren't knock-offs; they are the exact same components your machine was built with. Using OEM parts guarantees a perfect fit, preserving the original performance and safety of your equipment. Taking a shortcut with aftermarket parts is a risk that can lead to early failure, voided warranties, and even bigger repair bills down the line.

Being an authorized service center connects you directly to the manufacturer's quality standards. It guarantees that your warranty remains intact and your equipment is repaired with the precision and parts it was designed to have.

This commitment is more important than ever. North America's small engine market holds a massive 32.6% global revenue share in 2025, driven by the same construction and power equipment we service right here in San Luis Obispo. With tightening EPA regulations causing a 10% rise in repair needs for compliance, expert service is crucial. It’s a fact: properly serviced engines can last up to 50% longer, which is a huge deal for any contractor trying to get the most out of their investment.

Your Local Central Coast Service Hub

We’re proud to be the go-to service center for professionals all over San Luis Obispo County and the surrounding areas. If you’re a contractor on the Central Coast, we’ve got your back.

We Proudly Serve:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

Whether you're running a job in downtown SLO or managing a site up in North County, our shop is conveniently located to get you top-tier service without a long haul. We understand the unique challenges local pros face, and we’re set up to deliver solutions that keep your projects moving. Our deep brand knowledge is a huge plus—you can learn more about the Honda brand in San Luis Obispo, CA and see exactly why our authorized service makes such a difference.

Faster Turnaround with In-Stock Inventory

Downtime is the enemy. We know every hour your equipment is sitting in a shop is an hour you’re not making money. That’s why we keep a huge inventory of the most common parts for the brands we service right here on our shelves.

This means for many common repairs, there’s no waiting around for parts to ship. From airless sprayer components and pressure washer fittings to essential engine parts, having what we need on hand lets us get your equipment back to you much faster. We even offer specialized services like fabricating custom hydraulic hoses on-site, giving you a complete solution to get you back to work. This direct line between our parts stock, factory training, and brand dedication makes us the clear choice for small engine repair in the San Luis Obispo area.

Unlock Peak Performance with Preventive Maintenance

The best repair is the one you never have to make. While we’re experts at fixing equipment when it breaks down, we believe in a much smarter strategy: shifting from reactive fixes to a proactive maintenance plan. This approach is all about keeping your equipment running at its absolute best, ensuring you’re always ready for the next job without any surprises.

Think of it like the scheduled oil changes and tune-ups for your work truck. You don't wait for the engine to seize before you change the oil, right? You know that a small, consistent investment prevents a massive, costly failure down the road. Your small engine equipment deserves that same forward-thinking care.

The Real Cost of Skipping Maintenance

Unexpected downtime isn’t just an inconvenience—it's a direct hit to your bottom line. Unplanned equipment failures cost industrial operations a staggering $260 billion annually worldwide, which makes a proactive strategy non-negotiable for serious professionals.

The demand for reliable equipment is clear. The global market for small engine services was valued at US $6.9 billion in 2022 and is expected to grow significantly by 2035. This boom highlights just how crucial it is to keep your machinery in prime condition.

Our preventive maintenance programs are designed to catch those small, nagging issues before they snowball into major disasters. Scheduled inspections, fluid changes, and filter replacements don't just extend your equipment's life; they boost reliability and lower your total cost of ownership. For a complete guide, check out Your Equipment Preventative Maintenance Checklist.

A well-maintained engine is your best insurance against project delays and budget overruns. It’s the difference between staying on schedule and having to explain to a client why the job isn't done.

Maintenance Services for the Central Coast

We provide comprehensive preventive maintenance for hard-working professionals across the Central Coast. Whether you're in San Luis Obispo or the surrounding communities, our team is ready to help you set up a maintenance schedule that fits your fleet and your workflow.

Our service area for proactive maintenance includes:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

Even your generators benefit from this proactive approach. To keep them performing optimally, understanding the principles behind gas to electricity converter systems can help you appreciate the importance of effective maintenance.

By partnering with us, you’re not just fixing equipment—you’re protecting your valuable assets and keeping your business productive and profitable. Don't wait for a breakdown to start searching for "small engine repair near me"; let us help you prevent it from happening in the first place.

Answering Your Top Questions About Our Repair Services

When your equipment goes down, you've got questions. You need to know how long it'll take, what it'll cost, and who you can trust to get it right. Typing "small engine repair near me" into a search bar is easy, but getting straight answers is what really matters. Let's cut to the chase and cover the things our customers ask most.

We get it. Your tools are your livelihood. Our whole process is built around being upfront and clear, so you can feel confident handing your equipment over to us.

How Long Will My Small Engine Repair Take?

We know downtime is lost money, plain and simple. That’s why we move fast. Typically, we can get a full diagnostic inspection done within 1-2 business days of you dropping off your machine. Once we know exactly what we’re dealing with, we’ll give you a solid time estimate for the repair.

For most common problems, we have the parts right here on our shelves, which means we can often get you back up and running in just a few days. If we need to order a specialty part, we’ll let you know the ETA right away. You'll never be left wondering what's going on.

Do You Provide Estimates Before Starting Repairs?

Yes, always. We believe in total transparency. After our techs run a complete diagnostic, we’ll call you with a detailed, itemized estimate that breaks down all the parts and labor costs.

We have a strict no-surprises policy. We won’t touch a single bolt until you’ve reviewed the estimate and given us the green light. You're always in the driver's seat.

What Areas Do You Service?

Our shop has become the go-to repair partner for contractors and professionals all over the Central Coast. We’re located to be a convenient drop-off for a wide range of local communities, so expert help is never far away.

We proudly serve:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

Santa Maria

If you're working in or around these areas, we're your local shop.

What if My Equipment Is Still Under Warranty?

Not a problem at all. As an authorized service center for major brands like Honda, Graco, Wagner/Titan, and Multiquip, we’re fully set up to handle warranty claims. This is one of the biggest benefits of working with a certified shop instead of a general mechanic.

Just bring in your equipment with the proof of purchase. We'll take it from there, managing the entire warranty repair process directly with the manufacturer for you. This ensures the work is done exactly to their standards and keeps your investment protected.

When you need reliable diagnostics, expert repairs, and a team that’s committed to getting you back on the job fast, trust the pros. Contact Contractor's Maintenance Service today to schedule your repair or learn more at https://www.contractorsmaintenanceservice.com.