The Contractor's Guide to Choosing the Right 1 Inch Hose

- Dec 22, 2025

- 16 min read

Think of the 1 inch hose as one of the most hardworking, versatile tools in your rig. It really hits the sweet spot, giving you enough flow and power for serious jobs like dewatering a site or heavy-duty pressure washing, but without being a beast to handle and move around. This guide is your no-nonsense playbook for picking the right one, so your jobs run smoothly and safely every single time.

Why the 1 Inch Hose Is Your Most Versatile Tool

For any contractor working on the Central Coast, whether you're on a construction site in San Luis Obispo or maintaining equipment in the vineyards of Paso Robles, having the right gear isn't just a preference—it's essential. The 1 inch hose is often that unsung hero, the piece of equipment that can make or break your day's productivity.

It's the perfect middle ground. It’s got the muscle for demanding tasks but still offers the flexibility you need for practical, day-to-day use.

Picking the right hose has a direct impact on your efficiency, job site safety, and, let's be honest, your bottom line. The wrong choice can lead to killer pressure drops, a hose that fails way too early, or even a dangerous blowout. This guide is designed to cut through the confusing tech specs and give you clear, actionable advice.

Your Local Hose and Fitting Partner

Here at Contractor's Maintenance Service, we're not just a supplier; we're your partner for all things industrial hose. We've been serving pros across the region for years and know the unique demands of working right here in our local communities. We’re proud to provide expert service and solutions to San Luis Obispo and the surrounding areas, including:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Grover Beach

Pismo Beach

Morro Bay

We're here to help you sort through the options, whether you need a tough-as-nails rubber hose for pumping abrasive slurry or a high-pressure line for your sprayer. Our whole goal is to make sure you walk out with the right tool for the job.

By understanding the core differences in materials, pressure ratings, and applications, you can prevent costly downtime and make an informed decision that pays dividends in performance and longevity.

In this guide, we'll break down everything you need to know. We’ll get into different hose materials, decode what those pressure ratings actually mean for you, and match the right hose to the jobs contractors face every day. Let's dive in and find the perfect 1 inch hose for your needs.

Decoding Hose Materials and Construction

The material of your 1 inch hose is its backbone. It determines how tough it is, how it flexes on a cold morning, and ultimately, how long it’s going to last on your job site. Picking the right one means matching the hose's guts to the work you do, so it becomes a tool you can rely on, not another headache.

Think of it like choosing tires for a work truck. You wouldn't put highway tires on a rig that’s constantly in the mud. Each hose material has its own strengths and weaknesses, making it perfect for some jobs and a total liability for others. Get this choice right from the start, and you'll save yourself from the frustration of a blown hose in the middle of a project.

The Foundation: Your Hose Material

When you're looking at 1 inch hoses, you'll mostly run into a few common materials. Each offers a different trade-off between performance, durability, and cost. Knowing the difference is the first step to making sure the hose you buy for a job in Arroyo Grande or Atascadero can actually handle the work.

We see a lot of different hoses come through our shop, and for contractors, the choice usually boils down to these four:

PVC (Polyvinyl Chloride): This is your basic, budget-friendly option. A PVC hose is light and gets the job done for simple water transfer. The big downside? It gets stiff and unwieldy when the temperature drops, which can be a real pain on a cool Central Coast morning.

Rubber: Think of rubber as the all-terrain, heavy-duty option. It’s incredibly durable, stays flexible in hot and cold weather, and fights off kinks and abrasion like a champ. Its only real drawback is the weight—lugging a long rubber hose around all day is a workout.

Polyurethane: Here’s a great middle-ground material. Polyurethane is much lighter than rubber but gives you excellent abrasion resistance and stays flexible in the cold. It’s a solid all-around performer.

Hybrid Polymers: These are the new guys on the block, engineered blends that aim to give you the best of all worlds. They're typically lightweight like PVC, flexible like rubber, and tough as nails, making them a popular modern choice.

To make it even clearer, here’s a quick rundown of how these materials stack up for professional use.

1 Inch Hose Material Comparison for Contractors

Choosing the right material is a big deal. It directly impacts how a hose holds up under pressure and in the real-world environments you work in. A bad choice leads to downtime, while the right one lets you work without interruption.

Material Type | Key Advantages | Common Limitations | Best For Applications Like |

|---|---|---|---|

PVC | Lightweight, most affordable, decent chemical resistance. | Can become stiff and brittle in cold weather, prone to kinking. | General water discharge, light-duty fluid transfer, irrigation. |

Rubber (EPDM/SBR) | Excellent flexibility in all temps, highly durable, kink & abrasion resistant. | Heavier than other options, can be more expensive. | Hot water pressure washing, air lines, heavy-duty water suction/discharge. |

Polyurethane | Very lightweight, superior abrasion resistance, good cold-weather flexibility. | Can be more costly than PVC or some rubber types. | Airless paint sprayers, pneumatic tool lines, abrasive material transfer. |

Hybrid Polymer | Combines lightweight design with great flexibility and durability, easy to handle. | Performance can vary by brand/blend, newer technology. | All-purpose contractor water hoses, premium air lines, jobs requiring mobility. |

This choice is so critical that it shapes the entire industrial hose market. That market, where the 1 inch hose is a workhorse for critical tasks, was valued at USD 11.99 billion in 2025 and is expected to hit USD 13.92 billion by 2030. It’s no surprise that natural rubber holds the biggest share, thanks to its sheer toughness. You can read more about these industrial hose market trends to see just how much material choice drives the industry.

A Look Inside Your 1 Inch Hose

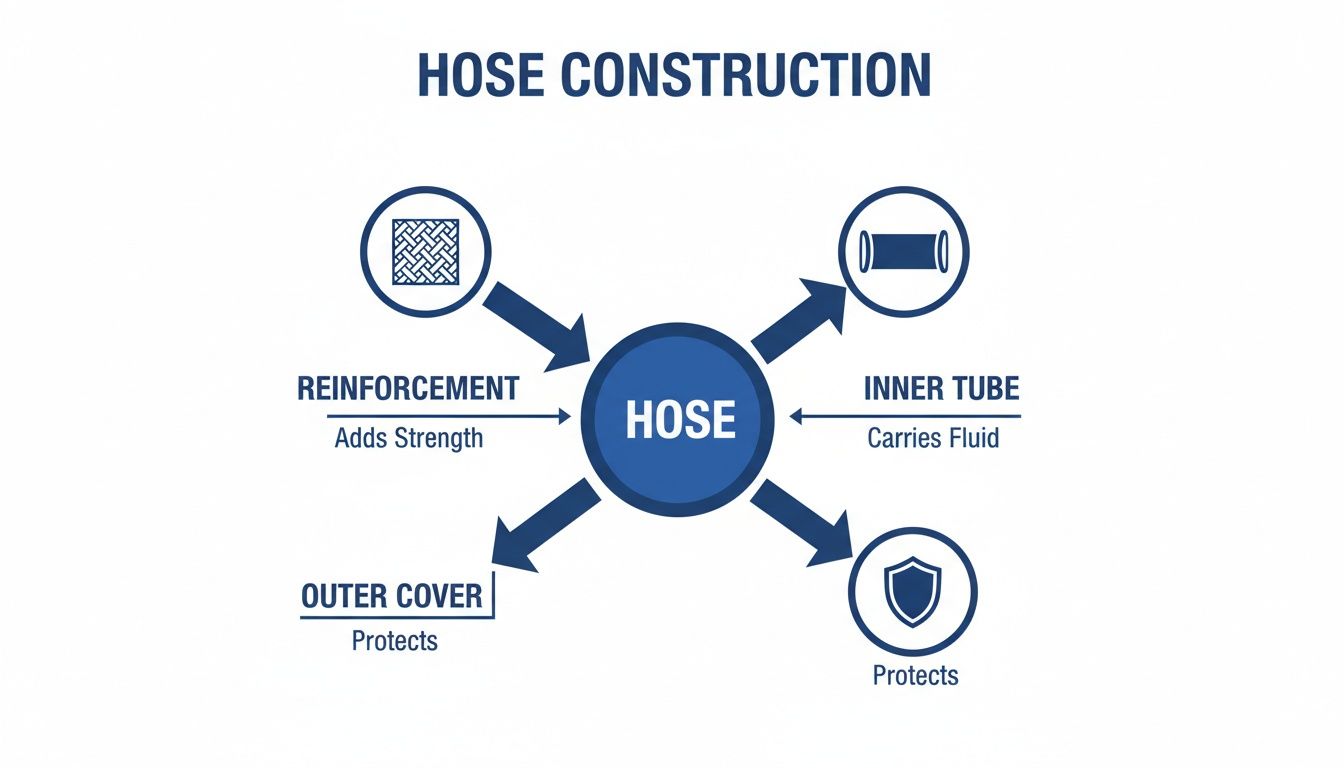

A hose isn't just a simple tube. It’s a layered system where each part has a job to do, all working together to handle pressure, provide strength, and survive the daily grind.

Think of a hose's construction like a three-person crew. You've got the inner tube containing the payload, the reinforcement layer providing the muscle, and the outer cover acting as the lookout and bodyguard. If any one of them fails, the whole job grinds to a halt.

Let’s break down that crew:

The Inner Tube: This is the layer that’s in direct contact with whatever you’re pumping. Its main job is to create a smooth, leak-proof path. The material here has to be compatible with what’s flowing through it, whether that’s water, hydraulic oil, or paint.

The Reinforcement Layer(s): This is where the hose gets its strength and its pressure rating. It’s usually made of braided or spiraled synthetic fibers (like polyester) or even steel wire for high-pressure jobs. The more reinforcement, the higher the pressure it can handle and the less likely it is to kink.

The Outer Cover: This is the hose's protective shield. It’s built to take a beating—getting dragged across rough concrete in Pismo Beach, baked in the sun, or exposed to chemicals. A tough outer cover is what gives a quality 1 inch hose a long life.

Once you understand this construction, it's easy to see why a high-pressure sprayer hose feels completely different from a simple pump discharge hose. It's all about that internal muscle and tough outer skin. Whether you’re working a job in Grover Beach, Morro Bay, or anywhere else in San Luis Obispo County, knowing what’s on the inside of your hose helps you make a smarter buy.

Mastering Hose Pressure Ratings and Specifications

Trying to read a hose spec sheet shouldn't feel like you need a secret decoder ring. Those numbers tell a critical story about what a hose can do—and more importantly, what it can't. Getting this right is absolutely fundamental to safety and performance on any job site, whether you're working right here in San Luis Obispo or anywhere else.

Think of a 1 inch hose as a highway for whatever you're pumping—water, air, hydraulic fluid, you name it. The most important metric isn't its overall size, but its Inner Diameter (ID). The ID is the true measure of its capacity, like the number of lanes available for traffic. A bigger ID means more fluid can move through, faster and with less friction. The Outer Diameter (OD) is really just about the hose's total bulk, which is good to know for fitting clamps or routing it through tight spaces. But when it comes to performance, the ID is what matters.

Decoding Pressure The Right Way

Now, let's get to the most critical spec of all: pressure. This is where guys make costly and sometimes dangerous mistakes. On any quality industrial hose, you're going to see two key numbers.

Working Pressure: This is your everyday limit. It's the maximum pressure the hose is designed to handle safely, day in and day out. Pushing past this number puts serious stress on the hose's reinforcement layers and will kill its lifespan.

Burst Pressure: This is the point of no return—catastrophic failure. It's the pressure where the hose will physically rupture. This number is NOT a target to aim for; it's purely a safety calculation used by engineers.

The relationship between these two is called the safety factor. For example, a hose with a 4:1 safety factor and a 1,000 PSI working pressure is engineered to have a theoretical burst pressure of 4,000 PSI. That buffer exists for a reason—to handle unexpected pressure spikes and account for wear over time. You should never, ever operate a hose anywhere near its burst pressure. For a deeper dive into managing these forces, check out our guide on high-pressure hoses and what you need to know.

A hose's pressure rating is a promise of performance under specific conditions. Ignoring it is like ignoring the load limit on a bridge—it might hold for a while, but eventually, the failure will be sudden and severe.

This diagram breaks down the three core components that work together to manage all that pressure and keep the hose in one piece.

As you can see, the smooth inner tube, the strong reinforcement braids, and the tough outer cover each have a critical job in containing pressure and resisting damage from the outside world.

Don't Overlook These Critical Specs

Beyond pressure and diameter, a few other specifications can absolutely make or break a hose's performance on your job. Pushing these limits is one of the most common causes of premature hose failure we see.

First up is the temperature range. Hoses are rated for both the temperature of the fluid running through them and the ambient temperature outside. Using a hose outside its specified range can make it brittle and prone to cracking in the cold, or soft and weak in the heat. A hose rated for cold water will fail in a hurry if you start pumping hot water through it from a pressure washer.

Next is the bend radius. This is the tightest turn you can make with a hose before you kink it or damage the internal reinforcement layers. A sharp kink creates a permanent weak point that's just begging to burst. Always route your 1 inch hose in smooth, wide curves to respect its bend radius and maintain its structural integrity.

Matching Your 1 Inch Hose to the Job

The best hose is always the one that’s right for the job. Just because a hose is 1 inch in diameter doesn't mean it can handle everything you throw at it. Matching the hose’s construction to the application is the secret to safe, efficient work and getting the most life out of your gear.

Think of it like choosing the right drill bit. You wouldn't use a wood bit on concrete and expect good results, right? The same logic applies here. A low-pressure discharge hose will fail spectacularly if hooked up to a pressure washer, and a heavy-duty pressure washer hose is just overkill and too rigid for simple dewatering.

This section connects the dots between the specs we've covered and your reality on the job site. Let's break down the most common places a 1 inch hose shines and what to look for in each scenario.

Hoses for Pressure Washing

When you're blasting grime off a building facade in Atascadero, your pressure washer hose is under an incredible amount of stress. This is no place to cut corners. A proper 1 inch hose for pressure washing has a few non-negotiable features.

First and foremost is a high working pressure rating, usually 3,000 PSI or more, to safely handle your machine's output. It also needs a tough, abrasion-resistant outer cover to survive being dragged across concrete and asphalt day after day. Finally, a non-marking cover is a must-have for many jobs to avoid leaving ugly black scuff marks on freshly cleaned surfaces.

Suction and Discharge for Dewatering

The game changes completely when you're pumping water out of a flooded basement or a trench in Arroyo Grande. For pump suction, the hose has to withstand a vacuum without collapsing on itself. That requires a very specific type of construction.

You'll need a rigid or semi-rigid 1 inch hose with a helical wire reinforcement. This internal spiral acts like a skeleton, keeping the hose from pancaking flat under the pump's negative pressure. For the discharge side, a simple lay-flat hose might work in a pinch, but a durable rubber discharge hose is a much smarter investment for rugged job sites. While we're focused on the 1-inch size here, you can learn more about bigger options in our practical guide to choosing a 2-inch discharge hose.

The crucial difference between a pressure hose and a suction hose lies in its reinforcement. One is built to contain internal force pushing out, while the other is built to resist external force pushing in. Using the wrong one is a recipe for instant failure.

Compressed Air and Pneumatic Tools

Running pneumatic tools like nail guns or impact wrenches means your hose has to handle not just the air pressure but also the compressor oil that often gets mixed in. An oil-resistant inner tube, typically made from nitrile or a similar rubber compound, is absolutely critical.

Without it, that oil will break down the hose from the inside out, causing it to get soft, bubble up, and eventually burst. A high burst pressure rating and a flexible, kink-resistant design are also key for easy maneuverability around a busy job site.

To get a handle on all these different hose types, many contractors use construction inventory software for contractors to track specs and assignments. This ensures the right tool is always deployed for the right job, preventing costly mistakes and downtime.

Matching the Hose to the Job

To make things simple, here’s a quick-glance table to help you pair the right hose with the right task.

Application | Recommended Hose Type | Critical Features to Look For |

|---|---|---|

Pressure Washing | High-Pressure Rubber or Wire-Braid Hose | High PSI Rating (3,000+), Abrasion-Resistant Cover, Non-Marking |

Pump Suction | Rigid PVC or Rubber Suction Hose | Helical Wire Reinforcement, High Vacuum Rating, Durability |

Water Discharge | Lay-Flat or Heavy-Duty Rubber Hose | Flexibility, Puncture Resistance, High Flow Rate |

Pneumatic Tools | Oil-Resistant Air Hose | Oil-Resistant Inner Tube, High Burst Pressure, Kink Resistance |

Using this as a guide ensures your hose isn't just a component but a reliable part of your workflow.

By taking a moment to match the hose to the application, you’re not just buying another piece of equipment. You're making a smart investment in a tool that will perform correctly, last longer, and keep your crew safe.

Hose Installation and Maintenance That Saves You Money

Even the best 1 inch hose on the market is only as good as its installation and upkeep. If you want to protect your investment, it starts the second you attach that first fitting. This isn't just about stopping a few drips; it's about job site safety, peak efficiency, and avoiding the kind of profit-killing downtime that comes from a surprise hose failure.

Think of proper installation as your first line of defense. A single leaky fitting can waste hundreds of gallons of water, create a nasty slip hazard, or starve your equipment of the pressure it needs to perform. Taking a few extra minutes to get it right from the jump pays for itself over and over again.

Smart Installation Starts with the Right Fittings

Let's be honest, the connection point is almost always the weakest link in any hose assembly. Getting the right fitting and attaching it correctly is everything if you want a secure, leak-free seal. For a busy job site in San Luis Obispo, you need connections that are both rock-solid and practical for your daily grind.

Here are a couple of go-to options for your 1 inch hose:

Camlock Fittings: These are a lifesaver for applications where you’re constantly connecting and disconnecting, like pump suction and discharge lines. The cam arms lock down for a tight seal without you having to bust out a single tool.

NPT (National Pipe Thread) Fittings: When you need a more permanent or semi-permanent connection, these threaded fittings are the way to go. Slap on some thread tape or sealant, and you’ve got a high-pressure connection perfect for air lines or pressure washer outlets.

No matter which fitting you choose, double-check that it's sized correctly for your hose and rated for your system's pressure. A mismatched or poorly crimped fitting is just a blowout waiting to happen. For a deeper dive into how these parts create a safer work environment, check out our article on hose safety and ensuring reliable operations.

Pro Tips for Hose Routing and Protection

How you run your hose across the job site is just as important as the hose itself. From what we see with contractors in Paso Robles and all over the Central Coast, careless routing is the number one killer of perfectly good hoses.

Treat your hose like a lifeline to your equipment. Protect it by following a few simple rules:

Avoid Sharp Edges: Never, ever drag a hose over the sharp corner of a building, a piece of machinery, or a pile of debris. Use hose ramps or guides to shield it from getting chewed up.

Respect the Bend Radius: Every hose has a minimum bend radius. Forcing it into a tighter turn will cause it to kink, which permanently wrecks the internal reinforcement and creates a major weak spot.

Keep it Out of Traffic: Don't let trucks or heavy equipment roll over your hose. That crushing force causes internal damage you can't always see from the outside—until it’s way too late.

A well-routed hose is a long-lasting hose. Taking a moment to find a safe path away from hazards and traffic is one of the most effective maintenance tasks you can perform.

A Simple Preventative Maintenance Checklist

A little proactive maintenance will stretch the life of your 1 inch hose and save you from ugly, expensive surprises. Understanding what is preventive maintenance is all about spotting the small problems before they turn into catastrophic failures.

Before you fire things up each day, give your hose a quick once-over. You're looking for:

Blisters, bulges, or any soft spots in the outer cover, especially right near the fittings.

Cracks, deep cuts, or any signs of serious abrasion.

Fittings that are leaking, rusted, or corroded.

When the day is done, cleaning and storing your hose properly makes a world of difference. Flush it out, coil it up loosely (don't crank it tight!), and store it out of the direct sun. Those UV rays will break down the outer cover over time, leaving it brittle and weak. A little discipline here ensures your hose is ready to work as hard as you are next time.

Your San Luis Obispo County Hose Experts

When a hose goes down on a job site, you need a replacement, and you need it now. Waiting for a shipment isn't an option. That's where having a local expert comes in—and for professionals on the Central Coast, that's Contractor's Maintenance Service.

We're not just a supplier; we're your partner in keeping the job moving. Whether you're in San Luis Obispo, Paso Robles, or Atascadero, our team is right here, ready to build the exact 1-inch hose assembly you need to get back to work. We know how much a failed hose can cost you in downtime.

Your Local Central Coast Partner

From Arroyo Grande and the Five Cities area all the way up to the North County, we've got you covered. Think of us less like a parts counter and more like an extension of your own crew. Our job is to get you the right solution, fast.

We understand the unique demands of working here, whether it’s for agriculture, construction, or industrial maintenance. From the coast in Morro Bay to the inland valleys, we stock what works because we’re part of this community, too.

We’re here to provide the specialized knowledge, durable products, and quick turnaround that keep your projects on schedule and under budget. That's our commitment.

More Than Just Hoses

Sometimes, an off-the-shelf hose just won’t work for a specific application. That's why we do more than just sell hose off a reel. Bring us your specs, and our team will provide custom hose fabrication to build the precise assembly you need.

And if a full replacement isn't necessary, we also offer professional-grade hose repairs. A properly repaired and tested hose can get your equipment running again safely and save you a good bit of money. Our goal is simple: to make sure you have the reliable equipment and support you need to keep your operations running smoothly.

Got Questions About 1 Inch Hoses? We've Got Answers.

Even with all the specs laid out, you're bound to run into questions out on the job. We get it. We pulled together the most common questions we hear from pros right here in our San Luis Obispo shop to give you some quick, straight-shooting answers.

Think of this as the stuff our team explains every day to contractors from Paso Robles to Pismo Beach. Let's dig in.

How Do I Know If I Need a 1 Inch Hose or a Different Size?

This one almost always comes down to two things: how much flow you need (GPM) and how much pressure you'll lose over distance. A 1 inch hose is a fantastic all-rounder. It delivers way more flow than a standard 3/4 inch hose without making you wrestle with the weight and bulk of a 1.5 or 2-inch line.

Here’s a good way to think about it: a small hose is like a one-lane road. Try to push too much through it, and you get a traffic jam. In hose terms, that traffic jam is a serious pressure drop at the other end. A 1 inch hose is like adding another lane—it lets more fluid move smoothly, making sure your equipment gets the power it needs to perform, even on a 100-foot run. If your gear's specs call for a GPM that a smaller hose just can't keep up with, it's time to size up.

Can I Just Repair a Damaged 1 Inch Industrial Hose Myself?

Look, for a simple garden hose running low pressure, a field repair kit might get you out of a jam for the day. But for any hose carrying high pressure, chemicals, or hydraulic fluid, our strong advice is to bring it to a pro. An improperly crimped fitting isn't just a leak waiting to happen; it's a catastrophic failure waiting to happen.

A DIY repair on a high-pressure line is a serious gamble with your equipment and your safety. The integrity of that crimp is everything when it comes to restoring the hose's original strength and preventing a dangerous blowout.

Here in our shop serving Atascadero and the surrounding areas, we use specialized, calibrated machinery to put on a new end. It creates a perfect, factory-spec crimp every time. You get reliability, peace of mind, and a hose assembly that's truly safe to put back to work.

What’s the Most Common Reason a 1 Inch Hose Fails Early?

Hands down, the number one killer of industrial hoses is external abrasion. Job sites are rough, unforgiving places. Every time you drag a hose across jagged concrete, sharp gravel, or the corner of a building, you're scraping away its protective outer cover.

Once that cover is compromised, the reinforcement layer underneath is exposed to moisture and more damage, and the hose's integrity is shot. A few other common culprits include:

Sharp Kinks: Bending a hose tighter than its minimum bend radius creates a permanent weak spot. It’ll never be the same.

Sun and Chemical Exposure: Constant UV rays and harsh chemicals will eat away at the cover, making it brittle and weak.

Pushing Past its Limits: Consistently running a hose above its rated working pressure will fatigue the reinforcement until it gives out.

Honestly, just using a few hose protectors in high-wear areas and storing your hose correctly can easily double its lifespan. It's a simple step that saves a lot of money and downtime.

When you need expert advice, a custom-built hose, or a fast, reliable repair, turn to the local team you can trust. Contractor's Maintenance Service is here to keep your jobs running smoothly throughout San Luis Obispo County. Visit us online or stop by the shop to get the right solution, right now. https://www.contractorsmaintenanceservice.com

Comments