Choosing and Using a Cordless Grease Gun

- Dec 28, 2025

- 16 min read

Making the jump from a manual grease gun to a cordless model is a game-changer. Think of it like swapping a hand wrench for an impact driver—sure, both get the job done, but one completely changes how you work. A cordless grease gun gives you consistent pressure with a simple pull of the trigger, taking all the guesswork and physical strain out of lubrication.

The Real-World Benefits of Cordless Lubrication

For any mechanic or technician, the daily grind involves fighting with stubborn grease fittings in tight spaces and awkward angles. A manual grease gun demands constant pumping and brute force, which gets old fast, especially when you're servicing large machinery. This struggle doesn't just slow you down; it often leads to under-lubrication, one of the biggest culprits behind premature part failure.

The cordless grease gun tackles these problems head-on. By automating the pressure, it transforms a physically draining chore into a quick, precise task. This is a massive win for anyone working on equipment ranging from agricultural combines to entire fleets of construction vehicles.

Boosting On-Site Productivity

The first thing you'll notice is a huge leap in speed. Technicians can hit more lubrication points in less time, which shortens maintenance windows and gets essential equipment back on the job faster. In fields where downtime can cost thousands an hour, that kind of efficiency is invaluable.

Think about what this means for your day-to-day workflow:

Faster Application: You can deliver grease up to twice as fast as with a manual gun, which seriously cuts down on routine service times.

Consistent Pressure: Every fitting gets the right amount of lubricant, easily pushing through old, hardened grease without you breaking a sweat.

Reduced Operator Fatigue: The ergonomic design takes the physical strain out of the job, lowering the risk of repetitive stress injuries and keeping your crew sharp all day.

Enhanced Portability: Your team can move freely around massive equipment or across an entire job site without being chained to an air hose—a major drawback of pneumatic models.

Precision and Equipment Longevity

To really get why cordless lubrication is such a big deal, you have to look at the bigger picture of equipment care. Proper lubrication is a pillar of good maintenance. If you want to dig deeper, this guide on the essentials of preventive maintenance for vehicles is a great resource. A cordless gun gives you the control to apply the exact amount of grease needed, preventing both under-lubrication and the messy, wasteful alternative of over-application.

Consistent and accurate lubrication is not just about maintenance—it's about asset preservation. Properly greased joints and bearings last longer, reducing long-term repair costs and extending the operational life of expensive machinery.

For professionals working in San Luis Obispo and nearby areas like Paso Robles, Atascadero, and Arroyo Grande, keeping equipment in the field is everything. Whether you're in agriculture, construction, or industrial maintenance in Pismo Beach, Morro Bay, or Santa Maria, the shift to battery power is undeniable. Just like battery-powered compaction equipment is changing how job sites operate, the cordless grease gun is setting a new standard for efficient maintenance.

Decoding Cordless Grease Gun Specifications

Picking the right cordless grease gun isn’t about grabbing the most expensive one off the shelf. It’s about matching the tool’s specs to what you actually do day-in and day-out. Those numbers on the box aren't just marketing fluff—they tell you exactly how the tool will perform under pressure, how long you can work before swapping batteries, and how fast you can get your maintenance rounds done.

Think of it like choosing an engine for a truck. A small four-cylinder is fine for light errands, but you wouldn’t try to haul a flatbed of steel with it. In the same way, a grease gun built for an auto shop just won't have the muscle needed for massive construction machinery. Let's break down the specs that really matter out in the field.

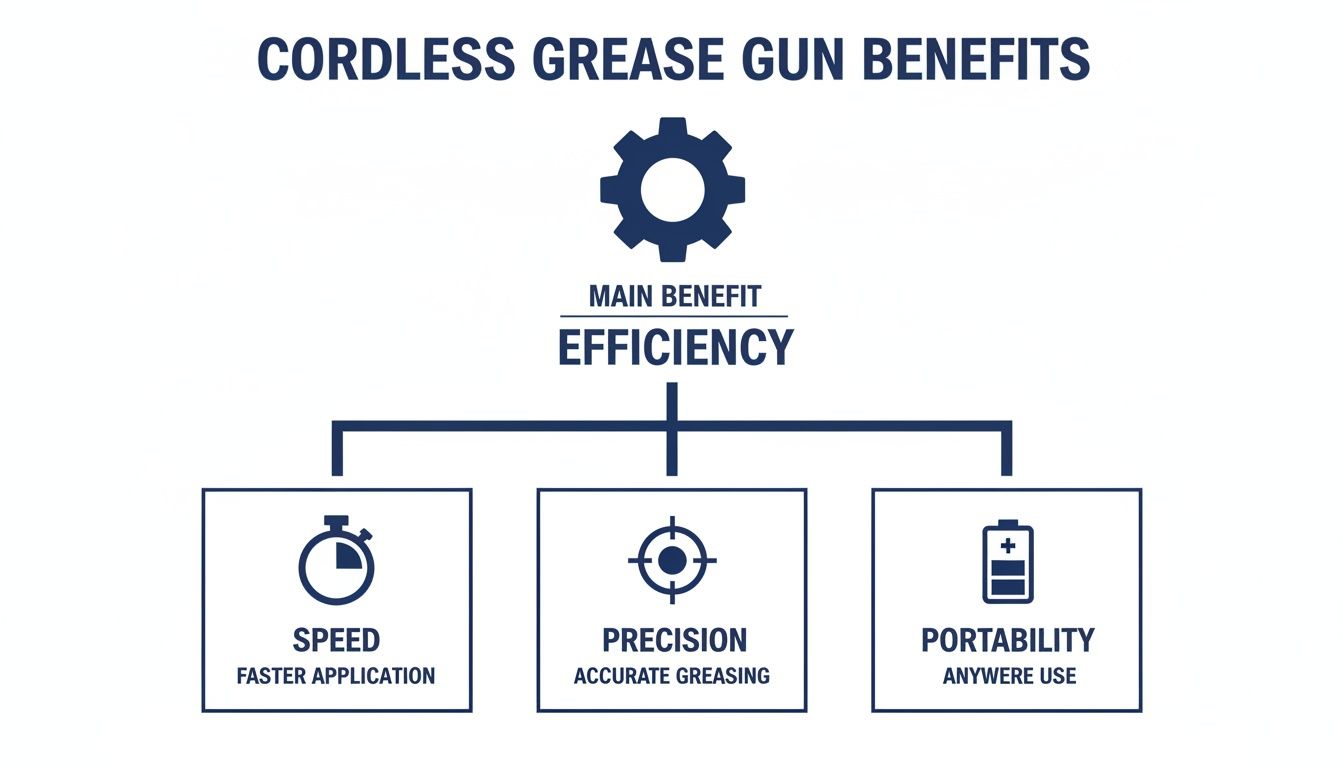

This infographic lays out the core benefits you get when you nail the specs.

As you can see, the real prize is efficiency, which comes from a blend of speed, precision, and portability—all of which are tied directly to the tool's core specifications.

Pressure Power Through PSI

Pressure, measured in Pounds per Square Inch (PSI), is the raw muscle of your grease gun. It's what lets the tool force fresh grease into a fitting, especially one that’s plugged up with old, hardened gunk. A gun with weak pressure is just going to struggle, leading to half-lubricated joints and, eventually, equipment damage.

For most professional work, a gun with a maximum pressure rating of 8,000 to 10,000 PSI is the sweet spot. That kind of power is enough to clear out stubborn blockages and properly service the tight-tolerance joints you find on heavy equipment. In fact, most pro-grade cordless units deliver working pressures in the 3,000–10,000 PSI range, with grease output rates typically between 1.5 and 5 ounces per minute.

This capability lets technicians service bearings and lube points way faster than with a manual gun, often cutting service time by 20–50% per fitting. You can learn more about the market data on battery-operated grease gun performance to see how the numbers stack up.

Battery Platform Voltage and Ah

The battery is the heart of a cordless grease gun, plain and simple. Your choice of battery system dictates the tool's power, how long it runs, and even how it feels in your hands. There are two numbers you need to pay attention to:

Voltage (V): This is all about power. Higher voltage, usually 18V or 20V, delivers more torque to push grease through difficult fittings. Sure, 12V models are lighter, but they often lack the punch needed for heavy-duty industrial or farm equipment.

Amp-Hours (Ah): Think of this as the size of the fuel tank. A higher Ah rating (like 4.0Ah vs. 2.0Ah) means you can get through more grease cartridges on a single charge. That's a huge deal for anyone servicing a large fleet or a factory full of machinery.

The smartest move is to pick a cordless grease gun that runs on the same battery platform as your other power tools. It makes charging on the job site a breeze and saves you from having to buy into a whole new battery system.

Loading Options and Flow Control

How you load grease and control the flow has a direct impact on your efficiency and your budget. Most cordless guns give you a few options. Standard 14-ounce cartridges are clean and easy to swap out in the field, while bulk loading from a pail is way more cost-effective if you're doing high-volume work in the shop.

Just as important is how you control the output. A variable speed trigger is a non-negotiable feature; it lets you apply just the right amount of grease. It helps you avoid over-lubricating (which can blow out seals) and under-lubricating (which leads to premature wear). Some higher-end models even have preset grease counters, so you can get a perfect, repeatable application every single time.

Build Quality and Ergonomics

A tool that feels flimsy in the store isn't going to survive long on a real job site. Look for tough materials like a steel barrel and a reinforced housing that can take a beating. The hose length is another practical detail to check; a longer, flexible hose (36 to 42 inches) makes it much easier to reach those awkward fittings buried deep inside complex machinery.

Finally, don't forget about ergonomics. A well-balanced tool with a comfortable, non-slip grip will save you from a world of fatigue, especially when you're working through a long list of PMs. Little extras like a built-in LED light, an air bleeder valve for easy priming, and a stable base that keeps it from tipping over are the kinds of details that make a huge difference in day-to-day use.

For pros working in San Luis Obispo and up and down the coast from Paso Robles to Santa Maria, a reliable tool that can handle tough conditions isn't a luxury—it's a necessity.

This table breaks down how different specifications align with different job demands, helping you see what matters for your specific line of work.

Cordless Grease Gun Specification Comparison

Specification | Standard-Duty Use (e.g., Automotive) | Heavy-Duty Use (e.g., Construction Equipment) | Why It Matters |

|---|---|---|---|

Pressure (PSI) | 6,000–8,000 PSI | 8,000–10,000+ PSI | Higher PSI is needed to push through clogged or tight fittings on large machinery. |

Battery Voltage | 12V–18V | 18V or 20V | Higher voltage provides more torque and power for demanding industrial applications. |

Battery Ah | 2.0Ah–3.0Ah | 4.0Ah or higher | A higher Amp-hour rating means longer runtime, crucial for servicing multiple machines. |

Flow Rate | 2-3 oz/min | 3-5 oz/min | A faster flow rate speeds up lubrication on equipment with many large grease points. |

Hose Length | 24-30 inches | 36-42+ inches | A longer, more flexible hose provides better access to hard-to-reach fittings. |

Loading Type | Cartridge primarily | Cartridge, Bulk, & Suction | Bulk loading is more cost-effective for high-volume shops, while cartridges offer field convenience. |

Ultimately, choosing the right specs comes down to honestly evaluating your workload. A mechanic in a small auto shop has very different needs than a heavy equipment technician maintaining a fleet of bulldozers. Matching the tool to the task ensures you get a grease gun that's a reliable partner, not a source of frustration.

Manual vs. Pneumatic vs. Cordless: Choosing Your Grease Gun

When it comes to lubrication, the tool you use makes all the difference. Picking the right grease gun isn't just a matter of preference; it directly impacts your efficiency on the job, the quality of your maintenance, and even your bottom line. Let's break down the three main players—manual, pneumatic, and cordless—to see where each one fits in a professional setting.

This decision is about more than just a power source. It's a balancing act between portability, consistent pressure, and pure ease of use, whether you’re working in a dedicated shop or out in the field.

The Old Standard: Manual Grease Guns

Manual grease guns are the classic, tried-and-true option. They're cheap to buy, simple to operate, and come in two flavors: lever-action and pistol-grip. For the occasional small job, they'll get it done.

But in a professional setting, their reliance on elbow grease is a major hang-up. Trying to maintain consistent pressure is tough because it's all up to the operator's strength. This can easily lead to under-lubricated joints or wasted time wrestling with a stubborn fitting. For a tech servicing a large machine with dozens of grease points, fatigue quickly becomes a real problem, slowing down the work and raising the risk of repetitive strain injuries.

The Powerhouse: Pneumatic Grease Guns

Pneumatic, or air-powered, grease guns are a huge leap forward in power and consistency. Hook one up to an air compressor, and you get a steady, powerful stream of grease with almost no physical effort. This makes them fantastic for shop-based work where you need high pressure to bust through blocked fittings or service heavy-duty gear.

The fatal flaw? The hose. A pneumatic gun is tethered to its air compressor, which kills its portability. For field service techs in San Luis Obispo or agricultural operators out in Paso Robles, dragging an air hose across a muddy field or a crowded job site just isn't going to happen. This limitation makes them a workshop specialist, not an all-around solution.

If you want to dig deeper into choosing the right power source for air tools, this contractor's guide to choosing a compressor for painting is a great resource.

The Modern Solution: The Cordless Grease Gun

The cordless grease gun truly offers the best of both worlds. It combines the raw power of a pneumatic gun with the untethered freedom of a manual one. Powered by rechargeable lithium-ion batteries, these tools deliver consistent, high pressure with a simple pull of the trigger, making quick work of clogged fittings and ensuring precise lubrication every single time.

A cordless grease gun solves the two biggest headaches in lubrication: inconsistent pressure and restricted mobility. It gives you the power to do the job right and the freedom to do it anywhere.

This blend of power and portability is exactly why the cordless model has become a must-have for modern maintenance crews. A technician can move freely around a massive excavator in Atascadero or service irrigation equipment across a farm in Santa Maria without being tied to a power source. That mobility is a massive boost to efficiency, ensuring every lube point gets the attention it needs, no matter how remote.

For professionals in Arroyo Grande, Pismo Beach, and Morro Bay, where equipment uptime is everything, the investment in cordless tools pays for itself in faster service, longer equipment life, and less wear-and-tear on your crew. For any team that values productivity and reliability, it’s the clear winner.

Mastering Your Cordless Grease Gun

Owning a high-performance cordless grease gun is one thing, but knowing how to handle it safely and keep it in prime condition is what really protects your investment—and your team. This is a powerful tool that demands respect, and a few good habits can make all the difference between smooth operation and costly downtime.

Let's start with the most important thing: safety. The pressure these guns generate—often hitting over 10,000 PSI—is no joke. It's more than enough to cause serious harm. A high-pressure grease injection, where grease actually pierces the skin, is a genuine medical emergency that can lead to severe tissue damage or even amputation if not handled immediately.

Essential Safety Protocols

Before you even think about pulling the trigger, make safety your first step. The risks are real, but they're completely manageable if you take the right precautions. Don't ever get complacent, even when you're just doing routine maintenance.

Here are the non-negotiable rules of the road:

Gear Up with Proper PPE: Always wear safety glasses and a pair of heavy-duty, grease-resistant gloves. This is your first line of defense against accidental sprays and injection hazards.

Never Point at Yourself or Others: It’s a simple rule, but a critical one. Treat it like any other power tool and keep the nozzle pointed away from your body, especially your hands and fingers.

Inspect Your Hoses Regularly: Give your hose a quick once-over before every use. Look for any signs of wear, cracks, or abrasion. A hose that fails under pressure is a recipe for disaster.

Depressurize Before You Service: Always pop the battery out and bleed any leftover pressure from the hose before you swap couplers or do any maintenance.

A grease injection injury might look like a simple puncture wound on the surface, but it’s far more dangerous. The grease travels under the skin, killing tissue and introducing toxins. If an injection happens, seek immediate medical attention.

Best Practices for Tool Maintenance

Good maintenance is the secret to a long and reliable service life. A well-cared-for cordless grease gun will give you consistent pressure year after year, while a neglected one will become a constant headache.

It all starts with how you load it. One of the most common hiccups is trapping air in the barrel when you pop in a new 14oz cartridge. To get it right, unscrew the barrel completely, pull the plunger rod all the way back, and then insert the new cartridge. After you screw the barrel back on, use the air bleeder valve to release any trapped air. Keep going until you see a steady flow of grease—this simple priming step is crucial for preventing air locks that kill the pressure.

From there, it’s all about routine cleaning and battery care.

Routine Cleaning and Battery Care

Think of the coupler and hose as the business end of your tool. You need to keep the coupler jaws clean to get a solid lock onto Zerk fittings. If it's dirty, it won't seal right, leading to messy leaks and wasted grease. Just give it a quick wipe-down after you're done for the day to clear out any grit and old lube.

Battery health is just as critical. For pros working in San Luis Obispo and nearby areas like Paso Robles and Atascadero, where tools are in constant use, getting the most out of every battery is a must. Try to avoid running your lithium-ion batteries completely dead. Store them in a cool, dry place and aim to keep them between a 20% and 80% charge if they're going to be sitting for a while. It’s a small habit that can seriously extend their working life.

By making these safety and maintenance steps part of your daily routine, you'll make sure your cordless grease gun stays a dependable and effective tool for your operation.

Understanding Grease Types and Applications

A powerful cordless grease gun is only half the equation. The other, equally critical half, is the grease you load into it. Think of it like putting diesel in a gas engine—using the wrong lubricant is a recipe for friction, overheating, and catastrophic failure.

It helps to imagine grease as a sponge soaked in oil. The "thickener" is the sponge, holding the lubricating base oil in place. While the oil does the real work of reducing friction, the thickener determines the grease's texture and compatibility. Getting that combination right is everything.

Decoding Grease Characteristics

When you grab a tube of grease, the most important label you'll see is the NLGI Grade. This simply measures its consistency, or "stiffness," on a scale from 000 (fluid) to 6 (very hard).

Most of the multi-purpose greases you’ll run through a cordless gun are NLGI No. 2. It has a consistency like peanut butter—firm enough to stay put but soft enough to pump easily.

Next up is the thickener. Lithium complex is the most common workhorse for general applications, but you’ll also find polyurea for high-temp electric motors or calcium sulfonate for jobs needing extreme pressure and water resistance.

The cardinal rule of lubrication is to never mix greases with incompatible thickeners. If you combine a lithium grease with a polyurea one, they can break down, liquefy, and drain right out of the bearing, leaving it completely unprotected.

Choosing the Right Grease for the Job

The right grease always comes down to the application. A backhoe grinding away in a dusty Paso Robles quarry has totally different needs than a food processing machine in a sterile facility. You have to match the grease to the machine's operating conditions.

Here’s a quick guide for common scenarios:

Construction & Agriculture: For equipment running in San Luis Obispo and Atascadero, you need a grease with excellent water washout resistance and extreme pressure (EP) additives. A lithium complex or calcium sulfonate NLGI No. 2 grease is a solid choice for pivot pins, bearings, and U-joints.

Industrial Machinery: Inside a factory, temperature is often the biggest enemy. Look for greases with a high dropping point (the temperature where it turns to liquid), like a polyurea or synthetic-based product.

Automotive & Fleet: For wheel bearings and chassis lubrication on vehicles working around Arroyo Grande or Santa Maria, a high-quality lithium complex grease is the reliable standard.

Best Application Practices

Even with the perfect grease, your technique matters. Always, always wipe the grease fitting (Zerk) clean before attaching your coupler. It’s a simple step that stops you from forcing dirt and grime directly into the joint.

When you're ready to pump, go slow and steady. Watch for a small amount of fresh grease to purge from the seal—that’s your sign that the joint is full. Over-greasing can blow out seals, but under-greasing leads to premature wear.

For a detailed look at various lubricants, you can find a great selection of high-quality maintenance fluids to match any equipment needs. Picking the right product and applying it correctly will keep your machinery humming, whether you're on a job site in Pismo Beach or Morro Bay.

Finding Local Service in San Luis Obispo County

When a critical piece of equipment like your cordless grease gun dies, your whole operation can grind to a halt. In that moment, you don't have time for a faceless call center or a week-long shipping delay. You need a local expert who gets the urgency.

That’s where having a trusted service partner right here on the Central Coast makes all the difference. It’s about minimizing downtime and keeping your projects moving forward.

Our Service Area on the Central Coast

We're proud to be the local maintenance and repair hub for hardworking professionals across San Luis Obispo County. Whether you're on a job site in San Luis Obispo, a vineyard in Paso Robles, or managing a fleet in Santa Maria, we provide the hands-on support you need.

Our service area includes:

San Luis Obispo

Paso Robles

Atascadero

Arroyo Grande

Pismo Beach

Morro Bay

Santa Maria

And other surrounding communities.

Choosing a local shop means more than just a quick fix. It means faster turnaround, direct access to someone who knows your tools, and the ability to get your hands on the right part, right now.

Comprehensive Support for Your Tools

We offer a full range of services designed to keep your cordless grease gun and other essential equipment running at peak performance. Our team handles everything from routine tune-ups to complex repairs, making sure your tools are always ready for the job.

Here’s a look at what we do:

Warranty Repairs: As an authorized service center for major brands, we process warranty claims efficiently to get your gear back in your hands, fast.

Preventative Maintenance: Let us help you stay ahead of breakdowns with thorough inspections and tune-ups before small issues become big problems.

Battery Testing and Replacement: Get maximum runtime and power. We offer expert battery diagnostics and replacement services to keep you going.

Full Parts Inventory: We stock a complete selection of replacement parts—hoses, couplers, batteries, you name it—to handle repairs without waiting on shipping.

When your business runs on equipment uptime, a local partner isn't a luxury; it's a strategic advantage. It’s about more than convenience. It's about having an expert in your corner who’s invested in seeing you succeed.

The demand for these tools is only growing. The U.S. market for grease guns was estimated at over USD 400 million in 2024 and is projected to keep climbing. This trend highlights just how important it is to have a local, authorized service center that stocks the right North American OEM parts and common battery platforms. You can read more about the grease gun market projections to see where the industry is headed. Our commitment is simple: provide that reliable, local support to keep your operations moving without a hitch.

Got Questions? We've Got Answers

Stepping into the world of cordless grease guns always brings up a few practical questions. It's one thing to read the specs on a box, but another to know how a tool will perform out in the field. Here are some clear, straightforward answers to the questions we hear most often.

How Many Grease Cartridges Can I Really Get Through on a Single Charge?

This is the big one, and the honest answer is: it depends. The number of cartridges you can run through on a single charge is all over the map, based on a few key factors. A beefy 4.0Ah or 5.0Ah battery on an 18V or 20V platform is obviously going to outlast a smaller 2.0Ah battery every time.

But the job itself matters just as much. Are you pushing grease into clean, easy-to-reach fittings? Or are you trying to bust through a stubborn, clogged zerk that hasn't seen grease in years? The tougher the job, the more power it's going to pull.

As a solid rule of thumb, you can expect a professional-grade cordless grease gun to dispense anywhere from 3 to 10 standard 14-ounce cartridges per charge under normal working conditions. For the most accurate numbers, though, it's always best to check the manufacturer’s specs for your specific model.

Can I Use Any Type of Grease in a Cordless Gun?

Pretty much, yes. A cordless grease gun is designed to handle most standard greases up to an NLGI No. 2 consistency. That covers almost everything you’ll run into, from multi-purpose and high-pressure greases to specialty lubricants used in commercial, farm, and automotive shops.

The single most important rule is to never mix incompatible grease types. Doing so can cause the thickeners to break down, which can lead to catastrophic lubricant failure and serious equipment damage. If you absolutely have to switch to a different grease chemistry, you need to completely clean out the gun first. No shortcuts.

Is a Cordless Grease Gun Actually a Good Investment?

For any serious contractor or maintenance shop, the answer is a resounding yes. The whole industry is moving toward battery-powered tools, and for good reason—they save time and make the job easier.

Cordless grease guns are one of the fastest-growing tool categories out there. The global market was valued between USD 1.2–1.6 billion in 2024–2025 and is expected to climb by 6–7% each year. That kind of growth isn't just hype; it’s proof that these tools deliver real value by boosting productivity and ensuring equipment gets the lubrication it needs. You can dig into more stats about the battery-operated grease gun market on ResearchAndMarkets.com.

For professionals working right here in San Luis Obispo, Paso Robles, Atascadero, and the neighboring communities, a cordless model is a no-brainer. Think about all the time you'll save and the improved quality of your maintenance work. Whether you’re managing a fleet in Arroyo Grande or servicing equipment in Pismo Beach, Morro Bay, or Santa Maria, the return on investment is clear.

For expert service, parts, and advice on your maintenance equipment, trust the local team at Contractor's Maintenance Service. Visit us online to explore our full range of products and services designed to keep your operation running smoothly. Find the right solution for your needs at https://www.contractorsmaintenanceservice.com.

Comments